Looking for a top-quality plastic injection molding service in New York? Look no further than Longsheng! With years of experience in the industry, we specialize in providing injection molding solutions that meet the demands of clients in a wide range of industries.

Our team of talented and experienced engineers is equipped to handle all types of projects, from small and simple to large and complex. We use advanced technologies and state-of-the-art equipment to ensure precision and consistency in every product we make.

But what exactly is plastic injection molding, and why is it so important? In this article, we’ll answer these questions and more, giving you a comprehensive overview of this groundbreaking technology.

What is plastic injection molding?

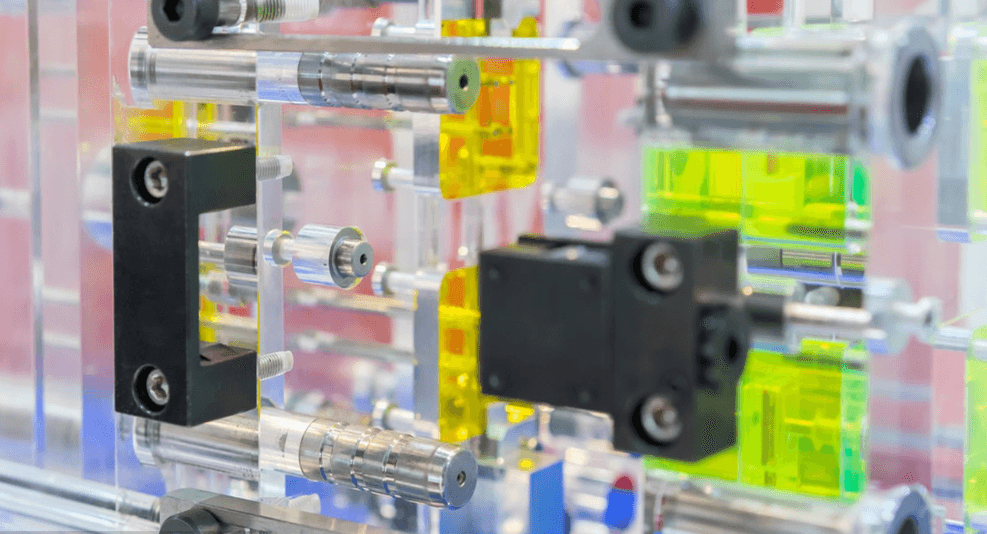

Plastic injection molding is a manufacturing process that involves the injection of molten plastic into a mold. The mold is then cooled and solidified, creating a finished product that can be used for a wide range of applications.

The process involves several key steps, including:

- Material selection: The first step in plastic injection molding is selecting the right material for the job. This may involve choosing from a range of plastic materials, each with its own unique properties and characteristics.

- Mold creation: Once the material has been selected, a mold must be created. This involves using specialized equipment to create a precise mold that matches the desired dimensions and specifications of the final product.

- Injection: With the mold in place, the molten plastic is injected into the mold using a high-pressure injection process. This ensures that the plastic fills every corner and crevice of the mold, creating a finished product that is free of defects and imperfections.

- Cooling and solidification: After the plastic has been injected into the mold, it is cooled and solidified, creating a final product that is ready for use.

Benefits of plastic injection molding

Plastic injection molding offers a number of key benefits over other manufacturing processes. These include:

- Versatility: Plastic injection molding can be used to create a wide range of products, from small and simple parts to large and complex products.

- Precision: The high-pressure injection process used in plastic injection molding ensures precision and consistency in every product.

- Efficiency: Plastic injection molding is a highly efficient process, allowing for the production of a large number of products in a relatively short amount of time.

- Cost-effectiveness: Because plastic injection molding is a highly automated process, it is often more cost-effective than other manufacturing processes.

Why choose Longsheng for your plastic injection molding needs?

At Longsheng, we are committed to providing our clients with the highest-quality plastic injection molding services available. Our team of experienced engineers and technicians is dedicated to ensuring that every project we undertake meets and exceeds your expectations.

We use the latest technologies and equipment to ensure precision and consistency in every product we make, and we are constantly exploring new and innovative ways to improve our processes and services.

So if you’re looking for a top-quality plastic injection molding service in New York, look no further than Longsheng. Contact us today to learn more about what we can do for you!