In rapid prototyping and precision manufacturing, selection of material evidently dictates product performance, cost, and ultimate use. Brass, due to its machinability, high thermal conductivity, and wear resistance is highly preferred where instant heat dissipation and electrical conductivity are required. Stainless steel renowned for its hardness, strength, and excellent corrosion resistance, is a top contender for harsh industrial environments and medical applications. Aluminum alloy, owing to its lightweight yet high-strength quality, strength-to-weight ratio, and ductility, is widely utilized by both the consumer electronics and aerospace industries.

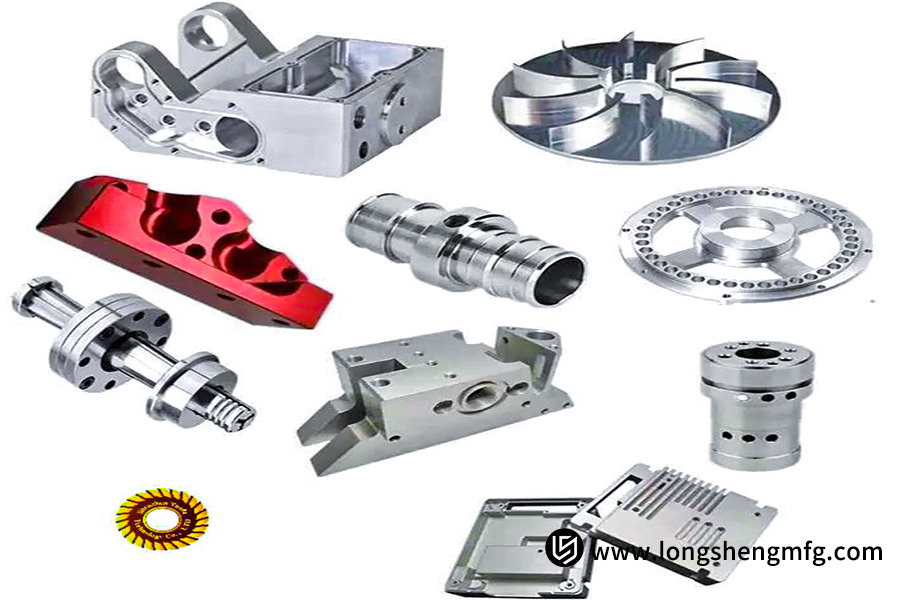

LS Precision’s leading-edge rapid prototyping technology platform can easily process everything from brass to stainless steel to aluminum alloys. Therefore, no matter the material you choose, you can obtain rapid prototyping parts with clear details and high quality. To save you time, here’s a quick overview of the core conclusions.

Brass, Stainless Steel, and Aluminum Alloy Rapid Prototyping Core Quick Reference

| Characteristics | Brass | Stainless Steel | Aluminum Alloy |

| Core Advantages | Excellent electrical and thermal conductivity, wear resistance, good mechanical properties | Extremely strong and hard, excellent corrosion resistance, durability | Lightweight, high strength-to-weight ratio, easy processing, cost-effective |

| Typical Applications | Radiators, electrical connectors, valves, decorative parts | Medical equipment, food processing machinery, high-strength structural parts, parts resistant to corrosive environments | Aerospace components, lightweight automotive parts, electronic equipment housings, prototype models |

| Cost Considerations | High material costs | Both material and processing costs are high | Best material and processing cost-effectiveness |

| Rapid Prototyping | Suitable for CNC machining, the finished product has a high surface gloss, and is easy to post-process and electroplating. | Laser sintering (SLM) technology can produce extremely complex and high-strength functional parts for direct use in end products. | Ideal for rapid prototyping, with high CNC machining efficiency and excellent SLM printing performance, it is the preferred choice for lightweight designs. |

The material is chosen according to the end usage:

- Brass is the material of choice for thermal conduction, electrical conduction, and abrasion;

- Stainless steel is the material of choice for ultimate strength and corrosion resistance;

- Aluminum alloy is the material of choice for optimal lightweighting, cost, and overall efficiency.

LS Precision, with its comprehensive process capabilities, provides high-precision, high-quality solutions for rapid prototyping in all three materials, ensuring your design is flawless from prototype to product.

Why Trust This Guide? Practical Experience From LS Experts

The insights in this guide are directly derived from LS Precision’s decade of experience in rapid prototyping. We not only possess a comprehensive suite of equipment covering advanced processes such as metal 3D printing (SLM) and five-axis CNC machining, but also, crucially, our engineering team deeply understands the characteristics and challenges of machining different materials (such as aluminum alloy, stainless steel, and brass).

LS Precision adheres to a strict ISO quality management system and serves clients across the aerospace, medical, and high-end consumer electronics industries. What this amounts to is that our recommendations are not theoretical but proven and tested solutions illustrated by rigorous project execution.

Consider the example of a stainless steel medical device component. The customer specification required not only a complex structure but also had conformal cooling channels which were difficult to machine using conventional methods, and also required a very high degree of biocompatibility in the surface finish.

LS Precision’s staff was also able to integrate all these features into a single process using metal 3D printing technology without subjecting the product to the risks and delays of assembling different parts. Through sophisticated post-processing and polishing, the product exceeded all requirements necessary.

This hands-on experience enables LS Precision to provide you with genuinely forward-thinking and feasible manufacturing solutions.

What Is Rapid Prototyping? How Does It Accelerate Product Development Cycles?

Rapid prototyping is a new manufacturing technology whose basic aim is to rapidly transform computer models into real parts or assemblies by means of 3D CAD data.

Rapid prototyping explicitly states what prototyping is—it is not merely creating a prototype; it proceeds with serious steps by traversing design verification, functional testing, analysis of assembly, and even market demonstration. It has an ultimate goal of reducing time to market by half and substantially decreasing uncertainty and risk at the early stage of development.

Time is money in product design. Rapid prototyping technology avoids the traditional time-consuming process of mold making, enabling designers to create prototypes in a matter of hours or days. This enables designers to iterate designs rapidly, find flaws, and implement customer feedback. This “fail fast, learn fast” concept removes flaws early and avoids costly redesigns.

Rapid metal prototyping, actually, offers the ability of generating functional prototypes in terms of structure and form for testing in real conditions, which has immense benefit for aerospace, medical, and automotive sectors.

Rapid prototyping is a major driver in modern product development. As it quickly converts virtual concepts into physical models, it brings valuable decision-making data into groups, and products are more successfully and more qualitatively inserted into market.

Why Use Metal For Rapid Prototyping?

For product manufacturing, metal rapid prototypes are better than plastic prototypes due to high requirements on performance, functionality, and durability. In addition to looking like the final product, metal prototypes also replicate its functional state in a realistic way, thereby making them the best way of quality proof and demonstration. Renowned rapid prototyping service providers can do this through different processes, some of which involve metal 3D printing and CNC machining.

The main advantages of metal prototyping lie in these unmatched characteristics:

1. Enhanced Functionality and Test Reliability:

Metal prototypes possess mechanical properties similar to mass production parts, which can be used directly for rigorous functional testing, i.e., pressure testing, fatigue testing, and fluid (gas/liquid) testing, with reliable data that plastic prototypes cannot provide.

2. Excellent Strength and Durability:

Metallic materials (including stainless steel and aluminum alloys) have greater hardness, stiffness, and strength. They allow prototypes to endure repetitive assembly, disassembly, and testing on use without failing or wearing out, and their useful life and verification are extended significantly.

3. High-Temperature Resistance and Stability:

Metal materials have the capability to withstand temperatures of more than hundreds or even thousands of degrees Celsius making them the only choice for prototyping engine components, heat exchangers, and high-temperature furnace parts. They keep the plastic components from softening, deforming, or releasing toxic fumes when subjected to heat.

4. Authentic Surface Finish and Treatment:

Metal prototypes can be finished in various ways, ranging from matte to mirror, with our range of post-process operations of polishing, sandblasting, and electroplating. This provides the appearance and the feel of the final product and makes presentations even more realistically persuasive for customers or management.

When your design extends beyond visual inspection and must survive actual mechanical and thermal environments in the outside world, metal rapid prototyping is a crucial step for reducing risk and ensuring product success.

Overview Comparison: Brass, Stainless Steel, and Aluminum Alloy Properties

To present a more organic comparison between brass, stainless steel, and aluminum alloy—three metals that are commonly in conflict in rapid prototyping—the following table summarizes the metals along some of the most relevant dimensions.

| Property | Brass | Stainless Steel | Aluminum Alloy |

| Strength-to-Weight Ratio | Medium | Very High | High (Leading Lightweight Advantage) |

| Corrosion Resistance | Good (but susceptible to dezincification) | Excellent | Good (can be enhanced by anodizing) |

| Machinability | Excellent (easy to cut, low tool wear) | Poor (high toughness, strong work hardening, high tool requirements) | Good (easy to cut, but may stick) |

| Thermal/Electrical Conductivity | Excellent (thermal and electrical conductivity close to pure copper) | Poor (poor thermal conductivity, average electrical conductivity) | Excellent (good thermal and electrical conductivity, second only to copper) |

| Relative Cost | High (high material cost) | High (high material and processing costs) | Low (best material and processing cost-effectiveness) |

| Typical Applications | Heat sinks, conductive connectors, valves, decorative hardware, musical instrument components | Medical implants, food processing equipment, high-strength structural parts, parts resistant to corrosive environments | Aerospace parts, lightweight automotive parts, electronic housings, functional prototypes |

- Aluminum alloy: The lightweight champion for economy and efficiency.The most common and affordable choice for rapid prototyping, essential when high strength is required at a low weight, particularly in consumer electronics, aerospace, and automotive industry uses.

- Stainless steel: A giant of strength and corrosion resistance. If your prototype needs to withstand harsh forces, abrasion, or harsh corrosive conditions (such as medical and food contact), stainless steel is the most reliable choice.

- Brass: The epitome of exceptional functionality and aesthetics. It possesses very good electrical and thermal conductivity, and that is why it is used in thermal management and electrical applications. It also carries a striking golden sheen and processability, which makes it commonly used in high-end ornaments and music instruments.

How Do I Choose The Most Appropriate Metal Material For My Project?

Choosing the most suitable metal material is a critical process in ensuring the success of your prototype.Use this concise decision-making guide to match your project goals with material properties:

1. Choose aluminum alloy:

If your primary requirements are weight, cost, and rapid processing times, aluminum alloy is suitable for structural parts, enclosures, brackets, and proof-of-concepts in aerospace and automotive engineering, and it is one of the initial options for functional verification and proof of concept.

2. Choose Stainless Steel:

If your prototype will be facing severe challenges requiring maximum hardness and strength, and improved wear resistance, or must be used in extremely corrosive environments (such as medical implants, food processing equipment, chemical storage tanks, or application in marine environments), stainless stell provides longevity and dependability.

3. Choose Brass:

If your application requires outstanding electrical or heat conductivity (such as heat sinks and electrical connectors), benefits from natural antimicrobial characteristics (such as certain bathroom fixtures and door handles), or demands a warm, upscale appearance (such as upscale decorative and musical instrument components), brass is the best choice for you.

Still unsure? LS Precision‘s knowledgeable personnel offers a free material selection consultation! We’ll recommend the ideal solution based on your design drawings and performance specifications.

LS Case Study: Rapid Prototyping of High-Precision Stainless Steel Sensor Housings

In medical device development, a good prototype often dictates the progress of the whole project. LS Precision showcased its competence in metal rapid prototyping technology with a successful collaboration.

1. Customer Challenge:

A medical device company needed a rapid prototype of a stainless steel sensor housing for invasive testing environments.

- The product must be stable in the long term in aggressive chemical environments, and thus the prototype needed to exhibit extremely high dimensional precision, complete sealing, and extremely good corrosion resistance.

- At the same time, the customer was facing very stringent time-to-market constraints and aggressive delivery timetables; any delays would impact subsequent clinical validation and product approval processes.

2. LS Precision Solution:

Faced with this challenge, LS Precision immediately recommended 304 stainless steel, which gives the best combination of corrosion resistance, strength, and biocompatibility. LS Precision’s rapid prototyping service process was initiated as early as possible:

- Precision machining was performed using five-axis CNC machining centers. The complex internal and external geometries and the high-accuracy threads were produced in a single clamping fixture, minimizing repeatable positioning errors and dimensional tolerances as well as flatness of the critical sealing surfaces.

- After machining, the part proceeded to post-processing, where it was sandblasted for uniform texture and harsh passivation treatment in order to significantly improve surface corrosion resistance, preparing it extensively for functional testing.

3. Results and Value:

The final stainless steel housing prototype exceeded the customer’s performance requirements to the point, passing all first-test environmental resistance and sealing tests. With LS Precision Manufacturing’s high-performance rapid metal prototyping technique, the customer shaved two weeks from their validation cycle, creating valuable time for a headstart product release. The prototype quality also served as an excellent starting point for any future small-batch trial production, putting away the specter of recurrent mold iterations.

This collaboration exemplifies LS Precision’s one-stop capabilities in material selection, precision machining, to surface treatment and its deep value in serving key customer projects.

How Does LS Precision Manufacturing Guarantee Your Rapid Prototyping Success?

Choosing the appropriate material is only the first step in a successful rapid prototyping project. True value lies in the integrated system of full technical service and support provided by the manufacturing partner. LS Precision ensures every project’s success—delivering intended functionality, cost-effectiveness, and high quality—through a full system of rapid prototyping services.

1. Leading Advanced Equipment and Process Technology:

LS Precision Manufacturing not only offers material selection know-how but also has strong manufacturing capability. LS Precision owns multi-axis high-precision CNC machining centers and metal 3D printing (SLM) equipment, allowing us to choose the best process solution based on physical properties of various materials, including aluminum alloys, stainless steel, and brass. Whether it is intricate integrated structures or extremely high-precision micro-features, our equipment and processes allow us to manufacture with precision.

2. Expert Engineering Assistance and Design Optimization:

LS Precision service begins even before your drawings are ready. Our professional engineers proactively get involved in design reviews and provide professional input from manufacturability-focused design feasibility for manufacture (DFM) perspectives, cost savings, and enhanced performance. This prevents you from potential issues, optimizes structures, and improves performance at a lower cost of time and money.

3. Strict Quality Control System:

LS Precision give significant value to the function prototypes serve to informed future decisions. We therefore maintain a meticulous First Article Inspection (FAI) procedure and end-to-end quality control. LS Precision inspect 100% of critical dimensions using high-accuracy measuring equipment to ensure that all shipped prototypes are meeting the drawing spec so real development from design through to manufacture can occur.

4. Rapid Response and On-Time Delivery:

Time is of the essence. LS Precision is committed to offering honest and prompt project cycle management. From the moment you place an inquiry, we ensure honest quote and delivery timeline in hours. We maintain clear communication and production progress update to keep your project on schedule, allowing you to seize market opportunities.

By choosing LS Precision Manufacturing, you are not merely choosing a supplier – you are choosing a solid business partner committed earnestly to your product development and to making you successful with excellent rapid prototyping services.

Let LS Precision utilize its advanced metal rapid prototyping capability and project experience to turn your innovative ideas into competitive strengths quickly and effectively.

From Design To Product: What Do I Need To Prepare For A Rapid Prototyping Quote?

Transforming your design into a high-quality product is simple and quick. Regardless of what rapid prototyping tool you are using (e.g., SolidWorks, CATIA, Fusion 360, etc.), LS Precision’s rapid prototyping technology can have your files worked on in a jiffy and provide a quick and accurate quote. To receive the most accurate quote and optimal production plan, please be prepared to provide the following information:

1. 3D Design Files:

The first and most important is to upload your 3D model files. For data integrity, LS Precision would prefer to accept files in general formats such as STEP or IGES. Also, please attach a 2D drawing in PDF, with major dimensions, tolerances, and special requirements clearly marked.

2. Material Preferences:

If you prefer a material of choice (for example, aluminum alloy 6061, stainless steel 304 or 316, brass, etc.), please let us know. If you’re not sure what material will be best for your application, the engineers at LS Precision would be pleased to make suggestions.

3. Quantity Requirements:

Contact LS Precision whether you require how many prototypes, either one test run or a limited production order. This will directly influence our recommendation of the most economic process.

4. Surface Treatment and Post-Processing Requirements:

Identify your final part surface requirements, e.g., sandblasting, color anodizing, plating, polishing, passivation, or silk-screen printing. This will allow LS Precision’s specialists to develop the entire manufacturing process for you.

Get started on your project today! Upload your 3D models for an instant quote! Contact LS Precision‘s engineering professionals for a complimentary Design for Manufacturability (DFM) analysis!

FAQs

1. What is the average lead time for metal rapid prototyping?

With our defined process sequence and efficient capacity planning, LS Precision Manufacturing typically has the capability to finish most metal prototype orders in 3-7 business days following final-approved drawings. LS Precision also offer expedited services for urgent needs. Actual lead time depends on complexity and part size, order load, and selected post-processing. We always quote a definite timeline at project commencement to ensure an efficient project plan.

2. Besides CNC machining, does LS Precision offer metal 3D printing services?

Yes. LS Precision offers not only CNC machining but also complete-service metal 3D printing services. This process is well suited to making parts with complex internal conformal cooling channels, built-in lightweight lattice structures, or unusual geometries hard to process with standard tools. Merging metal 3D printing with CNC machining gives us a more versatile solution, enabling us to choose the most appropriate and economical process for manufacturing high-performance metal functional prototypes or end-use parts.

3. Can LS Precision handle assembly for my prototype?

Absolutely. LS Precision provides one-stop integrated services, from parts to assemblies. Not only do we precisely machine individual components, but we also maintain a skilled team to perform follow-on assembly activities such as precision press-fitting, bonding, and thread locking, along with basic functional testing. This way, you can avoid the communication and management cost of contracting independent machining and assembly facilities and instead receive a final, reliable, and test-ready functional assembly, which optimizes R&D productivity.

4. How can I minimize my metal rapid prototyping costs?

Design optimization is key to controlling costs. LS Precision recommend stripping away unnecessary geometry complexity and relaxing unnecessarily tight tolerances; employing cost-effective materials (e.g., aluminum alloys) without compromising function; and above all, engaging in design for manufacture (DFM) discussions with our engineers before we approve your design. LS Precision’s long experience can proactively spot potential processing issues and provide recommendations for optimization to avoid rework and waste altogether—the best way to control cost.

Conclusion

In the comparison between brass, stainless steel, and aluminum alloy, there is no single winner—only the best choice for your specific project needs. The key to success is to precisely match material properties to your functional testing, environmental use, and cost requirements. Rapid prototyping technology is a turbocharged bridge to facilitate this match, and your product will be brought to life.

LS Precision Manufacturing not only provides cutting-edge metal rapid prototyping capabilities, but also employs professional engineering personnel that provides complete-cycle solutions from design for manufacture (DFM), material selection, and high-precision manufacturing. Contact LS experts today for free consultation and a customized quote to bring your next product to the market faster, more affordably, and more efficiently!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.