Ceramic materials’ excellent properties such as high hardness, high-temperature resistance, and corrosion resistance have popularized ceramics in aerospace, semiconductor, and medical fields. But the hardness and brittleness in their own nature make CNC machining of ceramics very difficult and require extremely high standards in CNC machining processes, tools, and technical personnel.

This artical will be a comprehensive discussion of the most significant factors and parameter optimization methods for efficient precision ceramic machining. It will also show how LS Manufacturing, with its extensive technical expertise, provides customers an enhanced ceramic CNC machining service, thus successfully overcoming the hurdles of ceramic part manufacturing. To save you time, here’s a quick overview of the core conclusions.

Ceramic CNC Machining Core Quick Reference

| Category | Key Points | Key Notes |

| Core Process | Hard Precision Grinding and Machining | Diamond/PCD turning and milling; precision grinding for true accuracy and surface quality. |

| Parameter Strategy | High Speed, Small Depth of Cut, Proper Feed | High speed to improve surface finish; micron depth of cut to manage edge chipping; correct feed to prevent burns. |

| Key Technologies | Firm Clamping and Effective Cooling | Workpiece positioning is ensured by special fixtures; high-pressure coolant is required for heat flow, chip removal, and tool protection. |

This quick reference table distills the essential principles of general ceramic CNC machining. LS Manufacturing’s successful experience confirms that an integration of these principles with specific materials and part structures is the solution to the consistent manufacturing of high-reliability ceramic parts.

Drawing on our deep-rooted expertise in the field, LS Manufacturing offers end-to-end ceramic machining services from process development to mass production optimization.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

LS Manufacturing has deep-rooted hands-on experience and in-depth technical knowledge of ceramic CNC machining. We understand that fighting against challenges posed by hard and brittle material like ceramics requires more than just theoretical knowledge.

Based on our deep experience with ceramic material properties, LS Manufacturing has taken the basic process parameters of ceramic CNC machining into a robust, production-proven system. From dealing with the close tolerances required in aerospace to satisfying the high surface integrity requirements for medical implants, the technical experts at LS Manufacturing have successfully helped customers overcome numerous manufacturing challenges with challenging ceramic parts.

Therefore, what you are reading here is not just a technical guide but a mini-clone of how LS Manufacturing, by virtue of its experience, provides customers with a one-stop, end-to-end solution for ceramic machining, from process optimization to problem solving.

Such hands-on experience is provided to give you hard facts that are truly worth your time at work.

Why Are Ceramics Considered One Of The “Hardest Materials To Machine”?

The inherent high hardness, brittleness, and low fracture toughness of ceramics make it much harder to machine than usual materials like metals, bringing severe challenges to ceramic machining technology. Such challenges are primarily caused by the following distinctive challenges:

1. Extremely Rapid Tool Wear:

Ceramics are far harder than the majority of tool materials. Under cutting, the tip of the tool is subject to heavy abrasive wear, causing very quick dulling and even tool failure. This renders regular carbide tools unsuitable, with the need to utilize ultra-hard tooling such as diamond, which is very expensive.

2. Susceptibility to Edge Chipping and Microcracks:

Compared to metals, which machine through plastic deformation and shed chips, ceramics are primarily subjected to brittle fracture when machining. This makes material removal difficult to control and is highly susceptible to chipping and microcrack defects on the machined edge, significantly degrading the final strength, fatigue life, and dimensional tolerance of the part.

3. Highly Sensitive to Machining Stress:

Ceramics are particularly prone to tensile stress. All thermal shock and stress concentrations that occur while machining can directly lead to microcrack development in the part or to even total fracture. Therefore, the deep cutting and high feed methods so prevalent in metalworking are totally unsuitable.

The conventional techniques of traditional metalworking completely fail in ceramic machining, pointing to the need for special equipment, modified processes, and high-grade experience.

What Are The Core Processes Involved In Successful CNC Machining Of Ceramics?

The basic process of effective CNC machining of ceramics is a sophisticated, interrelated system for progressively transforming a solid ceramic blank into a high-precision end-part. It is not a single cut, but a scientifically organized process divided into discrete steps to maximize efficiency, cost, and quality. Such an organized process primarily includes:

1. Blank Preparation and Datum Establishment:

The process serves as the foundation for subsequent machining. The sintered blank is first checked and treated, and a uniform process datum surface is created through precision grating or scribing. The accuracy of this datum directly affects the positioning accuracy of all subsequent process steps and is therefore very critical.

2. Roughing: Rapid Prototyping and Stock Control

The goal of this operation is to take most of the stock out in an efficient manner, leaving the part almost in its final configuration. The key is using parameters that achieve high removal rates with a compromise between workpiece internal stresses and machinability to generate even and adequate quantities of stock for subsequent operations without inducing severe material damage.

3. Semi-finishing and Finishing: Achieving Precision and Surface Quality

This is crucial in determining the final performance of the part. Semi-finishing also eliminates stock and shapes better, whereas finishing uses extremely low cutting parameters and sharp tools and removes material at nanometer or micrometer levels to achieve precise dimensions, optimal geometric tolerances, and an extremely high surface finish with little surface and subsurface damage.

For the entire sequence of ceramic CNC machining core processes, each link must be closely integrated and reinforced with strict quality inspections among processes to allow for systematic optimum final part quality.

How To Set Optimal Parameters?

Scientific and logical parameter definition of ceramic CNC machining is the key to optimizing machining efficiency, tool life, and product quality. Numerical values cannot simply be applied; it is a systematic optimization based on profound knowledge about material properties and machining mechanisms. Its essential principles are as follows:

1. Specialized Tools Are the Foundation:

Employ ultra-hard tooling materials such as diamond (such as PCD) and CBN. Their high hardness and wear resistance are the minimal requirements for effective cutting. Any other tool will wear away too rapidly, and ceramic CNC machining parameter settings will not be possible.

2. “High Speed, Small Depth” Is the Key Strategy:

Employ very high spindle speeds (frequently much higher than are commonly employed for machining metals) in conjunction with very small depths of cut (ap) and feed per tooth (fz). Together, these yield thin chips, decrease the cutting forces on a single abrasive grain, and consequently effectively inhibit chipping and microcracking and decrease cutting heat.

3. Optimizing Feed and Path:

Feed rate (vf) must be chosen with great care in order to correspond to the rotational speed and depth of cut. A feed rate that is too low will lead to frictional heating, and a feed rate that is too high will lead to brittle fracture. Also, programming must involve down-cut milling and even, unbroken toolpaths in order not to cause shock loads from abrupt changes in direction. This must be done in order to protect both the tool and workpiece.

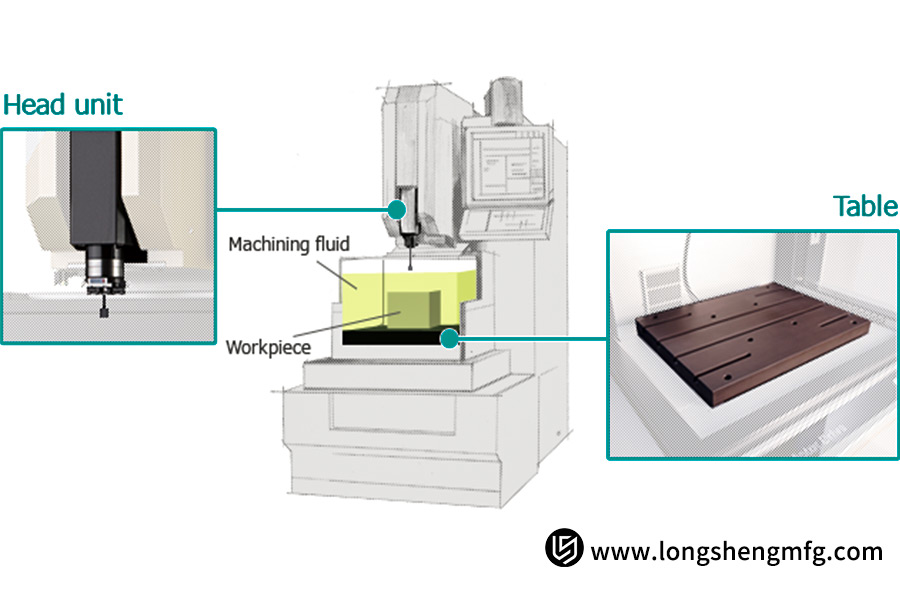

4. High-Pressure Coolant is Essential:

The coolant not only cools but, more importantly, its high-pressure jet cleans away abrasive chips before they have a chance to secondary scratch the machined surface. Proper and sufficient cooling plays a critical role in averted thermal stress damage and giving a stable machining process.

Successful parameter controls for ceramic CNC machining are a linked group of parameters that must be fine-tuned based on the specific ceramic material and part geometry. This is where LS Manufacturing exercises its established proficiency to make a value contribution to customers.

What Practical Techniques Must Be Mastered To Improve Yield?

Yield optimization is the final goal of ceramic CNC machining practical methods. The key is foreseeing and averting machining threats inherent in ceramics’ hardness and brittleness through a series of cautious steps. Based on a lot of experience at LS Manufacturing, the following core techniques have proven greatly to boost success rates:

1. Adopting contoured flexible clamping:

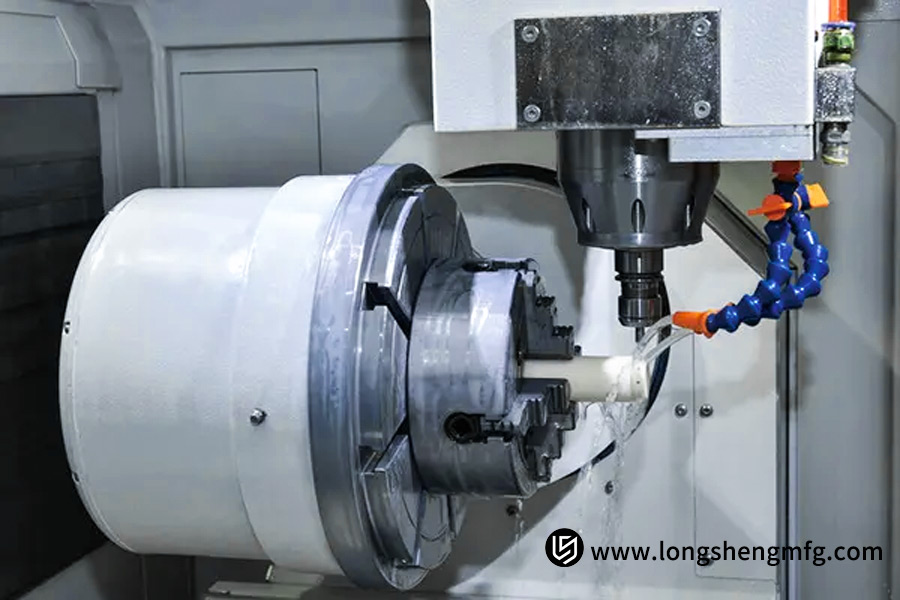

Too rigid hard contact must be eliminated. Yielding clamping technologies such as specially designed soft jaws, vacuum chucks, or low-melting-point-alloy castings exert uniformly distributed clamping forces and avoid stress concentration causing clamping deformation or cracking of the part inside. This is the secret to successful machining.

2. Implementing a “small depth of cut, fast feed” strategy:

Contrary to intuition, rotating at high speeds is coupled with a shallow depth of cut (ap) in the micron range and a high feed rate (vf) to attain productive, low-damage machining. The method creates thin chips, maintains low cutting forces, and keeps tool-workpiece contact time to a minimum, thereby suppressing edge chipping and reducing grinding heat.

3. Optimize toolpaths to avoid impact:

Gentle toolpaths must be used in CAM programming. Sharp tool turn or direct entry/exit into the workpiece contour must be avoided at all times. Circular patterns for entry and exit and inter-layer spiral cutting must be used to facilitate smooth tool entry and exit from the cutting zone. This is highly necessary to prevent chipping of the edge from impact.

These thoroughly tested practical approaches to ceramic CNC machining constitute the core know-how of LS Manufacturing, enabling reliable manufacturing of high-yield ceramic parts. They are the indispensable connection between theoretic parameters and ideal finished products.

How To Select Machining Strategies For Different Ceramic Materials?

Different engineering ceramics differ significantly in hardness, fracture strength, and microstructure, thus no one machine solution exists. Successful machining of the ceramics must be tailored to the unique properties of the material. LS Manufacturing employs its experience to properly correlate material properties with machining methods.

To facilitate comparison, the following table presents the most significant properties and machining suggestions for four representative ceramics:

| Material | Key Properties | Machinability Guidelines |

| Alumina | High hardness and high wear resistance. | High resistance to tool wear is most critical; highly quality diamond tools need to be applied to prevent surface roughness degradation. |

| Zirconium Oxide | High fracture toughness and phase transformation toughness. | High toughness prevents material peeling off and can easily initiate work hardening; best parameters are required to control cutting forces and prevent chipping of the edge. |

| Silicon Nitride | High hardness and good thermal shock resistance. | Its hardness and toughness combination makes it difficult to machine; it is highly sensitive to parameters and has to be optimized with great care to get a proper balance between surface quality and tool wear. |

| Silicon Carbide | Extremely high hardness and brittleness. | Make it highly susceptible to chipping and microcracking and necessitates very conservative cutting parameters and special edge preparation techniques. |

According to these differences, LS Manufacturing’s custom ceramic machining methods are:

- For extremely hard zirconium oxide, we use more acute cutting edges and proprietary cooling strategies to minimize material pull;

- For extremely hard silicon carbide, we focus on reduced depths of cut and increased rotational velocity, using a “grinding”-oriented technique to remove material in a very gentle way.

LS Manufacturing’s material-specific, precise approach is key to ensuring final part performance and yield.

What Are The key Areas Of focus For Different Machining Methods In Ceramic Applications?

For the production of intricate ceramic parts, no single process covers everything. Successful ceramic CNC machining relies on the custom choice and amalgamation of different machining processes based on part geometry and accuracy requirements. Leaping ahead of its full technical potential, LS Manufacturing can utilize a number of processes with flexibility to handle components ranging from simple to very intricate.

1. Surface/Cylindrical Grinding:

This is a basic process to achieve high-precision dimensions and high-quality surface finishes. It is primarily used for grinding planar surfaces for datum definition, cylindrical surface for exact fitment, or sleeve-type components. The technological challenge is the elimination of the subsurface microcracks generated by the grinding process without compromising very high geometric precision (e.g., flatness and roundness).

LS Manufacturing uses top-of-the-line diamond grinding wheels and sophisticated dressing techniques in order to create the perfect blend of dimension and surface integrity.

2. Micro-Drilling and Deep-Hole Machining:

The process is generally utilized in micro-holes and deep hole machining of components such as fuel nozzles and medical microfluidic chips. The primary issue in such cases is the highest likelihood of entry/exit edge chipping and drill failure due to poor chip evacuation and tool runout during drilling.

In drilling of such sensitive ceramic parts, LS Manufacturing uses proprietary drill tips with custom geometry, a high-pressure internal coolant system, and an optimized pecking drilling process to effectively create high-quality high-aspect ratio drilling.

3. Contour Milling and 3D Forming:

It is used for machining complex cavities, curved surfaces, specially-shaped parts, and threads, and is central to achieving multiple part functionalities. The challenge lies in complex tool paths, high corner chipping danger, and inconsistent cutting loads that never stay the same.

LS Manufacturing applies robust CAM programming capabilities, leverages smart techniques such as trochoidal milling to deliver a continuous cutting load, and employs PCD tools with optimally processed cutting edges to successfully achieve stable, low-damage shaping of complex 3D geometries.

Full ceramic CNC machinability is demonstrated by a broad understanding of the potential and limitations of all processes and the coordination of these processes in an organized manner. It is the foundation for LS Manufacturing’s ability to offer customers high-reliability ceramic part solutions.

LS Case: Overcoming The Difficulty Of Finishing Silicon Nitride Ceramic Chucks For Semiconductor Equipment?

In the manufacturing of semiconductors, ceramic chuck surface accuracy and integrity are directly related to chip production yield. Below is a case study demonstrating how LS Manufacturing applies its extensive history of ceramic CNC machining to address extreme finishing challenges for customers.

1. Customer Dilemma:

A leading semiconductor equipment manufacturer needed a batch of enormous silicon nitride ceramic chucks with very precise specifications: less than 5 microns of total flatness, and the surface must be flawless, microcrack-free by eye. A number of previous suppliers were unable to meet this due to stress, warping, and inescapable micro-chipping during machining, which led to the project being halted.

2. LS Manufacturing’s Solution:

Confronted with this challenge, the LS Manufacturing engineering team reacted in a non-traditional fashion.We first utilized a specially adapted heavy-duty ultra-precision gantry grinder to create system stiffness and purposely developed a proprietary diamond grinding wheel. Our innovation is utilizing our proprietary “flexible stress relief clamping technology,” which effectively counteracts and re-distributes machining and clamping stresses.

For ceramic CNC machining, we dropped the traditional one-step approach and adopted a multi-stage, progressive fine grinding process with parameter optimization to progressively release internal stress and compensate for deformation, ultimately realizing nanoscale material removal.

3. Results:

Through this systematic resolution, LS Manufacturing successfully achieved results beyond customer expectations: the flatness of the product was automatically controlled to 3 microns, and surface inspection by trained instruments testified to no damage. Finally, the yield of this batch of suction cups doubled from the industry norm of 60% to over 95%, making LS Manufacturing the only supplier of this fundamental component to this customer.

Do you as well struggle with low-damage, high-precision machining of ceramic parts? Contact the ceramic machining experts at LS Manufacturing today for a customized solution!

How To Ensure Flawless Quality Of Machined Ceramic Parts?

For high-value ceramic components, precision machining is just the starting point. A rigorous inspection system to their hard and brittle nature is the ultimate guarantee of having “zero defects.” In the entire process of ceramic CNC machining, LS Manufacturing employs unconventional methods of inspection to ensure that every detail is well considered.

1. High-precision dimensional and geometric tolerance inspection:

LS Manufacturing uses extremely accurate coordinate measuring machines (CMMs) to dimensionally inspect parts. The key is applying a microscopic measuring force on ceramic surfaces—much lower than that used for metal components, and applying hard probes such as ruby to avoid too much force causing tiny indentations or nicks at the contact point. Accurate measurement is achieved with little workpiece damage.

2. Surface and Subsurface Nondestructive Testing:

Trained dimensions do not by themselves provide internal integrity. We regularly utilize high-magnification digital microscopes or white-light interferometers to provide 100% inspection of critical surfaces to find micron-level chipping and scratching.

On parts with high reliability requirements, LS Manufacturing can utilize industrial CT scanning, which non-destructively inspects the interior of the part, graphically displaying any potential microcracks or material inhomogeneities. This is vital for ensuring long-term performance under difficult operating conditions.

3. Systematic In-Process Quality Control:

Final inspection is only the culmination. Successful ceramic CNC machining quality is a byproduct of rigid control of every process. We implement quality gates following roughing, semi-finishing, and finishing. Through inter-process inspections, we immediately reject defective parts and readjust the process, systematically addressing batch-by-batch quality risks.

Based on this interrelated test system, LS Manufacturing delivers not only dimensionally correct parts but also proven quality and reliability.

If you require the finest quality and consistency for your ceramic parts, please contact LS Manufacturing. We will provide you with a full test report and quality warranty.

Choosing A Professional Supplier: Beyond Equipment, What Should You Focus On?

Advanced equipment is only the beginning of achieving ceramic CNC machining; the real measure of success is the vendor’s extreme “soft power.” The highest value in choosing a partner like LS Manufacturing is in the surefire advantages we are able to bring to your project beyond the equipment itself.

1. Extensive Material Knowledge and Process Predictability:

LS Manufacturing has developed a comprehensive database of the properties of materials over a wide range of engineering ceramics from alumina to silicon nitride. What this does is enable us to predict what the anticipated behavior of different materials when machining them is, in advance, and thus avoid future possibilities of chipping and cracking during process design, as opposed to simply correcting for them afterwards.

2. A Proven Process Parameter Database and Rapid Response Capabilities:

LS Manufacturing has structured the parameters and results of thousands of successful cases into a comprehensive process database. For new parts, we can readily pull and optimize the optimal best machining solution available, significantly saving your process development time as well as keeping your project productive.

3. Experience in Handling Complex Problems and Strict Quality Control:

Real expertise is in having the capability to handle extreme cases. LS Manufacturing has acquired tremendous experience in handling extreme cases such as large part deformation and complex structure machining, which enables us to quickly diagnose and rectify a vast number of machining issues. Such practical experience along with stringent quality checks every step of the way is the ultimate guarantee of our relentless quality delivery.

Precise ceramic CNC machining is a carefully managed process. Choosing LS Manufacturing, which possesses these basic competencies, is the most reliable guarantee of the successful implementation of your project and achievement of your goals.

If you are looking for a partner who precisely understands and solves the problems of complex ceramic machining, LS Manufacturing greets your contact.

FAQs

1. What typical tolerances and surface finishes can LS achieve for ceramic parts?

We employ advanced equipment and proven ceramic CNC machining processes at LS Manufacturing to consistently achieve dimensional tolerances up to ±0.01mm and surface finishes below Ra 0.2μm. On high-end applications such as semiconductors and medical, we also control geometric and position tolerances and subsurface damage in critical areas through parameter optimization and precision grinding to ensure that the components can operate in the most severe conditions.

2. What is the minimum wall thickness/minimum hole diameter for machining ceramic parts?

With propriety tooling and solidly clamping processes, LS Manufacturing can typically reliably produce thin walls as minimum as 0.5mm and micro-holes as small as 0.3mm. However, it heavily relies on the actual ceramic material (e.g., zirconium oxide and silicon nitride’s varied machinability) and the overall structure. Our engineers would be happy to take a look at your design and provide professional feasibility analysis and optimization recommendations.

3. Is ceramic machining very expensive?

Ceramic CNC machining is more expensive than metal machining due to ultra-hard tool wear, long cycle time, and hard yield restriction. LS Manufacturing does exactly the opposite, though, maximizing process routes and building a database of parameters to maximize efficiency and material use and essentially controlling your overall cost and making an effort to provide the most cost-efficient solutions. For more information, contact LS Manufacturing and we’ll provide you with a quick reference and analysis.

4. How do I start my ceramic machining project?

Simply provide a part drawing or 3D model to get the partnership underway. LS Manufacturing’s experienced personnel will conduct a quick technical assessment and produce a detailed proposal with an effective process route, reliable delivery schedule, and transparent pricing. With dedicated personnel at each step, your project will go smoothly and efficiently. Get your ceramic machining project underway today!

Conclusion

Successful ceramic CNC machining is a highly specialized area that involves the skills of professional knowledge, hands-on know-how, and state-of-the-art equipment. It is not merely material processing; it is a precision craft that involves vast material properties knowledge and customized processes.

With our strong technical foundation and rich project history, LS Manufacturing is dedicated to becoming your go-to partner for precision ceramic parts production. Allow us to turn challenges into fundamental competitive strengths for your products.

Upload your design drawings now and get an instant CNC machining quote ( CNC machining price), let LS Manufacturing be your strong backing in pursuit of ultimate CNC machining precision!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.