Blanchard grinding is a flexible and environment friendly technique for eradicating giant quantities of fabric from one facet of a part. It provides a singular aesthetic attraction with its signature cross-hatching sample and might obtain excessive ranges of precision and accuracy. Its functions are wide-ranging, from giant ferrous supplies to small non-ferrous parts, making it a beneficial instrument in lots of manufacturing and fabrication contexts.

What’s Blanchard Grinding of Aluminum?

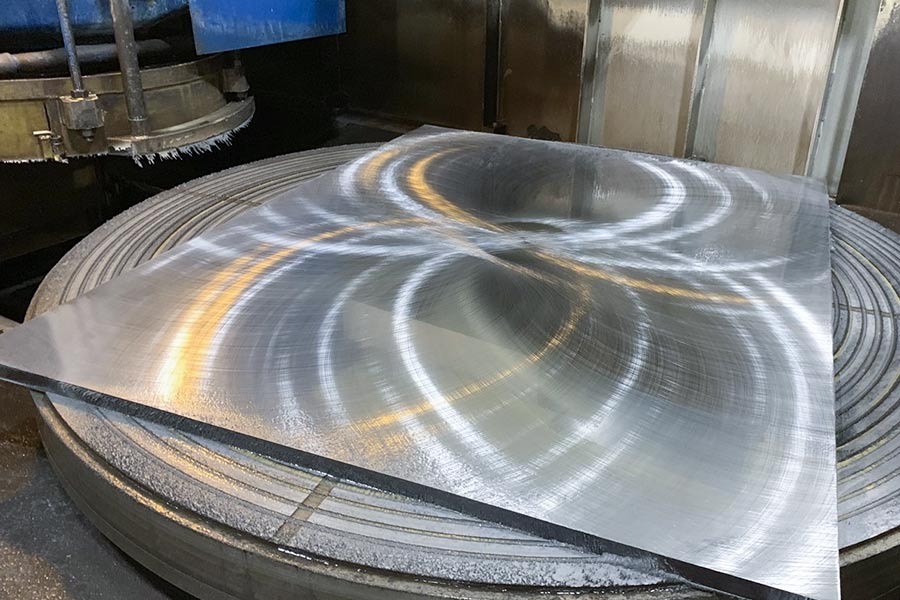

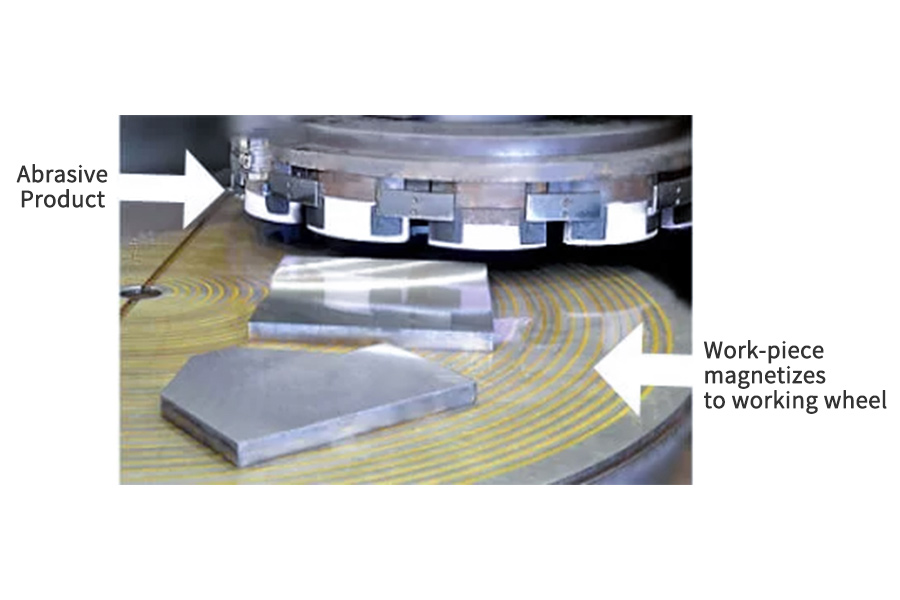

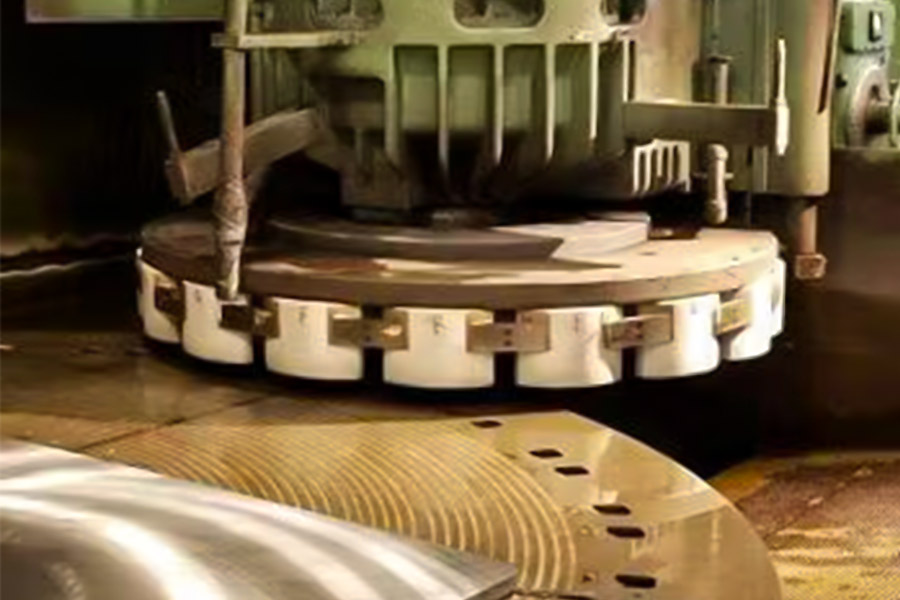

Blanchard grinding is a machining process identified for its effectivity in rapidly eradicating inventory from one facet of a part. It’s significantly well-suited for big items of fabric and is usually not used to grind something to a tolerance of lower than 0.001 inches. The process can go away a floor end round 65 RMS and in addition leaves a signature grinding mark that some think about to have aesthetic attraction. Blanchard grinding can work properly on a wide range of non-ferrous supplies, together with aluminum, stainless steel, brass, and a few plastics. Nevertheless, various varieties of holding units should be used for non-ferrous supplies. The process is critical for functions through which the removing of a considerable amount of materials is required, making it a beneficial instrument in lots of manufacturing and fabrication contexts.

Blanchard grinding is able to reaching very excessive ranges of precision and accuracy, with tolerances of plus or minus 0.001 inches. Nevertheless, the process is just not with out its challenges, as the big grinding wheels used could cause vibration and noise, making the process lower than preferrred for some functions. Regardless of this, when used correctly, Blanchard grinding could be a particularly efficient materials removing approach. It leaves a floor end of 63 Ra or much less, and its trademark cross-hatched floor end sample is usually seen as visually interesting.

Process Traits

-

Environment friendly Materials Removing: Blanchard grinding is thought for its skill to take away giant quantities of fabric rapidly and effectively. That is because of the process’s use of a giant grinding wheel that covers a broad floor space. This effectivity makes Blanchard grinding an excellent alternative for tasks that require vital materials removing.

-

Excessive Dimensional Accuracy: Regardless of its aggressive materials removing, Blanchard grinding can obtain spectacular dimensional accuracy. The process can preserve tolerances of plus or minus 0.001 inches, making it an appropriate alternative for tasks that require a excessive diploma of precision.

-

Glorious Floor End: Blanchard grinding can be identified for the standard of the floor end it produces. The process leaves a singular cross-hatched sample on the floor of the workpiece, which is usually thought-about aesthetically pleasing. Moreover, Blanchard grinding can obtain a floor end of 63 Ra or much less, which is sort of clean and appropriate for a lot of functions.

-

Sturdy Versatility: One of many key strengths of Blanchard grinding is its versatility. The process can be utilized on a variety of supplies, together with non-ferrous supplies like aluminum, stainless steel, brass, and a few plastics. This versatility, mixed with its effectivity, precision, and high quality floor end, makes Blanchard grinding a beneficial instrument in lots of manufacturing and fabrication contexts.

Tolerance Management

-

Dimensional Tolerance: Blanchard grinding can obtain high-precision dimensional tolerance management. Beneath preferrred working circumstances, Blanchard grinding can obtain tolerances of ±0.001 inches. This stage of precision makes Blanchard grinding an excellent alternative for tasks requiring high-precision dimensional management.

-

Flatness Tolerance: One other benefit of Blanchard grinding is its skill to realize excessive ranges of flatness tolerance. As a result of the big grinding wheel covers a lot of the floor of the workpiece in the course of the grinding process, constant flatness could be achieved throughout your entire workpiece. This makes Blanchard grinding an excellent alternative for tasks requiring excessive flatness.

-

Floor End Tolerance: Blanchard grinding can’t solely obtain high-precision dimensional and flatness tolerances but additionally obtain a high-quality floor end. Blanchard grinding can obtain a floor roughness of 63 Ra or much less, making it extremely beneficial in tasks requiring a high-quality floor end.

To make sure that the parts meet tolerance necessities, exact measurements and management should be carried out in the course of the Blanchard grinding process. Widespread measurement devices embody optical measuring devices, coordinate measuring machines, and floor roughness gauges. These devices can present correct measurement knowledge, serving to operators make needed changes in the course of the grinding process to make sure that the size, flatness, and floor end of the parts meet tolerance necessities.

Utility Fields

-

Automotive Parts: Blanchard grinding is broadly used within the automotive manufacturing business. Key elements resembling engine cylinder heads, cylinders, pistons, crankshafts, brake discs, and so forth., could be precision machined by way of Blanchard grinding. This technique ensures the dimensional accuracy and floor end of the parts, thereby enhancing the efficiency and sturdiness of the auto.

-

Aerospace Parts: The aerospace business can be an necessary utility area for Blanchard grinding. Key elements resembling wing skins, fuselage structural parts, touchdown gear parts, engine parts, and so forth., must be precision floor to fulfill strict aerospace requirements. Blanchard grinding can present an environment friendly and correct grinding resolution to fulfill these high-demand functions.

-

Digital Product Parts: In digital product manufacturing, Blanchard grinding has intensive functions. Warmth sinks, casings, baseboards, connectors, and different essential parts want precision grinding to make sure the efficiency and reliability of the product. Blanchard grinding can present excessive precision and high-quality floor remedy, assembly the high-standard necessities of digital product manufacturing.

-

Mechanical Parts: Machine instrument bases, guides, gears, bearings, and different mechanical parts are additionally necessary functions for Blanchard grinding. The precision and floor end of those parts straight have an effect on the efficiency and lifetime of mechanical tools. Blanchard grinding can present an environment friendly and correct grinding resolution to fulfill the wants of the mechanical manufacturing business.

-

Constructing Materials: Within the development business, Blanchard grinding additionally has intensive functions. Constructing supplies resembling door and window frames, curtain wall panels, ornamental panels, and so forth., could be processed by way of Blanchard grinding to enhance the dimensional accuracy and floor end of the supplies.

Conclusion

Blanchard grinding, or rotary floor grinding, is a machining process identified for its skill to take away vital quantities of fabric in a short while, offering excessive effectivity in manufacturing.

Key traits of Blanchard grinding embody its skill to realize excessive dimensional accuracy, a wonderful floor end, and powerful versatility, making it an excellent alternative for varied manufacturing and fabrication contexts. Exact measurements and controls are needed in the course of the Blanchard grinding process to make sure parts meet tolerance necessities, with widespread devices together with optical measuring devices, coordinate measuring machines, and floor roughness gauges.

Blanchard grinding finds intensive functions throughout a wide range of fields, from automotive to aerospace, electronics, mechanical parts manufacturing, and even within the development business. It’s significantly helpful in conditions that require giant materials removing and excessive precision.

Blanchard grinding is a robust instrument in manufacturing and fabrication, with its effectivity, precision, and high-quality floor end making it invaluable throughout many industries.

FAQs

What are the benefits of Blanchard grinding in comparison with different aluminum processing processes?

In comparison with different aluminum processing strategies, Blanchard grinding has a number of benefits. It may well rapidly and effectively take away giant quantities of fabric, making it preferrred for large-scale manufacturing. It additionally supplies a excessive stage of precision, making certain that parts meet strict tolerance necessities. Moreover, Blanchard grinding can obtain a clean, uniform floor end, which is usually needed for sure functions.

What do I want to concentrate to when Blanchard grinding aluminum?

When performing Blanchard grinding on aluminum, there are a number of issues to remember. First, it is necessary to make use of the right grinding wheel to stop the aluminum from sticking to the wheel. Second, the grinding parameters (such because the feed fee and depth of reduce) must be fastidiously managed to keep away from damaging the aluminum. Lastly, the aluminum must be repeatedly inspected in the course of the grinding process to make sure that it meets the required specs.

What’s the greatest materials for grinding stainless steel?

The very best materials for grinding stainless steel will depend on the particular necessities of the job. Nevertheless, basically, a grinding wheel made from aluminum oxide or silicon carbide is usually used. These supplies are onerous and sturdy, making them appropriate for grinding robust supplies like stainless steel.