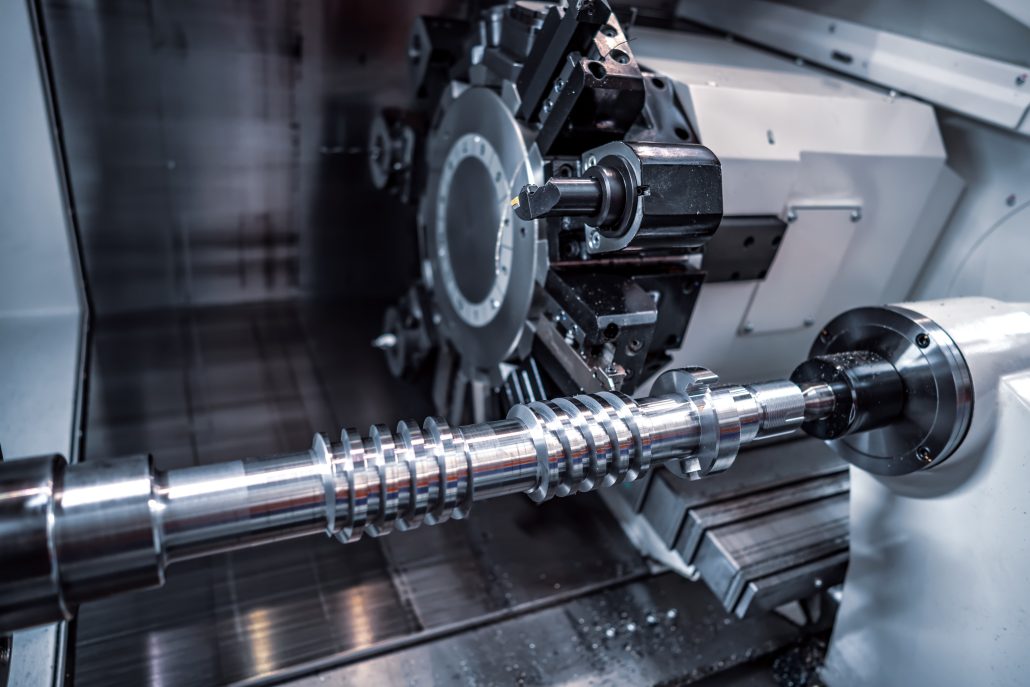

In today’s modern manufacturing industry, CNC machining has become an indispensable technology in manufacturing industry. CNC machining can not only improve production efficiency, but also accelerate the production cycle, reduce labor costs, reduce manual errors and precision errors. However, to achieve efficient CNC machining, choosing the right materials is crucial

If you are looking for aluminum suitable for CNC machining, then this article will provide you with useful information. In this article, you will learn how different aluminum models compare and how they are used in CNC machining. This article also explores the cost, importance, advantages, and disadvantages of each aluminum material to help you make a more informed choice.

Why aluminum?

First, aluminum is widely used because of its light weight, high strength, corrosion resistance and recyclability. It is widely used in automobile, aircraft, construction, electronics and other industrial fields. In addition, aluminum has excellent thermal and electrical conductivity, making it important for many applications.

Commonly used aluminum models

The following are the most commonly used types of aluminum in CNC machining:

6061 Aluminium alloy

6061 aluminum is an aluminum alloy with high temperature resistance and high strength. It has good machining performance, good corrosion resistance, widely used in aircraft, motorcycles, aerospace equipment and electronic fields. In addition, AA6061 also has high strength, excellent corrosion resistance and good malleability, and can be manufactured in a variety of sizes and shapes according to customer needs.

7075 Aluminium alloy

7075 aluminum is a high hardness aluminum alloy suitable for manufacturing parts requiring high hardness and strength. Its stable performance and wide range of applications are commonly used in aircraft, automobiles, sports equipment, offshore oil Wells and other high-strength applications. In addition, AA7075 has super strength, excellent wear resistance and excellent corrosion resistance. This makes AA7075 ideal for high-intensity applications

2024 Aluminium alloy

2024 aluminum has excellent machining properties and is widely used in aerospace, military, automotive and Marine fields. Because of its good toughness and corrosion resistance, it is also used to make aircraft casings made of alumina, and 2024 is also good machinability and malleability.

2024-T3 Aluminium alloy

The 2024-T3 alloy is a medium strength material that is ideal for shell and structural design. The material is not only resistant to wear and tear, but also to corrosion, and can be used to manufacture precise parts in CNC machining. 2024-T3 alloy materials can be CNC machined to make various types of parts, such as nuts and bolts, with precision, constant size and virtually no finishing required.

5083-H321 Aluminium alloy

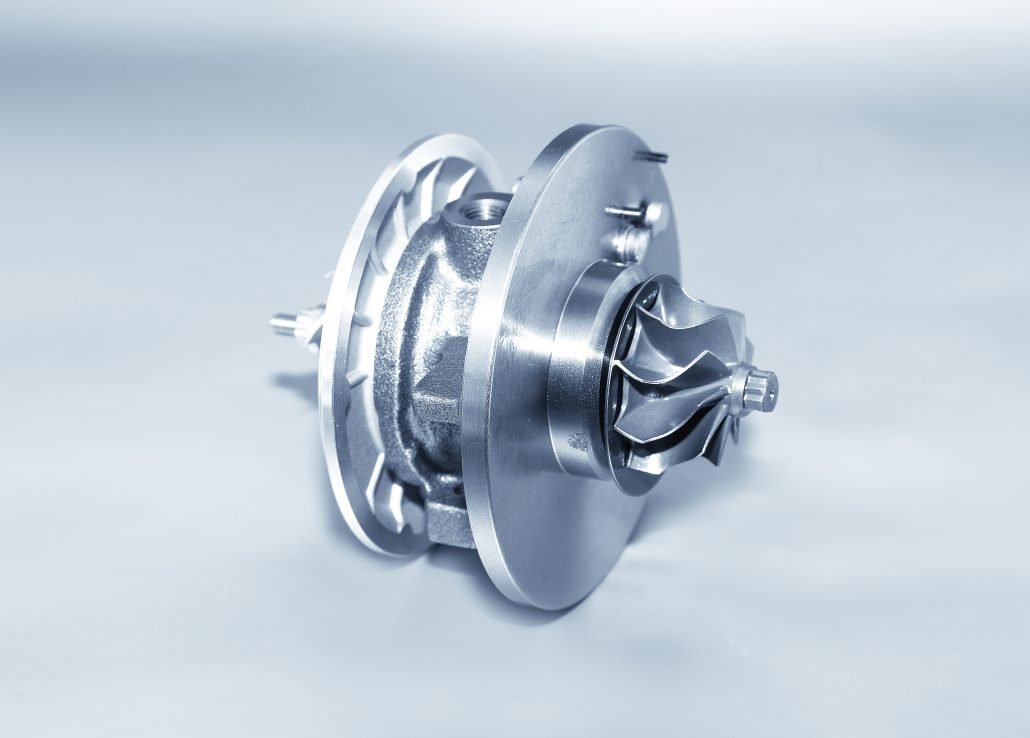

5083-H321 is a high-strength aluminum alloy material with excellent corrosion and heat resistance. It can use CNC machining and heat treatment to make various types of materials, such as hulls, submersibles and aircraft engines. 5083-H321 aluminum alloy in CNC machining, can manufacture its sheet, wire, pipe and riveting parts.

6061-T6 Aluminium alloy

6061-T6 is a simple aluminum alloy with high strength and excellent corrosion resistance. It is also easy to process, so it is the preferred material for making complex parts. It can be precisely machined using a variety of CNC machines, such as milling machines and drilling presses. It can be machined to obtain a consistent finished product, which is a very suitable material for the production of large quantities of products.

7075-T6 Aluminium alloy

7075-T6 alloy is a high strength, high corrosion resistance material, so it is widely used in the aviation and automotive industries. Its hardness and strength make it ideal for applications requiring high strength materials. And 7075-T6 is a relatively easy to process material, can be adapted to most CNC machining processes.

Comparison of the cost of CNC machining aluminum profiles

Price has always been an important consideration in material selection, especially in large production. Here are the average prices of the four aluminum models:

- 6061 Aluminum alloy: $2.5-3.50 / lb.

- 7075 aluminum alloy: $4- $5 / lb.

-2024 aluminum alloy: $3- $4 / lb. - 5083 aluminum alloy: $5- $6 / lb.

Cost analysis of traditional machining and CNC machining of aluminum profile

The traditional machining method is mainly to use human or mechanical directly machining aluminum profile. CNC machining is through the computer to the aluminum machining command control.

First, let’s look at the cost analysis of traditional machining methods. Traditional machining method has high labor cost for aluminum production process, which requires hiring workers, machinery and equipment, and the cost of these factors is also very significant, so the cost of traditional machining method is relatively high.

In contrast, CNC machining is more efficient and sustainable in the machining of aluminum. CNC machining equipment can last for several days, or even up to a week or more. In addition, CNC technology can be through its unique computer control, so that aluminum profiles can be more accurate machining. This can make the final output of aluminum profile more perfect and accurate. In other words, CNC machining has higher production efficiency and lower cost than traditional machining.

In the final cost analysis, we found that CNC machining aluminum profiles has more advantages than traditional machining methods in both labor cost and material cost. In addition, machining aluminum profiles through CNC machining has more advantages in precision. Therefore, in the production of aluminum profiles, we recommend the use of CNC machining.

If you think CNC machining of aluminum is more suitable for your plant or use scenario, consider a better CNC machining equipment. If you have any questions or need to consult, please contact us. We will provide you with the best technical support.

Cnc machining aluminum model advantages and disadvantages

It is important to know the advantages and disadvantages of the material you want to use before proceeding to CNC machining aluminum. This helps you select the best materials for your project, improve product quality and reduce costs. Let’s take a look at the pros and cons of each type of aluminum.

6061: This aluminum is very common in CNC machining and has a wide range of uses. Although the 6061 has good toughness and strength, it has the disadvantage that it is not easy to weld and has a high corrosion rate with other metals. The most suitable applications are those requiring high strength and durability.

7075: This is a radical high strength aluminum for durable and demanding high strength projects. However, compared with 6061, 7075 is more difficult to process and is more prone to cracking and microcracks. If your project needs high performance, then 7075 is a good choice.

2024: This aluminum is very lightweight and is used for projects that require light weight. However, 2024 is not as strong as 6061 and 7075 and is more brittle. Best suited for applications in medium load and very light applications.

2024-T3: This aluminum is stronger than 2024 and has higher corrosion resistance. Although the machining difficulty is not as good as 7075, it is relatively stable. This is a very suitable material for use in aviation.

5083-H321: This aluminum is resistant to corrosion and water and can be used in Marine and other saline environments. This is a very good choice of material that can be used to make vessels.

6061-T6: This aluminum has higher strength and better corrosion resistance than 6061. It is relatively stable in structure, but it requires higher production cost due to its poor weldability.

7075-T6: This is one of the most commonly used high-strength aluminum, showing excellent performance while also having strong corrosion resistance. Because of its light weight, high strength, hardness and other characteristics, can be used to manufacture a variety of products. However, it is also more difficult to process than other aluminum. Therefore, if you encounter problems in machining, it is recommended to consult professional processing manufacturers.

In general, different types of aluminum have their own unique advantages and characteristics, the selection of appropriate aluminum materials will help to improve product quality and reduce costs. Therefore, the selection of aluminum needs to consider the use of environment and machining methods. The trade-off between cost, strength and corrosion resistance is very important. Please remember to carefully weigh each factor in the selection to make your machining results better.

How to Choose the Best Aluminum Extrusions for Your Project

Let’s look at different kinds of aluminum profiles and their applications in CNC machining projects and how to choose:

6061: This aluminum profile is widely used in general structural and construction projects. It is easy to process, can easily achieve a variety of shapes and light weight. Therefore, if your CNC machining project needs high plasticity, strength and light materials, then choose 6061 profile is a good choice.

7075: If your CNC machining project requires high strength and hardness of materials, then 7075 aluminum is a better choice. It is a heat-treated alloy made by forging and heat treatment. This material is usually used in parts that require high strength and hardness.

2024: This aluminum profile is widely used in the aerospace industry. As a high-strength material, it is ideal for parts and components requiring high strength loads. For example, the high-stress parts of the plane, such as the skin and wings, are made of 2024 aluminum.

2024-T3: This is a premium, high-stiffness aluminum profile with advantages such as high bending strength and corrosion resistance. Therefore, it is ideal for use in highly precise parts or applications requiring frequent repairs.

5083-H321: This aluminum profile is commonly used in hull and automotive applications because of its excellent corrosion resistance, weldability and strength. If your CNC machining project is related to ships or automobiles, then 5083-H321 is a good choice.

6061-T6: This is a high strength, excellent corrosion resistance aluminum profile for highly reliable applications at extremely low temperatures. If your project needs to work in extreme temperatures and environments, the 6061-T6 is a good choice.

7075-T6: This aluminum profile is usually used in parts requiring high durability or parts requiring high load load. Compared with other types of aluminum, 7075-T6 aluminum has the advantages of higher strength, better toughness and better corrosion resistance.

Choosing the right aluminum profile for you is very important because it directly affects the cost and quality of your CNC machining project. By selecting different types of aluminum profiles, you can maximize their utility based on the application, requirements, and performance requirements of your project.

If you need help in CNC machining projects, or want to know more information, please contact us! Our team can help you select the best materials and provide high quality, CNC machining services for your project!