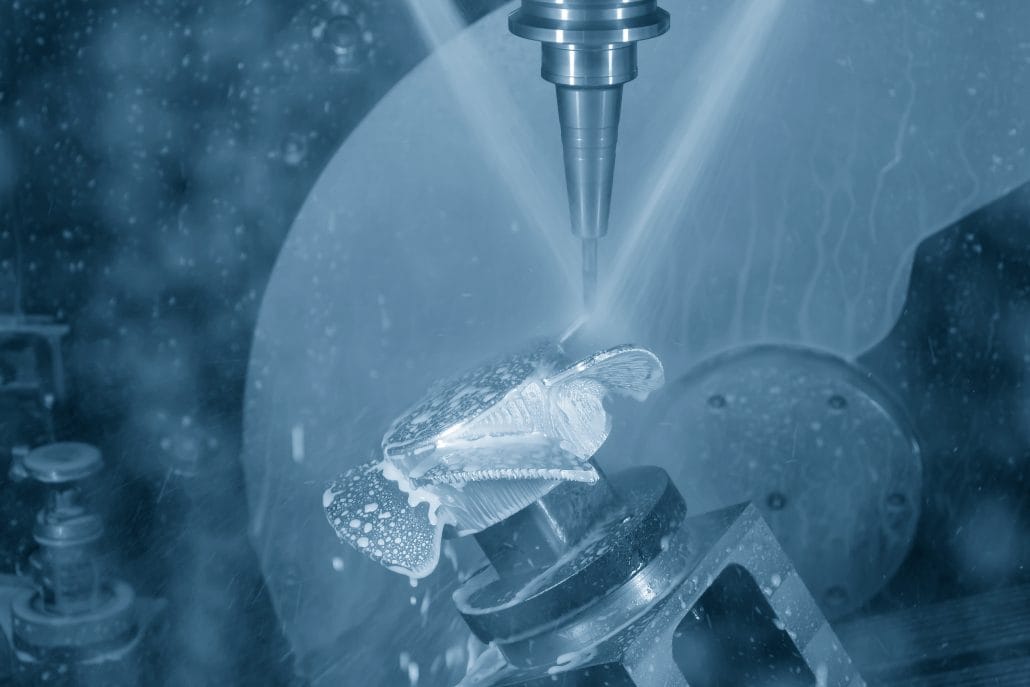

CNC machining is a kind of machining technology widely used in modern industry, through the CNC machine tool control tool trajectory, to process the workpiece. With the advancement of industrial intelligence, more and more enterprises began to use CNC machining technology and formulate the corresponding quotation strategy. In this process, how to establish a reasonable CNC machining quotation calculation formula is the top priority.

Basic principles

For CNC machining industry, senior technical personnel often have excellent mathematical ability and technical application ability. On this basis, to establish a reasonable and accurate pricing formula, the following principles should be strictly adhered to:

- Be reasonable and reasonable.

- Sufficient technical content to maintain the core competitiveness of the company.

- Ensure profit margin and normal operation of the enterprise.

- The change of the domestic market determines the reasonableness of the quotation standard, and the price should match the market trend.

- In the process of creating the quotation measurement system, avoid being too basic and tedious, and should be simple but not simple.

Data required for pricing formula

In the establishment of CNC machining quotation calculation formula, should consider all aspects of the data. Here are some basic data items:

- Equipment consumption and labor cost per unit time

- Quantity and unit price of cutting tools used

- Equipment depreciation costs and maintenance costs

- machining material cost and transportation cost

- Reasonable profit margin

Establish pricing formula

After reviewing the basic principles and necessary data items, we need to formulate a CNC machining quotation calculation formula by analyzing these data items and recombining them. The following is our suggested calculation formula. Please make specific adjustments according to the actual situation of your own enterprise

Quotation = equipment consumption cost + labor cost + tool cost + depreciation cost + maintenance cost + material cost + transportation cost + reasonable profit.

By using the self-described method, enterprises can determine their own CNC parts online quotation calculation formula according to its actual situation, in order to meet the needs of the market and help enterprises to achieve sustainable development.

On this basis, combined with the complexity of production requirements and their own needs to achieve intelligent measurement, we suggest adding data mining model and prediction algorithm to the formula, so as to further improve the accuracy and intelligence of CNC machining quotation calculation. In this way, enterprises can better adapt to market changes, better grasp the market opportunities, so as to achieve more competitive advantages.

In short, in the establishment of CNC machining quotation calculation formula, enterprises should be based on their own actual situation and market demand for customized adjustment, and consider increasing the data mining model and prediction algorithm and other technical means, in order to achieve intelligent measurement, so as to better meet the market demand for CNC machining quotation calculation.

CNC machining quotation calculation formula

To calculate the cost of CNC machining, you need to consider the following:

Material cost: Material cost is the most basic cost, usually accounting for more than 50% of the total cost. The cost of materials depends on factors such as the type of materials you choose, specifications, quality, etc.

Manufacturing cost: Manufacturing cost is also an important part of CNC machining. This includes the cost of equipment and tools, workers’ wages, electricity and other expenses.

Shipping costs: If you need to buy materials from other regions or countries, or if your customers are in other regions, then shipping costs will become another factor to consider.

Basic quotation:

Total CNC cost = material cost + machining and manufacturing time cost + express transportation cost

The workpiece material price in CNC basic quotation is usually calculated according to the market price. The cost of machining time is usually calculated in x hours, and the specific value of x should be related to the difficulty of machining and the hardness of the material. Courier charges refer to the Courier charges required to send the product back to the customer.

For example, if you are producing a batch of parts, you can calculate the cost as follows:

Material cost: You bought the material, 100 yuan per kilogram, you need 100 kilograms. Therefore, the material cost is 100 yuan/kg *100 kg =10000 yuan.

Manufacturing cost: You need to use CNC manufacturing equipment, which costs 200 yuan per hour, and you need to use 10 hours for machining . In addition, the hourly worker wage is 50 yuan and you need to use 2 workers to work. Therefore, manufacturing cost = (200 yuan/hour *10 hours) + (50 yuan/hour *2 workers *10 hours) =2500 Yuan.

Transportation cost: You need to use a truck to deliver the parts to the customer, the freight is 3 yuan per kilometer, you need to transport 100 kilometers. Therefore, transportation cost =3 yuan/km *100 km =300 yuan.

Total cost = material cost + manufacturing cost + transportation cost =10000 yuan +2500 yuan +300 yuan =12700 yuan.

CNC machining quotation calculation formula contains a number of variables, the different combinations of these variables will affect the results of the entire quotation. Understanding the role of each variable is crucial to saving costs and improving the manufacturing quality of parts and molds

Factors affecting the cost of cnc machining

machining mode:

CNC machining method has a great impact on CNC quotation, machining method is divided into CNC milling machining and CNC lathe machining . CNC milling machine machining is generally more complex, machining costs are high; CNC lathe procemachining ssing general operation is relatively simple, the machining cost is correspondingly lower. Therefore, different machining methods determine different quotes.

Workpiece size:

Workpiece size is also an important factor affecting CNC machining quotation. Generally, the larger the size of the workpiece, the higher the cost of machining . Because long time machining needs to consume more manpower and consumables.

Surface finish:

Surface finish is an important appearance standard, especially when making parts or molds. The higher the surface finish, the higher the machining cost.

Workpiece shape:

Workpiece shape also plays an important role in CNC machining quotation. Complex shapes require CNC machining to take more steps to complete. Simpler shapes can be made in less time and cost.

Because cnc machining price calculation formula is very complex, so you need to consider various factors, and according to the specific needs of the balance. If you have more questions, you can consult a professional cnc machining factory to get a more detailed price quotation calculation method.