When designing a CNC part, the first step is to determine what material it should be made of. When you decide that the CNC parts should be plastic & metal and CNC machined, does the choice end there? No, there are too many plastics & metals to choose from, each with its own combination of properties.

In this article, Longsheng Technology helps you to combine the project requirements with the plastic and metal materials suitable for the job, and narrow the selection to a few commonly used materials.

CNC machining metal materials advantages and disadvantages & applications

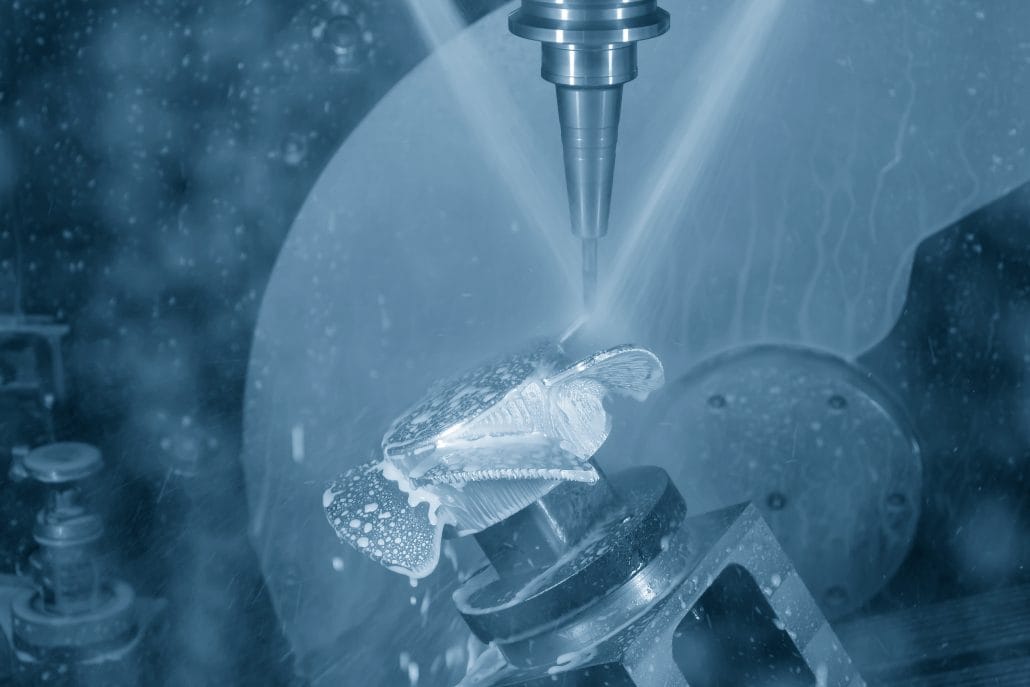

CNC machining of metal is a kind of material that can be processed accurately and quickly by using high-precision CNC machine tools. The following are some advantages, disadvantages and applications of CNC machining of metal parts:

aluminum

Aluminum alloy is a very common and widely applicable metal material, when choosing aluminum, we need to pay attention to its strength and cost factors.

Advantages: Low cost, easy to process, light weight, strong corrosion resistance

Disadvantages: low strength, poor elasticity

Applications: Aluminum is often used in electronics and automobiles. Its light weight and corrosion resistance, so that it is often used in aircraft, bicycles and other popular travel equipment, but also used in a variety of chassis, bracket, etc.

brass

Brass is a common conductive material

Advantages: High strength, easy to process, good corrosion resistance

Disadvantages: Poor thermal and electrical conductivity

Application: Brass is commonly used in a wide variety of connectors, pipe fittings and mechanical parts. Its general electrical and thermal properties make it widely used in the contact head, wire and buckle parts of electronic equipment, as well as in the manufacture of various pressure or high temperature pipes, such as water pipes, gas pipes and refrigeration components.

steel

Steel is a relatively inexpensive metal used in making auto parts and other mechanical structures

Advantages: Extremely high strength and wear resistance

Disadvantages: High cost, difficult to process

Applications: Steel is commonly used in the manufacture of demanding parts such as aircraft, vehicles, buildings and machinery. It can be used in some special situations, such as brake pads in cars, and supporting steel rods in buildings and Bridges.

Stainless steel

Stainless steel has a higher price than the other two metals, but is extremely strong, making it ideal for applications that require strength.

Advantages: Excellent corrosion resistance, high strength, easy to process

Cons: Higher cost

Applications: Stainless steel is highly resistant to corrosion, making it preferred in many industries, such as food, chemical and medical devices. It is also used in a variety of medical devices, such as surgical instruments, artificial joints, and other equipment components that must be in constant contact with the human body.

copper

Copper is a common conductive material used to make electronic components and plumbing systems, but it is relatively soft and can’t withstand as much pressure as other metals.

Advantages: Good electrical and thermal conductivity

Disadvantages: low strength, poor corrosion resistance

Application: Because of its excellent electrical and thermal conductivity, copper is widely used in the circuit boards of electronic equipment, as well as radiators used in a variety of refrigeration equipment. At the same time, copper is often used in various arts and crafts, such as sculptures, incense burners and other decorations.

CNC machining plastic materials advantages and disadvantages & applications

CNC machining plastic is a kind of material processed by high precision CNC machine tools. This kind of material has many types and characteristics. Below are some advantages, disadvantages and applications of CNC machining plastics:

ABS plastic

ABS is an all-purpose plastic. It provides high impact strength, toughness and resistance at a low price. It is also easy to finish, as it can be easily painted, glued, or soldered together. If left as is, it will have a matte finish.

Advantages: ABS is the best choice for general purpose prototypes, preformed prototypes, parts that are subject to impact and require toughness, or parts that require low cost.

Disadvantages: ABS does not have good wear or chemical resistance and will melt in acetone. It’s also not a particularly strong plastic. In addition.

Applications: The most common application of ABS is injection molding, where it is used to make electronic casings, home appliances and even the iconic Lego bricks.

nylon

Nylon is a strong and durable plastic suitable for many uses.

Advantages: Nylon has high strength and stiffness, holds over a wide temperature range, has good electrical insulation, and good chemical and wear resistance. Nylon is ideal for applications requiring low cost, strong and durable components.

Cons: Nylon absorbs moisture, causing it to expand and lose some dimensional accuracy. Due to the inherent internal stress of the material, distortion can also occur if a large amount of asymmetric material is removed during machining.

Applications: Nylon is most commonly found in medical devices, circuit board mounting hardware, automotive engine compartment components, and zippers. It is used as an economical alternative to metals in many applications.

PMMA

PMMA is acrylic, also known as plexiglass. It is tough, has good impact strength and scratch resistance, and can be easily bonded using acrylic cement.

Pros: It’s perfect for any application that requires optical clarity or translucency, or as a less durable but less expensive alternative to polycarbonate.

Cons: PMMA is a brittle plastic that will fail from cracking or crushing, rather than stretching. Any finish on a piece of acrylic will lose transparency and take on a frosted, translucent appearance. Therefore, it is usually best to note whether PMMA parts should be kept in stock thickness to maintain transparency. If the finished surface requires transparency, it can be polished as an additional post-treatment step.

Application: After processing, PMMA is transparent and is most commonly used as a lightweight alternative to glass or light tubes.

POM

POM is a special brand of acetal homopolymer with smooth, low friction surfaces, excellent dimensional stability and high stiffness.

Pros: POM is a good plastic for these or any other applications that require a lot of friction, require tight tolerances, or require high stiffness materials.

Cons: POMs are hard to glue. The material also has internal stresses that make it prone to warping in areas that are thin or have a lot of asymmetric material removed.

Application: POMs are commonly used in gears, bearings, bushings and fasteners, or in the manufacture of jigs and fixtures for assembly.

HDPE

HDPE is high density polyethylene.

Pros: HDPE is a very low density plastic. It also has excellent chemical resistance, electrical insulation and a smooth surface. It is great for making plugs and seals because of its chemical resistance and slippage, but is also a good choice for weight-sensitive or electrosensitive applications.

Cons: The main downside of HDPE is poor strength, especially when it comes to stretching and bending.

Applications: HDPE is commonly used in fluid applications such as fuel tanks, plastic bottles, and fluid flow tubes.

PC

PC is the most durable plastic we have.

Pros: It has high impact resistance and stiffness, and maintains function over a wide temperature range. It is also optically transparent, and can be dyed black if opacity is desired. PC is best suited for applications that require very rigid or very strong plastics, or for optical transparency. As a result, PC is one of the most used and recycled plastics.

Disadvantages: Pure PC does not have good wear resistance, easy to scratch. Scratch-resistant coating and steam polishing can be added as a post-treatment step if desired to improve wear resistance or optical clarity. It also doesn’t have readily available two-inch thick parts, which limits the size of PC parts.

Applications: The PC’s durability and transparency mean it can be used to make compact discs, safety glasses, light tubes and even bulletproof glass.

advantages of CNC Machining plastics

CNC cut plastic is a very popular choice because plastic materials are superior in many ways. Not only do they have very high durability, but they are lighter, easier to transport, and come in many different colors and textures to choose from. In addition, plastic materials are easier to form complex shapes than metals, providing more design freedom.

When choosing CNC plastic materials, there are several plastic substrates to choose from. Two of the most common plastic materials are polyvinyl chloride (PVC) and polypropylene (PP). PVC is a very strong and flexible plastic material, perfect for the task of making fences, signs, maps, advertising boards, etc. PP is a transparent and easier to shape material, perfect for making thin-walled containers or other more complex shapes.

Advantages of CNC machining of metals

CNC cutting metal is very similar to plastic in some respects, but completely different in others. Of course, metal materials are stronger and more durable than plastic materials, and are generally more suitable for use in the environment. Metals can also be welded using welders, which allows them to be kept in an environment of high temperatures and pressures that plastics cannot withstand.

Similarly, CNC cut metal also has different types of metal to choose from. Aluminum, stainless steel and steel are the most common. Aluminum is a lightweight metal suitable for lightweight parts and applications requiring high strength and corrosion resistance. Stainless steel is commonly used in applications requiring high strength, plasticity and corrosion resistance, such as kitchen equipment, furniture and automotive components. Finally, steel is a very durable and strong metal suitable for heavy duty users, such as the chassis of automobiles and parts of machinery and equipment.

There are many different factors that need to be considered when choosing CNC machining plastic materials and CNC machining metal materials, such as strength, cost, machinability and so on. Of course, you need to see the properties of these materials for yourself to make the right choice. Longsheng hopes this guide will help you make the right choice. If you need more cnc parts online information, you can check our website, or contact our professional team, we will be dedicated to serve you.