Stainless Steel CNC Machining

We provide fast, accurate and reliable CNC machining services, from part design, rapid prototyping and mass production, to provide you with the best quality custom stainless steel parts.

- Manufacturing on demand

- Tolerances down to ±0.01mm

- Delivery in as little as 3 days

- Get your custom parts at low prices

- All uploads are secure and confidential

Stainless Steel CNC Machining Services for Custom parts

Our instant CNC quotation service allows you to quickly respond to market changes on demand when obtaining CNC stainless steel parts. Our CNC machining services are flexible enough to meet the needs of all sizes and levels of urgency. We offer a quote immediately to make the best choice for you within a strict budget.

Our cnc machines are highly accurate and can handle a wide range of stainless steel materials, including 304 stainless steel, 316 stainless steel, etc. Whether you need to process a stainless steel part or mass production, we can provide customized services according to customer requirements

We are committed to providing high quality and fast service to our customers. If you have any requirements or questions, feel free to contact our team of cnc machining experts. We are happy to help you solve your problems and provide relevant solutions

Our Manufacturing Capabilities

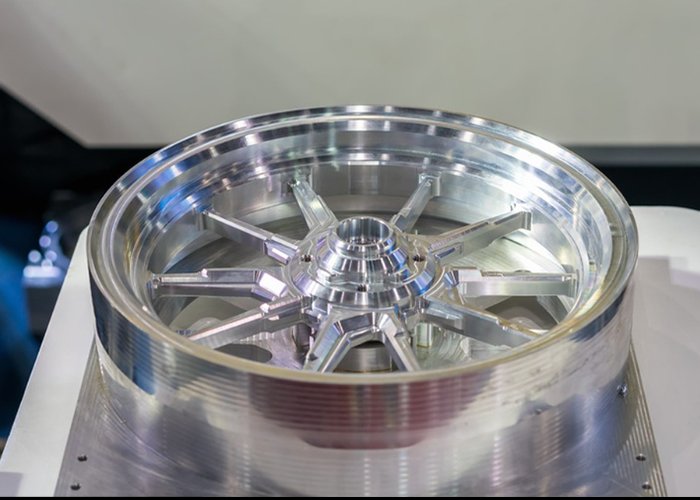

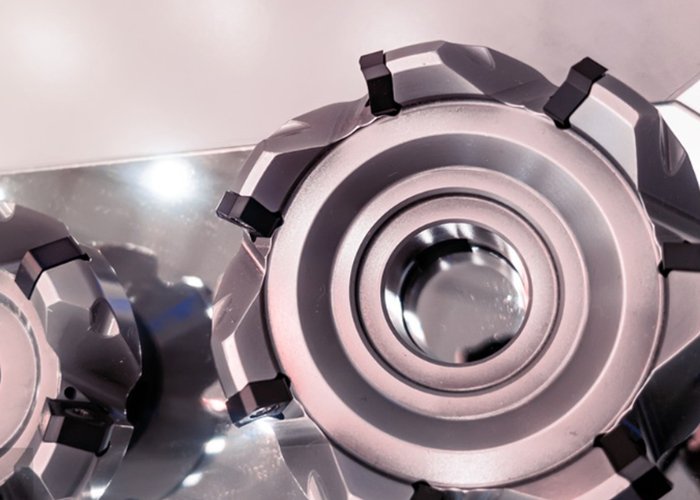

Longsheng Technology can achieve high precision, high efficiency milling parts processing. From rapid prototyping to custom production, our CNC milling machine can mill a variety of materials, including metal, plastic. Whether simple parts or complex structures, we use high quality CNC milling, obtain high precision and high quality CNC milling parts, contact Longsheng technology to help you translate the design into complex geometric shapes, and obtain customized milling parts that meet your strict requirements.

CNC milling machining

CNC milling is done by using a CNC milling machine to remove excess material from stainless steel workpieces to get the desired shape and size. In CNC milling, the workpiece is fixed to the milling machine and then the material is removed in a rotating manner by a tool controlled by a computer program. This machining method can realize the machining of high precision and complex shapes.

CNC turning machining

CNC turning is the use of CNC lathes to process stainless steel workpieces. In CNC turning, the workpiece is fixed to the lathe by a rotating fixture and then cut on the workpiece by a tool controlled by a computer program. The movement of the tool can be carried out along the axis (longitudinal) and radial (transverse) of the workpiece. This machining method can be used to make shaft parts, cylindrical parts and other custom parts with rotational symmetry.

Put your parts into production today

- All information and uploads are secure and confidential.

Stainless steel CNC machining material

Longsheng supplies most of the industry standard materials. If you do not find the materials you want in the list, please contact us

| Stainless steel alloy | Density (g/cm³) | Young's Modulus (GPa) | Tensile Strength (MPa) | Yield Strength (MPa) | Thermal Conductivity (W/m·K) | Melting Point (℃) |

|---|---|---|---|---|---|---|

| 304 Stainless Steel | 8.0 | 193 | 515 | 205 | 16.3 | 1400 |

| 316 Stainless Steel | 8.0 | 193 | 515 | 205 | 16.3 | 1400 |

| 430 Stainless Steel | 7.7 | 200 | 450 | 205 | 24 | 1425 |

| 201 Stainless Steel | 7.8 | 190 | 655 | 310 | 15 | 1400 |

| 17-4PH Stainless Steel | 7.8 | 196 | 1000 | 860 | 16.3 | 1450 |

| 2205 Duplex Stainless Steel | 7.8 | 200 | 620 | 450 | 19.2 | 1400 |

| 410 Stainless Steel | 7.7 | 200 | 655 | 310 | 24.9 | 1530 |

| 904L Stainless Steel | 8.0 | 185 | 490 | 220 | 13.0 | 1350 |

| 316L Stainless Steel | 8.0 | 193 | 485 | 170 | 16.3 | 1400 |

| 321 Stainless Steel | 7.9 | 193 | 515 | 205 | 16.3 | 1400 |

Stainless Steel Machining Applications

Stainless steel is a commonly used metal material suitable for manufacturing various types of CNC machining parts. The following are some common parts used in stainless steel CNC machining:

- Automotive parts

- Medical equipment components

- Pump and valve components

- Power engineering parts

- Electronic components

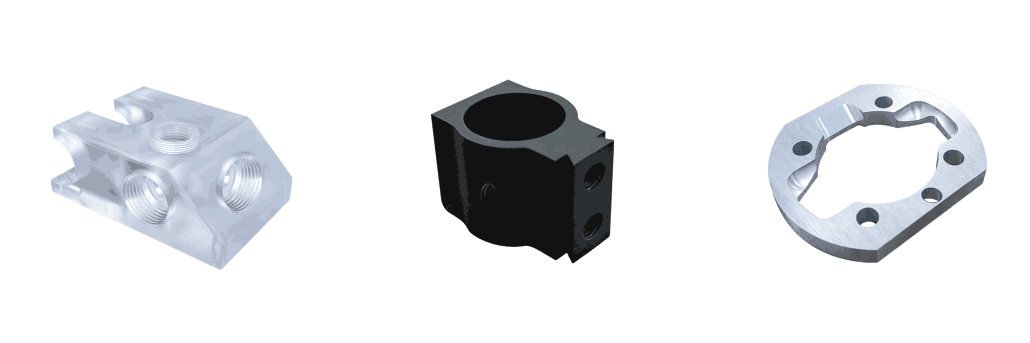

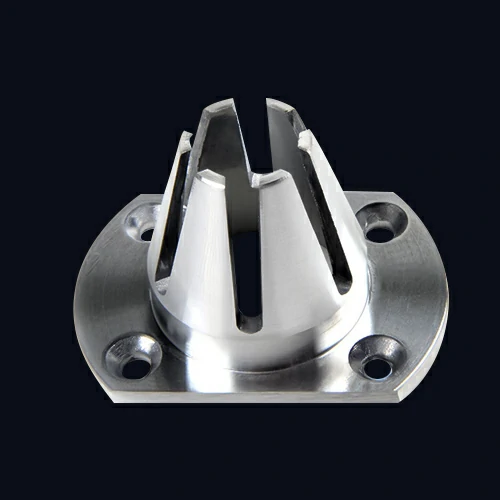

Gallery Of stainless steel Parts

View the custom stainless steel parts we process for customers, from rapid prototyping, small batch production to batch production orders

Our Machining Service For Various Industrial Applications

No matter what industry you’re in, Longsheng’s machining service are the perfect solution for all your needs. Our commitment to quality and customer satisfaction means that we always deliver on our promises, ensuring that you get the best parts at the best prices.

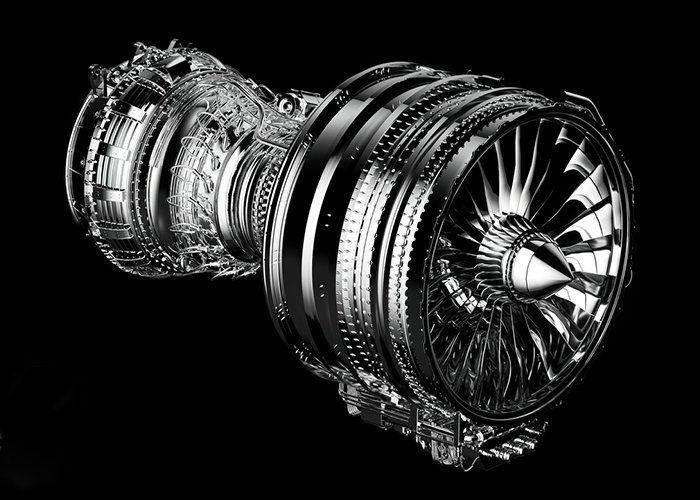

Aerospace

Our precision parts machining services provide durability and precision to meet the complex requirements required at different stages of the aerospace industry.

Automotive

From prototyping to production, our precision parts machining services are the ideal manufacturing solution for on-demand automotive parts.

Electronics

We specialize in providing high-quality machining services for a wide variety of electronics.

Medical Devices

We provide high-quality custom precision parts for various medical equipment, including surgical instruments, beds, monitoring equipment, and more.

Stainless steel parts Finishes and Post-Processing Options

We can deal with all kinds of stainless steel parts surface problems, at Longsheng Technology, our professional engineers will work with you, understand your needs, and customize stainless steel parts according to your requirements, for your products to bring more beautiful and excellent quality

Polishing: can make the surface of stainless steel smooth, improve its appearance quality.

Sandblasting: produces a uniform sand-stone effect on the stainless steel surface, increasing the texture and surface roughness.

Brush grain: A linear or circular texture can be formed on the stainless steel surface to provide a unique decorative effect.

Coating: Adding a coating to the surface of stainless steel can change its color, increase wear resistance or provide other special properties.

Printing and screen printing: Patterns, logos or text can be printed onto stainless steel surfaces for personalized decorative effects.

These options can be used individually or in combination, tailored to specific requirements to meet the functional and aesthetic needs of the product.

Stainless steel parts manufacturing FAQ

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required online CNC machining services support by reading FAQ.

CNC machining provides high precision, high efficiency and repeatability of the machining process. For materials with higher hardness, such as stainless steel, CNC machining can achieve precise machining of complex shapes and details, while having high processing quality and reliability.

A variety of stainless steel alloys can be CNC machining, including the common 304 stainless steel, 316 stainless steel and other types of stainless steel materials, such as 430 stainless steel, 17-4PH stainless steel, 2205 duplex stainless steel and so on.

For stainless steel materials, it is recommended to use a rigid blade. Such as natural diamond blade, PCBN blade, etc. Stainless steel processing hardness, good toughness, the use of high-speed tungsten steel blade is easy to wear. It is recommended that in the CNC machining process, the appropriate tool model should be selected according to the machining profile and size details.

Put your parts into production today

- All information and uploads are secure and confidential.

Latest Blog Posts