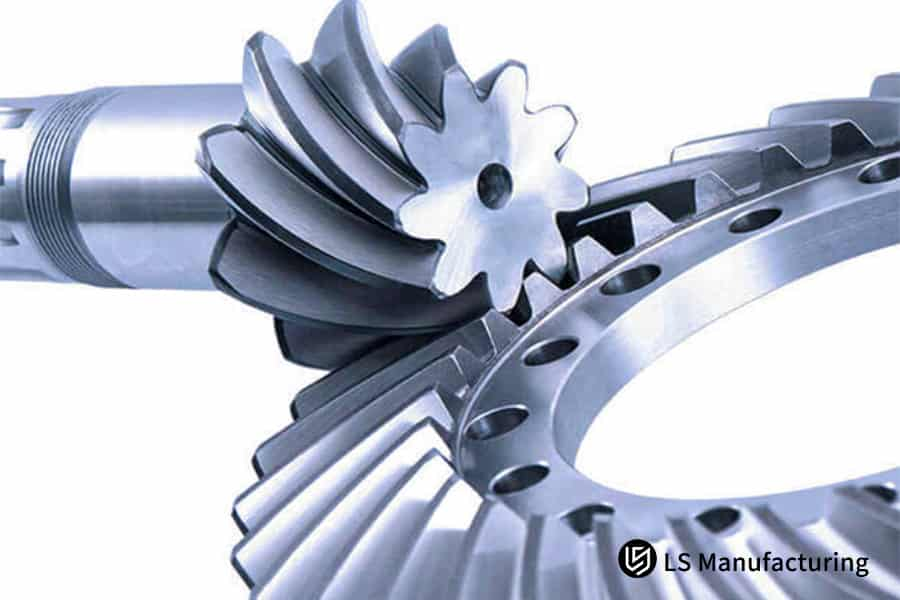

CNC gear manufacturing, as a core technology in precision transmission, directly determines equipment performance and reliability. However, it faces challenges like insufficient precision, excessive noise, and short service life when relying on manual experience or generic CNC systems lacking gear-specific expertise, resulting in products that fail to meet modern industrial standards for consistency and reliability.

It follows that the article is about the technological core in the CNC gear manufacturing area, and further, the role LS Manufacturing has played in integrating professional gear design software, advanced machining equipment, rich heat treatment experience, and a corresponding test system to establish a whole-process high-precision gear manufacturing solution which can help contribute toward comprehensive improvements in precision, quietness, and lifespan for customers’ transmission systems.

Quick Reference Table: CNC Gear Manufacturing

| Module Classification | Main Content Summary |

| Status | Gear precision is not high, noise is big and service life is short. |

| Core issues | Conventional machining relies on manual experience, whereas general CNC machines lack gear process experience. |

| Technical Solution | Professional design software matched with advanced CNC equipment, heat treatment process, and a comprehensive test system. |

| Process Benefits | High precision machining, repeatability, and reproducibility in mass production. |

| Quality Control | Full-process testing can greatly reduce noise during gear transmission. |

| Performance Outcome | To dramatically extend the service life and improve reliability in the transmission system. |

Technological innovation can also solve the precision control problem in traditional gear machining, namely, CNC gear manufacturing. It can integrate professional software, advanced equipment, and process experience deeply into a whole to build a complete quality assurance system starting from design and testing. The consequence is an improvement in gear machining accuracy and a prolongation of service life.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

There are quite a number of theoretical articles about how to manufacture CNC gears via the internet, but each and every point in this guide comes from the LS Manufacturing workshop. We strictly follow the severe standard IATF 16949 and ISO 13485 for medical devices, knowing that gear precision will directly affect the reliability and safety of the whole transmission system.

Our experience emanates from the well-executed delivery of over 50,000 customized gear parts. We can choose the best cutting parameters for materials such as 20CrMnTi and master the key effect of heat treatment processes on internal quality, doing a good job of balancing efficiency with consistency in mass production.

What you are reading isn’t textbook fluff; it’s real knowledge, tried and proven on the cut with oil through precision gauges. We further these core experiences utilized daily with the hope of enabling your journey, while also advancing together in precision manufacturing.

Why does CNC technology represent the most suitable solution for high precision gear manufacturing?

Consequently, the manufacture of precision gears requires high accuracy and dependability, which have made CNC become the norm since these overcome many of the inherent deficiencies of traditional machining. In exploring what is CNC gear manufacturing, it is clear that, in comparison with the traditional profiling machining dependent on the proficiency of operators, the advantages of CNC gear manufacturing are primarily embodied in the following aspects, constituting its incomparable technological superiority:

High Precision and Repeatability

CNC machine tools directly control the tool movement through digital instructions and get rid of uncertainties due to human operation. Whether producing the first batch or the ten-thousandth batch, micron-level tooth profile error control can be guaranteed, representing extremely high consistency and interchangeability in precision gear manufacturing.

Machining capability for complex tooth profiles

Traditional machine tools could hardly handle such complicated tooth profiles, optimizing noise and contact strength, like modified or convex profiles. CNC machining technology easily implements this in complex toolpath planning through accurate programming and replication of theoretically optimized designs onto the workpiece for fulfilling high-end transmission requirements.

Superior machining efficiency

CNC machine tools can conduct multitasking while arranging the automatic loading and unloading system to reduce a lot of auxiliary time, like clamping and measurement. This high efficiency allows for a rapid response from large-scale orders, at once arousing great improvement in the production efficiency and market competitiveness of enterprises.

It digitizes process knowledge and standardization of processes. Therefore, it turns precision gear manufacturing from the usual kind of “craft” into predictable and controllable “science.” Just for this very reason, it has turned into an absolute mainstream in modern high-precision and high-efficiency gear production.

From Drawing to Reality-What are the major processes in CNC gear manufacturing?

It takes a series of interrelated, detailed manufacturing processes to turn a design drawing into a high-performance, precision gear. Such a process will integrate material science with the most advanced CNC technology and thermal treatment processes in such a way that high-level CNC gear cutting process could be at the heart of realizing the accuracy in design. The table below gives a quick look at the important steps and describes how LS Manufacturing reaches professional control at every step.

| Key Steps | LS Manufacturing’s Professional Control Points |

| Gear Design and Optimization | Professional software is used to modify tooth profiles and simulate loads to optimize performance from the source. |

| Material selection and pretreatment | Materials are carefully selected based on the application scenario and pre-treated to optimize internal processing performance. |

| CNC machining | The tooth profiles formed by hobbing and gear shaping are fast and accurate, followed by excellent CNC gear cutting processes that ensure datum accuracy. |

| Material Selection and Pre-treatment | By strictly controlling process parameters, the wear resistance and fatigue strength of gears can be significantly improved. |

| Finishing | This involves grinding the gears after the heat treatment. Accurate correction for deformation in steel provides the final accuracy. |

| Precision testing and analysis | Full-dimensional final check by means of a gear measuring center or any other similar equipment ensures delivery with 100% qualification. |

Perfect gears require full control over the entire manufacturing process. At LS Manufacturing, our professionalism is evident in our proactive problem-solving during design simulation and our mature CNC vs manual gear cutting, efficient tooth profiling. This comprehensive approach is fundamental to the quality of our gear manufacturing process. Crucially, our accurate prediction and compensation for deformation in heat treatment and finishing ensure high batch consistency.

How to select the most suitable gear machining process based on the application scenario?

In the precision transmission system design, the scientific gear processing selection has to consider balancing performance, cost, and efficiency. The precision, efficiency, and application scenarios of various types of CNC gear machining have different emphases. Correct selection can avoid performance overkill or underkill. For clear comparison, core characteristics of mainstream processes are summarized below:

| Process Type | Precision Level & Applicable Scenarios | Efficiency & Cost Characteristics |

| Hobbing | Economical and efficient for roughing and semi-finishing most of the transmission gears. | High efficiency with low cost. The desired process in mass production. |

| Shaping | Internal gear machining and shoulder gear machining on machines can be performed; suitable for special structure requirement. | Lower efficiency than hobbing, but it solves some specific space problems. |

| Shaving | Finishing on untreated gears, with radical enhancement of the tooth surface quality and noise. | Highly effective, medium cost, a common method for achieving soft tooth surface finishing. |

| Grinding | Highest precision, suitable for precision gears with hardened tooth surface after heat treatment. | Lower efficiency, high cost, ultimate process to ensure final precision. |

In a nutshell, gear processing selection boils down to the best balance of precision, efficiency, and cost. LS Manufacturing has complete capabilities for CNC gears machining and provides free consultations in process selection. According to your special application scenarios, batch sizes, and budget, we will work out the most cost-effective solutions for your products to be competitive both in performance and cost.

LS Manufacturing Case Study: High-Precision Helical Gear Transmission Noise Reduction Solution for Wind Turbine Equipment

Gearbox noise control is one of the most important features affecting product quality in heavy-duty industrial product fields such as wind turbines. The following LS Manufacturing gear machining case study represents how we solve industry challenges through professional technology.

Client Challenge

A well-known wind turbine manufacturer faced an extreme challenge: its gearboxes generated excessive noise at high speeds. Testing showed that the root cause of this was in the helical gears, manufactured using traditional processes, achieving only a precision of grade 7, resulting in unstable meshing. This not only affected the operating experience of the equipment but could also lead to increased life-cycle maintenance costs.

LS Manufacturing Solution

To meet this core demand, we built a professional team and developed a systematic solution for helical gears. Using an imported German CNC gear hobbing machine ensures precise profile datums, while specialized software optimizes the tooth form for improved meshing. Controlled atmosphere heat treatment guarantees hardness and dimensional stability. Adherence to ISO 1328 standards throughout this process ensures stable achievement of precision class 5.

Results and Value

This solution has brought major results: it reduced the noise in the gearbox transmission by as much as 15 decibels, reaching silent operation standards. Because the improvement in meshing smoothness was immense, service life has increased by over three times. It brings a direct improvement in the market competitiveness of customers’ end products, while simultaneously reducing the annual maintenance cost by 40%, bringing about a double leap in economic benefit and product quality.

This typical LS Manufacturing gear machining case study shows that professional high-precision helical gear manufacturing capability is the key to solving deep-seated problems in transmission systems. Whether it is a problem of precision, noise, or lifespan for your project, we have experts ready to help you with a professional customized solution.

Set up an appointment today with our gear experts and let the precision transmission upgrade journey begin!

How to Find the Optimal Balance Between Cost and Quality in CNC Gear Manufacturing?

The crux of the matter is how to reach the optimum balance between cost and quality. By doing so through systematic value engineering applications, LS Manufacturing has always abided by the philosophy of “not the lowest price, but the best cost-performance ratio,” thus creating value beyond customers’ expectations. The most essential manifestations of our methodology are mainly reflected in the following three aspects:

Precise Optimization in the Materials Process:

We don’t just choose the most expensive material but analyze the real working condition, load characteristic, and failure mode of gears so as to precisely suggest materials with the best cost-performance ratio. Through scientific gear manufacturing cost control, we prevent waste from the source in performance and realize the greatest utilization of resources.

Efficiency and consistency through process innovation

For instance, the optimization of cutting parameters and toolpaths has contributed to a 15% reduction in machining time per piece, with the surface finish kept unchanged. This is a typical manifestation of the continuous improvement of process details while applying value engineering, which directly decreases the cost per piece and ensures quality stability.

Smart Manufacturing to Reduce Quality Losses

Make use of online inspection and monitoring data to realize real-time detection and compensation for dimensional deviation in processing. The scrap rate remains ultra-low. This quality control model at the front prevents huge hidden costs caused by rework and scrap, achieving the purpose of end-to-end gear manufacturing cost control.

In a nutshell, cost and quality balance is not a simple trade-off but synergistic optimization at LS Manufacturing via professional technology and meticulous management. Every suggestion we put forward is based on the in-depth value engineering application of how to help customers avoid falling into the trap of low price and quality risk and get reliable gear products with optimal total cost.

How does LS Manufacturing ensure uniformity in each gear lot?

In the manufacturing industry of precision gears, consistency at a high level in batch products is the most direct indicator of the core competitiveness of an enterprise. LS Manufacturing has established a closed-loop system for precision gear quality control, ensuring stability management right from raw material to finished product. The core of our Assurance System is based on:

- Precise Source Control: We have established a strict system of supplier management and incoming inspection. Spectral analysis of the composition and mechanical property testing of the steel are implemented on every batch to first ensure that the material properties are originally stable from their source, so as to lay a reliable foundation for subsequent processing.

- Process Data Monitoring: In production, we will establish control points at each key process and monitor the data in real time through the SPC system. Early warning analysis of core parameters such as hobbing accuracy and heat treatment temperature is done for trending and immediate correction.

- Final Precision Inspection and Traceability: We strictly follow international gear inspection standards, including ISO 1328. Gear measuring centers and coordinate measuring machines are used for 100% quantitative inspection of parameters such as tooth profile and tooth direction. Meanwhile, a full-process data traceability system has been established to make sure the quality problems can be traced back precisely to a certain process.

The abstract objective of “consistency” has been turned into quantifiable, traceable, and continuously optimizable practices. By deepening the integration of stringent gear inspection standards with preventative process control, we are able to assure that every gear in each and every batch delivered has highly consistent superior performance.

How does LS Manufacturing ensure a seamless transition from sample development to volume production?

From successful sample validation down to the delivery of stable and efficient mass production, true manufacturing capabilities come to the fore. This is especially vital in providing a solid gear mass production guarantee. LS Manufacturing gear CNC, supported by systematic management capabilities, ensures a smooth transition to achieve perfect continuity in product quality, efficiency, and reliability. Our core assurance rests on three pillars:

- Comprehensive Production Planning and Strict Cycle Control: We adopt end-to-end digital scheduling for meticulous management of the production cycle. Every phase in this process, right from receiving orders to fulfilling materials, would be scheduled with an Early Warning Mechanism that guarantees the execution of plans and the visibility of progress for timely delivery.

- Robust Processes and Consistent Quality Assurance: Process stability is crucial for ensuring smooth gear mass production. Through standardized operating procedures, Statistical Process Control (SPC), and first-article inspection, we ensure a high degree of consistency between batch products and sample quality, reliably replicating the superior performance of the sample stage in every product.

- Strong Supply Chain & Collaborative Network: We have fostered deep collaborative relations with core suppliers, brought safety stock and backup supply strategies into being, and in so doing guarantee that raw material sources are adequately supplied to form a basis for smooth gear mass production and to actively respond to market fluctuation, hence ensuring continuous production.

In a word, LS Manufacturing precisely replicates sample performance in mass production through integrated systematic management. Our scientific production cycle control drives the entire process, supported by robust quality systems and a reliable supply chain. This ensures a 99% on-time delivery rate, providing customers with seamless, assured manufacturing from prototyping to full-scale production.

Why Choose LS Manufacturing as Your Gear Manufacturing Partner?

It’s about the choice of a machining provider and a long-term, reliable technical partner for the production of gears. The process of choosing a gear manufacturing supplier is therefore critical, and from deep technical capability to comprehensive service coverage, LS Manufacturing has become one of the preferred choices of many high-end equipment manufacturers. Our core value comes from the following dimensions:

- Professional Technical Team: We have a team of engineers with more than 20 years working experience and complete-process technical capabilities from gear profile optimization, process planning to failure analysis which enable us to provide professional customized solutions to our customers.

- Advanced Equipment Guarantee: Equipped with the most advanced equipment, including German CNC gear hobbing machines and gear measurement centers, to meet the needs of high-end fields such as aerospace and medical equipment with stable ISO 5-level precision.

- Extensive Industry Experience: We have delivered over 500,000 precision gears, covering more than 20 industries including wind power, new energy vehicles, and robotics, and have a deep understanding of the technical key points of different application scenarios.

- Comprehensive Aftersales Support: Full-cycle services include technical consultation, production, and delivery, with after-sales tracking. We establish a rapid response mechanism that ensures orderliness in the implementation of projects we undertake for our clients.

The core advantage of LS Manufacturing is the organic combination of professional technology and comprehensive service. We will supply the gear products that meet only the requirements of precision, focusing on long-term value creation for clients. In view of this, we guarantee that every project can reach “zero-defect” delivery through precise process planning, strict quality control, and efficient supply chain management. Choose a gear manufacturing supplier, and LS Manufacturing promises to provide:

- 24-hour rapid quotation response

- Completely visualized tracking of production progress

- Comprehensive quality traceability system

- Lifetime free technical support

LS Manufacturing means reliability, precision and efficiency. With decades of expertise in precision engineering and advanced production systems, we ensure every component meets the highest standards of performance and durability. Empower your products with our knowledge and develop even more competitive transmission solutions together.

FAQs

1. What is the minimum module and maximum diameter range for gear machining?

We have mature precision gear machining capabilities that can stably machine gears with a module range of 0.5 to 25 and a maximum outer diameter of 800mm. For special specifications or larger sizes to cater to your needs, we can give our customers customized process and equipment solutions to meet the stringent requirements of different application scenarios.

2. What heat treatment processes are available for gears?

We provide a complete set of heat treatment processes for meeting diversified performance requirements, including carburizing and quenching, high-frequency quenching, tempering, and nitriding. Our engineers will choose an appropriate heat treatment plan according to the selected gear materials and specific service conditions and apply it to maximize wear resistance and fatigue strength.

3. How can you guarantee the gear precision grade?

We guarantee machining precision by using advanced equipment, such as imported CNC gear hobbing machines and gear grinding machines, to conform to international standards such as ISO 1328. With this kind of equipment, we can perform 100% inspection at a gear measurement center during production, providing data feedback on the tooth profile and tooth direction to ensure every batch of gears consistently meets the agreed precision grade (up to ISO 5).

4. How is the price for small-batch gear processing calculated?

For small batch of gears, the price would be quoted considering a comprehensive evaluation: the structural complexity of the gear, precision grade, selected material, and heat treatment processes. We do our best to optimize the process and control cost. We commit to offering you the most competitive and transparent quotations in the market while maintaining the same quality.

5. How long is the ordinary lead time for gear processing?

Our standard lead time for our standard-sized gear products is 7-10 working days. If the gears have complex structures or extremely high precision needs, their lead times are usually 15-20 days. For urgent needs, we have an expedited production channel that prioritizes resource allocation to shorten your waiting time.

6. Do you offer gear design and optimization?

We provide free gear design consultation and optimization services. Our engineering team can assist you in tooth profile modification, parameter optimization, etc., enhancing meshing performance, lowering noise, and extending service life at the design stage, helping to enhance the overall competitiveness of your products.

7. How do you solve gear noise problems?

Solving gear noise is a systematic project. We mainly improve smoothness in transmission through accurate design of tooth profile and direction modification, gear accuracy raised to a higher level, and strictly control the parameters of meshing in manufacturing, which can effectively reduce gear noise and vibration during operation.

8. What is the maximum size gear that you can process?

The maximum diameter processed by our existing equipment is 800mm. If the project requires the machining of ultra-large-size gears beyond this specification, please specify the technical parameters. We will start a customized solution evaluation and arrange dedicated resources to meet customer needs.

Conclusion

CNC gear manufacturing is a core support for modern industrial equipment, and its technological level directly guarantees the performance and reliability of the transmission system. A manufacturing partner must be deeply technically competent and experienced in projects. LS Manufacturing with its professional gear design team, advanced CNC machining equipment, comprehensive quality inspection system, and cross-industry application experience, is committed to providing customers with high-precision, low-noise, long-life gear products and customized solutions.

If your project faces transmission challenges, please contact our gear experts at once. You shall get free solution consultation and accurate quotation. You will be experiencing professional services throughout the whole process from technical demonstration to production delivery. Let us use technology as the engine and inject strong and reliable transmission power into your products.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.