LONGSHENG

Instant Die Casting Parts online quotes

Tolerances down to ±0.002mm

Get your custom parts at low prices

Hot and cold chamber die casting

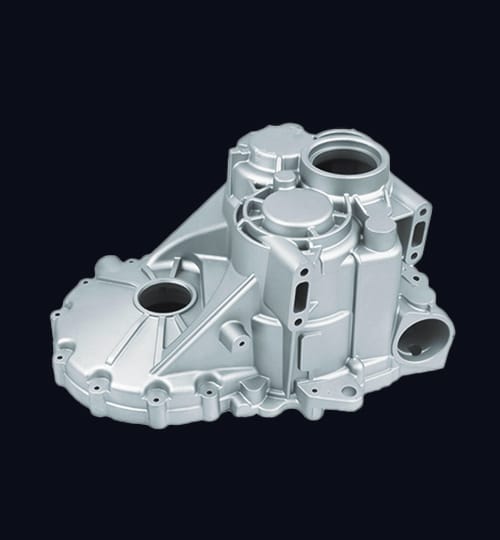

Custom Die Casting Parts Service

Pressure die casting is an ideal method for making large quantities of metal parts with excellent surface finish and dimensional stability.We provide cast parts in aluminum, zinc and magnesium.

Why Choose Die Casting Parts Machining?

When it comes to manufacturing high-quality metal parts, die casting is one of the most popular and efficient methods. This process involves injecting molten metal into a mold at very high pressures, which allows for the creation of complex and precise parts with a smooth surface finish. die casting parts machining is an efficient, durable, versatile, and cost-effective manufacturing method that is ideal for producing high-quality metal parts.

If you are in need of metal parts for your business or project, die casting is definitely worth considering. Longsheng adopts the latest die-casting technology to provide high quality on-demand components. For aluminum and zinc materials, typical tolerances are usually in the ±0.05 mm to ±0.1 mm range, depending on the customer’s specifications.

Die Casting Parts Machining Material

Longsheng supports most of the industrial standard materials,The processing materials not listed above can consult customer service customization

Die Casting Parts Machining Surface Treatment Option

Surface treatment is the last step of precision die casting parts processing. It can be used to remove surface defects of castings, enhance mechanical or chemical properties, and improve the appearance of products. Users can choose different surface treatment processes according to different needs

Components made of zinc and zinc-aluminum alloy are very resistant to corrosion and can be retained in this state while remaining as is after die casting. But magnesium and aluminum require coating to resist corrosion.

Aluminum components are usually anodized. Type II (sulfuric acid) anodizing results in a corrosion-resistant oxidized surface on the component surface. Different colors can be used to anodize parts, including black, gold, clear, and red.

Type III (hard) anodizing can form a thicker surface layer and produce a waterproof layer, and has the corrosion resistance of Type II anodizing. Anodized parts do not conduct electricity.

All parts produced by die casting are powder sprayed. In this process, parts are electrostatic sprayed with powder coating and then baked in a high temperature oven.

Other die casting processes and finishes are available upon request.

Fast delivery

Our die casting mold stock time is very short: for fast tooling, only 6 working days; For production tooling, up to 10 days.

Multiple choices

Using a variety of different materials, it offers dozens of different combinations of finishes, tolerances and markings. We also provide material certification, testing and measurement reports.

ISO 9001 certification

Longsheng has a well-equipped quality assurance department and quality management system. We monitor all Die Casting Parts Machining through our trained QC and QA teams to ensure that your project meets strict quality specifications.

Accuracy

Longsheng offers a wide range of tolerance options in compliance with ISO 2768 (Standard, fine) and ISO 286 (grades 8, 7, 6).

Experienced technical team

Our experienced team focuses on high -precision components with strict quality standards and strict tolerance requirements.

Continuous production

Longsheng provides high quality on demand manufacturing parts, very suitable for the production of more than 100 parts, Longsheng technicians will be strict internal quality control, to ensure that the parts without defects

Frequently Asked Questions about Metal Parts Manufacturing

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required CNC machining support by reading FAQ.

We work with a variety of materials, including aluminum, brass, copper, stainless steel, and titanium. If you have a specific material requirement, please let us know and we will do our best to accommodate your needs.

We use a variety of processes, including CNC milling, turning, sheet metal fabrication, metal extrusion, die casting, metal stamping, and spring machining. Each process is chosen based on the specific requirements of the part in question.

We offer a variety of finishes, including anodizing, plating, powder coating, and painting. If you have a specific finish requirement, please let us know and we will do our best to accommodate your needs.

Our lead time varies depending on the complexity and quantity of the parts being manufactured. We will provide you with an estimated lead time when you submit your order, and we will keep you informed throughout the manufacturing process.

We have a rigorous quality control process that involves multiple inspections and tests throughout the manufacturing process. We use advanced inspection and testing equipment to ensure that all parts meet or exceed industry standards.

We do not have a minimum order quantity. Whether you need a single part or thousands of parts, we are happy to work with you.

Our pricing is based on the complexity and quantity of the parts being manufactured. We will provide you with a detailed quote when you submit your order.

Yes, we have a team of experienced engineers who can assist you with design and prototyping. We can work with you to optimize your designs for manufacturability and efficiency.

We offer a warranty on all of our products. If you experience any issues with our products, please contact us and we will work with you to resolve the issue.

You can submit an order by contacting us directly or through our website. We will work with you to ensure that your order is submitted correctly and that you receive the parts you need on time and within budget.