What’s Cast Iron?

Cast iron is a family of ferrous alloys with a high carbon content, typically ranging from 2 to 4 percent, as well as varying amounts of silicon and other elements. This iron-carbon alloy is made through the process of casting, which involves melting, pouring, and solidifying the molten iron into a mold to form various shapes. Cast iron is known for its excellent castability, heat resistance, wear resistance, and durability. However, due to its high carbon content, it is also brittle, making it less flexible and more prone to breakage under heavy loads or impacts.

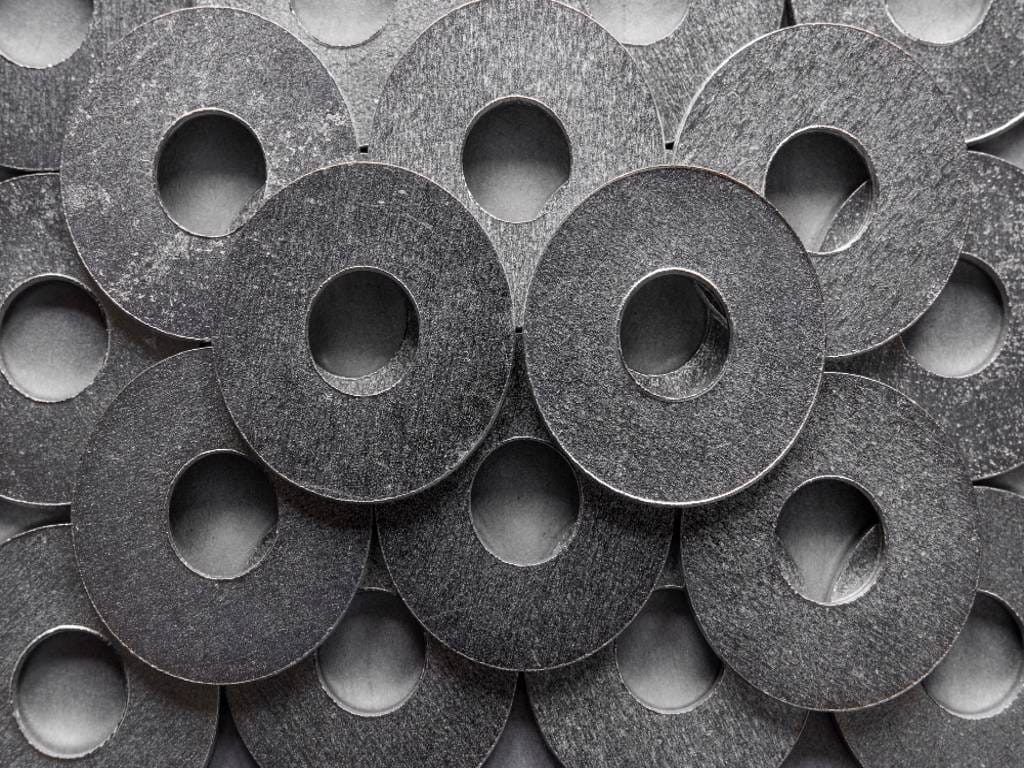

Image by Freepik

Types of Cast Iron

- Gray Cast Iron: Gray cast iron is the most common form of cast iron. It gets its name from its grayish fractured surface, which is due to the presence of graphite flakes within the structure. Gray cast iron has good damping properties, wear resistance, and castability, making it suitable for engine blocks, pipe fittings, brake discs, and machinery bases.

- White Cast Iron: White cast iron contains its carbon in the form of cementite (iron carbide), which gives the iron its characteristic hard and brittle white fractured surface. It has good abrasion resistance and is often used in wear-resistant applications, such as liners for grinding mills, pumps, and crusher parts.

- Ductile (Nodular) Cast Iron: Also known as spheroidal graphite (SG) iron, ductile cast iron contains graphite nodules that give the iron far greater ductility and tensile strength than other cast irons. This increased strength and reduced brittleness make it suitable for heavy-duty automotive components, agricultural machinery, and various infrastructure applications.

- Malleable Cast Iron: Malleable cast iron is produced through a specialized heat treatment process that transforms its carbon structure into irregularly shaped nodules of graphite. This process gives the iron improved ductility and makes it less brittle than gray or white cast iron. Malleable cast iron is often used in pipe fittings, clamps, brackets, and hangers for construction and industrial applications.

Applications of Cast Iron

Cast iron is used across a wide range of industries due to its unique properties. Some common applications include:

- Automotive components (e.g., engine blocks, brake discs, and cylinders)

- Pipes and pipe fittings for water, sewage, and gas transport

- Machinery bases and machine tool components

- Engine casings, manifolds, and gearboxes

- Structural components in buildings and bridges

- Agricultural equipment and implements

- Cooking utensils, such as skillets, griddles, and dutch ovens

Image by Freepik

What’s Steel?

Steel is an alloy primarily composed of iron and a small percentage of carbon, typically ranging from 0.02% to 2% by weight. The addition of carbon and sometimes other elements, such as manganese, chromium, nickel, or molybdenum, improves the hardness, strength, and ductility of the iron. This combination of properties makes steel a highly versatile material with applications in numerous industries.

image by evening_tao on Freepik

Types of Steel

1. Carbon Steel

Carbon steel is divided into three subcategories, based on the proportion of carbon within the alloy:

- Low Carbon Steel (Mild Steel): Contains up to 0.3% carbon and is relatively soft, ductile, and easily machined. It is used in construction, automotive components, and simple structural elements.

- Medium Carbon Steel: Contains approximately 0.3% to 0.6% carbon, providing a balance of strength, ductility, and hardness. It is used in railways, crankshafts, gears, and forged components.

- High Carbon Steel: Contains between 0.6% and 1% carbon, resulting in high strength and hardness. However, this increased hardness comes at the cost of reduced ductility, making it more brittle. High carbon steel is often used in cutting tools, blades, and springs.

2. Alloy Steel

Alloy steels have additional alloying elements, such as manganese, chromium, nickel, or molybdenum, which improve their mechanical properties and add unique characteristics. Alloy steels are widely used in automotive parts, pipelines, and high-strength structural applications.

3. Stainless Steel

Stainless steel is a corrosion-resistant steel alloy containing a minimum of 10.5% chromium. The chromium forms a passive oxide film on the steel’s surface, preventing further oxidation and imparting corrosion resistance. Stainless steel is widely used in kitchen utensils, appliances, chemical processing equipment, and medical devices.

4. Tool Steel

Tool steels are high-carbon alloys specially designed for high hardness and abrasion resistance. They are suitable for manufacturing cutting tools, molds, dies, and other tools that require strong, wear-resistant materials.

Applications of Steel

Owing to its versatility, steel is employed across various industries and sectors. Some common applications include:

- Construction: structural steel, beams, bars, and reinforced concrete

- Automotive: car bodies, drivetrain components, and chassis

- Infrastructure: railways, roads, and bridges

- Aerospace: aircraft landing gear and structural components

- Energy: power plants, turbines, and pipelines

- Manufacturing: machinery, tools, and equipment

- Consumer goods: appliances, cookware, and furniture

image by BalashMirzabey on Freepik

Cast Iron Vs Steel: What Are Their Differences

| Cast Iron | Steel | |

| Carbon content | 2% to 4% | Less than 2% |

| Melting Point | 2200 degree Fahrenheit | 2500 – 2800 degrees Fahrenheit |

| Strength | More Compressive strength | More Tensile strength |

| Castability | Easy to cast because of low shrinkage and good flowability | Less easy to cast than cast iron as it has low flowability and more shrinkage. |

| Corrosion Resistance | More corrosion resistant | Not as resistant as Cast iron |

| Impact Resistance | More Impact resistant | Less impact resistant |

| Cost | Cheaper because of the lower material cost, labor, and energy needed to produce the final product | More expensive than cast iron, although there are cheaper alternatives, like prefabricated steel forms like; rods, bars, beams, and tubes. |

| Applications | Pipe fittings, washers, farm equipment, machine parts, mining hardware, hand tools, and electrical fittings. | Infrastructure, vehicles, electrical appliances, rockets, tools, and weapons. |

Cast iron and steel differ primarily in their structure. Cast iron is made up of more carbon than steel. Steel is a mixture of iron and carbon. Cast iron is stronger than steel because it has a higher tensile force. Steel is more expensive than cast iron to produce.

Cast iron is a mixture of iron and other elements such as sulfur orphosphorus. It is denser and less malleable, but it can be used for projects that need a durable material that will resist corrosion.

Steel, on the other hand, offers more design flexibility as it can be shaped into any size or shape required by the project. Steel’s superior strength makes steel ideal for applications that need structural integrity, like bridges and skyscrapers. Galvanizing steel will also protect outdoor furniture and fencing from corrosion.

To summarize:

- Steel is stronger than iron cast.

- Cast iron is less resistant to corrosion than steel.

- Cast iron is less heat resistant than steel.

- Cast iron is cheaper than steel.

- Cast iron is more suitable for some cooking applications than stainless steel.

Cast Iron Vs Steel: Which One to Choose?

Advantages and Disadvantages of Cast Iron

Advantages

- Excellent Castability: Cast iron’s high carbon content lowers its melting point and enhances fluidity, making it easier to cast complex shapes with intricate details.

- Good Wear Resistance: The high carbon content in cast iron makes it hard and wear-resistant, ideal for applications where parts are exposed to abrasive or high-wear conditions.

- Vibration and Noise Damping: Cast iron’s microstructure, thanks to the presence of graphite flakes, enables it to absorb vibrations, making it suitable for machinery bases, engine components, or other applications where noise and vibration reduction is crucial.

- Heat Resistance: Cast iron has good thermal conductivity and can withstand high temperatures, making it a suitable material for applications exposed to heat, such as engine blocks and cooking utensils.

- Cost-Effectiveness: Cast iron is generally less expensive than other materials like steel or aluminum, particularly in terms of raw material costs.

- Corrosion Resistance: Cast iron’s corrosion resistance is better than that of carbon steel due to the presence of graphite in its structure, which can slow down the oxidation process.

Disadvantages

- Brittleness: Cast iron’s high carbon content and brittle nature make it prone to breakage under heavy loads or impact, limiting its use in applications requiring high tensile strength or flexibility.

- Difficulty Welding: Welding cast iron can be challenging because of its high carbon content, leading to the formation of hard and brittle areas during the process. Special techniques and preheating are often required for successful welding.

- Low Ductility: Cast iron has low ductility, making it more susceptible to breakage when subjected to bending or tensile stress.

- Prone to Oxidation: While cast iron exhibits better corrosion resistance than carbon steel, it is less resistant to oxidation than materials like stainless steel or aluminum.

In summary, cast iron’s advantages, such as excellent castability, wear resistance, vibration damping, and cost-effectiveness, make it suitable for various applications. However, its disadvantages, such as brittleness, difficulty welding, low ductility, and susceptibility to oxidation, may limit its use in certain scenarios. Considering your specific application’s requirements and material properties is crucial when selecting cast iron or alternative materials.

Advantages and Disadvantages of Steel

Advantages

- Strength: Steel possesses high tensile strength, making it an ideal material for applications that require resistance to heavy loads, impacts, or high-stress scenarios.

- Ductility: Steel exhibits higher ductility compared to cast iron, allowing it to be bent, deformed, or stretched without breaking. This ductility is particularly significant for construction, transportation, and machinery applications.

- Malleability: Steel’s malleability enables it to be worked, shaped, or rolled into various forms, such as sheets, plates, and structural beams, which is crucial in many industries.

- Weldability: Steel is generally more straightforward to weld compared to cast iron, enabling strong and reliable connections between components. However, the specific weldability depends on the steel’s composition and alloying elements.

- Wide Range of Alloys: Steel can be alloyed with various elements such as manganese, chromium, nickel, and molybdenum to tailor its properties for specific applications. This versatility makes steel suitable for an even more extensive range of uses.

- Recyclability: Steel is a highly recyclable material, making it an environmentally friendly choice for numerous applications. The recycling process doesn’t compromise steel’s quality, and it can be repurposed continuously.

Disadvantages

- Corrosion: Steel, especially carbon steel, tends to corrode more easily than materials like stainless steel or aluminum. However, adding elements such as chromium to steel can enhance its corrosion resistance, as is the case with stainless steel.

- Higher Weight: Steel is generally denser and heavier compared to materials like aluminum, which can pose limitations in specific applications where weight reduction is essential, such as aerospace or automotive industries.

- Cost: Although steel is generally more cost-effective than some other metallic materials, the costs associated with using steel can be higher than other alternatives, depending on factors like production techniques, alloying elements, and regional variation in raw material prices.

In summary, steel offers various advantages, such as strength, ductility, malleability, weldability, and the availability of different alloys, making it a widely employed material across diverse applications. However, its disadvantages, such as susceptibility to corrosion, higher weight compared to some alternatives, and cost considerations, should be taken into account when deciding whether to use steel in a specific application.

Conclusion

Both cast iron and steel are both good and bad. The specific application will determine which one to use. Cast iron is more durable and stronger for heavy loads. It is heavier and more difficult to transport. Steel is flexible, versatile and resistant to heat and rusting, but is also more expensive. It requires special tools to handle. Cast iron also retains heat better, making it a good choice for cooking appliances. Iron is also easily available and fire resistant, which makes it perfect for construction. It is prone to rusting over time, and it can be too soft to use in its purest form. The decision depends on what is needed and required for the project.

Choose LongSheng for Metal Casting Services

You have clearly chosen your side in the debate between cast iron and steel. Getting the right metal cast services for prototypes and production can be a challenge.

LongSheng can handle both the prototyping of metal parts and products as well as their production. Die casting and other services are provided by our professional team. This ensures that you receive the best metal parts, with high capacity and strict inspections. We also offer a variety of metal materials for you to choose from. These metals are geared towards manufacturing high-quality parts.

It’s not all! You will receive a free quote and DFM analysis once you upload your project on our platform.

FAQs

Iron is a form of steel?

Iron and steel are different in that iron is a metal and steel is an alloy. Iron is an element that occurs naturally on Earth. Steel is an alloy made by humans from iron and carbon.

What is more durable, cast iron or steel?

This question is not easily answered. The strength of both materials is different. Steel has a higher tensile than compressive strength. Steel is generally more durable than iron.

What is the difference between cast iron and steel?

Use an abrasive ring to identify the metals. Use the abrasive wheels to grind each metal sample and check for color and pattern of sparks. While steel produces bright yellow sparks and iron produces orange or red ones, it is important to know that both metals emit sparks.

Why is steel stronger than iron?

Steel is a mixture and has a little more carbon than pure ferrum. Steel becomes more durable as its carbon content increases. Steel is therefore stronger than iron, as it contains more carbon. This allows it to withstand greater pressures. Steel has a long history of use.

Can steel get rusted?

Steel will rust as it is made up of iron and carbon. The element chromium is what separates stainless steel from steel. It creates a shield that resists corrosion, and makes stainless steel more resistant to rust.