This article discusses the various factors that affect CNC machining costs, including material, complexity of parts, volume of production, machining time, and tooling and fixturing. Additionally, the article provides tips on how to save on machining costs and answers frequently asked questions about CNC machining. By understanding these factors and implementing the provided tips, you can optimize your production process and achieve high-quality results at competitive prices.

Factors Affecting CNC Machining Costs

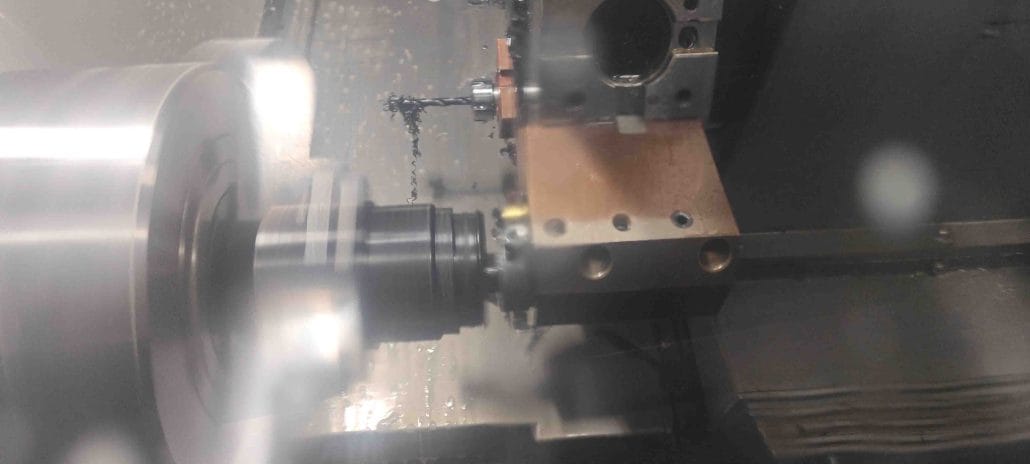

CNC machining is an essential manufacturing process that involves the use of computer-controlled machines to produce high-quality parts from various materials. The cost of CNC machining depends on several factors, including:

- Material: The type of material used for the production of parts can significantly affect the cost of CNC machining. Materials such as steel, aluminum, and titanium are more expensive than plastics and composites.

- Complexity of parts: The complexity of the parts to be produced, including their design, size, and shape, can increase the cost of CNC machining. precision machining Parts that require intricate designs and precise tolerances may require more machining time and specialized equipment, which can increase the cost.

- Volume of production: The volume of parts to be produced can also affect the cost of CNC machining. Large production runs can result in lower costs per unit due to economies of scale, while smaller runs may result in higher costs per unit.

- Machining time: The amount of time required to machine a part also affects the cost of CNC machining. Longer machining times can result in higher costs due to increased labor and machine usage.

- Tooling and Fixturing: The use of specialized tooling and fixturing can also affect the cost of CNC machining. These tools and fixtures are often required to hold and position the parts during machining and can add to the overall cost of production.

In conclusion, understanding the factors that affect CNC machining costs can help you optimize your production process and achieve the best possible results at the most competitive prices.

Most Expensive Items in CNC Machining

CNC machining is an intricate manufacturing process that involves the use of high-end technology and equipment. As such, it is no surprise that the cost of CNC machining can be quite high.we will discuss the most expensive items in CNC machining.

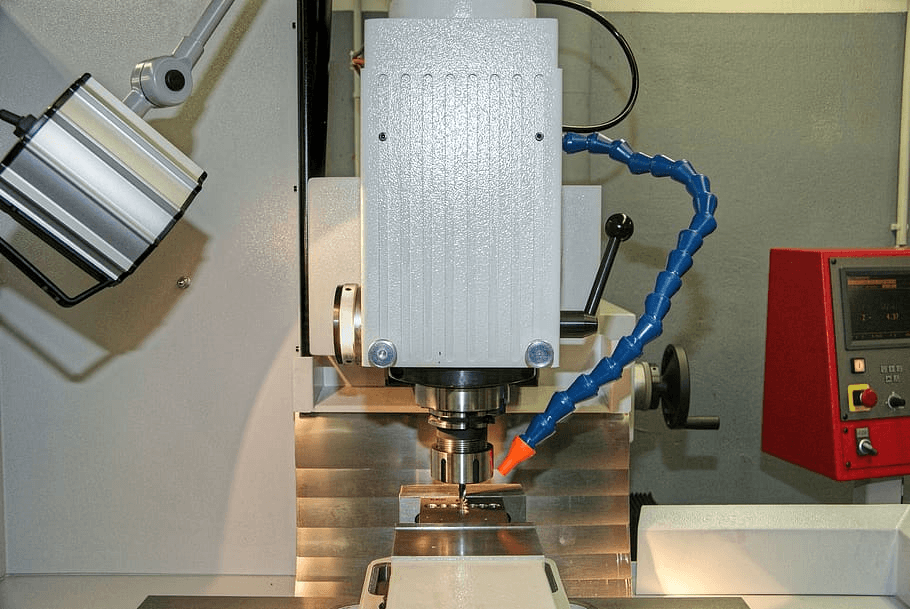

1. CNC Machines

CNC machines are undoubtedly the most expensive items in CNC machining. The cost of a CNC machine can range from a few thousand dollars to several million dollars. The price of a CNC machine depends on its size, complexity, and capabilities. Large and complex machines that can handle heavy-duty tasks are the most expensive.

2. Tooling

Tooling is another expensive item in CNC machining. High-quality tooling is essential for achieving accurate and precise results. The cost of tooling depends on its material, size, and complexity. Carbide tooling, for instance, is more expensive than HSS tooling.

3. Materials

The cost of materials used in CNC machining can also be high. Materials such as titanium, cobalt chrome, and Inconel are expensive due to their unique properties. These materials are commonly used in aerospace, medical, and defense industries.

4. Labor

Labor is another factor that contributes to the cost of CNC machining. Skilled CNC machinists are in high demand, and their salaries are typically higher than those of other manufacturing professionals.

In conclusion, CNC machining can be an expensive process due to the cost of CNC machines, tooling, materials, and labor. However, the benefits of CNC machining, including high accuracy, precision, and repeatability, make it a worthwhile investment for many industries.

How to Save Machining Costs

CNC machining is an expensive process, and the cost depends on several factors. To save machining costs, you need to consider various aspects such as the material used, complexity of parts, volume of production, machining time, and tooling and fixturing. Here are some tips to help you save machining costs:

Design for manufacturability: When designing parts, keep simplicity and manufacturability in mind. A simple design will reduce machining time and complexity, resulting in lower costs.

Minimize material waste: Optimize your part design to minimize material waste and reduce the amount of material needed for production. This will help you reduce the cost of material, thus lowering the overall machining cost.

Optimize production volume: Plan your production volume carefully to take advantage of economies of scale. Large production runs can result in lower costs per unit due to economies of scale, while smaller runs may result in higher costs per unit.

Consider alternative materials: You can also consider using less expensive materials or alternatives to reduce the cost of production without sacrificing quality or function. For example, instead of using costly materials such as steel, aluminum, and titanium, you can use plastics and composites.

Optimize tooling and fixturing: The use of specialized tooling and fixturing can add to the overall cost of production. Therefore, it’s essential to optimize tooling and fixturing to reduce the amount of time and labor required for machining and reduce costs.

In conclusion, understanding the factors that affect CNC machining costs and implementing the tips above can help you optimize your production process and achieve the best possible results at the most competitive prices.

CNC Machining Hourly Rates

The cost of CNC machining per hour varies depending on several factors including the complexity of the part design, the size of the part, the quantity of parts to be produced, and the type of material to be used.

On average, CNC machining services range from $30 to $100 per hour. However, some highly specialized services may charge more than $200 per hour.

It is important to note that some companies may also charge a minimum hourly rate, regardless of the quantity of parts produced. It is best to contact the CNC machining service provider for a detailed quote based on your specific project requirements

How to Calculate CNC Machining Cost per Hour

Calculating the cost of CNC machining per hour can be a complex process that involves several factors. The cost of the machine, labor, and material are the primary factors that determine the hourly rate. The complexity of the part, the number of operations required, and the required tolerances also affect the cost.

To calculate the hourly rate, start by determining the machine cost per hour. This can be done by dividing the purchase price of the machine by its expected lifetime in hours. Add to this the cost of labor per hour, which includes the operator’s wages and benefits. Finally, add the material cost per hour, which is the cost of the raw material used to produce the part.

Once you have calculated the hourly rate, use it to estimate the cost of the part. Multiply the hourly rate by the total time required to produce the part, including setup time, programming time, and machining time. This will give you the total cost of producing the part.

By calculating the cost of CNC machining per hour, manufacturers can accurately estimate the cost of production and set competitive prices for their products.

In conclusion, CNC machining is a versatile and precise manufacturing process that can be applied to a wide range of industries, including automobile manufacturing, aerospace, medical equipment, electronic devices, and mold manufacturing. By leveraging CNC machining and understanding the factors that affect its cost, you can produce high-quality, cost-effective parts and stay ahead of the competition.

FAQ

The cost of CNC machining is influenced by many factors, such as material, complexity of parts, volume of production, machining time, and tooling and fixturing. To calculate the cost of CNC machining, you need to consider these factors and calculate the cost of each one, then summarize them to obtain the total cost.

CNC machining can produce high-precision, high-quality parts, and the production process can be automated, improving production efficiency and speed. In addition, CNC machining can be used for mass production and custom production to meet different needs.

CNC machining and 3D printing are both commonly used technologies in the manufacturing industry, but they differ greatly. CNC machining is a cutting process that can cut out the required parts from block material, while 3D printing is a layer-by-layer stacking process that can directly output design files into parts. In addition, CNC machining can produce higher precision, higher quality parts, suitable for mass production, while 3D printing is suitable for small batch production and personalized production.

CNC machining can be applied to many fields, such as automobile manufacturing, aerospace, medical equipment, electronic devices, and mold manufacturing. CNC machining can produce high-precision, high-quality parts, suitable for mass production and custom production.