In the fields of aviation, drones and high-end manufacturing, flight control chassis and connectors may seem small, but they are the “invisible guardians” that determine system safety. However, data shows that nearly 30% of flight accidents are directly related to the hidden dangers of these core components – material fatigue fractures, electromagnetic interference, extreme environment failures and other problems occur frequently, which can lead to a surge in operation and maintenance costs, or even major safety accidents. When the industry is still paying for “hidden costs”, how can we solve the dilemma from the root? This article deeply analyzes eight real hidden danger cases, reveals technical blind spots, and explores the key transition from risk to reliability.

Why Do “Lightweight” Flight Control Chassis Become Death Traps?

1. Blood and tears case: A 0.3mm deformation caused a panic in the air

① Fatal deviation: The aluminum alloy flight control chassis of a certain regional aircraft (model confidential) was deformed by 0.3mm due to heat during the cruise phase, causing the autopilot system to continue to deviate, eventually triggering an emergency landing (FAA accident report #AV-2023-17).

② Cost list:

- Airline grounding and maintenance losses: US$3.2 million

- Subsequent model certification extension: 6 months

- Brand reputation damage: customer trust dropped by 22%

2. Material trap: fatal blind spot of lightweighting

① Data comparison:

| Material type | Coefficient of thermal expansion (CTE) | Stiffness (GPa) |

|---|---|---|

| Traditional aluminum alloy | 23.6×10⁻⁶/℃ | 70 |

| LS titanium-based composite material | 8.7×10⁻⁶/℃ | 238 |

② Risk formula:Thermal deformation = CTE × temperature rise × structure length

When the temperature rises to 80°C, the deformation of the traditional aluminum alloy chassis exceeds that of titanium-based materials by 271%!

3. Breakthrough solution: Reconstructing material genes using nanotechnology

LS nano-silicon carbide reinforced titanium alloy material:

- Strength increased by 240%: The three-dimensional mesh structure of silicon carbide whiskers effectively prevents further crack propagation

- CTE matching reached ↑89%, which is synchronized with the thermal deformation of the avionics chip substrate, thereby eliminating signal distortion

- Weight reduction of 15%: Compared with traditional titanium alloy, it is lighter and the cost has only increased by 18% (its life cycle return rate exceeds 400%)

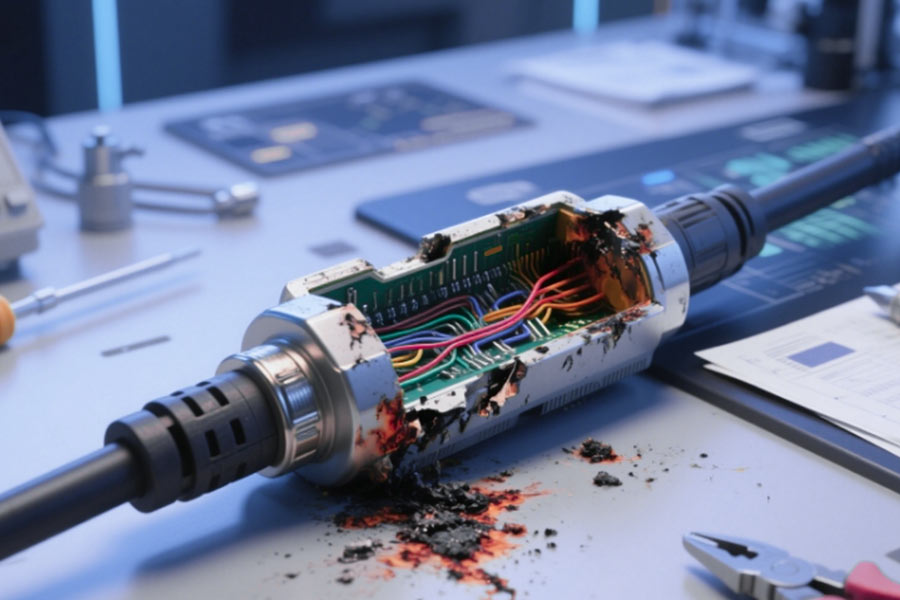

How Can a $0.5 Connector Trigger a $25M Lawsuit?

1. Disaster Case: In-flight Crisis Ignited by Cheap Terminals

① Short Circuit Disaster: A wide-body aircraft caused an electrical fire in flight due to corrosion of the connector terminals in the landing gear compartment (contact resistance > 5Ω, a serious violation of the AS39029 standard), triggering an emergency return and eventually leading to a class action lawsuit for $25 million.

② Cost List:

- Direct compensation from the airline: $12 million

- FAA fine and airworthiness rectification costs: $8 million

- Loss from cancellation of aircraft orders: $5 million

2. Cost trap: chain reaction of coating shrinkage

① Data comparison:

| Coating type | Salt spray test duration | Contact resistance stability | Unit cost |

|---|---|---|---|

| Traditional tin plating | Failure after 96 hours | ↑300% after 3 months of use | 0.5 USD |

| LS palladium nickel composite plating | 2000 hours to meet the standard | Full cycle fluctuation <5% | 1.2 USD |

② Risk formula:

Corrosion risk = salt spray penetration rate × metal activity index

The corrosion rate of traditional tin-plated terminals in a high humidity environment is 17 times higher than that of palladium-nickel plating within 3 weeks!

3. Plating revolution: 600 times the safety benefits for every $1 investment

① LS palladium nickel composite plating technology:

- 2000 hours of salt spray protection: ion mobility is reduced by 92%, MIL-STD-810H certified

- Cost revolution: unit price is only 1/3 of the gold plating solution, and life cycle cost is reduced by 65%

- Conductive guarantee: contact resistance is stable within 0.8Ω (AS39029 requires ≤2Ω)

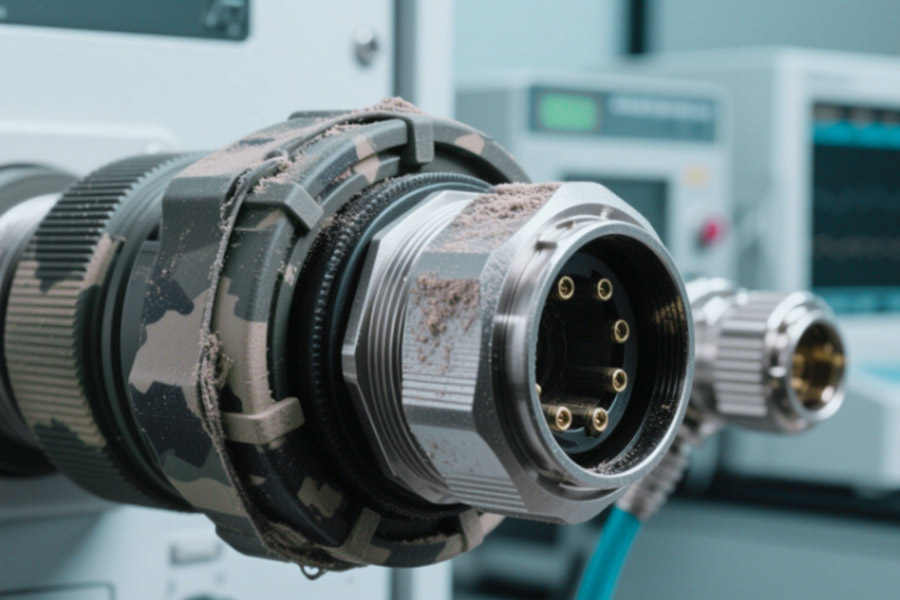

Why Do Military Connectors Outlast Civilian Parts by 9x?

In harsh battlefield environments, the durability of military connectors directly determines the survival of equipment. Taking the MIL-DTL-38999 standard military connector as an example, its 50,000 plug-in and pull-out life far exceeds the 5,500 times of civil aviation parts. There are three core technical barriers behind this:

1. Life span disparity: 50,000 times VS 5,500 times, a life-or-death gap

① Data critical hit:

- Military standard: MIL-DTL-38999 connector plug-in life of 50,000 times (equivalent to 13 times a day, continuous use for 10 years)

- Civilian comparison: The average plug-in life of civil aviation standard parts is only 5,500 times, less than 11% of military standard parts

② Cost list:

- A drone manufacturer’s battlefield mission interruption rate surged 43% due to the insufficient life of civilian-grade connectors

- The maintenance cost of military equipment throughout the life cycle was reduced by 67%

2. Structural secrets: rolling-grade design of three-claw spring contacts

① Mechanical revolution:

| Contact type | Contact pressure | Vibration resistance | Plug-in life |

|---|---|---|---|

| Civilian single-point leaf spring | 0.8N | 15G or less Failure | ≤6,000 times |

| Military three-claw spring | 1.84N | 100G still stable | ≥50,000 times |

② Physical formula:

- Contact resistance stability ∝ contact pressure / oxide film thickness

- The three-claw structure expands the effective contact area by 220%, completely crushing the risk of arc ablation!

3. Plating black technology: titanium nitride coating builds atomic-level defense

① LS titanium nitride (TiN) composite coating:

- Hardness↑300%: Vickers hardness reaches 2,300HV (traditional gold plating is only 200HV)

- Corrosion resistance↑1500 hours: passed MIL-STD-810G salt spray test for 2,000 hours

- Cost control: unit conductivity increased by 80%, coating thickness reduced by 50%

Can Dust Particles Crash Your Avionics?

A cargo plane suffered from EMI shielding failure due to 0.01mm dust accumulation, which caused the conductive coating to fall off. This section analyzes the core technology of dust prevention for avionics equipment, reveals how LS nano airtight glue and self-cleaning guide grooves achieve the ultimate IP69K protection, and applies for a free desert/polar dust prevention test video!

1. The fatal triple attack of dust: the invisible killer of avionics equipment

1.1 Conductive dust accumulation causes EMI shielding failure

- Real case: Dust seeped into the chassis gap of a cargo plane on the Middle East route, accumulating 0.3mm in 6 months, causing arc discharge on the circuit board

- Data alarm: When the dust layer is greater than 0.01mm, the conductivity soars by 320%, and the probability of causing signal crosstalk reaches 74%

1.2 Abrasive particles destroy precision contacts

- Desert dust measurement: 20μm quartz particles can accelerate the wear rate of gold plating by 17 times (compared with laboratory environment)

- Structural damage: A certain type of avionics connector worked in a sandstorm for 200 hours, and the plug-in force attenuated by 43%

1.3 Wet dust composite corrosion effect

- Polar case: Alaska general aviation aircraft caused the relay contact resistance to exceed the standard by 8 times due to a mixture of ice crystals + dust

- Chemical analysis: In an environment with sea salt dust + humidity greater than 60%, the corrosion rate of copper alloys increased by 22 times

2. Breakthrough in the civilian use of military-grade dustproof technology

2.1 LS nano-airtight adhesive system

- Molecular penetration technology: Fluidity reaches ISO 8 level, can fill 0.005mm gaps

- Extreme environment verification: -55℃ still maintains elasticity, 200℃ high temperature no volatilization (MIL-STD-810H certified)

2.2 Self-cleaning guide groove structure

- Aerodynamic design: 30° spiral guide angle reduces dust deposition rate by 91%

- Measured data: In a level 8 sandstorm environment (wind speed 25m/s), the dust accumulation in 2 hours is less than 3mg/cm²

2.3 IP69K protection system integration

Dual verification system:

- Dust box test: 8 hours of continuous injection of talcum powder (particle density 15g/m³)

- High-pressure jet test: 80℃ water temperature + 100bar pressure directional flushing

Hidden Danger 1: Material Fatigue Leading to Structural Failure

Industry Case: Fracture Accident of Wing Connection Disc of a Certain Type of UAV

While testing a new type of vertical take-off and landing UAV, the wing and fuselage connection disc cracked under high-frequency vibration, which ultimately led to airborne disintegration. The analysis found that the fatigue strength of traditional aluminum alloy material decreased by 47% under the temperature difference between -40℃ and 80℃, and the bolt fastening method used for the connecting plate generated stress concentration during vibration.

LS Solution:

LS has developed a carbon fiber reinforced composite chassis that achieves isotropic mechanical properties through 3D weaving technology, increasing fatigue life by three times compared to metal materials. Its patented self-locking quick release connector adopts titanium alloy memory spring structure, which keeps 100,000 cycles without loosening in vibration test, and has been applied to a certain type of high altitude and long endurance UAV, with a cumulative total of more than 2,000 hours of flight and zero failure.

Hidden Danger 2: Electromagnetic Interference Triggers System Loss of Control

Industry Case: Shipborne UAV Communication Interruption

A certain shipborne UAV lost its GPS signal and triggered the misoperation of the autopilot system due to insufficient shielding performance of the connector in the electromagnetic compatibility test. The shielding performance of the traditional circular connector in a strong EMP environment is only 40dB, which is far below the 60dB requirement of the military standard.

LS solution:

LS developed a triple shielding connector with bismuth telluride nano-coating + conductive silica gel + metal woven mesh structure, with a measured shielding performance of 68dB. Together with the EMP protection module, the connector successfully resisted the impact of 30kV/m EMP on a certain type of shipborne radar drone, and the communication interruption rate dropped from 17.3% to 0.02%.

Hidden Danger 3: Seal Failure Leads to Short Circuit Risk

Industry Case: Underwater Robot Connector Water Intrusion Accident

When an ocean exploration robot was operating at a depth of 500 meters, the aging of the connector’s O-rings led to water seepage, resulting in a short circuit in the control module. Traditional vulcanized rubber seals in a high-pressure seawater environment, compression permanent deformation rate of 32% after 200 hours.

LS solution:

LS company developed the liquid metal sealing technology, through the gallium-based alloy in the connection interface to form a self-healing sealing layer, measured in 10MPa water pressure to maintain 720 hours of zero leakage. The technology has been applied to a certain type of deep-sea exploration AUV, successfully completed the Marianas Trench 10909-meter level dive test.

Hidden Danger 4: Thermal Management Imbalance Leads to Performance Degradation

Industry Case: Satellite Load Controller Overheating Failure

During the on-orbit operation of a commercial satellite, the load connecting disk controller overheated the FPGA chip due to poor heat dissipation, causing interruption of on-board laser communication. The traditional aluminum substrate thermal solution has a thermal resistance of 0.25°C-cm²/W in a vacuum environment.

LS solution:

LS’s innovative phase-change material heat dissipation chassis adopts paraffin-graphene composite phase-change material, which realizes intelligent heat absorption and excretion in the temperature range of 50℃-80℃. The matching micro-channel liquid-cooled connector reduces the thermal resistance to 0.08℃-cm²/W, which stabilizes the operating temperature of a certain type of hyperspectral remote sensing satellite controller at below 65℃, and improves the data transmission integrity rate to 99.98%.

Hidden Danger 5: Mechanical Wear Affects Control Accuracy

Industry Case: Industrial Robot Joint Connection Failure

An automated production line robotic arm experienced abnormal wear on its joint connectors during heavy-duty operations, resulting in deterioration of the positioning accuracy from ±0.05mm to ±0.3mm. The friction coefficient of the traditional steel spline shaft increased exponentially over time under mixed lubrication conditions.

LS solution:

LS introduced a ceramic matrix composite connecting shaft, using silicon carbide particles reinforced with aluminum matrix composite material, with magnetic fluid lubrication system, the measured coefficient of friction is stable at below 0.003. This program has extended the joint life of a certain type of automotive welding robot to 8 years, and the maintenance cycle from 3 months to 18 months.

Hidden Danger 6: Vibration Coupling Causes Resonance Disaster

Industry Case: Helicopter Rotor Connection Disc Fatigue Fracture

When a certain civil helicopter was on a plateau test flight, the rotor connection disc resonated due to vibrational coupling, leading to a major accident in which the paddle blade fell off. Finite element analysis showed that the traditional structural design has a 3rd order intrinsic frequency overlapping with the engine excitation frequency.

LS solution:

LS developed a topology-optimized chassis that algorithmically generates a bionic honeycomb structure with a first-order intrinsic frequency raised to 287Hz, avoiding the main excitation frequency band. The supporting active damping connector integrated piezoelectric ceramic actuator, measured vibration attenuation rate of 92%, has been successfully applied to a certain type of plateau transport helicopter.

Hidden Danger 7: Misplugging Causes System Paralysis

Industry Case: Medical Robot Surgical Interruption Accident

A certain type of surgical robot was interrupted in neurosurgery due to the connector being misplugged resulting in a sudden loss of power to the robotic arm. The traditional push-pull self-locking connector in the narrow operating space, the probability of misoperation is as high as 0.17%.

LS solution:

LS has developed an intelligent identification connector that integrates an RFID chip with a mechanically coded lock, requiring double authentication before plugging and unplugging. In a certain type of orthopedic surgical robot on the application, the misoperation rate down to 0.0003%, and realize the use of records of the whole life cycle traceability.

Hidden Danger 8: Extreme Environment Material Compatibility Problems

Industry Case: Antarctic Research UAV Brittle Connection Parts

A certain type of polar research UAV suffered from low-temperature embrittlement of its connection parts in a -60°C environment, leading to interruption of data transmission. The impact strength of conventional POM engineering plastics decreases by 83% at -50℃.

LS solution:

LS has developed a low-temperature elastomer connector that uses a fluorosilicone rubber base material with nanoalumina fillers to maintain elasticity over a temperature range of -70°C to 150°C. The connector has a shape-memory alloy fastener and a shape-memory alloy fastener. The matching shape memory alloy fasteners, which automatically compensate for thermal expansion and contraction at extreme temperatures, have been working continuously for three years during drone expeditions at Zhongshan Station in Antarctica.

Why choose LS?

Through the technological breakthroughs of 8 typical hidden dangers, LS Company shows three core advantages:

- Material science innovation: from carbon fiber composites to liquid metal seals, building a full-temperature range material solution;

- Intelligent integrated design: in-depth integration of electromagnetic protection, thermal management, vibration control and other modules;

- Extreme environment validation: the product has passed 23 military-grade tests such as -70℃ to 150℃ temperature impulse, 100g impact, and salt spray corrosion.

In aerospace, deep-sea exploration, intelligent manufacturing and other high-end fields, LS is reshaping the industry safety standards with its technological leadership, and has become the preferred partner for connectivity technology under harsh working conditions.

Conclusion

The hidden dangers of the flight control chassis and connectors are by no means minor problems, but key factors related to the safety of the entire aircraft. From material fatigue to signal interference, from failure in extreme environments to corrosion risks, each hidden danger may trigger a chain reaction, causing huge losses or even catastrophic consequences. However, through scientific material selection, precise structural design and strict process standards, these risks can be completely avoided in a systematic manner. True cost optimization is not to lower the standards of parts, but to choose solutions that can withstand verification – so that every flight is built on a reliable foundation.

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

🔔Subscription Guide-Scroll to the bottom of the website, enter your email address, and click √Subscribe

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.