This document explains how to use G41 and G42 in CNC turning and the advantages of using these codes to achieve accurate cuts and precise dimensions for machined parts. The document starts with a brief introduction to the importance of tool radius compensation in CNC turning, followed by an overview of G41 and G42 and their functions. The document then explains how to use G41 and G42, provides examples of the codes in action, and outlines the advantages of using these codes in CNC turning. The document concludes by emphasizing the importance of understanding how to use G41 and G42 to increase the productivity of CNC turning machines and reduce the need for manual adjustments.

how to use g41 and g42 in cnc turning?

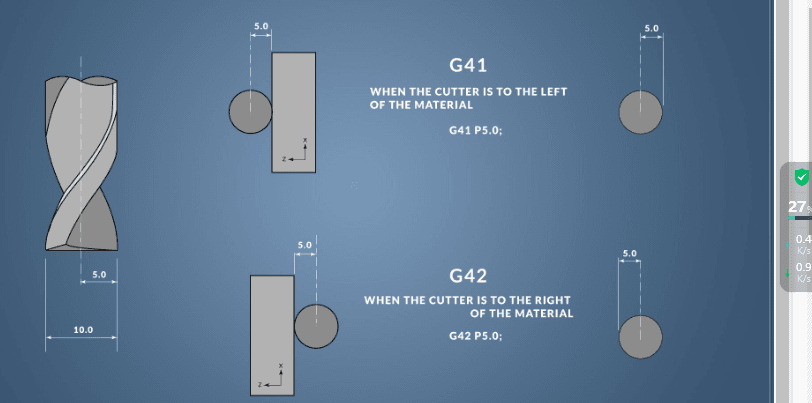

When programming a CNC lathe, it’s important to know how to use tool radius compensation to achieve accurate cuts. G41 and G42 are two codes used for this purpose.

G41

G41 is a code used for tool radius compensation to the left of the programmed path. This means that the tool will be moved to the left by the amount specified in the offset value. The offset value is the distance between the tool tip and the centerline of the CNC lathe.

Here’s an example of how to use G41 in CNC turning:

N10 T0101

N20 G00 X50 Z5

N30 G01 X30 F0.1

N40 G41 D01 X20 Z-10

N50 G01 X10 Z-20

In this example, G41 is used in line N40 to compensate for the radius of tool D01 to the left of the path. The tool is moved to the left of the programmed path by the amount specified in the offset value.

G42

G42 is a code used for tool radius compensation to the right of the programmed path. This means that the tool will be moved to the right by the amount specified in the offset value. Here’s an example of how to use G42 in CNC turning:

N10 T0101

N20 G00 X50 Z5

N30 G01 X30 F0.1

N40 G42 D01 X20 Z-10

N50 G01 X10 Z-20

In this example, G42 is used in line N40 to compensate for the radius of tool D01 to the right of the path. The tool is moved to the right of the programmed path by the amount specified in the offset value.

Advantages of Using G41 and G42 in CNC Turning

Using G41 and G42 in CNC turning provides several advantages. By compensating for the tool radius, these codes help to achieve accurate cuts and precise dimensions for the machined parts.

Moreover, G41 and G42 codes help to increase the productivity of CNC turning machines as they reduce the need for manual adjustments. Since the codes are automated, the operator can program the CNC lathe once, and the machine will perform the necessary tool compensation for all the parts.

Conclusion

Using G41 and G42 is essential for achieving accurate cuts in CNC turning. By understanding how these codes work, you can program your lathe to produce high-quality parts with precise dimensions. The codes help to increase the productivity of the CNC turning machines and reduce the need for manual adjustments.

How do you use G41 and G42?

When programming a CNC lathe, it’s important to know how to use tool radius compensation to achieve accurate cuts, and that’s where G41 and G42 come in.

G41 and G42 are two codes used for tool radius compensation in CNC turning, and they have different functions. G41 is used for tool radius compensation to the left of the programmed path, while G42 is used for tool radius compensation to the right of the programmed path.

When using G41, the tool will be moved to the left by the amount specified in the offset value. The offset value is the distance between the tool tip and the centerline of the CNC lathe. In contrast, when using G42, the tool will be moved to the right by the offset value.

To get a better understanding of how to use these codes, let’s take a look at an example.

In the following code:

N10 T0101

N20 G00 X50 Z5

N30 G01 X30 F0.1

N40 G41 D01 X20 Z-10

N50 G01 X10 Z-20

G41 is used in line N40 to compensate for the radius of tool D01 to the left of the path. The tool is moved to the left of the programmed path by the amount specified in the offset value.

Similarly, in this code:

N10 T0101

N20 G00 X50 Z5

N30 G01 X30 F0.1

N40 G42 D01 X20 Z-10

N50 G01 X10 Z-20

G42 is used in line N40 to compensate for the radius of tool D01 to the right of the path. The tool is moved to the right of the programmed path by the amount specified in the offset value.

Using G41 and G42 in CNC turning provides several advantages. By compensating for the tool radius, these codes help to achieve accurate cuts and precise dimensions for the machined parts. Moreover, G41 and G42 codes help to increase the productivity of CNC turning machines as they reduce the need for manual adjustments. Since the codes are automated, the operator can program the CNC lathe once, and the machine will perform the necessary tool compensation for all the parts.

In conclusion, understanding how to use G41 and G42 is essential for achieving accurate cuts in CNC turning. By compensating for the tool radius, these codes help to increase the productivity of CNC turning machines and reduce the need for manual adjustments.

What is G41 code for turning?

G41 is a code used for tool radius compensation to the left of the programmed path in CNC turning. This code is essential for achieving accurate cuts and precise dimensions for the machined parts. By compensating for the tool radius to the left of the programmed path, G41 helps the machine to cut the workpiece with the exact shape and size that is required.

When using G41, the tool will be moved to the left by the amount specified in the offset value. The offset value is the distance between the tool tip and the centerline of the CNC lathe. This means that the tool will be offset by the radius of the cutting tool to the left of the programmed path to achieve accurate cuts.

In the example provided earlier, G41 is used in line N40 to compensate for the radius of tool D01 to the left of the path. The tool is moved to the left of the programmed path by the amount specified in the offset value. This ensures that the tool cuts the workpiece with the exact shape and dimension that is required.

Using G41 in CNC turning provides several advantages. By compensating for the tool radius, this code helps to achieve accurate cuts and precise dimensions for the machined parts. Moreover, G41 helps to increase the productivity of CNC turning machines as it reduces the need for manual adjustments. Since the code is automated, the operator can program the CNC lathe once, and the machine will perform the necessary tool compensation for all the parts.

In conclusion, understanding how to use G41 is essential for achieving accurate cuts in CNC turning. By compensating for the tool radius to the left of the path, G41 helps to increase the productivity of CNC turning machines and reduce the need for manual adjustments.

When type of operation and direction of movement is G41 & G42 to be used?

G41 and G42 are both codes used for tool radius compensation in CNC turning. The purpose of these codes is to ensure accurate cuts and precise dimensions for machined parts. When programming a CNC lathe, it is important to understand when to use G41 and G42 and in what direction they should be used.

G41 is used when the cutting tool is to the left of the programmed path, while G42 is used when the cutting tool is to the right of the programmed path. In other words, if the shape being cut needs to be wider than the tool, G41 is used to compensate for the tool radius on the left side of the path. Conversely, if the shape being cut needs to be narrower than the tool, G42 is used to compensate for the tool radius on the right side of the path.

When using G41, the tool will be moved to the left by the amount specified in the offset value. The offset value is the distance between the tool tip and the centerline of the CNC lathe. This means that the tool will be offset by the radius of the cutting tool to the left of the programmed path to achieve accurate cuts.

Similarly, when using G42, the tool will be moved to the right by the offset value. This ensures that the tool compensates for the radius of the cutting tool on the right-hand side of the programmed path.

By using G41 and G42 codes in CNC turning, the accuracy and productivity of the machine are increased, as these codes reduce the need for manual adjustments. The operator can program the CNC lathe once, and the machine will perform the necessary tool compensation for all the parts. This saves time and ensures consistency in the production process.

In conclusion, understanding when to use G41 and G42 is essential for achieving accurate cuts in CNC turning. By compensating for the tool radius in the correct direction, these codes help to increase the productivity of CNC turning machines and reduce the need for manual adjustments.