CNC machining is a widely used manufacturing process that is known for its precision and accuracy in creating parts, components, and prototypes for various industries. However, the cost of CNC parts machining can vary depending on several factors, making it essential to understand the variables that contribute to the final cost.

Factors Affecting the Cost of CNC Machining

Material

The type of material used for CNC metal machining can significantly impact the cost. The cost of materials such as aluminum, brass, and plastic is typically lower than that of steel, titanium, and other exotic materials. However, the material’s cost can add up quickly, especially if you need to use high-end materials to meet your project’s specific requirements.

Complexity

The complexity of the design and the number of operations required to machine the part can affect the cost. Intricate designs and parts that require multiple operations will cost more than simple ones. The more complex your project is, the more time and resources are required to manufacture it, which will drive up the cost.

Quantity

The quantity of parts being machined can also affect the cost. Typically, the more parts being produced, the lower the per-unit cost. This is because the setup time and cost of tooling can be spread out over a larger number of parts. If you need only a few parts, you can expect to pay more per part than if you are ordering hundreds or thousands of parts.

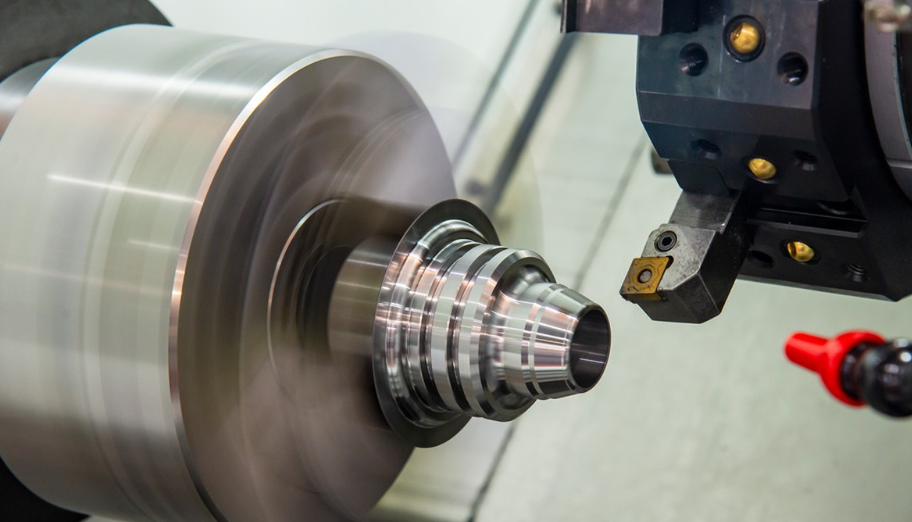

Tolerance

The level of precision required for the part can also impact the cost. Tighter tolerances require more precise machining, which can increase the cost. If your project requires a high degree of accuracy, you can expect to pay more for the machining process.

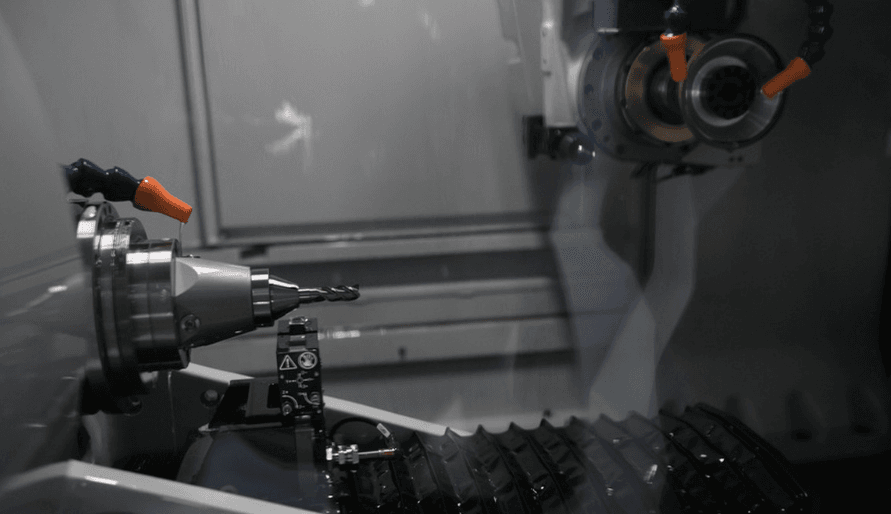

Machine and Labor Costs

The cost of the CNC machine and labor required to operate it are also factors that affect the overall cost of CNC machining. The more advanced the machine, the higher the cost of the machining process. Additionally, the cost of labor is directly related to the complexity of the project and the time required to complete it.

Finish

The finishing touch of the machined part is another factor that can affect the cost of CNC turning machining services . If you require a specific finish, such as sandblasting or anodizing, it will add to the final cost.

Average Cost of CNC Machining

The average cost of CNC machining varies depending on the above factors. However, the typical hourly rate for CNC machining is between $50 and $100 per hour. For small parts, the cost can range from $10 to $100 per piece, while larger parts can cost several hundred or even thousands of dollars.

Conclusion

In summary, understanding the factors that affect the cost of CNC machining is essential to make informed decisions about your project and ensure that you get high-quality results that meet your needs and budget. Collaborating with a reliable CNC machining service provider can help you get the best value for your money while achieving your project goals.