In the high-end production industry, the ability to consistently achieve and maintain a ±0.01mm tolerance is the deciding factor that separates exceptional suppliers from outstanding ones. This level of precision literally unlocks the certainty of medical device safety and end-product reliability of aerospace components, essentially guaranteeing product performance and lifespan. So, how can this ideal standard become a reality? It is a role that requires so much more than one high-end piece of equipment; it requires a system of process, technology, and quality control.

This article will address the basic considerations of making ±0.01mm ultra-precision machining a reality from tool management and machine tool choice through process optimisation to environmental control. Precision is not an accident but rather a repeatable, verifiable, and inevitable outcome to us at LS Precision that ensures every single important aspect of your business is flawless.

LS Precision would appreciate it if you would let us be your trustworthy partner for secure precision machining services, and create excellence together. To save you time, here is a concise summary of the most essential information.

High-Precision CNC Lathe To Achieve ±0.01mm Tolerance Core Quick Lookup Table

| Dimensions | Key Features |

| Base in Machine Tool | Highly rigid structure, thermally stable base, and closed-loop high-precision feedback system. |

| Tool Fixtures | Ultra-precision machines, high-precision tooling holders, and fixtures exhibit low runout and distortion. |

| Process Control | Thermal control of controlled environment, machine preheating, optimal cutting parameters, and smooth tool paths. |

| Quality Assurance | First-article inspection and process control (SPC) through ultra-high-precision measurement equipment. |

| Typical Applications | Medical devices, aerospace, optical communications, and other applications with very high reliability requirements. |

Beyond advanced equipment, expert technical support must be provided to achieve and sustain on a routine basis the record maximum tolerance of ±0.01mm. It encompasses a complete system that includes first-class hardware (tools/machine tools), rigorous procedures, closed-loop quality control, and an environment under control.

LS Precision Manufacturing’s best practice demonstrates that it is only through enhancing precision control to a “systematic management” from a “technical operation” that ultra-precision machining becomes repeatable, predictable results, and hence provides actually reliable precision machining services to many high-end industries.

Why Trust This Guide? Practical Experience From LS Experts

LS Precision Manufacturing has been directly engaged with ultra-precision machining for over a decade and a half. Not only are our company staffed by seasoned mechanical engineers and programmers, but much more importantly, we also have a dedicated “Technology Center” entirely dedicated to researching tolerances within the scope of ±0.01mm and beyond.

The center is equipped with ultra-precision CNC lathes and metrology labs that are state-of-the-art. This implies that our process design is not computational theory but actual empirical research into machine tool capability limits, material characteristics, and cutting dynamics. We have been able to implement this knowledge system on over 200 precision component applications ranging from pacemaker housings to valve seats for satellite propulsion systems.

Each of these lessons in this book is based on real issues that we have resolved for our clients. For example, we once machined a component out of aluminum alloy for an aerospace firm that manufactured sensors with a ±0.008mm required internal cavity tolerance. During first-time production, thermal deformation stability caused lasting precision deviation.

Through systematic process research, as well as optimizing the temperature of the cutting fluid and pouring angle, we also employed an innovative method of “micron-level segmented machining” in order to actively counteract thermal expansion, increasing the yield rate from 75% to more than 99.8%.

It is this kind of proven track record in live production settings that constitutes the solid foundation on which all LS Precision counsel is presented.

Why Is A ±0.01mm Tolerance Such An Insurmountable Barrier For Many Suppliers?

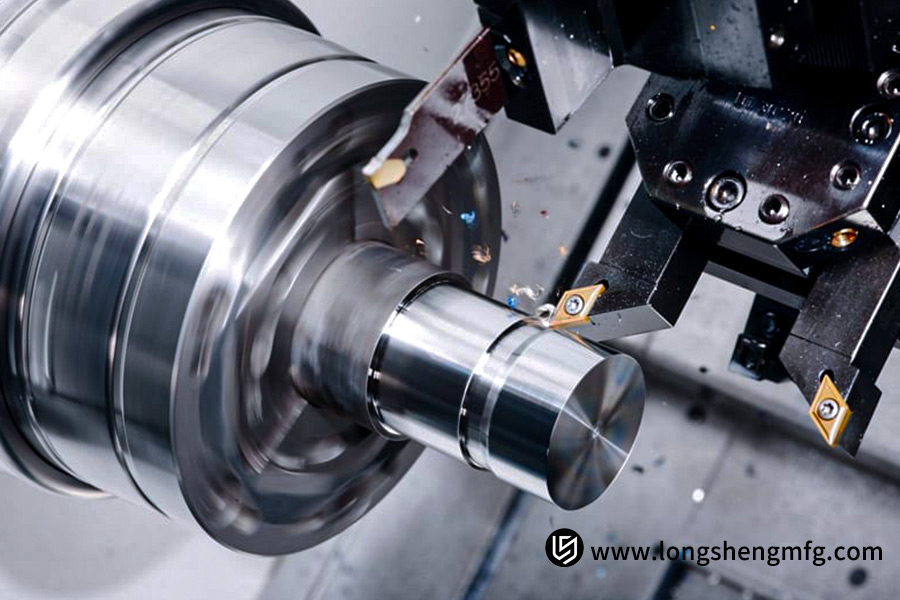

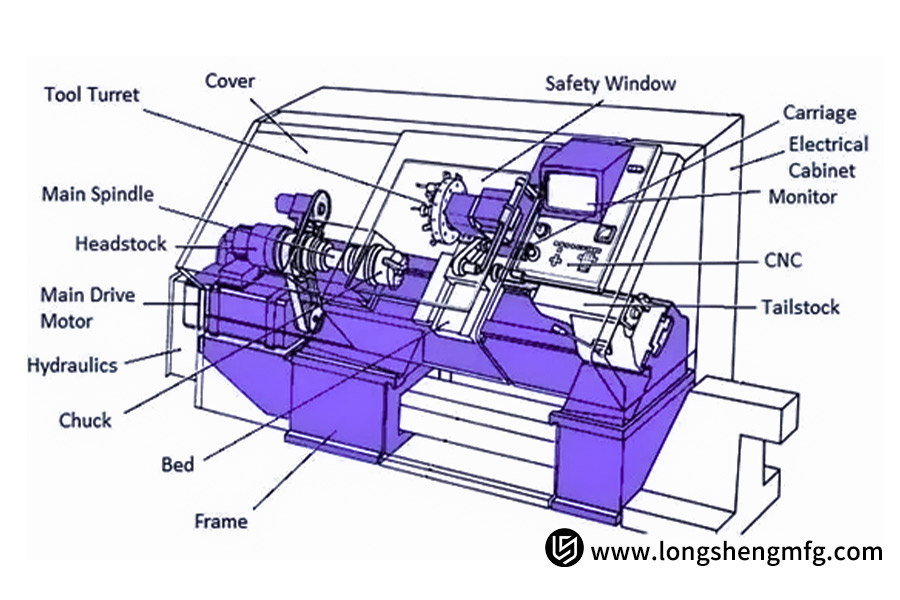

Achieving ±0.01mm (10 microns) tolerance is a matter far larger than merely purchasing a high-performance, high-precision CNC lathe. It is really a challenge to the integrity of the whole production system; to allow loss of control in some small way in any part can ruin everything that has been accomplished up to that time. Top-class machine shops can’t span this “chasm” because they don’t possess systematized control of the resulting complicated chain of parameters:

1. Thermal deformation and dynamic errors of machine tools:

Thermal expansion caused by the spindle high-speed running itself, or even by room temperature change by 1-2°C, will result in over 0.01mm dimension drift. In addition, the dynamic errors such as guideway straightness and lead screw backlash, though minuscule in comparison with traditional machining, are the highest priorities at this ultra-high precision level.

2. Tool wear and vibration control:

Microscopic wear on the cutting tool is directly proportional to the workpiece size. Shops typically do not have large tool life management and on-line monitoring and hence predictive compensation is not feasible. Also, unless fine vibrations caused by cutting are being damped, then they can directly affect surface integrity and dimensional constancy.

3. The combined effects of programming strategies and measurement errors:

Improper cutting parameters and feed rates (e.g., speed and feed rate) may impose extra stress and heat on the job during machining. Most critically, if the measuring process itself is off by a few microns, the description “precision machining” is meaningless.

Strength of LS Precision‘s approach is its logical, data-driven approach, partitioning all these variables into a closed cycle of on-line feedback and correction. This translates “accidental” quality to “inevitable” precision, actually realizing the goal of increasing machining accuracy.

What Truly Depends On Achieving Ultra-Precision Tolerances?

One widespread myth is that investing a lot of money in a top-of-the-line, high-accuracy CNC lathe will somehow magically attain a ±0.01mm tolerance. But leaving all the precision to the machine tool alone is a little like thinking that having a costly brush in one’s hand will guarantee a work of art.

High machine tools, and especially their extremely rigid lathe structures, by themselves are a foundation, providing a firm precision foundation. But the issue is to properly safeguard and activate the potential of this foundation during the entire machining process. Ultra-precision machining relies solely on an extremely networked precision production system:

1. Environmental control beyond the shop floor:

Machine tools themselves generate heat, and around them temperatures also fluctuate. These slight variations can easily erode microns of accuracy. A stable temperature (e.g., 20 ± 0.5°C) and a clean workshop environment are therefore crucial to ensuring that machine tool basic accuracy does not shift. This is a “soft skill” which most ordinary factories like to overlook.

2. “Last Centimeter” Clamping and Tooling Technology:

With incredibly precise spindle capability in a machine tool, it will be pointless if power is transferred by an out-of-tolerance fixture or a worn toolholder. LS selects high-precision hydraulic clamps and shrink-fit toolholders with utmost care, and uses strict tool life management and compensation procedures to make the “last centimeter” of cutting as repeatable and accurate as the potential of the machine tool.

3. The Accumulated Wisdom of Process Engineers:

To program and define parameters for different materials and piece forms relies significantly on the engineers’ experience. They can predict stress and thermal deformation behavior during machining and intervene in advance through specialized process trajectories (e.g., sequential machining and compensation at the micron level). It is the key to transforming the capabilities of the equipment into steady precision.

LS Precision has established an environment that closely couples high-rigidity lathe frames, clean-room environmental control, micron-level tooling and fixturing systems, and deep process expertise.

Ultra-precision machining is not a single-point technology effort within this environment, but instead a repeatable, predictable, and standardized result.

What Level Of Precision Does Your Industry Require?

The term “precision” takes different shades of meaning and stress in different high-precision manufacturing fields. It is not just a question of pursuing dimensional tolerances; real proficiency requires a complete understanding and meeting the specific performance requirements of each field. LS Precision, with a vast cross-discipline experience, perfectly understands the required standards of each industry.

1. Medical Device Machining Tolerances:

Medical device machining tolerancing accuracy is equated with life and health. The most critical specifications far outweigh mere dimensional fit:

- Very high surface finish and biocompatibility: Parts’ surfaces need mirror-like finish (e.g., Ra < 0.2µm) so as not to harbor microbes and create unconditional safety when in direct skin contact. A single scratch or imperfection is accepted.

- Total reliability and reproducibility: A mass-produced surgical robot joint or one-time-use implant, each piece must have flawless performance uniformity with zero tolerance for variation. This demands precise control of every process parameter.

2. CNC Lathe Machining of Aerospace Parts:

Contrary to medical devices, the challenge of CNC lathe milling of aircraft parts is to retain total integrity under extreme conditions:

- High strength-to-weight ratio and resistance to fatigue: Parts must endure harsh alternating loading, vibration, and temperature changes and be as lightweight as possible.. Thus, machining methods (such as five-axis straight positioning) should focus on maintaining the integrity of material flow lines and aim to remove all sources of stress concentration that result in fatigue cracking.

- Demanding material consistency and thermal stability: To cut difficult materials such as high-temperature alloys and titanium alloys, it is essential to maintain the structure of the material stable after cutting. Cutting heat has to be controlled precisely to avoid deterioration during cutting of the material.

LS Precision Manufacturing is firmly convinced that it requires distinct process philosophies and technical strategies to achieve the “pure” tolerances required for medical device machining and the “tough” requirements required for aerospace component CNC lathe machining.

From Programming To Measurement: A Closed-Loop Workflow Ensuring ±0.01mm Tolerances

It is not through a single step of machining that one can obtain very high tolerances of ±0.01mm, but through a data-based, end-to-end, closed-loop process. Whereas old methods will keep programming, machining, and measurement as different steps, LS Precision weaves them together as an end-to-end, closed-loop, smart system that can test itself and compensate for it in real time. This is the crux of the capability of LS Precision to run CNC lathes constantly at ±0.01mm tolerances.

1. Proactive Intelligent Programming and Simulation:

In the code generation phase, LS Precision engineers utilize CAM software along with artificial intelligence algorithms for in-depth simulation. The system not only anticipates tool paths but also sees ahead to cutting forces, thermal deformation trends, and probable points of vibration. This means many possible deviation factors are already optimized before metal cutting and offer a firm foundation for improved machining accuracy from its roots.

2. Real-time perception and compensation during processing:

LS Precision’s ±0.01mm tolerance CNC lathes are equipped with high-precision in-machine probes and tool breakage detection systems. The probes will automatically measure the workpiece on-machine, both prior to and following machining critical dimensions, and present the measurements back to the CNC system. The system will immediately compare measured and theoretical values, automatically compute and compensate for micron-scale deviation from tool wear or thermal deformation, thus providing an online closed-loop “machining-measurement-compensation” process.

3. Final Verification and Data Traceability:

The part machining is not finished yet. It is moved to a temperature-compensated measurement room for final, full-size inspection by a high-accuracy coordinate measuring machine (CMM). This detailed inspection report not only confirms acceptance but also gives feedback to our process database for continuing improvement of programming techniques and compensation logic, creating a closed-loop process on many lots of production.

LS Precision’s closed-loop system transforms post-process inspection into pre-process prediction and control.

This means every part shipped out possesses accuracy that is the unavoidable result of successive verifications of data, and customers get the genuine guarantee of accuracy of higher value than the equipment itself.

Which Materials Are Most Suitable For Ultra-High-Precision Turning?

Material selection has an impact on complexity and reliability of achieving end tolerance in ultra-precision machining. As a precision parts maker, LS Precision knows that no one “all-purpose” approach can be used across the board. Physical characteristics (toughness, hardness, thermal sensitivity) of various materials determine the machining behavior. Below are the details of common materials and our solution in acquiring ±0.01mm tolerances:

| Material Category | Processing Difficulty | Core Challenges | LS Solution |

| Aluminum Alloy | Relatively Easy | Soft material, prone to scratching and deformation. | Diamond tools, optimized parameters and clamping. |

| Stainless Steel | Medium | Toughness, prone to work hardening and tool wear. | Specially coated tools, high-pressure precision cooling. |

| Titanium Alloy | Difficult | High strength, poor thermal conductivity, prone to failure at high temperatures. | Special tools and low-speed strategies, efficient cooling. |

| Engineering Plastics | Special | Sensitive to heat and force, prone to deformation and springback. | Extremely sharp tools, micron-level parameters, air mist cooling. |

Material machinability is relative, not absolute; ultimate accuracy is based on compatibility of process solutions and material properties. As a precision parts company, LS Precision derives value from its large database of processes and tooling technology over a wide range of materials, from simple to complex.

LS Precision can tailor machining methods to your specific material, eliminate challenges due to material properties, and deliver stable ultra-high-accuracy results.

LS Success Story: How To Create A Core Joint Component For A Minimally Invasive Surgical Robot?

In precision manufacturing, the true power is demonstrating how to solve seeming impossibilities. Below is an actual success story of how we helped a leading medical technology company overcome a production challenge in its core joint components.

1. Client’s Dilemma:

The customer was developing a next-generation minimally invasive surgical robotic system. The micro-titanium alloy joint elements had very stringent requirements: dimensional tolerances had to be maintained within ±0.008mm, and surface roughness had to be Ra < 0.2μm in order to enjoy completely smooth and lag-free motion.

Several suppliers made attempts prior to learning about LS Precision but without success. Uncontrollable micro-vibrations and material stress deformation during machining resulted in dimensional out-of-tolerances and surface imperfections, strongly discouraging the customer’s product launch.

2. LS Precision’s Solution:

LS Precision never tackled this problem as a turning operation but instead approached it in a systematic precision engineering manner:

- Ultra-High Rigidity Platform: We selected a five-axis turning and milling center, whose ultra-high structural rigidity and dynamic accuracy provided a stable platform for micron-level machining.

- Customized Vibration-Improving Fixtures: In response to the deformation-prone tendency of thin-walled parts, our engineers created a proprietary fixture based on principles of stress relieving in an attempt to virtually eliminate deformation under clamping force.

- Micro-Nano-Level Cutting Strategy: With progressive finishing technology step by step, the process takes a minimal depth of cut, optimum feed rate and speed, and high-precision high-pressure cooling in order to eliminate successfully the cutting vibration and thermal deformation.

- Constant Temperature Guarantee: From the machining to the final coordinate measuring, the process is carried out in a constant-temperature cleanroom of 20±0.5°C, thus eliminating the impact of the change of ambient temperature on accuracy.

3. Results:

The solution was a first-pass success. The first release of parts fully satisfied all design requirements and was approved by the customer. Not only did this allow the customer to complete timely critical product registration and market introduction, but most importantly, this set of parts has had a superb “zero failure” record since installation, serving as a solid basis for the reliability of the surgical robot.

Is your project furthermore characterized by the challenge of close tolerances as well? Contact LS precision’s machining specialists today for an honest solution to your critical parts!

Choosing A Partner: Are You A “Custom Precision Parts Manufacturer” Or A “Parts Fabricator”?

When faced with stringent precision parts manufacturing requirements, your project’s success hinges on determining whether your prospective partner is indeed a custom precision parts fabricator or merely a “parts fabricator.” The distinction between the two reaches far beyond the meanings of dictionary definitions.

1. Core Value: Solution Provider vs. Drawing Executor

The fundamental role of a regular parts fabricator is to “make to drawings,” to purchase, from drawings that the customer supplies. As a genuine custom precision parts producer, the value of LS Precision begins even before drawings exist. We provide design for manufacturability (DFM) analysis, designing through material science, process feasibility, and cost-effectiveness, risk-free and project-success assured right from day one.

2. Scope of Service: Full-Process Service vs. Single-Step Processing

True precision machining services encompass the whole process, technical consultation, material choosing, process planning, precision processing, delivery and product inspection. We serve as both a technology partner and a quality protector for our clients, and we are a solution of a full range. Processors usually only control the manufacturing process, and the customer will plan and bridge the entire process.

3. Nature of the Relationship: Strategic Partner vs. Short-Term Supplier

Due to active participation throughout the whole process, LS Precision intends to create strategic long-term stable relationships with customers. We don’t just want sporadic orders but want to deliver long-term, stable volumes of components of core products of customers by maintaining continuous process improvement and ensuring quality.

Choosing LS Precision isn’t really purchasing a component; it’s purchasing peace of mind from our experience and ability in the system so that any concept that you develop is done right.

FAQs

1. How does LS Precision ensure consistent precision for every part in mass production?

LS Precision achieves mass production precision through a systematic industrial process. First, we practice aggressive tool life management and change tools well before critical wear levels are reached. Second, our manufacturing lines are equipped with an on-machine automatic dimensional measurement and compensation system. Critical dimensions are taken every few parts produced, and the system automatically compensates micron-level tool compensation to offset deviations in real time. Finally, we implement Statistical Process Control (SPC) to track and monitor key data in real time throughout the entire manufacturing process, providing us with early warning and process adjustment before dimensions go out of tolerance ranges.

2. Can I provide a sample for replication?

Yes. LS Precision possess high-accuracy CMMs as well as blue-light scanning technology that will allow us to reverse engineer your sample and accurately measure all of the geometric dimensions and form and position tolerance data. Above all, our process-conscious engineers will examine the sample for areas where it can be optimized (e.g., stress concentration sites or inefficient machining striations) and work on them in real time during the new production run, advancing the mark from “accurate duplication” to “optimized production,” with product performance and reliability improved over the original.

3. Is achieving high precision expensive?

In comparison to conventional machining, ultra-precision machining does entail a reason-cost premium driven by the cost of equipment of sophisticated equipment, stringent environmental controls, and highly trained engineers. But our fundamental philosophy is giving you optimum overall value, not minimum initial unit cost. LS Precision can do it by maximizing material and first-pass yield by applying scientific process design without offsetting it with any indirect rework and scrap cost.

4. How long does it take from inquiry to quote?

To respond to your requirements with maximum efficacy, LS Precision maintains a formal, efficient quoting procedure. With a request that entails full 3D drawings and technical specifications, our engineers conduct an immediate review, normally taking a process capability study, capacity control, and issuing a clear, open first quotation within four working hours. In the event of extremely complex projects, we will also get back to you within four hours to agree on the schedule for follow-up technical discussions so that you are always kept informed in advance.

Conclusion

It is not within the capability of any single device or technology to achieve and maintain an ultra-tolerance of ±0.01mm; it’s an enterprise challenge with cutting-edge machine tools, strict processes, closed-loop quality control, and enormous quantities of engineering expertise. It is an ongoing endeavor to make the “impossible” norm.

By joining forces with LS Precision, you choose established and proven performance and unwavering confidence for your toughest projects. We will employ our dedication to accuracy as a means of enhanced performance and marketplace triumph.

Your innovative designs require a similarly high-quality production. Contact LS Precision and submit your precision part designs to us today and qualify for a complimentary Design for Manufacturing Analysis (DFA) and expert estimate from LS’s highly experienced engineers! Let us transform your precision vision into a perfect reality together.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.