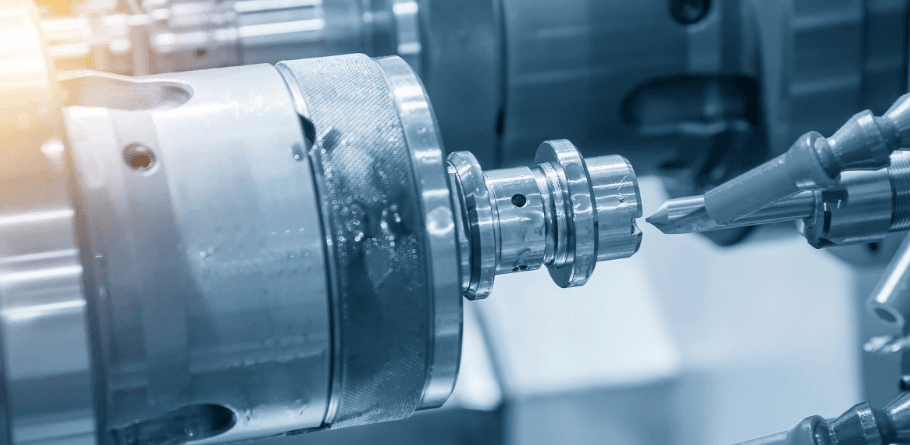

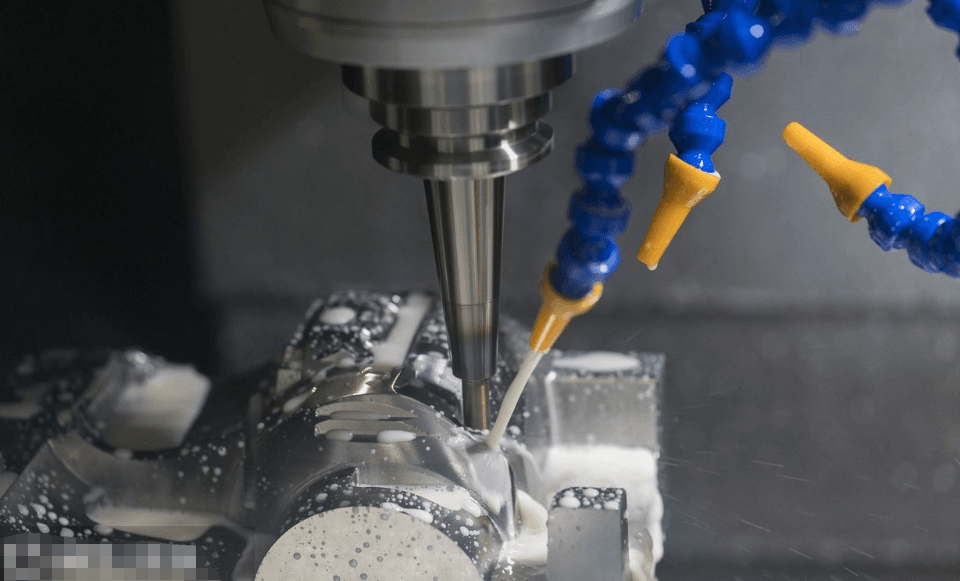

CNC milling is an advanced manufacturing process that requires high precision and accuracy to create complex cnc parts and components. So it is considered one of the most reliable ways to produce parts for aerospace, automotive and other industries, but ensuring the quality and accuracy of CNC milling parts requires strict adherence to quality control measures. Therefore, in this article, Longsheng technology and you will discuss in detail the importance of quality control in CNC milling parts manufacturing and how to ensure CNC milling process precision control, so that you have a more in-depth understanding

Ensuring CNC Milling Parts Precision and Accuracy

CNC milling is widely used because of its precision and accuracy in creating complex parts and components. The manufacturing process involves cutting and shaping materials into specific shapes and sizes using specialized tools and equipment. Quality control measures such as inspection and testing are critical to ensuring that the parts produced by CNC milling machines are accurate and precise. Any deviation from the required specifications can result in faulty or defective parts, which can compromise the safety and reliability of the final product. Therefore, quality control is essential to ensure that the parts and components produced meet the required standards of the industry.

Improving Efficiency and Reducing Costs

Implementing quality control measures in CNC milling can improve efficiency and reduce costs. By identifying and addressing issues early in the manufacturing process, manufacturers can avoid costly rework, delays, and other inefficiencies. Quality control measures such as statistical process control (SPC) can also help identify areas for improvement in the manufacturing process, leading to more efficient and cost-effective production. SPC involves collecting and analyzing data to identify variations and patterns in the manufacturing process. By doing so, manufacturers can make informed decisions about process improvements that can lead to significant cost savings.

Meeting Industry Standards and Regulations

Many industries have strict standards and regulations for the parts and components they use. CNC milling manufacturers must adhere to these standards to ensure that their products meet the required specifications and are safe for use. Quality control measures such as inspection, testing, and documentation are necessary to demonstrate compliance with industry standards and regulations. Failure to comply with these standards can result in legal and financial repercussions for manufacturers. Therefore, quality control is essential to ensure that the parts and components produced meet industry standards and regulations.

Enhancing Customer Satisfaction

Quality control measures can also enhance customer satisfaction by ensuring that the finished product meets their expectations. CNC milling manufacturers that implement quality control measures can provide customers with a high-quality, reliable product that meets their needs. This can lead to increased customer loyalty and repeat business. By prioritizing quality control, manufacturers can establish a reputation for producing quality products that meet the needs of their customers. In today’s competitive market, customer satisfaction is critical, and quality control measures can help manufacturers achieve this goal.

Conclusion

As mentioned above, in conclusion, quality control is an important aspect of CNC milling parts manufacturing. Implementing quality control measures can ensure precision and accuracy of CNC parts online, improve efficiency and reduce costs, meet industry standards and regulations, and improve customer satisfaction. By prioritizing quality control, CNC milling manufacturers can produce high-quality, reliable products that meet the needs of their customers and build a reputation for excellence in their industry. Investing in quality control measures is key to ensuring the success and longevity of CNC milling parts manufacturing.