Injection Molding Services

Our injection molding services help you save time and money on product development. The turnaround time for design feedback is only a few hours, and we offer free injection molding quotes.

- OEM ODM MOQ 1 PCS

- Tolerances down to +/- 0.005mm

- Suitable for continuous production of plastic parts

- All uploads are secure and confidential

Your Reliable Plastic Injection Molding Services

Want to turn creativity into tangible products? We are your reliable supplier of plastic injection molding services. Through our professional technology and high-quality service, we will help you achieve unique plastic products. Whether you need personal customization or mass production, we can meet your needs.

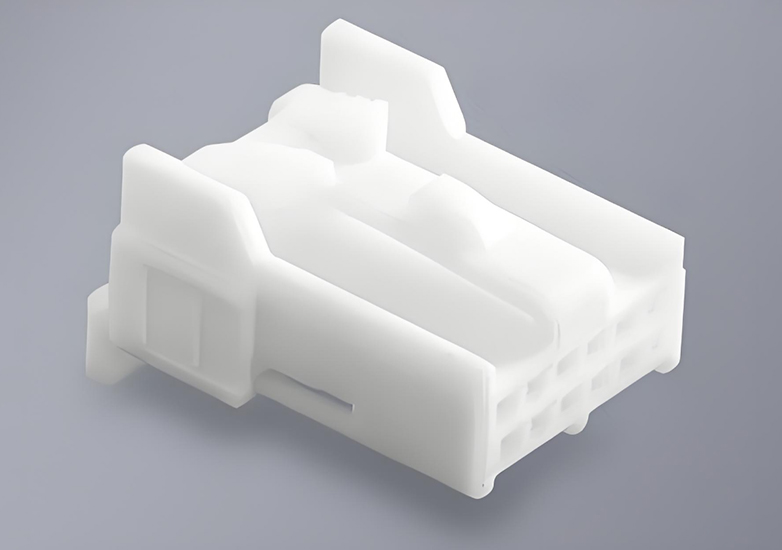

Plastic Injection Molding

Plastic injection molding is the injection of molten resin into a mold, a process that can efficiently produce large quantities of plastic parts and can manufacture complex geometric shapes.

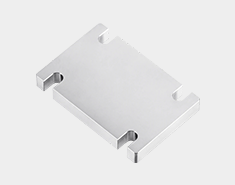

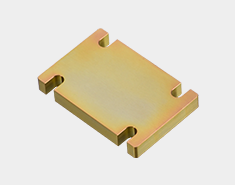

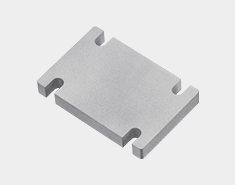

Plastic Injection Molds

Our professional mold design and manufacturing team has strong design and engineering capabilities, and can design and manufacture various injection molds according to customer requirements.

Insert Molding

Insert molding is the use of thermoplastic materials to mold materials around preformed parts into finished parts. This process is often used to create composite parts that contain multiple materials

Overmolding

Overmolding is an advanced manufacturing process that involves covering one material, such as plastic, with another material, such as metal or rubber, through a chemical bonding process.

1 day

Lead time

0.005

Tolerances

1 pc

MOQ

20 +

Surface Finishes

From Rapid Prototyping To Production

Are you looking for professional rapid prototyping services to assist in product development? LS Manufacturing provides high-quality and fast prototyping services to help customers transform creativity and concepts into actual product prototypes. We have advanced technology and an expert team that can quickly manufacture prototypes and accelerate the product development process.

Start Your Project With

A Free Quote

Our plastic injection molding process produces custom prototypes and end-use production plastic parts with delivery times of up to 3 days. And stock about 100 different thermoplastic resins. Our goal is to help you finish quickly and provide quality plastic parts.

Our Injection Molding Processes

Check out our efficient injection molding process and learn how we deliver your high-quality plastic parts on time within 3 days.

Request parts quotation

By uploading your design file to request a quote, our engineers will provide a response within 2 hours and start your project.

DFM Feedback

Conduct a feasibility review of your design to ensure that I, Moen, can produce functional molds that meet your requirements.

Mold Flow Analysis

Using mold flow analysis software to predict the flow and mode of action of molten materials within the mold can help improve and ensure the quality of the parts.

Part Mold Production

Start producing mold tools according to your requirements.

T1 Sample Verification

Before starting the production of plastic parts, we provide T1 samples for customer inspection to ensure the accuracy and quality of the parts.

Low Volume Production

After the sample trial production is completed, small batch production will begin. We utilize advanced processing technology to efficiently produce plastic parts.

Quality Control

We conduct strict inspections on the functionality, size, and appearance of plastic parts to ensure that they meet your specifications and requirements.

Delivery

After strict inspection, we will deliver your injection molded parts to you as soon as possible.

From Injection Molding to Production

Our Injection Molding aims to provide a seamless and guided process, taking you from the beginning of creativity to creating the perfect final product. It emphasizes the precision and caution of each step to ensure that your design vision is fully realized.

On-Demand Production

On-demand Injection molding reduces the need for extensive inventory storage. You can produce parts as needed, reducing carrying costs and minimizing the risk of excess or obsolete inventory.

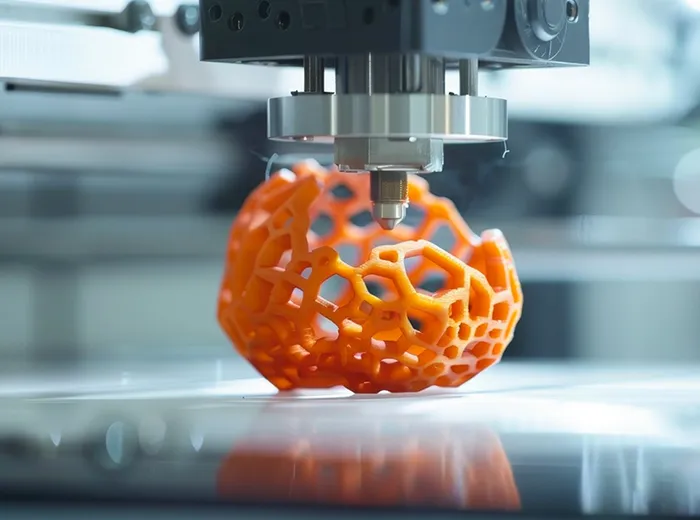

Rapid Prototyping

LS Manufacturing's Injection molding capabilities allow for the rapid transformation of your CAD designs into physical prototypes. This speed is essential for quickly evaluating and iterating on your product concepts.

Production Parts

Bridge Production approach is designed to seamlessly transition from the prototyping phase to full-scale production. This ensures that the knowledge and data gained during prototyping are effectively carried over into the manufacturing process.

From Tooling to Prototyping Production

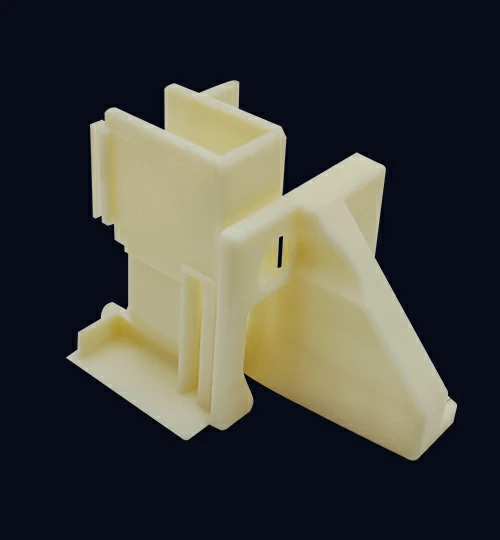

Rapid Tooling

Create prototype molds within 3 days to ensure that your injection molded plastic parts can quickly undergo functional testing and be launched into the market.

Prototyping Production

Creating injection molds for manufacturing prototypes can help you validate design and material selection before formal production, reducing potential design errors and production issues.

Plastic Injection Molding Tolerances

| Types | Size Tolerance |

|---|---|

| Maximum Part Size |

1000 × 800 × 300 mm

39.37 × 31.49 × 11.81 inch |

| Minimum Part Size |

1 × 1 × 1 mm

0.039 × 0.039 × 0.039 inch |

| Mold Cavity Tolerances |

+/- 0.1 mm

+/- 0.0039 inch |

| Part to Part Repeatability |

+/- 0.15 mm or less

+/- 0.0059 inch or less |

| Surface Finishing Options | Mirror polishing, electroplating, spraying, screen printing, etc |

| Available Mold Types | Steel and aluminum tooling |

| Production Grades Available | From 105 grade (prototype tools) to 101 grade (high production tools) |

| Tool Ownership | Customer-owned with mold maintenance |

| Lead Time | Starts at 3 business days, including fast quote responses with design-for-manufacturing (DFM) feedback |

* Tolerance: Typically, Longsheng can maintain a machining tolerance of+/-0.01 millimeters (+/-0.0039 inches).

Class of Injection Molding Mold

Please check our injection molding parts manufacturing capabilities, For custom tolerances, mark them clearly on your drawing.

| Mold Class | Purpose | Shot Life | Tolerance | Lead Time |

|---|---|---|---|---|

| Class 101 | Large-Scale Production | Over 1,000,000 cycles | +/- 0.01mm | 13 days |

| Class 102 | Medium-Batch Production | High Volume | +/- 0.01mm | 10 days |

| Class 103 | Medium to Small-Batch Production | Less than 500,000 cycles | +/- 0.01mm | 10 days |

| Class 104 | Medium to Small-Batch Production | Less than 100,000 cycles | +/- 0.01mm | 9 days |

| Class 105 | Advanced Prototype Testing | Up to 500 cycles | +/- 0.01mm | 5 days |

Injection Molding Material Selection

We offer a wide range of injection molding materials to meet the diverse needs of various industries. Our selection includes metals, plastics, and composites to ensure that your parts are manufactured with the best-suited material for your application. Below are some of the materials we commonly work with:

Metals

Plastics

We offer customization based on your specific material requirements. If you need a material not listed here, our team can source and process it to meet your exact needs.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

Surface Finishing for Injection Molding

Our surface finishing allows you to customize the appearance and texture of your milling parts. Various textures, colors, and finishes are available to match the aesthetic requirements of your product or brand.

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

Why Choose LS Manufacturing for Custom Injection Molding Services

Multi material machining

We have the ability to handle multiple materials, and we can provide professional solutions no matter what material of cnc parts you need to process.

Customized Services

Provide customized solutions based on customer design requirements and specifications to ensure that CNC parts meet their unique needs.

No MOQ

This unrestricted ordering method for plastic molded parts will help improve efficiency and reduce production costs, making your production process more competitive.

Rapid delivery

We have efficient production processes and flexible production plans, which enable us to timely deliver customer orders and meet urgent project needs.

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

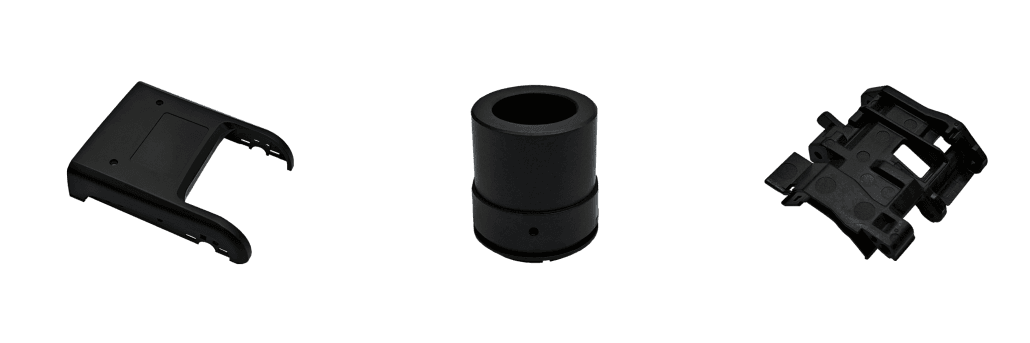

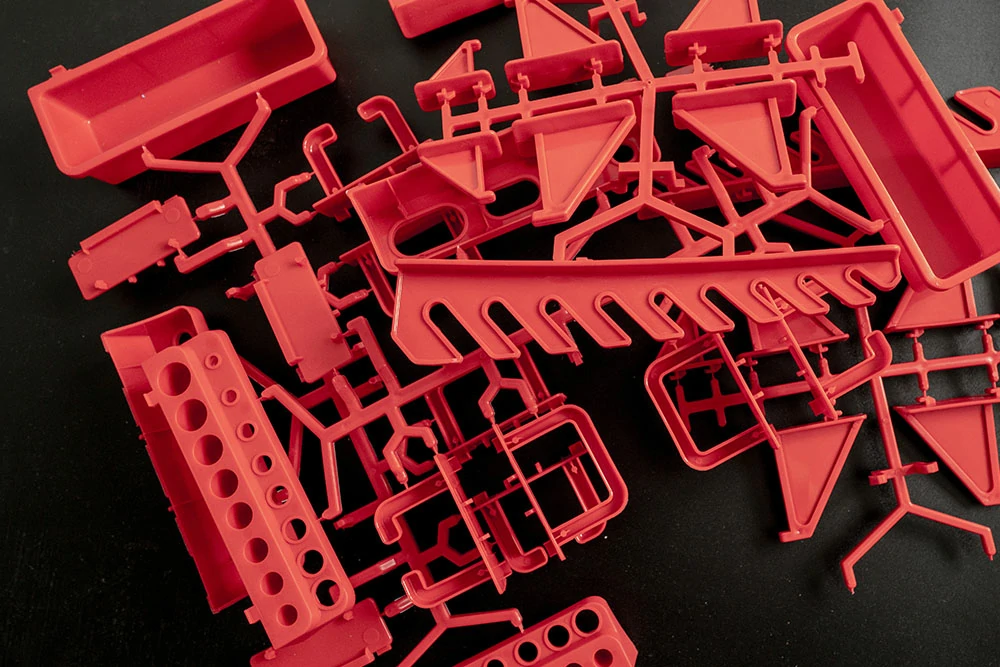

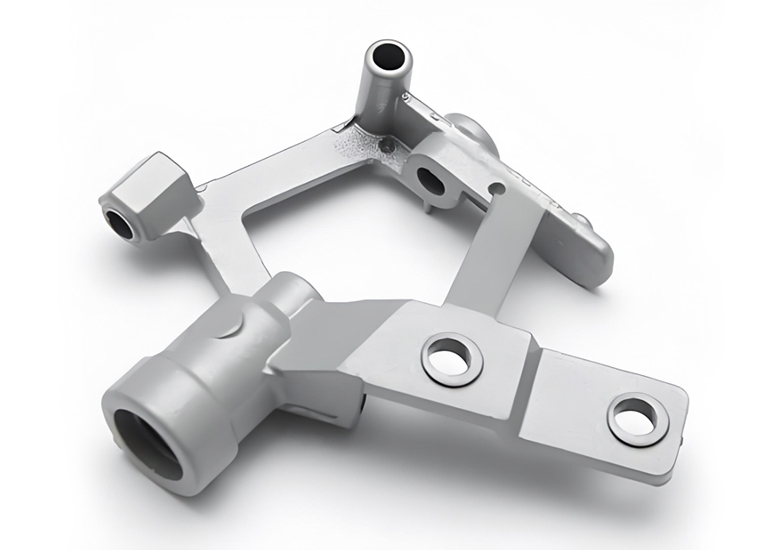

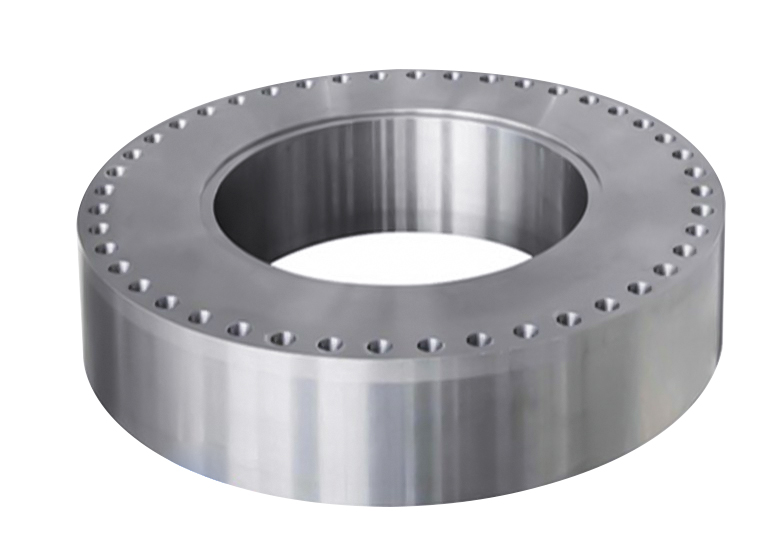

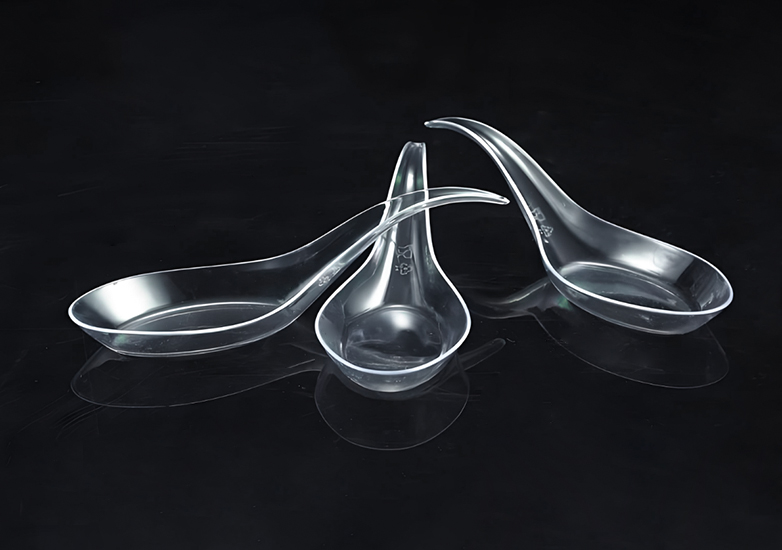

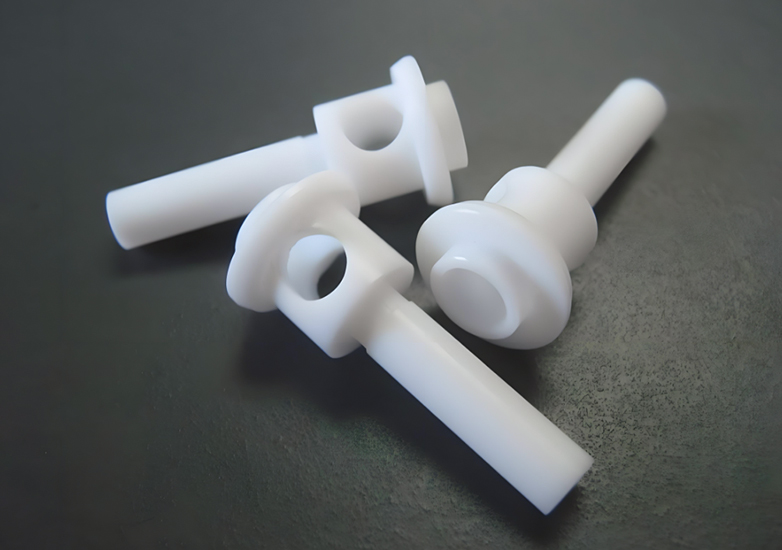

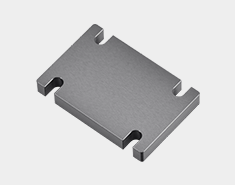

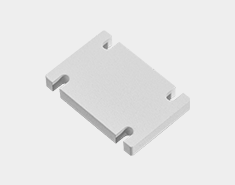

Gallery of Injection Molding Parts

Check out our extensive gallery, which showcases some of our finished injection molding parts, and trust us to create your plastic injection molding project according to your strict specifications.

Our Injection Molding for Various Industrial Applications

Crossing numerous industries, LS Manufacturing uses highly advanced technology, from prototype production to on-demand manufacturing, and then to large-scale production, to ensure the excellent quality and reliable performance of parts, ensuring the success of your project.

Advantages of Injection Molding

Injection molding is an efficient, precise and flexible manufacturing technology that produces plastic parts with great precision, speed and repeatability.

- - Complex geometries parts

- - Minimal material waste

- - Large selection of thermoplastic and thermoset materials

- - Precision and high tolerance

- - Cost-effective for large volumes

Applications of Injection Molding

Injection molding finds applications in a wide range of industries and products due to its versatility and efficiency in producing intricate parts.

- - Parts for washing machines

- - Various structural components

- - Medical equipment housings

- - Switches and enclosures

- - Helmets, protective gear, handles, and components

Injection Molding Overview

What is injection molding?

Injection molding is used to manufacture plastic parts and products. During the injection molding process, melted plastic is injected into the mold, then cooled and hardened to form the required parts or products.

>What is injection molding process steps?

Injection: Heat the plastic into a molten state and inject it into the mold. Plastic filling: Ensure that the plastic fills the cavity of the mold to form the required parts. Cooling: Allow plastic to cool and harden, usually using a cooling system to accelerate. Mold opening and discharge: Open the mold and remove the formed parts, and then proceed with subsequent processing.

Why is injection molding used for plastic?

Efficient production: suitable for large-scale production and reducing costs. High precision: Manufacturing precision parts to ensure consistency. Strength and durability: Manufacturing parts with high strength and wear resistance. Complex structure: Parts that can manufacture complex internal structures.

How does injection molding work?

Injection molding involves heating plastic materials to a molten state, then injecting them into a mold, allowing them to cool and solidify within the mold, ultimately forming the required parts or products. This process combines the plasticity of plastics with the precise shape of molds, allowing the manufacturing of various shapes and sizes of parts, from small parts to large components, to meet the needs of different industries and applications.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

Frequently Asked Questions about

Plastic Injection Molding

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required plastic injection molding service support by reading FAQ.

What type of plastic injection molding can you handle?

We can handle various types of plastic materials, including common ABS, PP, PE, PC, etc. Based on your needs and application scenarios, we will choose the most suitable material for you.

Can you provide product design services?

Yes, we can provide product design services. We have an experienced design team that can help you design and develop products from concept to reality.

Do you accept small batch orders?

Yes, we accept small batch orders. We understand that different customers have different needs, whether it’s mass production or small batch customization, we can meet your requirements.

How long is your production cycle?

The production cycle varies based on project complexity and order volume. We will do our best to complete your order in the shortest possible time. After confirming the design and requirements, we will provide you with the estimated production cycle.

Can you handle the design file format I provided?

Yes, we can handle various design file formats, such as CAD, SolidWorks, etc. Please provide us with your design documents in an acceptable format.

What information do we need to provide to obtain a quote?

In order to obtain an accurate quotation, we need you to provide the product’s design drawings, size requirements, material selection, and estimated order quantity.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.

The Ultimate Guide to CNC Milling: Advantages, Limitations & Applications

Design for Manufacturing (DFM): Principles, Process, and Application Explained

CNC Turning Parts:Everything You Need to Know| LS Manufacturing

CNC Machining: The Ultimate Guide to Processes, Materials, and Applications

What Are The Parts Of A Plasma Cutter Gun?

What Are Taps In Machining?

How to Cost a Xiaomi YU7 Auto Part?

What Is The Difference Between Sheet Metal And Machining?

Put your parts into production today

- All information and uploads are secure and confidential.