In conventional manufacturing, did excessively long processing time and bureaucratic quoting and communication procedures tend to push your project and innovation schedules? Time is now your highest overhead cost. LS Precision’s fast 3D printing service online was created exactly with this in mind, transforming the concept of rapid manufacturing: not merely technological improvement, but the ultimate quest for manufacturing efficiency.

Our web flagship website, in conjunction with the astute LS precision instant quote system, allows you to upload your 3D file and be provided with an accurate price and manufacturability report in real time, instantly.

By merging the new print technology with a high-speed, digital manufacturing process, we ensure lightning-fast delivery from order entry through to product handover, allowing you to reduce your R&D cycle by significant amounts and capture all market opportunity. Test drive it today and put your ideas on the fast track. To make things easier for you, below is a brief recap of our key points.

Quick Reference: Summary of Online Quick 3D Printing Services

| Key Questions | Answer Summary |

| Service Definition | A digital manufacturing model that enables instant quotes, one-click ordering, and rapid production through an online platform. Its core value is extreme speed. |

| Reasons to Choose LS | Instant quotes (AI-generated in seconds), ultra-fast delivery (24-72 hours), a variety of materials and processes, and professional quality assurance. |

| Applicable Part Types | Functional prototypes, small-batch end-use parts, fixtures, and concept models. |

| Ordering Process | Upload file → Instant quote/analysis → Select parameters → Confirm payment → Print quality inspection → Shipment tracking. |

| Pricing and Discounts | Pricing is based on material, time consumption, and post-processing. Optimize your design, place bulk orders, and select the right process for the best quote. |

| File Preparation Software | Common CAD software (such as SolidWorks and Fusion 360) is acceptable. The final output requires a watertight STL/STEP file. |

| 24 Hour Fast Case Study | Medical device prototype: Order in the afternoon → AI-powered quote → Print that evening → Next-day quality inspection and shipment, delivered within 24 hours. |

| Quality Assurance Measures | Industrial-grade equipment, full-process quality inspection (before, during, and after printing), original materials, and review by a team of engineers. |

LS Precision’s web-based rapid 3D printing service, with its unique strengths of real-time quoting and amazingly fast turnaround (as fast as within 24 hours), completely eliminates the agonies of long conventional production cycles and provides customers with fast, efficient and cost-effective digital manufacturing solutions.

Why Trust This Guide? Real-World Experience from LS Experts

When you’re hiring a manufacturing partner for a mission-critical project, you don’t require promises – you require battle-hardened expertise. Every step and suggestion in this guide has been crafted from LS Precision’s extensive experience in additive manufacturing across the multiple decades that we’ve had the privilege of operating.

We’re not an agency; we’re a partner, working with hundreds of clients to find and crack challenging manufacturing mysteries. LS Precison team of experts has actually completed hundreds of thousands of orders, ranging from applications of high-precision functional parts within the aerospace industry to biocompatible prototypes of medical devices, to demanding test fixtures for the automotive industry.

That is having a test and certified library solution to help you with nearly every issue you are facing, from material selection to design optimization, post-process, and on schedule. Most importantly, LS Precision “instant quote” and “quick delivery” promises aren’t marketing hype; they’re norms we practice every day.

LS Precison believe true trust is built on an open and observable history of success. So, with this guide, you’re choosing a seasoned, trustworthy manufacturing expert who can bring success to your project.

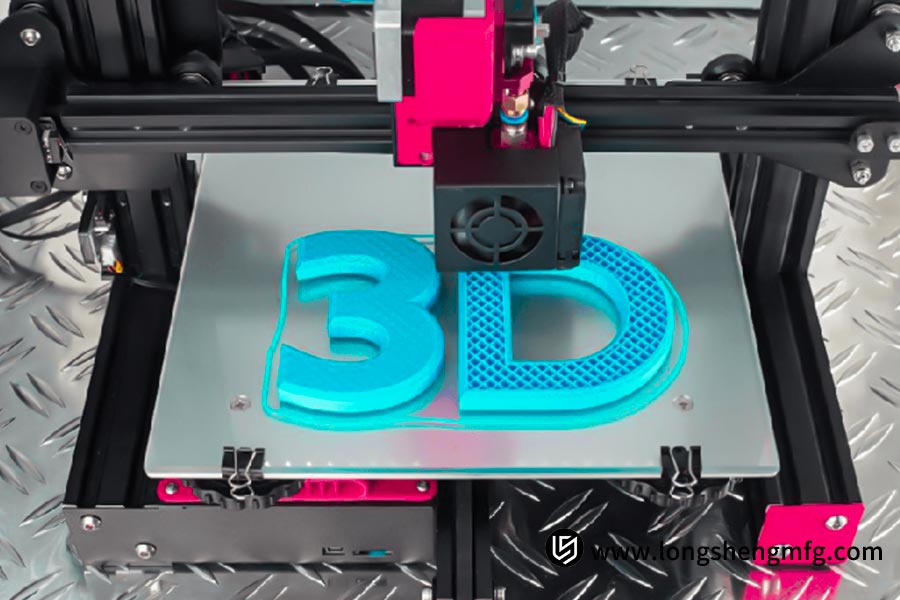

What Is Online Rapid Manufacturing 3D Printing Service

Online Rapid Manufacturing 3D Printing Service is an Internet-enabled manufacturing service offered via an online platform. Simply post your 3D model file online, and the system will automatically compute a quote based on intelligent algorithms with support for one-click ordering. Online Rapid Manufacturing 3D Printing Service eliminates the long communication, inquiry, and scheduling process in traditional manufacturing with significant efficiency improvement.

The greatest strength of LS Precision in this service is swift response and extremely quick delivery. With the adoption of high-end printing machines, process-matched post-processing processes, and intelligent logistics arrangement, we are able to complete the whole process from file to delivery within 24-72 hours. For a prototype or small batch, you can enjoy a repeat agile manufacturing experience.

Online 3D printing service not only redefines the top edge of production velocity but also becomes a safe approach to allow innovative iteration and respond to emergent requirements.

Why Opt For LS’s Online 3D Printing Service?

Choosing LS Precision’s online 3D printing service will allow you to experience what a efficient manufacturing process is like. We provide real-time online quotes and seasoned design analysis, which means that much less time is wasted on waiting for questions and your project can start that much sooner. That’s the start of efficient custom 3D printing manufacturing.

1.Unequalled quality:

We promise not only speed but also unequalled quality. LS Precision uses precision equipment of industrial class and high-quality raw materials, combined with strict quality control, to ensure each custom 3D-printed part achieves high dimensional accuracy and functional consistency, satisfying a variety of needs from prototyping to end-use production.

2.Professional post-processing services:

In addition, LS Precision Manufacturing also offers professional post-processing services like polishing, painting, and line penetration, and ensures meticulous quality control from printing through shipping. What this means is that any order, from beginning to arrival, is traceable and controllable, resulting in a hassle-free and assured one-stop custom 3D printing manufacturing experience.

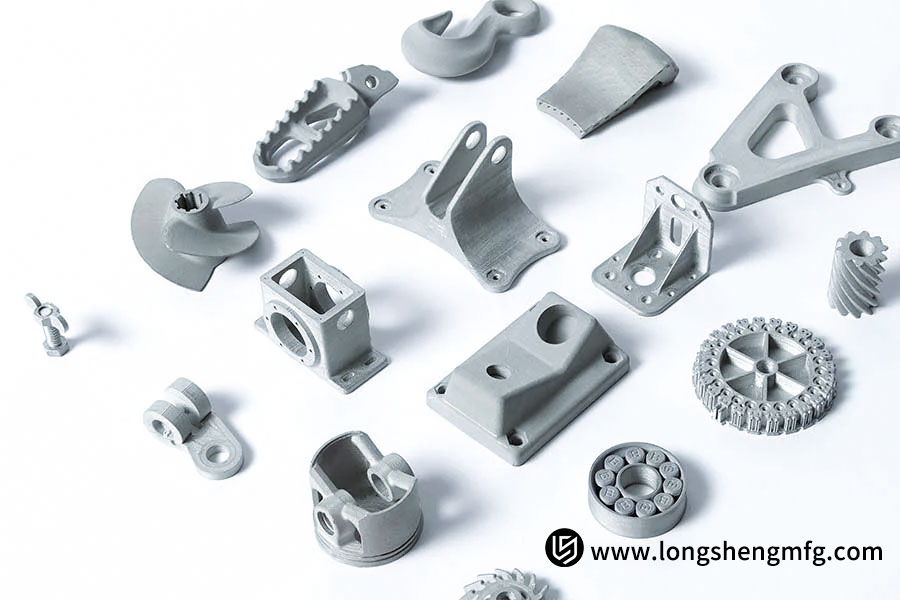

Which 3D-Printed Parts Are Most Suitable For Rapid Manufacturing?

Traditional manufacturing has a delayed lead time and late quotes, which tend to delay project progress. Our rapid 3D printing services online cut out this problem with instant quotes and very fast delivery, making manufacturing easy and your ideas able to be quickly prototyped without any delay.

1.Functional prototypes:

Functional prototypes are the most common 3D-printed parts. Rapid mode three-dimensional printing services allow designers to obtain physical models in hours for checking appearance, assembly relationships, or functional tests. It is highly time-saving and reduces product development cycles significantly, and it is the best way to iteratively improve designs.

2.Low-quantity production parts:

Low-quantity production parts are a well-suited candidate for web-based 3D printing services as well. When making end-use parts in lot sizes of 50-500 units, the mold-free nature of 3D-printed parts is an excellent advantage—evolutionarily reducing unit cost and evolutionally speeding the overall design-to-market process.

In addition, complex internal structures, embedded shapes, or lightweight topology optimization details that are hard or impossible to make with conventional machining are easy or impossible to produce using legacy machining techniques. Rapid 3D printing technology is well-suited for this kind of free-form modeling with unparalleled design freedom for product innovation.

Online fast 3D printing with instant pricing and lightning-fast shipping solves the whole problem of production timelines. It’s ideal for accelerating innovation, testing concepts, and even small batches. Leave your projects progressing at full speed to LS Precision.

What’s The Whole Process For Ordering 3D Printing Services Online?

Goodbye to the tedious traditional manufacturing process. LS Precision online ordering system simplifies 3D printing into four simple-to-see steps so that you can easily enjoy quick manufacturing service:

Step 1: Upload 3D File

Visit our site and directly upload your 3D model file in STL/STEP format. The software automatically performs an initial manufacturability check.

Step 2: Get an Instant Quote

LS Precison intelligent quoting engine generates an extensive price and delivery schedule in seconds as a function of the model volume, material selection, and process requirements.

Step 3: Pay and Confirm Order

Once satisfied with the quote, select your preferred post-processing method online and go ahead to confirm order. Pay securely via an approved payment gateway, and your order immediately enters the production pipeline.

Step 4: Production and Speedy Delivery

LS Precison professional team will carry out printing, post-processing, and quality check in accordance with rigorous standards. We then deliver high-quality finished products to you through our efficient logistics network.

This efficient online ordering process integrates intelligent and standardized management, offering efficiency, transparency, and reliability every step of the way, from document to end product. This indeed provides the convenient “one-click order, wait for delivery” experience.

How Is 3D Printing Quoted? How Do I Obtain The Best Competitive Price?

An in-depth look at 3D printing pricing factors will allow you to more accurately plan your project and achieve maximum cost-effectiveness. LS Precision’s intelligent quoting mechanism accurately computes the following basic factors, with a clear and open process so you can appreciate every dollar.

Price is first and foremost calculated by four factors:

- Material usage is the base cost; the system accurately measures the real amount of material that the model uses;

- Print time is derived from the machine run time required by the model; tedious parts typically take longer to print;

- Post-processing activities such as polishing, painting, plating, and assembly are all additional costs;

- The costs of different printing material and technologies vary significantly, where industrial material is usually more costly than normal material.

To help you achieve the best 3D printing price, LS Precision Manufacturing recommends the following optimization methods:

- Design optimization to reduce support material and use lightweight designs such as hollowing or thin-walled parts can greatly reduce material usage and printing time;

- Making several parts one order for a bulk order usually provides a better unit cost;

- Using the most economic printing technology as per the real functional requirements of the part to avoid unnecessary cost caused by over-performance.

In short, LS’s intelligent quoting system enables our online platform to provide you with an understandable and transparent 3D printing cost detail. Through the application of above optimization techniques, you can achieve the optimal value-for-money manufacturing solution while product quality is ensured.

LS Precision would recommend that you upload your design files for real-time quotes directly so that our experienced staff can provide you with the best optimized manufacturing solution.

What Do I Have To Employ In Order To Make 3D Print Files?

Choosing the right 3D prototyping application is crucial in order to provide quality prints. Having the right tools, you not only efficiently create your artistic vision but also naturally ensure your models’ great printability, avoiding print failure or quality defects because of design fault, thus saving valuable time and money.

1. For professional engineers and designers:

For professional engineers and designers, LS Precision strongly recommends using industry-standard engineering 3D prototyping software such as SolidWorks, Fusion 360, or CATIA.These softwares allow for strong parametric modeling and precise dimensional control, so that models with complicated surfaces and tight tolerances are effortlessly generated.

Direct export of high-accuracy, high-fidelity STL or STEP files is possible with these softwares with few chances of mistakes during post-production conversion. These are ideal for creating working prototypes, test assemblies, and accurate mechanical parts.

2. For 3D printing beginners:

For 3D printing beginners, you may use a simple software like Blender, Tinkercad, or SketchUp if you’re new to 3D printing, or concept designing or making artworks. These offer a gentle learning curve and allow you to create your concepts into 3D models quickly.

Regardless of the software you use to create your design, before exporting your final print file, LS strongly recommends that you do a final check and repair of your model with Netfabb, Meshmixer, or an online repair tool like 3D Builder.

This critical step correctly identifies and automatically fixes problems such as non-manifold geometry, missing meshes, malformed normals, gaps, or overlaps in the mesh, leaving your model a watertight, closed body with a good start for a successful print.

From high-end professional engineering software to handy and flexible concept model software, having the proper 3D prototyping software for your specific use, along with some post-processing and file checking and repair, can maximize the chances of your design turning into a physical part from digital model, enabling your project to progress smoothly and efficiently.

LS Case Study: How To Complete An Urgent Order For Medical Device Prototype In 24 Hours?

1. Client challenge:

A medical devices company required a functioning prototype of a new surgical instrument handle within a week for a significant clinical assessment. Traditional CNC machining would take five days, and the complex inner structure was difficult to acquire, and the client was left struggling to complete validation on time.

2. Traditional constraints:

With traditional outsourced manufacturing, just to communicate and plan would take one to two days, with more processing and post-processing taking even longer. This simply wasn’t capable of meeting the timely need for 24-hour delivery.

3. LS’s revolutionary methodology:

Following the customer input of a 3D model file via the LS online portal, our 3D printing prototyping service is underway immediately:

- Smart Quoting and Analysis: The system provides an auto-quote in 30 seconds, while engineers, simultaneously, perform manufacturability checking.

- Fast Production Response: Once the order is confirmed, equipment is planned for SLA printing on medical-grade resin.

- Parallel Post-Processing: Post-processing solutions are prepared in parallel as the printing goes on, and meticulous cleaning, support removal, and surface treatment are done after the print.

- Stringent Quality Check and Shipment: After all post-processing is complete, the quality check crew quickly conducts critical dimension checks to ensure functional integrity, and arranges express shipment immediately.

4. Results and value:

From the time the customer placed an order online to receiving their excellent 3D printed prototyping product, the entire process took only 22 hours. The prototype of the handle, which went through full functional test requirements, was able to successfully enable the customer to meet the clinical evaluation meeting within deadline, saving valuable time for product release.

This case demonstrates the speed and reliability of our 3D printing prototyping service for mission-critical and complex demands.

How Do We Ensure Print Quality On Online Orders?

Quality is the customers’ number one concern when one makes an online order. LS Precision has instituted a robust quality assurance system to ensure that every online order is of high factory quality.

1. Equipment Calibration:

LS Precision ensures equipment accuracy right from the beginning. All industrial-grade 3D printing equipment is professionally calibrated and serviced regularly to ensure build platform level, laser precision, and extrusion system remain in top working order, delivering stable and consistent output from a hardware perspective.

2. Multi-Level Quality Inspection:

In practical terms, quality inspection is conducted throughout the process. This entails:

- Pre-print: Design for manufacturing (DFM) analysis is performed on uploaded files to proactively remove potential issues;

- During printing: Real-time equipment operation monitoring allows for quick fault identification;

- Post-print: All post-processing operations, from the removal of supports to surface treatment, are controlled by normalized operating procedures and auto-tests.

3. Final Inspection Standards:

All parts must go through final inspection before shipment. Our professional quality inspection personnel thoroughly checks major dimensions, assembly dimensions, and cosmetic defects based on customer order specifications to only ship 100% qualified products to our customers.

LS Precision Manufacturing’s three guarantee of precision-calibrated equipment, regulated process controls, and a quality inspection department committed to allowing you to order online without having to come in, but still having faith in the final quality.

FAQs

1. What is the fastest lead time?

LS Precision values the importance of timely delivery. Regular orders can be manufactured and shipped out within 24 hours, and priority orders can be completed and shipped out in only 6 hours. Our intelligent scheduling software, large inventory of materials, and good relationships with high-quality logistics companies allow timely order processing, actually achieving the efficient “order today, deliver tomorrow” service.

2. What 3D printing materials are supported?

LS Precision offers over 50 materials with a wide range of needs, from proof of concept to functional testing. Our offerings are primarily made up of cost-effective and biodegradable PLA, tough and strong ABS, long-lasting nylon, highly accurate and smooth photosensitive resins, and various specialty engineering-grade materials (e.g., high-heat resistant and rubber-like materials). All of our materials are thoroughly tested for reliable performance and optimal print outcomes.

3. How is confidentiality guaranteed in the model?

Intellectual property of our customers is our highest concern at LS Precision Manufacturing. We transmit and store your files through bank-grade SSL encryption, and we obtain a legally binding Non-Disclosure Agreement (NDA) from each customer. After completing a project, all your design files are automatically deleted permanently, with no possibility of leaks and full security of your designs.

4. What if the print output is not satisfactory?

LS Precision promises quality and offers you a sound warranty. In case the finished product delivered is below standards or order requirements agreed upon, kindly let our customer service know. On confirmation, LS Precision will re-print it for you for free and incur all the costs on your behalf. This is LS Precision’s quality promise, enabling you to place your order with complete confidence.

Conclusion

No more waiting for lengthy manufacturing cycles. LS Precision Manufacturing‘s online presence makes 3D printing services quicker, easier, and more reliable than ever. In just a few easy steps, you can transform your ideas into superior products, enjoying a one-stop process from instant quote to speedy delivery. Act now and have professional, efficient manufacturing services safeguard your project.

Upload 3D file now and experience the convenience of LS Precision’s intelligent quoting system! Get an instant accurate price in 60 seconds. Relax once you’ve confirmed your order with quick, professional service with shipping in 24 hours. Bring your ideas to life sooner—starting now.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

You could definitely see your expertise in the paintings you write. The arena hopes for more passionate writers like you who are not afraid to say how they believe. Always go after your heart. “Billy Almon has all of his inlaw and outlaws here this afternoon.” by Jerry Coleman.

Some truly great articles on this internet site, thankyou for contribution.

Thank you so much for your encouragement! I will continue to strive to share valuable content, and please feel free to visit again.

Definitely believe that which you stated. Your favorite reason seemed to be on the internet the simplest thing to be aware of. I say to you, I definitely get annoyed while people think about worries that they just do not know about. You managed to hit the nail upon the top and also defined out the whole thing without having side effect , people can take a signal. Will likely be back to get more. Thanks

I like this post, enjoyed this one appreciate it for putting up.

Pingback: LS Manufacturing: 40% Faster Product Development With Rapid Prototyping