Take a moment to think about the components that make up a plane. Engines, seats, wings, landing gear – the list goes on. But have you ever stopped to consider how these parts are made? In the aerospace industry, precision and reliability are everything, and the process of manufacturing components requires the utmost attention to detail. That’s where injection molding comes in.

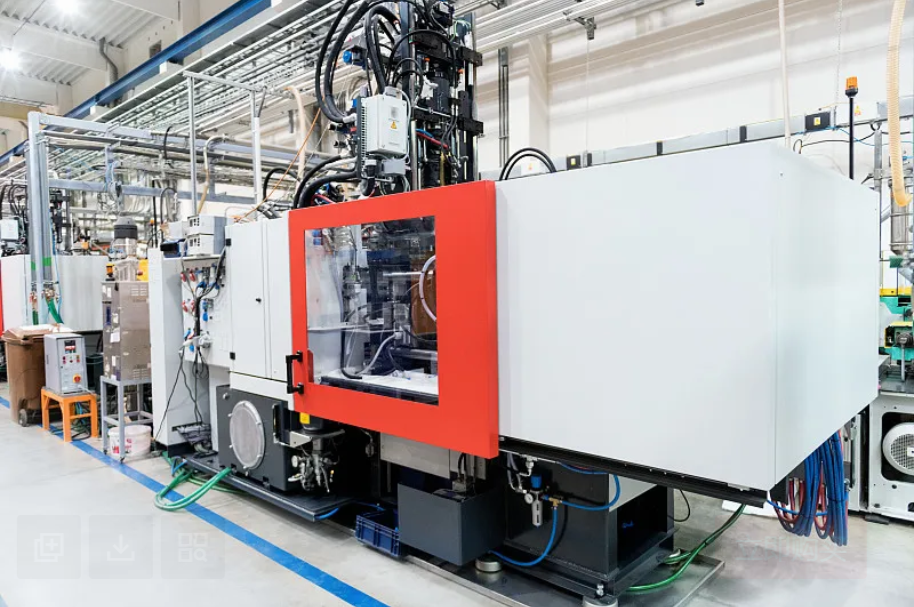

At Longsheng, we provide plastic injection molding services to a range of industries including aerospace. We know firsthand the benefits of using this process for the production of complex aerospace components. Here’s why:

- High Precision and Consistency

Injection molding is a highly precise process that ensures consistent, repeatable results. This is essential in the aerospace industry, where even the slightest variation can create catastrophic consequences. By using injection molding, manufacturers can produce parts with incredibly tight tolerances, ensuring that they fit and function as intended every time.

- Cost-Effective

The aerospace industry is notoriously expensive, and every effort to reduce costs without sacrificing quality is welcome. Injection molding is an affordable option for the production of small to medium-sized components. The process is highly automated, making it efficient and cost-effective compared to traditional manufacturing methods.

- Faster Production Times

The speed of production is a critical factor in the aerospace industry. Any delay can have a ripple effect on the entire supply chain, and ultimately, the customer. With injection molding, parts can be produced quickly and efficiently, reducing lead times and ensuring that assemblies are completed on time.

- Versatility

Injection molding is a versatile process, capable of producing complex shapes and designs that would be difficult or impossible to achieve using other methods. This allows for greater creativity and innovation in the design of aerospace components, resulting in better performance, safety, and reliability.

- Longevity

Finally, the durability and longevity of injection-molded parts are critical, particularly in the aerospace industry. Aerospace components must withstand harsh environments, high temperatures, and extreme pressures. Injection molding produces parts with exceptional strength and durability, ensuring that they can withstand the rigors of flight and continue to perform reliably over extended periods.

In conclusion, the use of injection molding in the aerospace industry is revolutionizing the manufacturing process, delivering unparalleled precision, consistency, cost-effectiveness, speed, versatility, and longevity. At Longsheng, we’re proud to provide plastic injection molding services to the aerospace industry, helping our clients stay ahead of the competition and exceed their customers’ expectations.

If you’re interested in learning more about our plastic injection molding services, contact us today. With our experienced team and state-of-the-art facilities, we’re confident that we can help you achieve your aerospace manufacturing goals.