Powder Coating Services

Powder coating is available in a wide range of colors and finishes, allowing for customization to meet aesthetic preferences and functional requirements.

Powder Coating Specifications

| Materials | Colors | Glossiness | Thickness | Texture | Applications |

|---|---|---|---|---|---|

| Aluminum, Steel, Stainless steel | Black, White, any RAL code or Pantone number |

Glossy (Above 60 gu) Matte (Below 20 gu) |

40μm to 140μm | glossy, matte, textured, and metallic finishes | automotive, architecture, aerospace, and electronics |

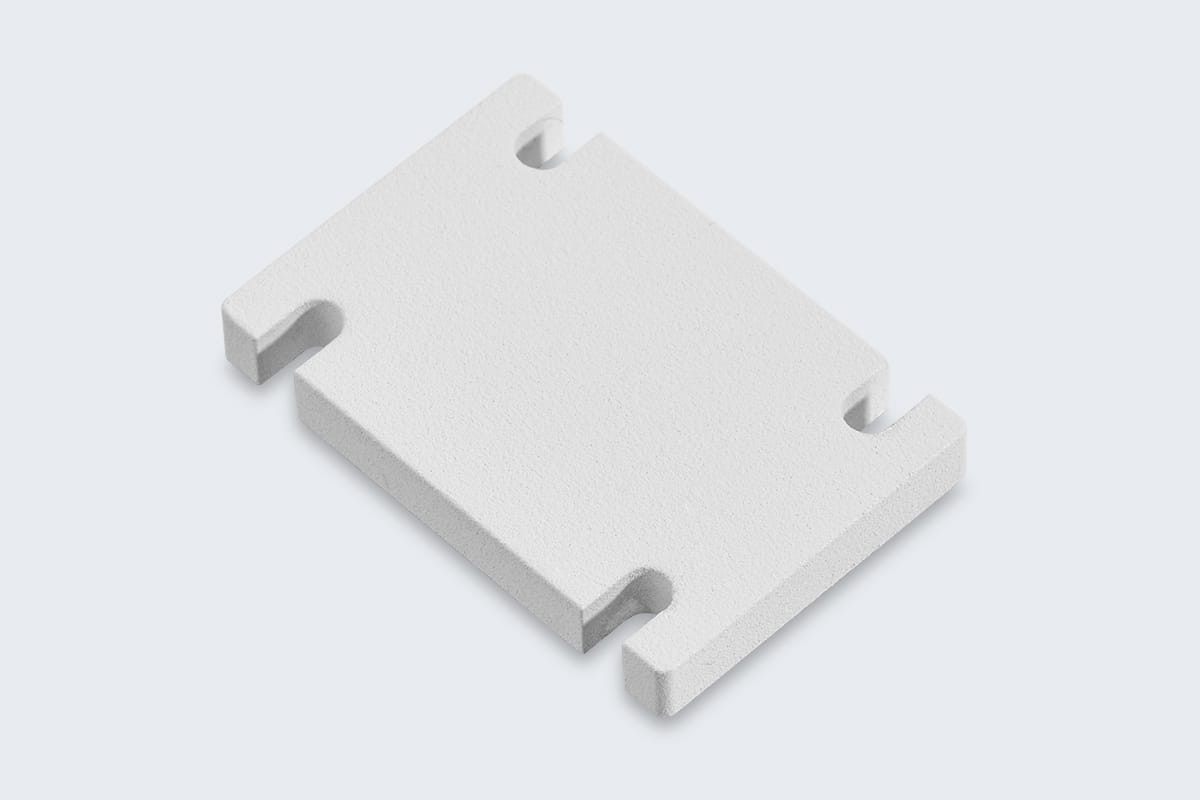

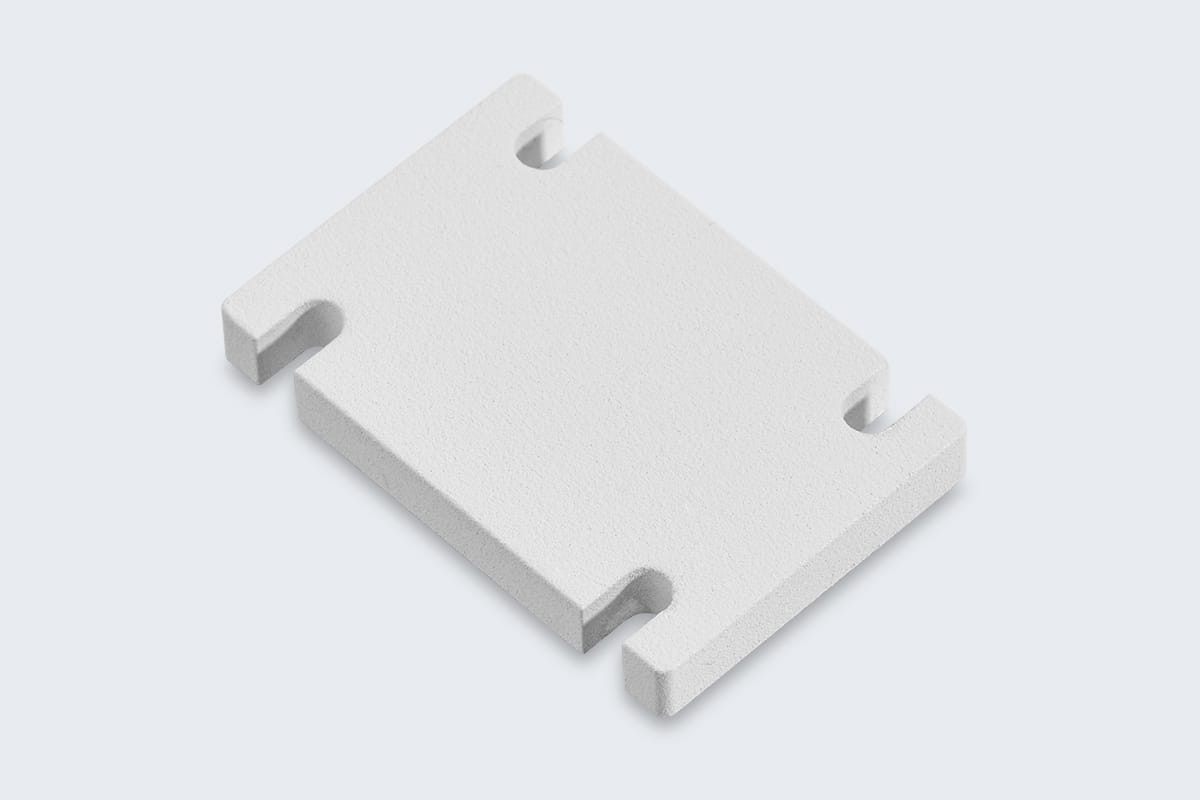

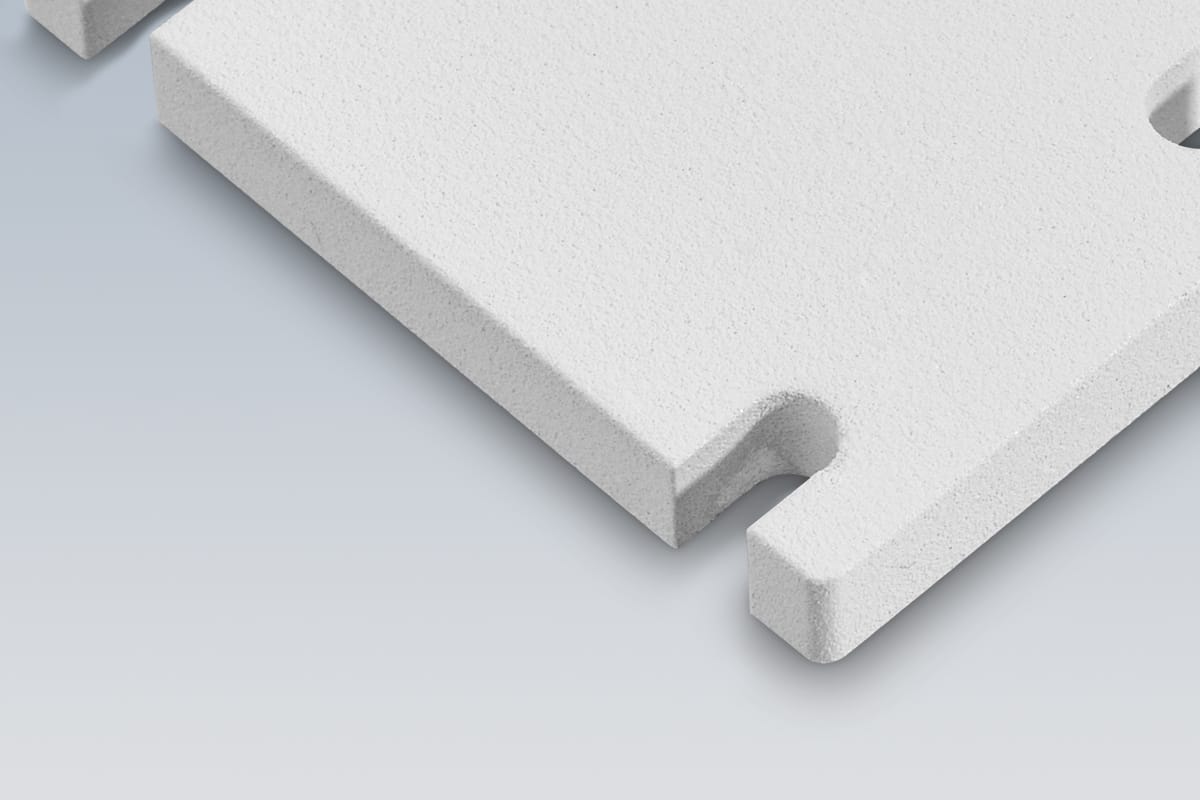

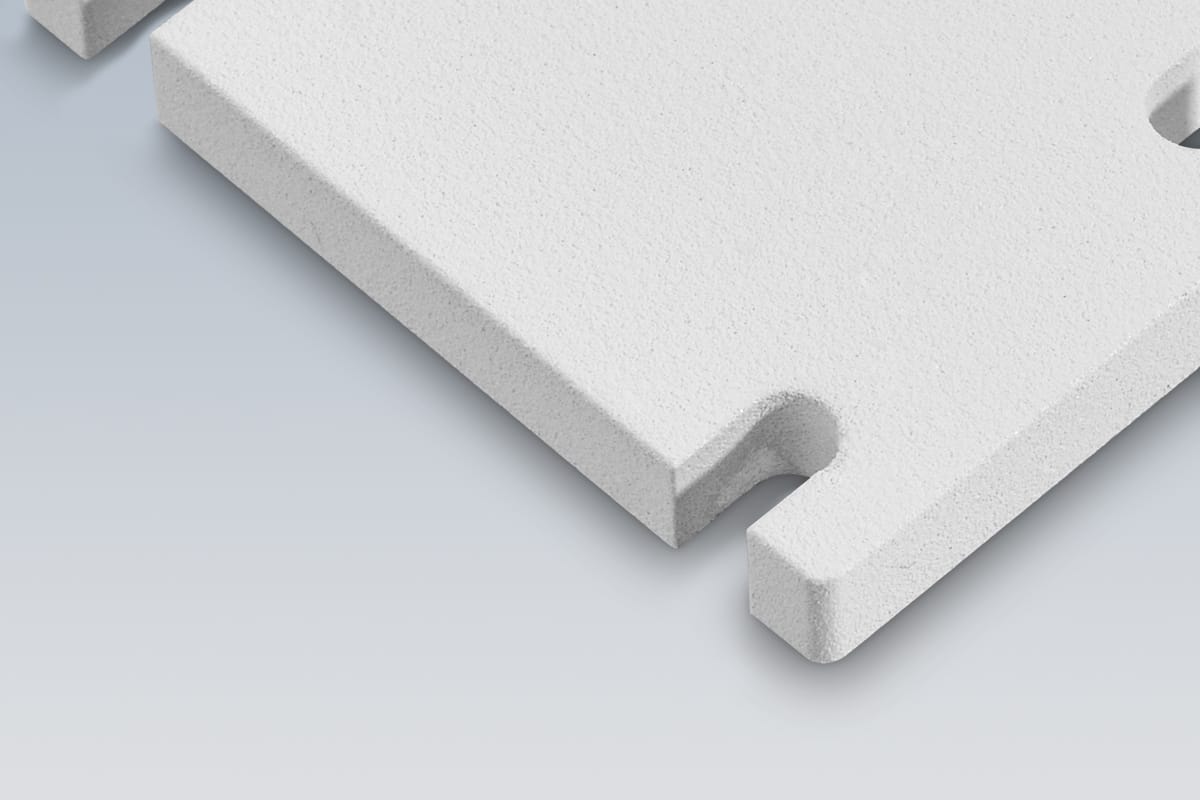

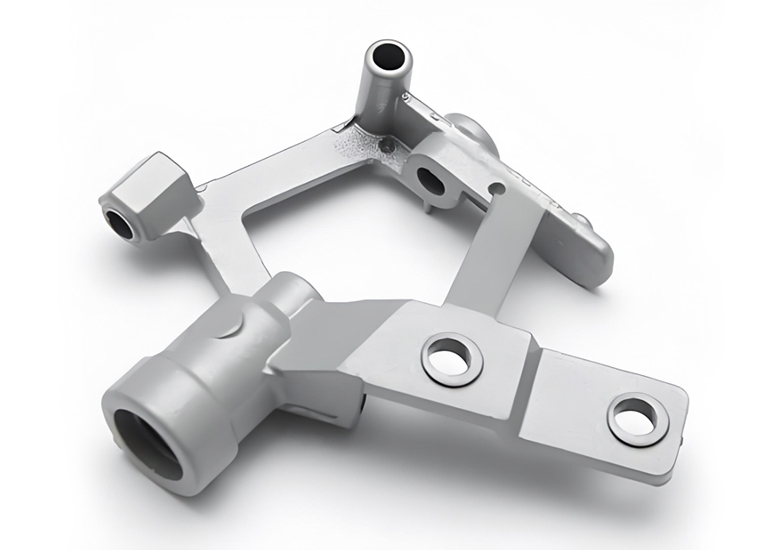

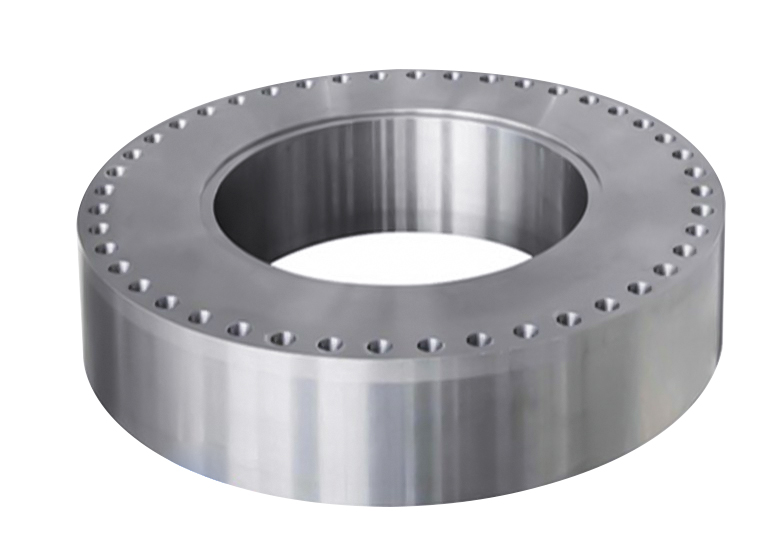

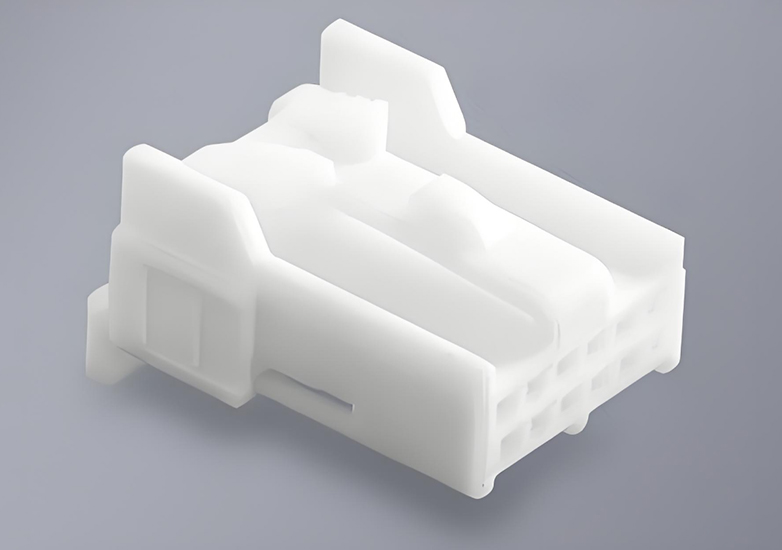

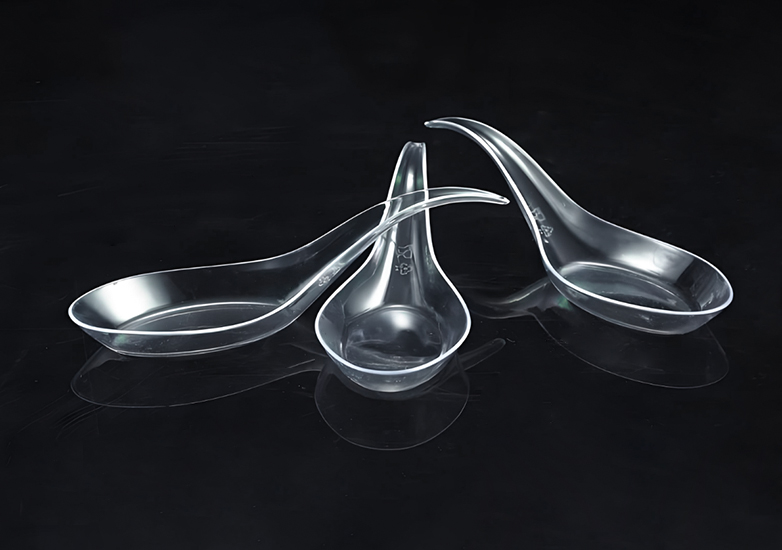

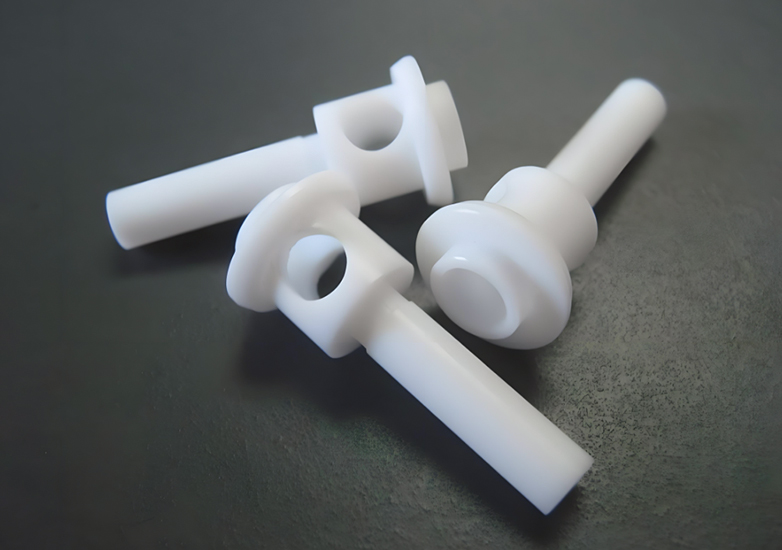

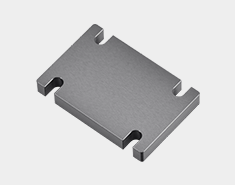

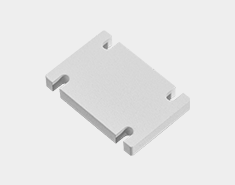

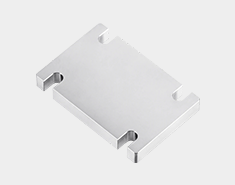

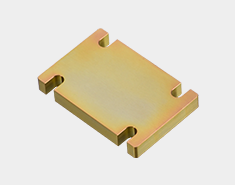

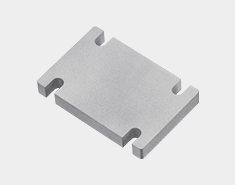

Example Of A Powder Coating Parts

About Powder Coating

Powder coating involves applying a dry powder to the surface of the object to be coated. The powder consists of finely ground particles of pigments and resins.

Powder coating offers several advantages over traditional liquid paint, including superior durability, resistance to chipping, scratching, and fading, as well as better chemical and corrosion resistance. It also produces a uniform and smooth finish with no drips or runs.

Material Selection

We offer a wide range of materials for powder coating to meet the diverse needs of various industries. Our selection includes metals, plastics, and composites to ensure that your parts are manufactured with the best-suited material for your application. Below are some of the materials we commonly work with:

Metals

Plastics

We offer customization based on your specific material requirements. If you need a material not listed here, our team can source and process it to meet your exact needs.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

Surface Finishing for Black Oxide Services

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

Why Choose Our Powder Coating Services

By choosing our precision powder coating services manufacturer, you will receive high-quality, customized parts, fast delivery, and competitive prices. We will cooperate with you to provide excellent sheet metal solutions for your project.

Quick quotation

Just upload your design file and configure the materials, finishing options, and requirements. Our engineers analyze your part geometry and provide real-time and competitive pricing as well as comprehensive DFM feedback.

Assured High Quality

We are a sheet metal fabrication factory certified by ISO 9001:2015 and can provide sheet metal component materials and full size inspection reports according to your requirements.

Reliable Delivery

From prototype design to efficient production, we deliver high-quality sheet metal parts within our standard delivery time of 3 days.

Readily available capacity

We have over 70 machines, and your sheet metal fabrication services can provide immediate and available production capacity.

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

Design considerations for powder coating

Hanging and Jigging Marks

When designing for powder coating, consider that parts are hung on racks or jigs, which may leave marks. Plan your part placement accordingly and specify areas where marks are acceptable in technical drawings.

Masking

Clearly indicate in your CAD file which areas should be masked or plugged to protect critical surfaces like threaded holes. Discuss masking requirements with your coating service.

Tolerances

Ensure parts meet required tolerances before coating. Discuss tolerance considerations with your design team and coating service provider.

Communication

aintain open communication with your coating service provider to address specific requirements, material considerations, and any challenges related to your parts.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

FAQ

1. What materials can be powder coated?

We powder coat metals such as aluminum, steel, stainless steel, and brass to provide durable and attractive finishes.

2. What are the benefits of powder coating compared to traditional painting?

Powder coating offers superior durability, corrosion resistance, environmental friendliness, and a uniform finish without runs or drips.

3. What color options are available for powder coating?

We offer a wide range of standard and custom colors, including matte, glossy, satin, and textured finishes.

4. How thick is a typical powder coating layer?

The coating thickness usually ranges from 50 to 100 microns, depending on the application requirements.

5. Can powder coating be applied to parts with complex geometries?

Yes, powder coating can uniformly cover complex shapes, although certain recessed areas may require special attention.

6. What is the typical turnaround time for powder coating services?

Lead times typically range from 5 to 10 business days depending on batch size and finish complexity.

7. How should parts be prepared before powder coating?

Parts must be thoroughly cleaned and free of oils, dirt, and rust to ensure proper adhesion and finish quality.

8. Is powder coating environmentally friendly?

Yes, powder coating is a low-VOC, solvent-free process that produces minimal hazardous waste.

9. Can powder coating be repaired if damaged?

Minor damages can often be repaired through touch-up powder coating or spray painting.

10. Do you provide quality inspections for powder coated parts?

Yes, we perform thickness measurements, adhesion tests, and visual inspections to ensure coating quality.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.

The Ultimate Guide to CNC Milling: Advantages, Limitations & Applications

Design for Manufacturing (DFM): Principles, Process, and Application Explained

CNC Turning Parts:Everything You Need to Know| LS Manufacturing

CNC Machining: The Ultimate Guide to Processes, Materials, and Applications

What Are The Parts Of A Plasma Cutter Gun?

What Are Taps In Machining?

How to Cost a Xiaomi YU7 Auto Part?

What Is The Difference Between Sheet Metal And Machining?

Put your parts into production today

- All information and uploads are secure and confidential.