In sheet metal fabrication, bending is the basic forming process, and the bending quality has a direct influence on the structural strength, dimensional accuracy, and aesthetic appearance of the final product. But in actual production, the bending process is always accompanied by a series of inconvenient technical issues, such as sheet metal cracking, angular deviation, springback deformation, and surface indentation.

Essentially, these defects typically result from an intricate interaction of factors, including material properties, process parameters, mold selection, and equipment performance. This article thoroughly investigates the causes of bending cracking and deformation and provides a series of proven, all-encompassing solutions which range from material pretreatment and process optimization to creative mold applications.

The goal is to provide industry colleagues with a practical guide to help companies achieve stable, efficient, and high-quality lean production.To save you time, here’s a quick overview of the core conclusions.

Quick Reference Guide for Core Sheet Metal Bending Problems

| Problem Type | Main Symptom | Main Solution |

| Bend Cracking | Visible cracks or fractures in the outer edge of the bend. | Use high-quality material or anneal; Properly increase bend radius; Modify the layout so the bend line is crosswise to the direction of the fibers; Check the quality of the blanking edge and deburr. |

| Springback | Bent angle is larger than desired angle, and the part is unable to retain the intended form. | Use angle compensation (overbending); Reduce the punch radius or use a sharp cutting die; Pressure correction (stamping) or bottom piercing. |

| Angle/Dimension Deviation | Variation of bend angles and erroneous length sizes. | Periodically, calibrate the machine; Inspect and replace worn dies; Increase incoming material inspection; Use high-precision stops and positioning units. |

| Surface Indentations/Scratches | Scratches or die marks on the work surface. | Use a special polish die or soft die (e.g., polyurethane); Use a protective coating between workpiece and die; Select proper V-groove width based on sheet thickness. |

This useful reference chart concisely presents the root causes of sheet metal bending and their interrelations. The key to achieving quality bending is a philosophic system, which is consideration of the entire materials, molds, equipment, and processes. In real production, defects should not be addressed one by one in production, but remedies should be set up from the root causes through systematic study and analysis.

By adhering to the guidelines in this LS Manufacturing manual, businesses can indeed improve the stability and pass rate of bending operations to achieve cost reduction, efficiency enhancement, and a breakthrough in quality.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

Every suggestion in this guide is not theory; it is the distillation of years of sheet metal production experience of LS Manufacturing, explained, refined, and calibrated by hundreds of thousands of bending samples throughout ten years of actual practice.

LS Manufacturing’s experienced team of professionals has been supplying the aerospace, communications, and precision medical equipment high-reliability quality markets with consistently dependable performance of challenging bending applications across a wide range of materials, from stock cold-rolled sheet to high-strength steel, aluminum alloy, and stainless steel.

LS Manufacturing not only boasts advanced CNC bending centers and automatic lines, but most importantly, we have established a complete database of processes for resolving many challenging issues. For example, we have demonstrated how to curve ultra-slim aluminum sheets for sub-zero cavity components without deformation, and how to completely suppress the cracking defect of a specific type of high-strength steel bracket through a new integration of mold design and process parameters.

These proven experiences, learned in the trenches of production and tried-out on the masses, are the solid foundation for the worth of this manual. LS Manufacturing is sharing an approach that we use and continually hone day by day, an approach that does indeed create value.

Why Do Your Sheet Metal Bends Keep Cracking or Breaking?

Cracking or sheer rupture at the exterior corners of workpieces is a common and infuriating metal bending problem in sheet metal bending. To keep this long-standing problem in check, however, having a firm understanding of the science behind it is important. LS Manufacturing based on experience studies the following key causes:

1. Material Properties:

The bending performance of metal is dependent primarily on its yield strength and elongation. Poor elongation indicates low capacity of plastic deformation. When tensile stress that the material can endure exceeds its limit, cracking in bending will occur. This is the most important measurement that we check under material pre-inspection.

2. Bending Direction:

When bending, sheet metal develops a fiber orientation. When the bending line of the sheet metal aligns with the fiber orientation, it becomes easy to localize the stress along the fiber boundaries, substantially increasing the chances of cracking. Experienced technicians will change the setup so that the bending line is parallel to the fiber orientation in order to distribute the stress.

3. Process Parameters:

Insufficiently narrow lower die V-groove width will make too small an inner radius, over-stretching and thinning the outer layer of material too much at the bend, effectively “tearing” the material apart. LS Manufacturing insists upon stringent process planning to ensure that the bend radius is precisely matched to sheet thickness and V-groove width, which prevents over-stretching of material and essentially minimizes the likelihood of cracking.

To essentially prevent bending cracking, we must redirect the focus from the individual “bending action” to the source of materials and processes.

How to overcome springback and deformation after bending and achieve stable dimensions?

Inadequate bending control of the target angle leading to springback or distortion is one of the most typical sheet metal deformation problems. The elastic character of the material develops the “springback” effect, which, in turn, directly affects the dimension inaccuracy and assembly problem. An orderly bending solution has to be applied in order to completely solve this problem:

1. Precise Overbending:

The simplest method is angle compensation. Our engineers pre-set a small overbending value smaller than the target angle in the CNC machining based on the material properties, thickness, and bend angle. The “overbending” going forward anticipates springback so that the workpiece achieves the target angle after springback.

2. Die Correction and Pressing:

For materials of high strength or complex structures, we use corrective surface dies or perform a bottom press process. Extremely high pressure is used in the later part of the bending stroke to equalize stress at the bend point, restricting springback at the plastic level and achieving dimension stability.

3. Data-Driven Intelligent Compensation:

LS Manufacturing’s biggest asset is translating experience into an accurate process database. From broad experimental data, we developed a springback predicting model for different materials and integrated it in CNC programming. That is, the machine will compensate automatically and intelligently, offering superior consistency on every batch, from first article to production.

Utilizing data models to translate experience into precise smart compensation is the most efficient path towards achieving dimensional stability for mass production and an elementary bending solution to springback.

How can accurate calculations be used to avoid material waste?

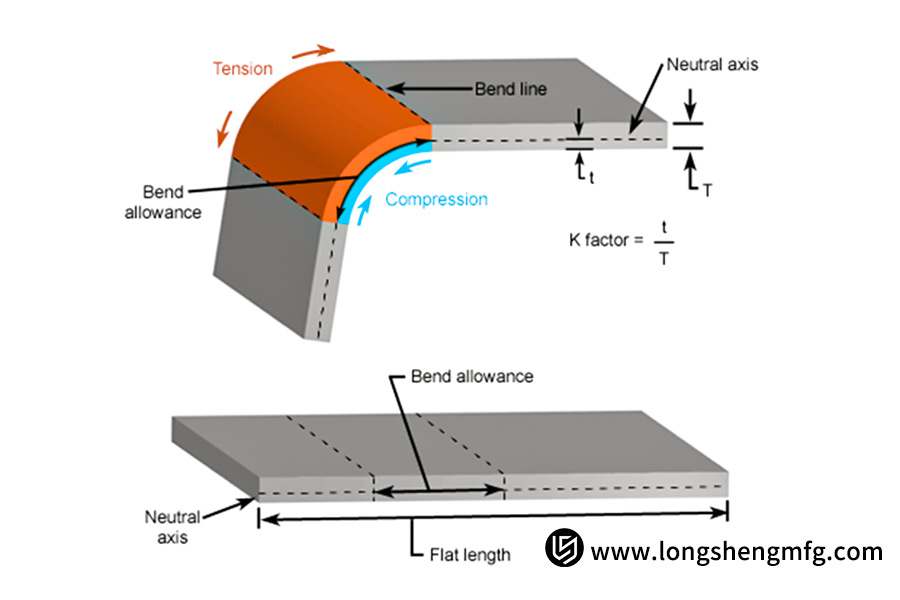

A basic issue in sheet metal bending is calculating the size correctly when unfolded. Oversizing results in material wastage, while underestimating it to a lower level automatically renders the workpiece unusable. The problem solution requires understanding two key concepts: bend allowance and K-factor.

1. Understanding the Core Role of the K-factor:

The K-factor can be described as the material’s deviation coefficient of the neutral layer (theoretical layer that neither gets stretched nor compressed) when bent. It is a dynamic value that depends on the material, thickness, bend radius, and angle. The use of the wrong K-factor value will generate systematic errors in the computation of all future unfolded dimensions and induce cascaded dimensional errors and material waste.

2. The Value of Empirical Data:

Taking advantage of measured data aggregated from many sheet metal bending service, LS Manufacturing has developed an empirical database of K-factors for a broad spectrum of materials and process conditions. This enables us to deliver realistic estimates in the programming stage with a firm basis to optimize layouts and maximize material usage, ultimately saving customers money.

3. Accurate Calibration Ensures Infallibility:

Theoretical values must be tested in practice. During a serious trial bending, we test the calculated unfolded dimensions against actual measurements, adjusting the K-factor to its optimal value. This “theoretical calculation + practical calibration” method of systematic procedure ensures precise unfolded dimensions in mass production and is the ultimate guarantee for achieving high material utilization.

True control of K-factor and bend allowance is an essential link between production and design, and cost management. It turns the apparently uncontrollable distortion of material into quantifiable, scientific factor, minimizing waste of material and being the core of lean manufacturing.

What material properties are the driving force behind bending success?

In sheet metal bending, the majority of common metal bending defects really occur not due to the process itself but as a result of an unawareness of material properties. Different metals behave differently while being bent due to their unique mechanical properties, and the variation is particularly strong in difficult thick plate bending scenarios.

| Material Type | Core Bending Characteristics | Key Challenges and LS Manufacturing Strategies |

| Mild Carbon Steel | With good ductility and a medium yield strength, it is one of the easiest to bend. | Be cautious with surface protection against rusting; when bending thick plates, consider the equipment limitation. |

| Stainless Steel | While having a high strength, it also has a high tendency to work hardening, and so it is a frequent cause of metal bending problems. | Use a higher bending radius and inter-process annealing. |

| Aluminum | While light and ductile, its softness is easily damaged on the surface. | Use specialized polishing dies or protective coatings to achieve an ideal compromise between forming requirements and surface quality. |

| Copper | Due to the higher ductility and high springback effect, careful springback compensation | Calculations have to be done, and utmost care must be exercised in surface protective measures. |

LS Manufacturing draws upon its extensive material knowledge base to accurately predict the bending characteristics of any material. Not only do we recommend the most suitable material based on the product’s ultimate use (structural load-carrying and appearance requirements, for instance), but also develop complete solutions for specialized situations like thick plate bending, such as tool selection and process parameters, to ensure bending success from the outset.

Materials are the foundation of the bending process. Understanding the dynamics of these “behind-the-scenes drivers” and developing related bending strategies accordingly are the keys to avoiding metal bending defects and generating high-quality output.

What unique challenges does thick plate bending present, and how are they addressed?

Unlike thin plate, thick plate bending is a technically unique area with three basic problems: exponentially larger bending force, larger springback, and potential initiation of internal cracks. These problems render conventional process parameters useless, necessitating a systematic bending solution.

1. Conquering the Intense Bending Forces:

Forming thick plate requires extremely high pressure. Our large-tonnage hydraulic press brakes provide sufficient and stable pressure, ensuring sufficient plastic deformation during the bending process, which is essential for achieving acceptable angles.

2. Mitigating the Risk of Internal Cracking:

Too small bending radii can subject the middle layer of the plate to too much tensile stress so that it tears. Our fundamental solution is to use specially designed upper dies with large R-angles and to adhere to a scientific “plate thickness-R-angle” matching rule in order to guarantee enough space for material flow, eliminating the possibility of internal cracking at its roots.

3. Precisely Controlling Springback and Accuracy:

The springback of heavy plate is much more significant than that of thin plate and is difficult to predict. We use a multi-step, segmented bending method, breaking up one big-angle bend into a number of little-angle forming steps. With a precise springback compensation algorithm incorporated, we pre-bend the material in CNC program, relieving internal material stress effectively and ensuring steady angles and correct dimensions.

Successful thick plate bending relies on a scientific solution to bending that involves equipment capability, custom chemical equipment, and high-level processes. This requires a better understanding of the material mechanical behavior under high pressure and precise control through scientific process design.

How do mold selection and process parameters affect bending quality?

In metal sheet bending, superior craftsmanship is reflected in careful attention to detail. Most common issues of metal bending, such as inaccurate angles, damage to surface, or variability in dimensions, most likely are caused by inappropriate mold selection and adjustment of process parameters. LS Manufacturing’s engineers ensure the superior quality of every product through accurate adjustments of these minute details.

1. The mold is the cornerstone of forming:

The top mold’s R-angle directly determines the internal R-angle of the part and the bend allowance. Poor choice can lead to dimensioned deviations or interference. The bottom die’s V-neck width is quite critical. A too-narrow V-neck can exacerbate springback, even leading to damage to the die, and an excessively wide V-neck can conceal the bend line and significantly increase the pressure required. This is the foundation of metal bending issues.

2. Speed and pressure are the art of control:

Reduction of bending speed is favorable to full material flow and improve forming quality, especially in case of crack-prone materials like stainless steel. Pressure regulation is necessary to maintain constancy of angles and effectively reduce product deviations caused by pressure fluctuations.

3. Holding time is the secret to achieving a stable shape:

Utilization of constant holding pressure once the bend has already been created is a basic procedure in the fine-tuning of LS manufacturing processes. Sufficient holding time allows proper creep relaxation within the material, effectively eliminating internal stresses, significantly reducing springback and stabilizing the bend angle. It is a process that is largely overlooked in the average process.

Excellent bending quality results from a combination of scientific calculation and extensive field experience. Through systematic adjustment, we find the optimal parameter combination tailored to each individual part.

How does LS Manufacturing solve the bending and deformation challenges of high-end device casings?

In producing high-end products, casing flatness and assembly precision directly correlate with product quality and company reputation. However, the material’s inbuilt springback property and complex structural configuration tend to easily cause unpredictable deformation upon bending sheet metal, which becomes an enormous barrier to improving product quality. Below is the case study that shows how LS Manufacturing employs systematic bending solutions to effectively address customer problems.

1. Customer Dilemma:

A high-end network devices manufacturer was experiencing a critical manufacturing problem: its 304 stainless steel enclosures exhibited significant warping, springback, and torsional distortion following bending of the long edges, so the cover wouldn’t close easily. This ubiquitous sheet metal warping issue generated a 25% or higher product defect rate. Relying on unsuccessful on-site manual repairs, quality consistency was extremely poor, slashing significantly into product delivery and reputation in the market.

2. LS Manufacturing’s Solution

With this challenging metal bending problem, our technical team did not simply fiddle with parameters and rather utilized a systematic bending solution:

- LS Manufacturing inspected the batch characteristics of the 304 stainless steel that the customer was utilizing and finely adjusted the K factor and the springback compensation value.

- By combining the bending sequence optimization, we were in a position to modify successfully the stress that had accumulated within the material.

- Most importantly, we implemented a dedicated bending process with bottom-leveling function and designed a simple-and-efficient anti-deformation fixture for the long-side frame, in effect eliminating deformation.

3. Results and Value:

After implementing our solution, the customer’s residence flatness fully met rigorous assembly criteria, providing for single-time smooth closure of the cover. The efficiency of production was increased by 40%, and the frequency of defects in the product dropped significantly from 25% to below 1%. Not only did this innovation resolve a pressing problem, but it also significantly enhanced the market competitiveness of the customer company’s products, leading to the establishment of a long-term, stable strategic partnership between the two corporations.

Through precise material examination, innovative process engineering, and necessary tooling support, we can find better bending solutions for even challenging long-side bending of high-end device housings, ultimately turning manufacturing bottlenecks into quality achievements.

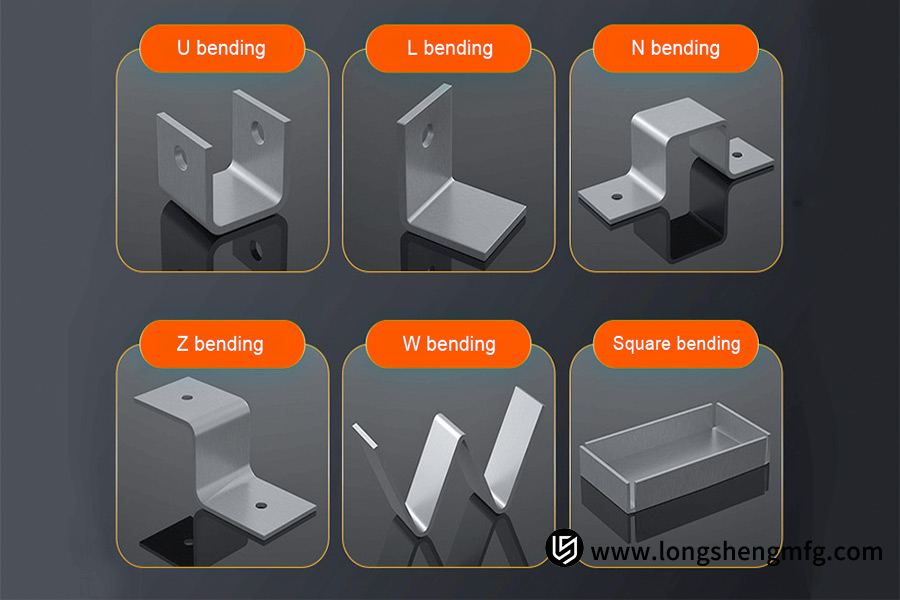

What are the “golden rules” of sheet metal bending that must be followed during the design phase?

Quality sheet metal bending begins with good design. Most process issues and money wasted are consequences of neglecting process behavior in design. Following these tried-and-true “golden rules” will not only significantly improve manufacturability of the product but will also provide the most economical and productive bending solutions.

1. Properly set the inner radius:

Keep the very small radiuses away. Generally, the inner radius must be at least equal to the material thickness (T). Very small radiuses enhance the possibility of cracking significantly and limit tooling potential significantly.

2. Ensure minimum bend edge height:

The height of the bend edge must be sufficient; otherwise, it cannot be effectively clamped by the tooling. The minimum height should generally be greater than or equal to 1/2 V-groove width in the bottom die plus material thickness. A reliable rule of thumb is a minimum of 1.5 times sheet thickness.

3. Predict and Avoid Interferences:

When creating parts with multiple bends or closed shapes, dynamic bending simulation is critical to actively check for interference of the bend area and nearby edges, or with the press brake tool itself. This is a task that’s usually skipped, but could have catastrophic repercussions.

Having a professional sheet metal bending partner early on in your project provides you with the ability to gain valuable DFM (Design for Manufacturability) suggestions up front through the design process, preventing future problems prior to their onset on the drafting table and expensive mold changes and scrap material.

What is the value of choosing a professional sheet metal bending partner?

When selecting a sheet metal bending supplier, their value must extend beyond mere “make to print” production. A professional partner will offer comprehensive bending engineering assistance over the product life cycle, developing your concepts into reliable and stable products. This is the very essence of professional sheet metal services.

1. Reduce costs and increase efficiency at the source:

In the design and material selection phase, LS Manufacturing’s rich bending engineering experience can detect manufacturing risks in advance and provide the optimal solution. This can prevent costly downstream design changes and material waste from the outset, significantly shortening your R&D cycle.

2. Achieving a Leap in Quality and Stability:

LS Manufacturing adopts a systematized process database and precise parameter control to ensure high consistency from first-article to mass production. This stability is translated directly into consistent product quality delivery, thus your quality inspection and management costs are significantly reduced.

3. Gaining Synergistic Value from Continuous Optimization:

LS Manufacturing automatically brings the optimization possibilities identified during manufacturing back to clients, thus creating a virtuous circle. This synergy effect repeatedly incurs iterative optimization of your products in cost, performance, and manufacturability.

LS Manufacturing does far more than basic bending and forming; it is a strategic partnership that allows you to reduce total manufacturing costs, accelerate time to market, and remain market competitive with total bending engineering support along the way.

FAQs

1. How do I determine whether a sheet metal part is susceptible to bending cracking?

The answer relies on the material’s internal plasticity and external stress. We also test the material’s elongation (less than 5% indicates higher risk) and bend radius-thickness ratio (R/T). When R/T is extremely low (for example, <1), the outermost fibers of the material will be over-stressed and break. LS Manufacturing engineers shall conduct a risk analysis as per material certification report and, if necessary, determine the cracking risk exactly through trial bends or simulation so that they may modify the process plan ahead of time.

2. Why do I always experience excessive springback even with the same drawing?

The degree of springback depends upon equipment condition, tool match, and process parameters. With the same sketch, press brakes’ variance in precision, small tool wear, and operator variance of setting such as press depth, speed, and dwell time can transform the actual springback value drastically. LS Manufacturing utilizes infrequent calibration of highly accurate machines, a standard tool library, and process core database based on a massive quantity of hands-on experience to replicate parameters to the exact degree for every bend, effectively eliminating springback.

3. What should the K factor be? Is there a universal value?

No single value of K for all. It is an interacting variable, highly a function of material grade, batch performance, bend radius, choice of tool, and even method of bending. Trying to use a single fixed value (e.g., 0.4) in every case is a major root cause of dimension error. The most notable benefit of LS Manufacturing is that it has a vast process database that can be calibrated to your specific material thickness, bend angle, and mix of tooling.

4. Can you handle complex, multi-bend parts made of high-strength steel or aluminum alloy?

Yes. High strength steel and aluminum alloy‘s high rebound and low ductility and aluminum alloy’s scratch sensitivity require special process methods. LS Manufacturing has extensive experience in doing this: we employ large-tonnage presses and tooling specifically designed to surmount high-strength steel forming pressures; we employ precise springback compensation models for angle; and we employ special protective processing for aluminum alloys. With state-of-the-art CNC programming and multi-axis control technology, we can confidently guarantee the geometric precision and surface finish of complex, multi-bend shapes.

Conclusion

Cracking and sheet metal bending deformation are essentially systemic issues due to interaction among material, design, and process. These issues could be optimised with scientific investigation, correct processes, and experience.

LS Manufacturing’s excellent technical capabilities and customer-centric service philosophy are now a successful engineering partner to numerous businesses in the precision sheet metal fabrication industry.

Don’t let bending issues compromise your product quality and project schedule. Contact LS Manufacturing today and transmit your design or specifications to receive a free Design for Material Function (DFM) analysis report and preliminary process plan from our experienced staff. Let us leverage our professional engineering knowledge to safeguard your product and, together with you, transform manufacturing issues into quality advantages

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Love how you bring people together through your work! Inspiring

Your work continues to inspire positive change 🚀 in so many lives worldwide