Custom Spring Manufacturing

- Customization of springs to your exact specifications

- Precision cutting of springs to required lengths

- Stress relieving and shot peening to improve spring performance

- Heat treatment services for increased durability and reliability

- All uploads are secure and confidential

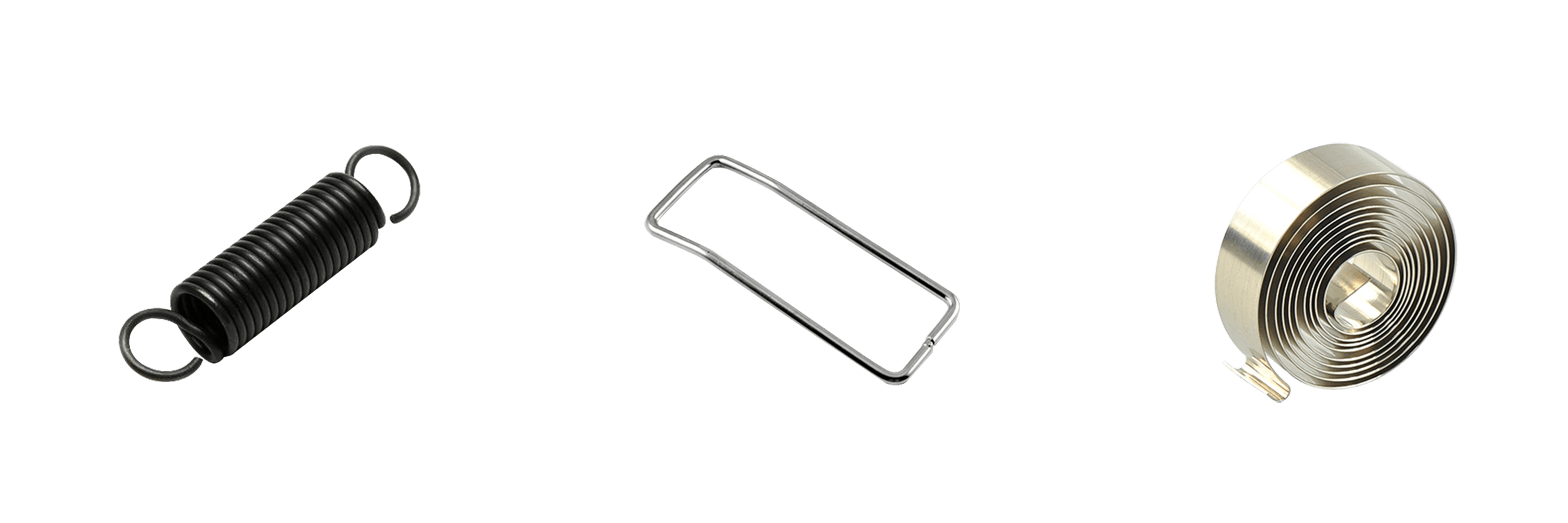

Types Of Springs

Get quality custom metal Spring all type for rapid prototyping and end-use production. Lead times are as fast as 3 day.

Springs

Wire Forms

Flat Springs

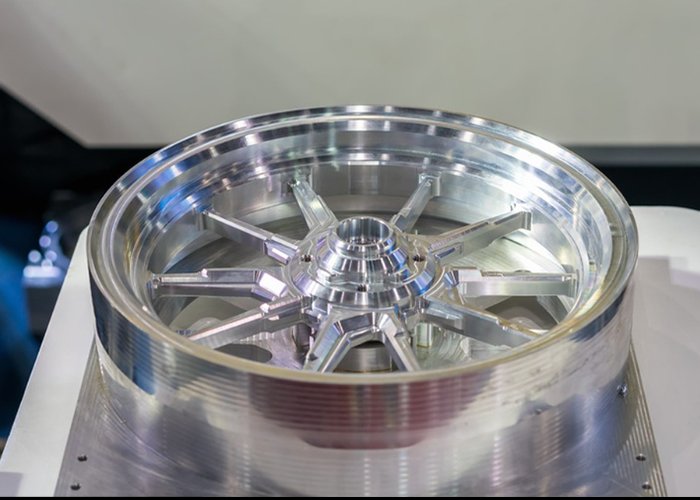

Our Custom metal all type Spring

Manufacturing Services

We have advanced metal spring manufacturing setup and perfect inspection equipment to meet your various needs, we offer only the best metal spring manufacturing services and the ability to refine that even more. So if you are looking to have parts turned in with a high level of accuracy and need parts made right the first time, you have come to the right place.

You can always get more competitive pricing at higher quantities. We also offer DFM, first article inspection (FAI) reporting, and material certifications.

LS Manufacturing Metal Spring Manufacturers

- - Instant Pricing

- - Free DFM analysis

- - Parts as Fast as 1 day

- - Tight Tolerances

- - ISO 9001 Certificated

- - ISO 14001 Certificated

- - IATF 16949 Certificated

The metal springs we often process now include compression springs, extension metal springs, torsional metal springs, and custom metal springs, which are often used in various industries such as automobile hardware parts, Electrical equipment, Electronic products, Medical equipment, Gym equipment parts, Industrial equipment, Mechanical parts, Office equipment, Children’s toys, Etc.

Spring Manufacturing Process Tolerances

Process Stage | Key Control Parameter | Precision Grade & Typical Tolerance Reference | Control Points / Equipment Requirements |

1. Raw Material | Wire Diameter (d) | Commercial Grade: ±0.01 mm | Material certificate verification, batch management |

| Surface Quality | Free of cracks, rust, scratches | Visual inspection, surface defect detection (if necessary) |

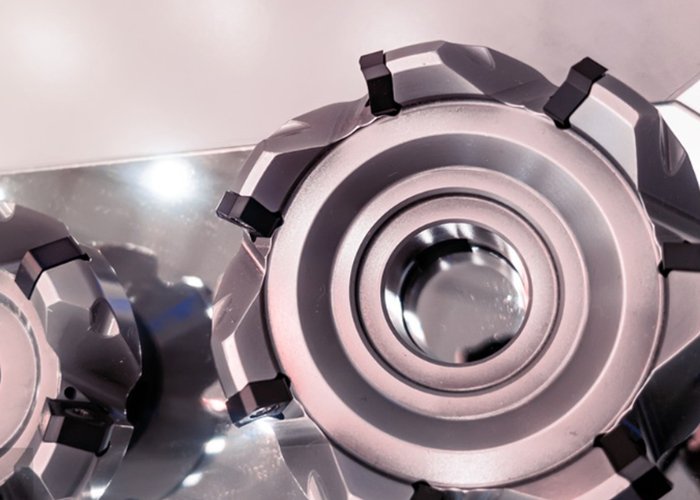

2. Coiling/Forming | Outside Diameter (D)/Inside Diameter | Commercial: ±(0.01×D) mm or ±0.5% | CNC spring coiling machine accuracy, feed stability, tooling wear management |

| Total Coils (n1) | Commercial: ±1/4 coil | CNC program control, servo motor accuracy |

| Pitch | Uniform, conforming to drawing | Cam or servo axis control of coiler |

3. Heat Treatment | Hardness (HRC/HV) | As per material spec, e.g., ±2 HRC | Precise control of temperature, time, furnace atmosphere (Controlled atmosphere/Vacuum furnace) |

| Surface Decarburization | Commercial: Slight allowed | Strict control of furnace atmosphere carbon potential |

4. End Finishing | Grinding Angle (Squareness) | Commercial: ≤2° | Grinding wheel flatness, fixture accuracy, grinding parameters |

| End Thickness | ≥ 0.3d (to prevent end gap) | Control grinding amount |

| Bearing Plane Flatness | Contact area > 80% |

|

5. Surface Treatment | Plating/Coating Thickness | As per standard, e.g., 5-15μm ±3μm | Control of plating current, time, solution concentration |

| Hydrogen Embrittlement Risk | Hydrogen embrittlement relief mandatory | Strict control of baking temperature and time |

6. Stabilization | Free Height (H0) Stability | Height change after setting < 1% (Precision) | Press accuracy, control of compression stroke and cycles |

| Load Loss | Initial load loss < 5% (Precision) |

|

7. Final Inspection | Free Height (H0) | Commercial: ±(2%H0) mm | 100% inspection or AQL sampling |

| Load (P) @ Specified Height | This is the most critical functional indicator | Spring tester requires regular calibration, accuracy higher than tolerance requirement |

| Straightness/Squareness | Commercial: ≤1.5%H0 |

Customize Extrusion Moulding Parts Service

Put Your Parts Into Production Today

- All information and uploads are secure and confidential.

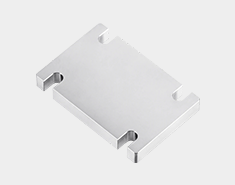

Custom Spring Parts Material

LS Manufacturing supplies most of the industry standard materials. If you do not find the materials you want in the list, please contact us

| Aluminum alloy material | Stainless Steel | Alloy Steel | Copper alloy | Other alloy |

|---|---|---|---|---|

| Aluminum alloy 6061 | Stainless steel 303 | Q235 (A3 steel) | Bronze-H59 | Electrician pure iron-DT4C |

| Aluminum alloy 5052 | Stainless steel 304 | 45 steel | Bronze-H62 | Electrician pure iron-DT4E |

| Aluminum alloy 2A12 | Stainless steel 316 | Cr12 | Copper-T2 | Titanium alloy-TC4 |

| Aluminum alloy 7075 | Stainless Steel 316L | 3Cr13 | Oxygen Tu2 | Magnesium alloy -AZ91D |

| - | Stainless steel 420 | Spring Steel-65MN | Tin Bronze-QSN-6-6-3 | - |

| - | Stainless Steel-17-4PH | Mold Steel-SKD11 | Beryllium copper-C17200 | - |

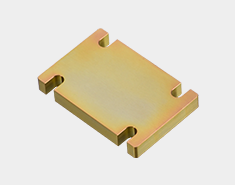

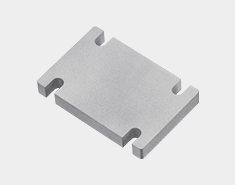

Surface Finishing for Custom Spring Manufacturing

Our surface finishing allows you to customize the appearance and texture of your milling parts. Various textures, colors, and finishes are available to match the aesthetic requirements of your product or brand.

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

Why Choose Our Custom Spring Manufacturing Services

By choosing our precision custom spring manufacturing manufacturer, you will receive high-quality, customized parts, fast delivery, and competitive prices. We will cooperate with you to provide excellentsheet metal solutions for your project.

Quick quotation

Just upload your design file and configure the materials, finishing options, and requirements. Our engineers analyze your part geometry and provide real-time and competitive pricing as well as comprehensive DFM feedback.

Assured High Quality

We are a sheet metal fabrication factory certified by ISO 9001:2015 and can provide sheet metal component materials and full size inspection reports according to your requirements.

Reliable Delivery

From prototype design to efficient production, we deliver high-quality sheet metal parts within our standard delivery time of 3 days.

Readily available capacity

We have over 70 machines, and your sheet metal fabrication services can provide immediate and available production capacity.

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

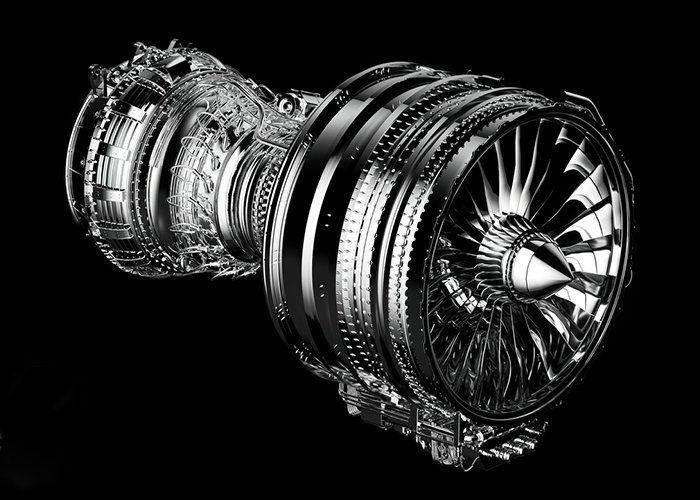

Our Machining Service For Various Industrial

Applications

No matter what industry you’re in, LS Manufacturing’s machining service are the perfect solution for all your needs. Our commitment to quality and customer satisfaction means that we always deliver on our promises, ensuring that you get the best parts at the best prices.

Aerospace

Our precision parts machining services provide durability and precision to meet the complex requirements required at different stages of the aerospace industry.

Automotive

From prototyping to production, our precision parts machining services are the ideal manufacturing solution for on-demand automotive parts.

Electronics

We specialize in providing high-quality machining services for a wide variety of electronics.

Medical Devices

We provide high-quality custom precision parts for various medical equipment, including surgical instruments, beds, monitoring equipment, and more.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

![]() We respect your privacy and will not use your information for other purposes.

We respect your privacy and will not use your information for other purposes.

Frequently Asked Questions about Spring

Parts Manufacturing

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required spring parts machining services support by reading FAQ.

Spring manufacturing is the process of designing, producing, and testing springs. Springs are used in everything from cars to pens to medical devices. They are an important component in many products because they help regulate motion and force.

Springs can be made from a wide variety of materials, including steel, titanium, and even plastic. The choice of material depends on the specific application and the desired properties of the spring, such as flexibility, resistance to corrosion, and strength.

There are many different types of springs, including compression springs, extension springs, torsion springs, and flat springs. Each type of spring has different properties and is used in different applications.

Our spring manufacturing company has been in business for over 00 years and has a reputation for producing high-quality springs that meet or exceed industry standards. We use the latest technology and employ skilled technicians to ensure that our springs are precisely engineered and manufactured to the exact specifications of our customers.

We have a rigorous quality control process that involves multiple inspections and tests throughout the manufacturing process. We use advanced inspection and testing equipment to ensure that all parts meet or exceed industry standards.

We do not have a minimum order quantity. Whether you need a single part or thousands of parts, we are happy to work with you.

Our pricing is based on the complexity and quantity of the parts being manufactured. We will provide you with a detailed quote when you submit your order.

Yes, we have a team of experienced engineers who can assist you with design and prototyping. We can work with you to optimize your designs for manufacturability and efficiency.

We offer a warranty on all of our products. If you experience any issues with our products, please contact us and we will work with you to resolve the issue.

You can submit an order by contacting us directly or through our website. We will work with you to ensure that your order is submitted correctly and that you receive the parts you need on time and within budget.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.

The Ultimate Guide to CNC Milling: Advantages, Limitations & Applications

Design for Manufacturing (DFM): Principles, Process, and Application Explained

CNC Turning Parts:Everything You Need to Know| LS Manufacturing

CNC Machining: The Ultimate Guide to Processes, Materials, and Applications

What Are The Parts Of A Plasma Cutter Gun?

What Are Taps In Machining?

How to Cost a Xiaomi YU7 Auto Part?

What Is The Difference Between Sheet Metal And Machining?

Customize Extrusion Moulding Parts Service

Put Your Parts Into Production Today

- All information and uploads are secure and confidential.