CNC (CNC) manufacturing process is a manufacturing method, refers to the use of computer software to control machinery to produce the required parts and components according to specifications and requirements. Many factors need to be considered before the project starts, including the selection of CNC materials. Product quality and precision depend on the type of CNC processing material to be used, but it may be difficult to determine which material is suitable for your project. If the improper material will affect the product performance, it will lead to the product failure.

Don’t worry, our guide can help you choose the right material according to the project requirements. We will briefly introduce different CNC processing materials, and compare their characteristics, performance, applications, so that you will not feel confused when choosing, below, let’s walk into the knowledge of the ocean!

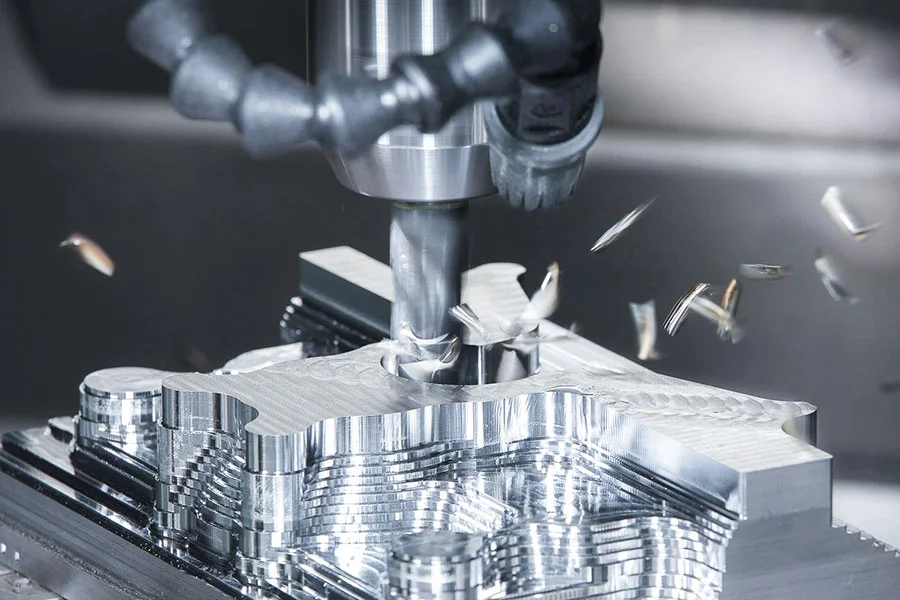

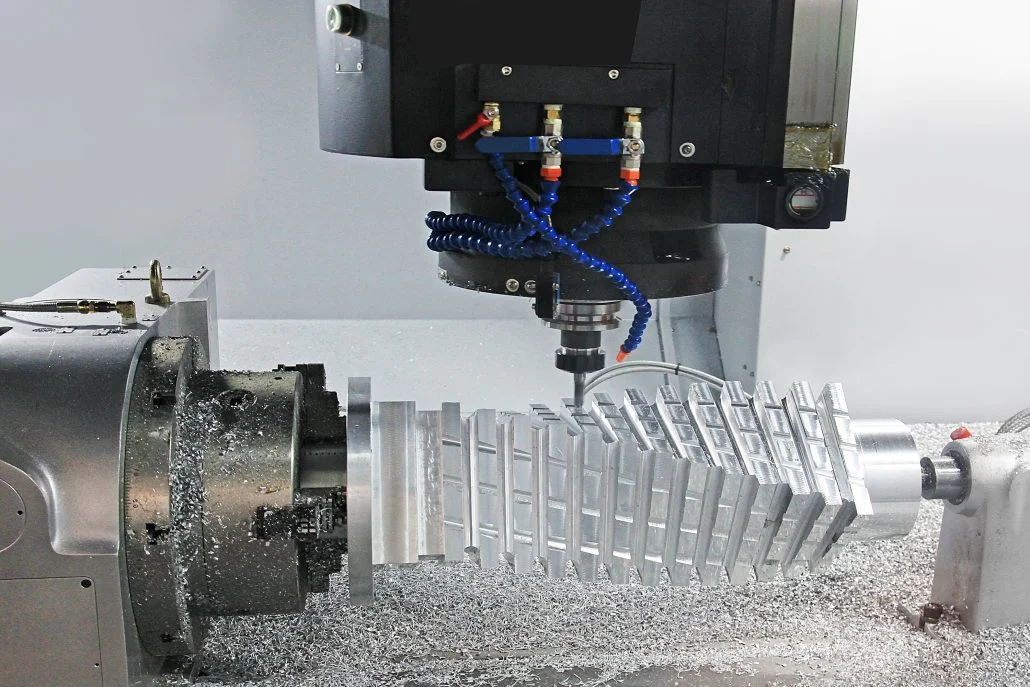

What’s CNC Machining?

CNC machining is a producing process through which pre-programmed pc software program directs the motion of manufacturing unit instruments and equipment. CNC stands for “Pc Numerical management,” and this machining permits a wide range of complicated machines, akin to milling machines, lathes, laser cutters, and water knives, to routinely carry out detailed slicing duties. This expertise improves on historically manually managed processes by growing accuracy, complexity and repeatability whereas lowering human error.

CNC machines can be utilized to chop steel, plastic, wooden, glass, foam and composite materials in a variety of purposes from automotive manufacturing to aerospace, development and electronics. Designs are created utilizing CAD (computer-aided design) software program after which transformed into applications particular to CNC machines that may exactly manufacture parts and parts in accordance with preset parameters and designs.

What’s CNC material?

Numerical control materials refer to the basic constituent elements of the objects that are processed in numerical control machining technology. These materials can be metal, non-metallic or other materials, which have different physical and chemical properties, so the processing process according to the characteristics of the material.

What are the machable materials for CNC processing?

Metallic material

1.Aluminium alloy

Aluminum is a widely used metal material with light weight, high strength, easy processing and good corrosion resistance. Aluminum has a density of about 2.7g / cm³, only a third of copper and steel, but the strength is very high. Moreover, aluminum has excellent electrical conductivity and thermal conductivity, so that it is widely used in electric power, electronics, heat exchanger and other fields.

There are many kinds of common aluminum alloy and its common aluminum alloy, such as 2024,5052,6061,7075 and so on.2024 aluminum alloy high strength, good fatigue resistance, often used in aircraft structure; 5052 aluminum alloy good corrosion resistance, often used in the manufacture of oil tank, pipe, etc.; 6061 aluminum alloy welding, processing, often used in the manufacture of body structure; 7075 aluminum alloy high strength, often used in manufacturing high strength parts.

When processing aluminum, there are several points to pay attention to: first, the cutting capacity of aluminum is relatively small, but the thermal conductivity is high, which will produce a lot of heat, so the appropriate cutting parameters and coolant should be selected. Secondly, due to the low hardness of aluminum, it is easy to produce chips, so appropriate cutting tools and cutting methods should be selected. Finally, the surface of aluminum is easy to oxidize, so it should be cleaned and protected after processing to prevent oxidation and corrosion.

2.Steel

A variety of steel alloys can be used for CNC processing. Steel alloy can be selected if parts require higher formability and greater weldability, such as gears, shafts, or certain high-stress applications. Stainless steel, low carbon steel, alloy steel and tool steel are the main types of CNC steel. Stainless steel is highly recommended when parts require high strength, high ductility, excellent wear resistance and corrosion resistance. In addition, stainless steel has good workability and is easy to weld and polish. Low carbon steel (low carbon steel) is appropriate when the cost plays an important role and the application is for general use. Carbon steel also has good weldability and corrosion resistance. Alloy steel and TiSCO are the exceptions when you consider higher hardness, greater stiffness, and heat resistance.

3.Copper alloy

Copper is a popular CNC processing material with unique properties, including excellent electrical and thermal conductivity. Because to its excellent electrical conductivity, product engineers consider copper and its alloys ideal for electrical and electronic components. Similarly, copper alloy is the perfect CNC material for jewelry production because of its excellent beauty. Wire, jewelry production, and magnetic equipment are typical applications of copper.

Brass, bronze and copper are indispensable for CNC processing materials. Brass and bronze are common copper alloys with unique properties. Brass is composed of copper and zinc. It is a very soft metal that can be processed without lubrication. It has excellent electrical conductivity, corrosion resistance and workability. Manufacturers often use brass for applications that do not require high strength, such as the manufacture of low-strength fasteners, electrical equipment, consumer goods, and piping equipment.

Bronze, on the other hand, consists of copper, tin, and other composite elements. It is strong and durable, and has a strong corrosion resistance. Bronze has excellent workability, which is perfect for machining precision parts such as bearings and gears. In addition, the addition of aluminum and phosphorus can improve the impact resistance, toughness, and strength of bronze.

4.Titanium alloy

This CNC metal is very strong and light in weight, with an excellent strength to weight ratio. The corrosion resistance, thermal conductivity and biocompatibility of titanium make it compatible with CNC processing in the biomedical industry. Titanium is compatible with welding, passivation and anodizing processes for enhanced appearance and protection. Although titanium has poor electrical conductivity, it has good thermal conductivity and high melting point.

In addition, titanium is well suited for manufacturing high-performance mechanical parts in the medical, military, aerospace and automotive industries. More noteworthy, titanium is suitable for manufacturing cutting tools for CNC machine tools.

Non-metallic material

Engineering plastics

Engineering plastics are also a very popular choice for CNC processing because of its wide selection range, relatively low price, and significantly faster processing time required. According to different characteristics and uses, plastics are divided into many species, such as POM, ABS, PVC, etc. Plastics are characterized by small density, high strength and strong plasticity, and are widely used in electronics, automobile manufacturing, environmental protection and other fields.

Wood

As a common biomass material, wood has its advantages of light weight, high strength and good processability. CNC machines can create complex designs and shapes on wood, making it a popular choice for woodworking applications. The process can yield precise cutting, even with complex designs. Some of the most popular types of wood used in CNC processing include maple, oak, walnut, birch, and cherry wood.

Glass material

Glass is a common inorganic non-metallic material with high transparency, high hardness and strong pressure resistance. Glass is commonly used in product processing, construction, optics, electronics and other fields.

Ceramic material

Ceramics is another common non-metallic material, with the advantages of high strength, high hardness, high wear resistance, corrosion resistance and high temperature resistance. Among them, alumina ceramics, silicon nitride ceramics, silicon carbide ceramics and other types are common in industrial manufacturing, electronics, aerospace and other fields.

Material selection factors

Choosing a suitable CNC processing material depends on your specific needs. considerations include:

Part function

When selecting the machined materials for CNC processing, it is necessary to comprehensively consider the mechanical properties, wear resistance, corrosion resistance, thermal conductivity, electromagnetic performance, aesthetics, weight and cost according to the specific functional requirements of the parts. Through reasonable selection of materials, the quality and performance of the parts meet the design requirements.

Application

The use requirement of the parts is the key basis for the selection of the materials. For example, aerospace parts have very high material requirements, requiring high strength, lightweight, high temperature and corrosion resistant materials, while medical device parts need to consider the biocompatibility and non-toxicity of materials.

Processability

- Cutting ability: the cutting ability of materials directly affects the processing efficiency and processing cost. Materials with good cutting ability are easy to process, with high machining efficiency and small tool wear.

- Grinding: Grinding is also an important consideration for materials that require grinding processing.

- Processing hardening: some materials will appear in the processing process, resulting in increased processing difficulty and tool wear.

Material cost

The cost of materials is an important factor to consider when selection. High-performance materials are usually more expensive, while generic materials are less expensive. Need to choose reasonably according to the product requirements and budget.

Environmental requirements

In the modern manufacturing industry, the environmental protection requirements are getting higher and higher. When choosing materials, we should consider their recyclability, environmental protection treatment difficulty and other factors.

Aluminium alloy:Characteristics, Properties, Applications

Characteristics of aluminum alloy

| Characteristics | Elaborate |

| Low density | Aluminum alloy has a low density, usually between 2.63~2.85g/cm³, giving it the advantage of lightweight. |

| High strength | the strength of aluminum alloy is higher, can be close to or higher than high quality steel, at the same time, its specific strength is close to high alloy steel, specific stiffness more than steel. |

| Strong plasticity | aluminum alloy has good plastic processing performance, can be processed into various shapes and sizes of parts. |

| Good conductivity and thermal conductivity | aluminum alloy has good conductivity and thermal conductivity, better than copper, iron and other metal materials. |

| Good corrosion resistance | the aluminum alloy surface is easy to form a layer of dense alumina film, with good corrosion resistance. |

| Easy to process | aluminum alloy cutting processing is good, processing process is not easy to stick knife, tool service life is long. |

Properties of aluminum alloy

Aluminum alloy processing performance is excellent, and can be processed by casting, forging, rolling, extrusion, stretching, forging and other methods for plastic deformation processing. Aluminum alloy has good casting performance and can be directly cast into various shapes of mechanical parts. In addition, aluminum alloy can also be enhanced by heat treatment to improve its mechanical properties and corrosion resistance.

Applications of aluminum alloy

- Building: aluminum alloy has the characteristics of light weight, corrosion resistance, strong decoration, widely used in manufacturing doors, Windows, curtain walls and other building components.

- Transportation: Aluminum alloy is widely used in the manufacture of cars, trains, aircraft and other transportation parts, including the body, wheels, interior decoration, etc.

- Electronic products: the electrical conductivity and heat dissipation of aluminum alloy make it widely used in the manufacturing of electronic products components, such as computer heat sink, mobile phone shell, battery and so on.

- Packaging materials: The corrosion resistance and plasticity of aluminum alloy make it ideal for the production of food and beverage packaging materials, such as pull ring cans, food packaging boxes, etc.

Steel :Characteristics, Properties, Applications

Characteristics of steel

| Characteristics | Elaborate |

| High strength | the strength of steel is very high, can withstand a lot of external pressure and weight, so that it is widely used in construction, bridge, mechanical manufacturing and other fields. |

| Rigidity | Steel can keep its shape and size unchanged after the force, which makes it an important application in areas requiring high stability and precision, such as engineering machinery, precision instruments, etc. |

| Plasticity | Steel has good plasticity, and can be processed into various shapes and sizes by bending, cutting, stretching and other processes. |

| Erosion resistance | the steel has a good corrosion resistance, which can resist the erosion of the atmosphere, water and other chemicals to a certain extent. |

| Stability | The physical and chemical properties of the steel give it a good stability, being able to maintain structural integrity at high temperature, fire, etc. |

Properties of steel

Steel processing performance is good, can be processed through casting, forging, rolling, welding and other processes. The hardness, plasticity, toughness and strength of steel products have an important influence on its processing performance. For example, steel with high hardness has good wear resistance but is difficult to process; steel with good plasticity is easy to process into various shapes; steel with good toughness is not easy to break when impacted or vibration; steel with high strength can withstand greater external pressure.

Applications of steel

Due to its wide use, steel is widely used in various industries. Some common applications include:

- Construction: structural steel, beams, bars, and reinforced concrete

- Automotive: car bodies, drivetrain components, and chassis

- Infrastructure: railways, roads, and bridges

- Aerospace: aircraft landing gear and structural components

- Energy: power plants, turbines, and pipelines

- Manufacturing: machinery, tools, and equipment

- Consumer goods: appliances, cookware, and furniture

Copper alloy:Characteristics, Properties, Applications

Characteristics of copper alloy

| Characteristics | Elaborate |

| Mechanical properties | Copper alloy has good mechanical properties, such as strength and hardness. |

| Conductivity | Copper alloy has high conductivity, which makes it widely used in the electrical industry. |

| Corrosion resistance | copper alloy has a strong corrosion resistance, especially in the environment containing sulfuric acid, nitric acid and other chemical substances. |

| Thermal conductivity | Copper alloy has good thermal conductivity, so it is often used to manufacture equipment that needs heat dissipation. |

| No magnetic property | The copper alloy is no magnetic property, which makes it very useful in some special applications (such as electromagnetic shielding). |

Properties of copper alloy

Copper alloy has good processing performance, using various processing methods:

- Good malleability: copper alloy is easy to die forging, stretch and stamping forming.

- Cold processing and hot processing: copper alloy processing mode is divided into cold processing and hot processing two kinds. Generally speaking, the deformation stress of copper alloy at room temperature is large, which is prone to crack, so the copper alloy needs to be heated to the specified temperature before processing. Copper alloy with low melting point is more suitable for cold processing.

- High precision processing: in the high precision processing, copper alloy along the crystal less corrosion, low deformation and hardening degree, not easy to appear residual stress and deformation distortion.

Applications of copper alloy

- Electrical industry: copper alloy is widely used in power transmission, motor manufacturing, communication cable and other aspects. They are mainly used for power wire and cable, junction row, transformers, switches, connection elements and connectors, etc., to improve the efficiency and safety of electrical equipment.

- Mechanical manufacturing: Copper alloy can be used in the manufacture of various mechanical parts and components, such as gears, bearings, valves, etc. Because of its good corrosion resistance and thermal conductivity, these parts can operate stably for a long time in a harsh environment.

- Chemical industry: In the field of chemical industry, copper alloy can be used to manufacture a variety of corrosion-resistant equipment and pipelines, such as heat exchangers, condensers, reactors, etc. These devices need to withstand erosion by various chemicals, and the corrosion resistance of copper alloys ensures their long-term stable operation.

- Shipbuilding: in ship manufacturing, copper alloy is widely used in manufacturing hull structure, propeller, propeller and other parts. These components are required to withstand the erosion of seawater and the Marine environment, and the corrosion resistance of copper alloys ensures their long-term stable operation.

- Construction field: In the field of construction, copper alloy can be used to manufacture doors and Windows, roofs, decorative materials, etc. These materials not only have good corrosion resistance and thermal conductivity, but also have an aesthetic appearance and lasting durability.

Titanium alloy:Characteristics, Properties, Applications

Characteristics of titanium alloy

| Characteristics | Elaborate |

| High strength | The tensile strength of titanium alloy can reach 100~140kgf / mm², and its specific strength (tensile strength / density) is high, and the density is only 60% of that of steel. |

| Corrosion resistance | Titanium alloy can quickly form a uniform and dense oxide film in the atmosphere, thus having the ability to resist the erosion of various media. Excellent corrosion resistance in seawater, wet chlorine gas and chloride solutions. |

| Heat resistance | titanium alloy has good heat resistance, which can maintain the required strength at moderate temperature, and can even work at a long-term temperature of 450~500℃. |

| Low temperature performance | some titanium alloys can still maintain certain plasticity at very low temperature, such as TA7 can still maintain certain plasticity at-253℃. |

| Low elastic modulus, low thermal conductivity, and no ferromagnetism | these characteristics give titanium alloy unique advantages in some specific fields. |

Properties of titanium alloy

The processing performance of titanium alloy is relatively poor, its hardness is high (the hardness of annealed state is 32~38), the cutting resistance is large, and it is easy to affinity and adhere to the abrasive, resulting in the grinding wheel wear and reduced grinding performance. Therefore, in the processing of titanium alloy, it is necessary to use special cutting process and tool materials, such as the selection of impact resistant ultrafine grain carbide, high temperature performance with good high speed steel, and keep the blade sharp, to ensure the smooth discharge of debris, to avoid debris collapse. The cutting speed should be low, the feed amount is moderate, the cutting depth can be large, and the coolant needs to be fully cooled during processing.

Applications of titanium alloy

- Aerospace: Due to the characteristics of high strength and lightweight, titanium alloy is widely used in manufacturing engine parts, wings, propellers and other aerospace parts.

- Medical equipment: The biocompatibility and corrosion resistance of titanium alloy makes it ideal for manufacturing medical devices and implants, such as bone screws, artificial joints, dental implants, etc.

- Chemical industry: the corrosion resistance of titanium alloy makes it widely used in the chemical industry, such as the manufacturing of reactors, valves, pipelines and other corrosion resistant equipment.

- Sports equipment: the high strength and lightweight of titanium alloy make it widely used in the manufacture of sports equipment, such as bicycle frame, golf clubs, tennis rackets, etc.

Non-metallic material:Characteristics, Properties, Applications

Characteristics of non-metallic material

Engineering plastics

- Processing properties: plastics has excellent processing properties, can be easily processed by CNC into various shapes and sizes.

- Low cost: Plastics are usually cheaper and suitable for mass production.

- Lightweight: the plastic material density is low, and the products are relatively light.

- Corrosion resistance: plastics have good corrosion resistance, not easy to be eroded by chemical substances.

- Heat resistance: different kinds of plastic have different heat resistance, and some plastic is easy to deform at high temperature.

Wood

- Strong plasticity: wood has good plasticity and processivity, CNC processing can produce exquisite wood products.

- Natural texture: the wood has a unique natural texture and color, so that the processed products have a natural aesthetic feeling.

- Environmental protection: Wood is a renewable resource that is more environmentally friendly than other materials.

- Stability: the stability and durability of wood is poor, easily susceptible to moisture, deformation and cracking.

- Cost: Some high-quality wood costs higher.

Glass

- High transparency: glass has extremely high transparency, suitable for the need for high light transmittance occasions.

- Corrosion resistance: glass materials also have excellent corrosion resistance.

- High hardness: glass material hardness, but easier to process than ceramics.

- Fritability: The glass material is fragile and needs to be particularly careful during processing.

- Processing difficulty: glass processing needs special equipment and technology, such as CNC glass fine carving machine, processing is difficult.

- Cost: the glass processing cost is relatively high, but the products have high added value.

Ceramics

- High hardness: ceramic material hardness is very high, good wear resistance, processed products have a long service life.

- Corrosion resistance: Ceramic materials have excellent corrosion resistance and can resist the erosion of most chemicals.

- High temperature resistance: ceramic materials can still maintain good performance at high temperature.

- Brittleness: ceramic materials are brittle, easy to break or damage in the processing process, requiring special processing technology and equipment.

- Cost: ceramic processing cost is relatively high, suitable for high precision, high value-added products.

Properties of non-metallic material

| Material | Advantage | Disadvantage |

| engineering plastics | Good corrosion resistance, electrical insulation and molding processing | Poor heat performance, high temperature is easy to deformation or coke, low hardness, poor wear resistance |

| wood | Good plasticity and processing properties, durability, and weathering resistance | vulnerable to moisture, deformation and cracking |

| glass | High transparency, high hardness, strong pressure resistance | Fragile, high processing costs |

| ceramics | High hardness, temperature resistance, and corrosion resistance | Easy to produce cracks or damage, and the processing cost is higher |

Applications of non-metallic material

- Engineering plastics: widely used in electronics, automotive manufacturing, environmental protection and other fields.

- Wood: mainly used in furniture, architecture, art and other fields.

- Glass: commonly used in product processing, construction, optics, electronics and other fields.

- Ceramics: widely used in industrial manufacturing, electronics, aerospace and other fields.

Material selection advice

- For applications requiring high hardness, high wear resistance, and high chemical stability, materials such as carbide carbide, ceramic tools, or cubic boron nitride (CBN) can be selected.

- Diamond is the best choice for applications requiring extremely high hardness and wear resistance. But note that diamond prices usually ally expensive.

- Aluminum alloy is a good choice for applications that require lightweight, good thermal conductivity and good machining performance.

- For applications requiring high strength, good wear resistance and certain corrosion resistance, stainless steel and nickel-based alloys may be better choices.

Longsheng: Choose the right materials for your next metal manufacturing and rapid molding

Whenever you need help or expert advice, choose the right CNC machining material, Our Longsheng CNC processing service is readily available. We also help you select alternative materials and provide you with quality manufacturing that fits your budget.Therefore, proceed on CNC processing, 3D printing or sheet metal manufacturing projects. You can also upload design files and receive online quotes within a few hours.

Conclusion

This guide introduces the characteristics, properties and applications of metal materials (aluminum alloy, steel alloy, copper alloy, titanium alloy) and non-metal materials (engineering plastics, wood ceramics, glass) often used in CNC processing. In the selection of CNC processing materials, it is necessary to comprehensively consider the application requirements, physical properties, processing properties, environmental requirements, thermal conductivity and economic factors and other aspects. By carefully evaluating and comparing the strengths and disadvantages of different materials, the materials best selected for a specific application.

FAQs

How to choose the appropriate processing methods and equipment to deal with different materials?

For different materials, appropriate cutting tools, processing strategies and processing equipment can be selected according to their characteristics, such as high-speed milling, wire cutting, milling and processing centers, etc.

How to deal with the fracture problem of cutting brittle material in CNC processing?

For cutting brittle materials, suitable fixtures and support structures can be used to reduce material vibration and deformation, and appropriate cutting tools and parameters can be selected to reduce the risk of fracture.

How to choose the right material?

When selecting materials, the specific requirements and application requirements of the parts should be considered, such as mechanical properties, corrosion resistance, temperature stability, and etc.

Resource

Titanium as a Reconstruction and Implant Material in Dentistry: Advantages and Pitfalls