What is Stainless Steel Parts Machining

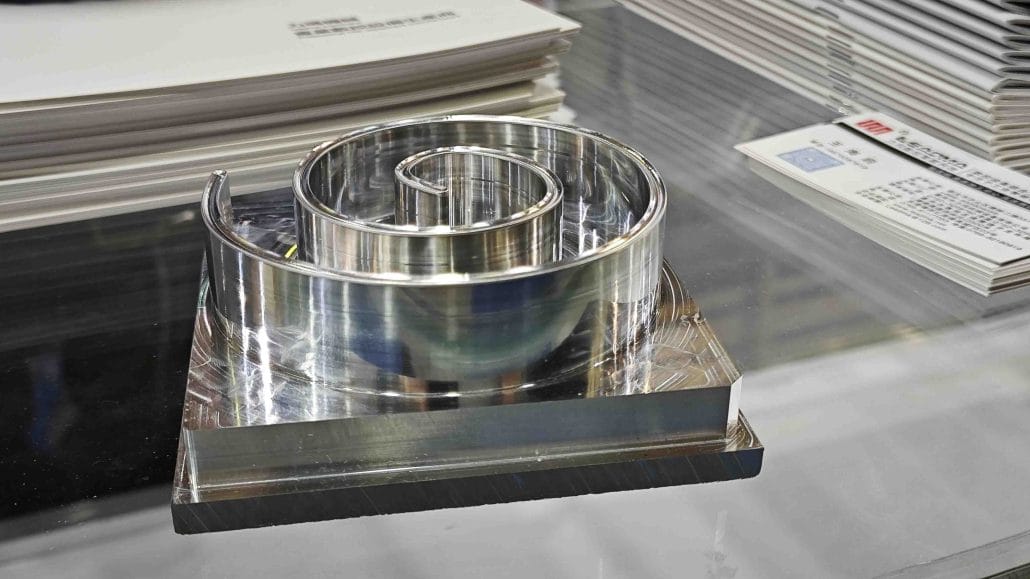

Stainless steel parts machining is the process of shaping, cutting, and finishing stainless steel materials to create precise parts and components. This process involves using various machining tools and techniques to remove material from the raw stainless steel material, transforming it into the desired shape and dimensions.

Stainless steel is a popular material for parts machining due to its strength, durability, and resistance to corrosion and wear. It is commonly used in the manufacturing of parts for the automotive, aerospace, medical, and food processing industries, among others.

The machining process for stainless steel parts involves several steps, including:

- Design and planning: The first step is to design the part and plan out the machining process, including selecting the appropriate tools, equipment, and techniques.

- Material preparation: The raw stainless steel material must be prepared for machining, which may involve cutting, drilling, or shaping it into the required size and shape.

- Machining: The actual machining process involves using tools such as lathes, drills, and milling machines to remove material from the stainless steel and shape it into the desired form.

- Finishing: Once the part has been machined, it may undergo additional finishing processes such as polishing, sanding, or coating to improve its surface finish or protect it from corrosion.

Overall, stainless steel parts machining is a complex process that requires skilled technicians and specialized equipment. However, it is essential for producing high-quality, precision parts that meet the specific requirements of various industries.

Difficulty of Machining Stainless Steel Parts

Stainless steel is a popular material used in many industries due to its corrosion resistance, durability, and aesthetic appeal. However, machining stainless steel parts can be challenging due to its toughness and hardness.

One of the main difficulties in machining stainless steel is its high work hardening rate. This means that as the material is machined, it becomes harder and more difficult to cut. To overcome this, it’s important to use the right cutting tools and techniques such as using high-speed steel or carbide tools with a sharp edge and slow cutting speeds.

Another challenge in machining stainless steel is its tendency to produce heat and work hardening quickly. This can lead to tool wear, chipping, and breakage. To avoid this, it’s essential to use coolant or lubricant during the machining process to reduce heat and friction.

Stainless steel also has a tendency to produce built-up edge (BUE) during machining. BUE occurs when the material adheres to the cutting edge of the tool, causing it to dull quickly. To prevent BUE, it’s important to use a sharp tool, a low cutting speed, and a high feed rate.

In conclusion, machining stainless steel parts can be challenging due to its toughness, high work hardening rate, and tendency to produce heat and BUE. However, with the right cutting tools, techniques, and coolant/lubricant, these difficulties can be overcome to achieve high-quality and precise parts.

Best Way to Machining Stainless Steel Parts

Stainless steel is a widely used material in various industries, including automotive, aerospace, medical, and construction. Machining stainless steel parts can be a challenging task due to its high strength, hardness, and low thermal conductivity. However, with the right techniques and tools, machining stainless steel can be done efficiently and effectively.

Here are some best practices for machining stainless steel parts:

- Use the right cutting tools: Stainless steel has a tendency to work harden, which can cause premature wear on cutting tools. Therefore, it is essential to use cutting tools that are specifically designed for machining stainless steel. Carbide inserts, ceramic inserts, and high-speed steel (HSS) tools are suitable for machining stainless steel.

- Use the right coolant: A coolant is necessary for machining stainless steel to reduce heat and friction, which can cause work hardening and tool wear. Water-soluble coolants are recommended for machining stainless steel. These coolants contain lubricants and corrosion inhibitors that protect the workpiece and cutting tools.

- Control the cutting speed: Stainless steel has a low thermal conductivity, which means that it can quickly build up heat during machining. Therefore, it is essential to control the cutting speed to avoid overheating and work hardening. The cutting speed should be slower than that used for machining carbon steel.

- Use the right feed rate: The feed rate is the speed at which the cutting tool moves along the workpiece. A high feed rate can cause work hardening and tool wear, while a low feed rate can result in poor surface finish. Therefore, it is essential to use the right feed rate for machining stainless steel.

- Choose the right machining process: There are several machining processes that can be used for machining stainless steel, including milling, drilling, turning, and grinding. The choice of machining process will depend on the part’s geometry, size, and surface finish requirements.

By following these best practices, machining stainless steel parts can be done efficiently and effectively, resulting in high-quality parts that meet the required specifications.

Application of Stainless Steel Parts Machining

Stainless steel parts machining is a process of removing unwanted materials from a piece of stainless steel to achieve a desired shape and size. This process is widely used in various industries, including automotive, aerospace, medical, and food processing.

The automotive industry utilizes stainless steel parts machining for engine components, exhaust systems, and suspension components. In aerospace, stainless steel parts machining is used for manufacturing aircraft engine parts, landing gear, and structural components. Medical devices such as implants and surgical instruments are also made using this process.

The food processing industry uses stainless steel parts machining for manufacturing equipment such as mixers, conveyors, and storage tanks. Stainless steel is used in the food processing industry due to its corrosion resistance, durability, and hygiene properties.

Stainless steel parts machining involves several techniques, including turning, cnc milling, drilling, and grinding. These techniques require specialized equipment and skilled operators.

In conclusion, the application of stainless steel parts machining is vast and plays a crucial role in many industries. It enables the production of high-quality, durable, and reliable components that are essential for various applications.

Stainless Steel Parts Machining Services

Stainless steel is a popular material used in many industries due to its strength, durability, and corrosion resistance. Machining stainless steel parts requires precision and expertise to ensure the final product meets the required specifications. At our machining services, we specialize in providing high-quality stainless steel parts machining services to meet your specific needs.

Our team of skilled professionals uses advanced machining techniques and equipment to produce accurate and precise stainless steel parts. We offer a wide range of services, including CNC turning, milling, drilling, and grinding, to meet the needs of various industries.

We understand that each project is unique and requires a customized approach. Our team works closely with you to understand your specific needs and requirements to ensure we deliver the best possible results. We ensure that our stainless steel parts machining services meet the highest standards of quality and accuracy.

We pride ourselves on our commitment to customer satisfaction and strive to exceed your expectations with our services. We offer competitive pricing, fast turnaround times, and a dedication to delivering the best possible results.

If you require stainless steel parts machining services, contact us today to discuss your project requirements. Our team is ready to provide you with the highest quality services to meet your needs.

FAQ

Stainless steel is a strong, durable, and corrosion-resistant material that can withstand harsh environments and extreme temperatures. It is also easy to clean and maintain, making it ideal for use in industries such as automotive, aerospace, and medical.

Once the part has been machined, it may undergo additional finishing processes such as polishing, sanding, or coating to improve its surface finish or protect it from corrosion. These finishing processes are essential for ensuring that the part meets the specific requirements of the industry in which it will be used.

Stainless steel parts machining involves the use of a variety of tools, including lathes, drills, milling machines, and grinders. These tools are used to remove material from the raw stainless steel and shape it into the desired form.

Stainless steel parts are used in a wide range of industries, including automotive, aerospace, medical, and food processing. These industries require strong, durable, and corrosion-resistant parts that can withstand harsh environments and extreme temperatures.