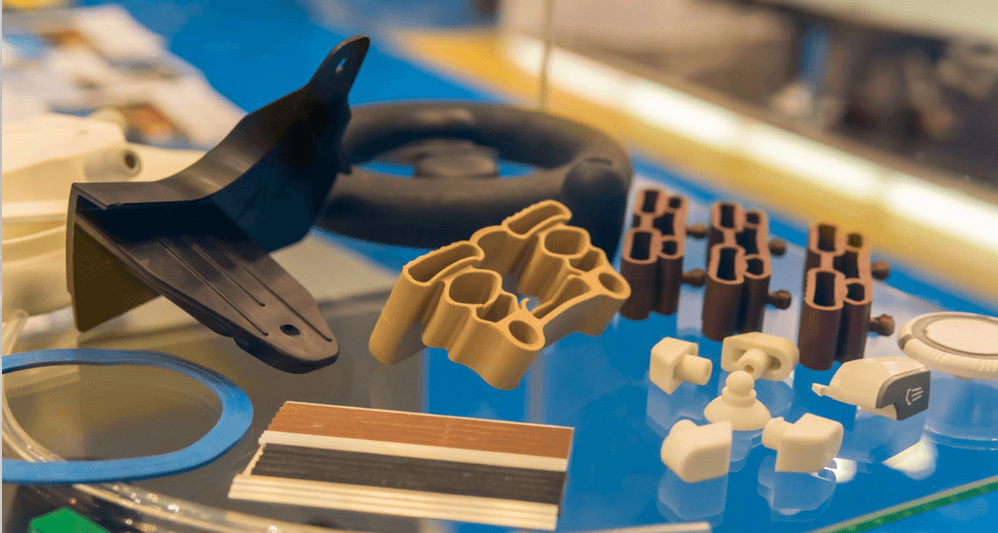

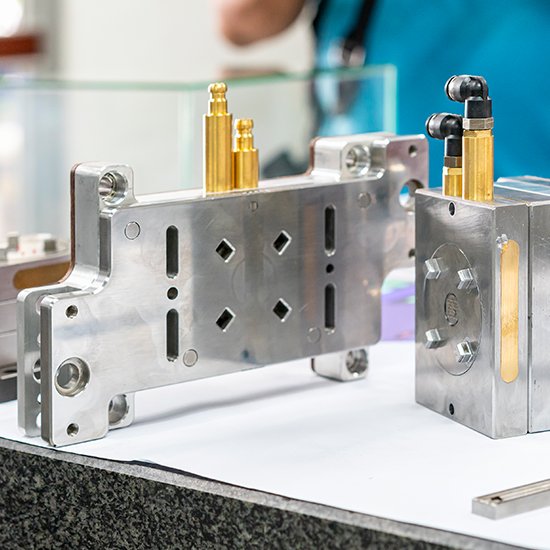

Injection Molding Terms and Definitions

As a professional in the injection molding industry, it’s critical to have a solid understanding of the fundamental terms and definitions related to this field. From understanding the basics of the molding process to mastering the various components involved, having a thorough grasp of injection molding terminology is essential to ensuring top-notch results.

Injection Molding Terms and Definitions Read More »