CNC machining and plastic injection molding are two manufacturing processes that are widely used in the production of various products. Both processes have their own unique features and advantages.

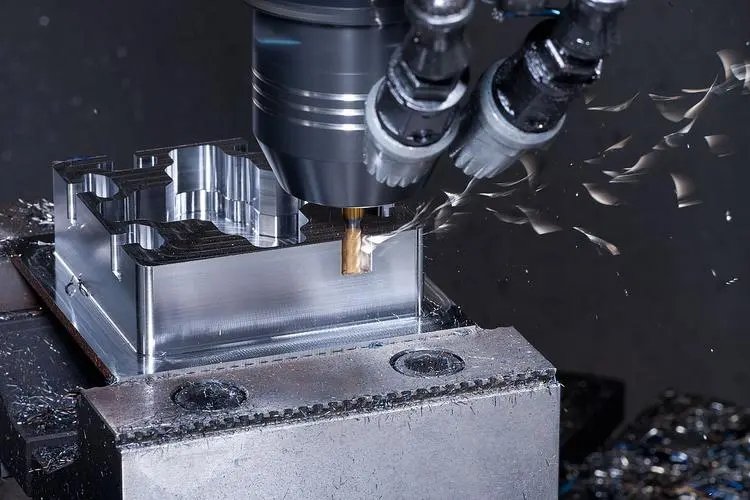

CNC machining is a manufacturing process that uses computer-controlled tools to create precise and complex shapes. The process involves using a computer program to control the movement of a cutting tool, which removes material from a solid block of material to create the desired shape. CNC machining is often used for creating parts with complex shapes or geometries that cannot be easily produced using traditional machining methods.

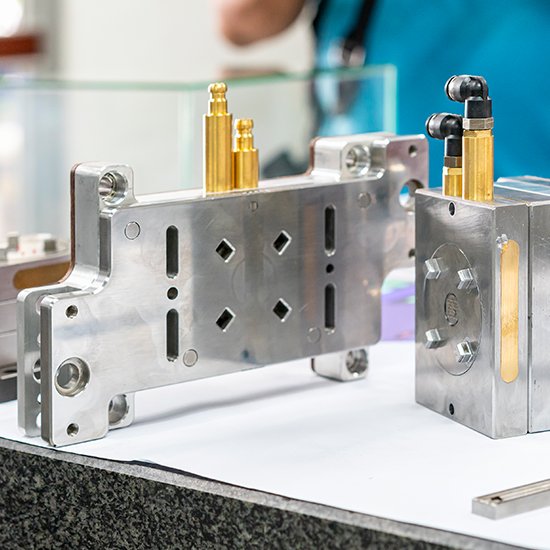

Plastic injection molding, on the other hand, is a manufacturing process that involves injecting molten plastic into a mold cavity to create a specific shape. The molten plastic is then cooled and solidified to create the final product. This process is often used for creating large quantities of parts that are consistent in shape and size.

One of the main advantages of CNC machining is its ability to create highly precise parts with tight tolerances. This makes it ideal for creating parts that require a high degree of accuracy, such as medical devices or aerospace components. Additionally, CNC machining can be used to create parts from a wide range of materials, including metals, plastics, and composites.

Plastic injection molding, on the other hand, is ideal for creating large quantities of parts quickly and efficiently. This process can produce parts with complex geometries and is often used for creating consumer products, such as toys or electronic components. Additionally, plastic injection molding can be used to produce parts with a wide range of properties, including flexibility, strength, and durability.

In conclusion, both CNC machining and plastic injection molding are important manufacturing processes that have their own unique advantages. The choice of process will depend on the specific needs of the product being produced. CNC machining is ideal for creating precise, complex parts, while plastic injection molding is better suited for creating large quantities of parts quickly and efficiently.

When deciding between CNC machining and plastic injection molding, it’s important to consider factors such as cost, time, and quantity. CNC machining is generally more expensive than plastic injection molding, but it can produce parts with greater precision and accuracy. On the other hand, plastic injection molding is less expensive and can produce parts more quickly, but it may not be suitable for parts that require high levels of precision.

Another factor to consider when choosing between these two manufacturing processes is the type of material being used. CNC machining can work with a wide range of materials, including metals, plastics, and composites, while plastic injection molding is typically used for plastics and other materials that can be melted and molded.

Regardless of which manufacturing process is chosen, it’s important to work with a reputable manufacturer that has experience with both CNC machining and plastic injection molding. This will ensure that the final product meets the necessary specifications and quality standards.

Overall, CNC machining and plastic injection molding are both valuable manufacturing processes that play important roles in the production of various products. By understanding the advantages and limitations of each process, manufacturers can make informed decisions about which process to use for their specific needs.