Which is more suitable for your custom parts application, 3D printing or CNC machining? Analyzing their advantages and uses in depth, as well as how to distinguish them, can better help you make choices.

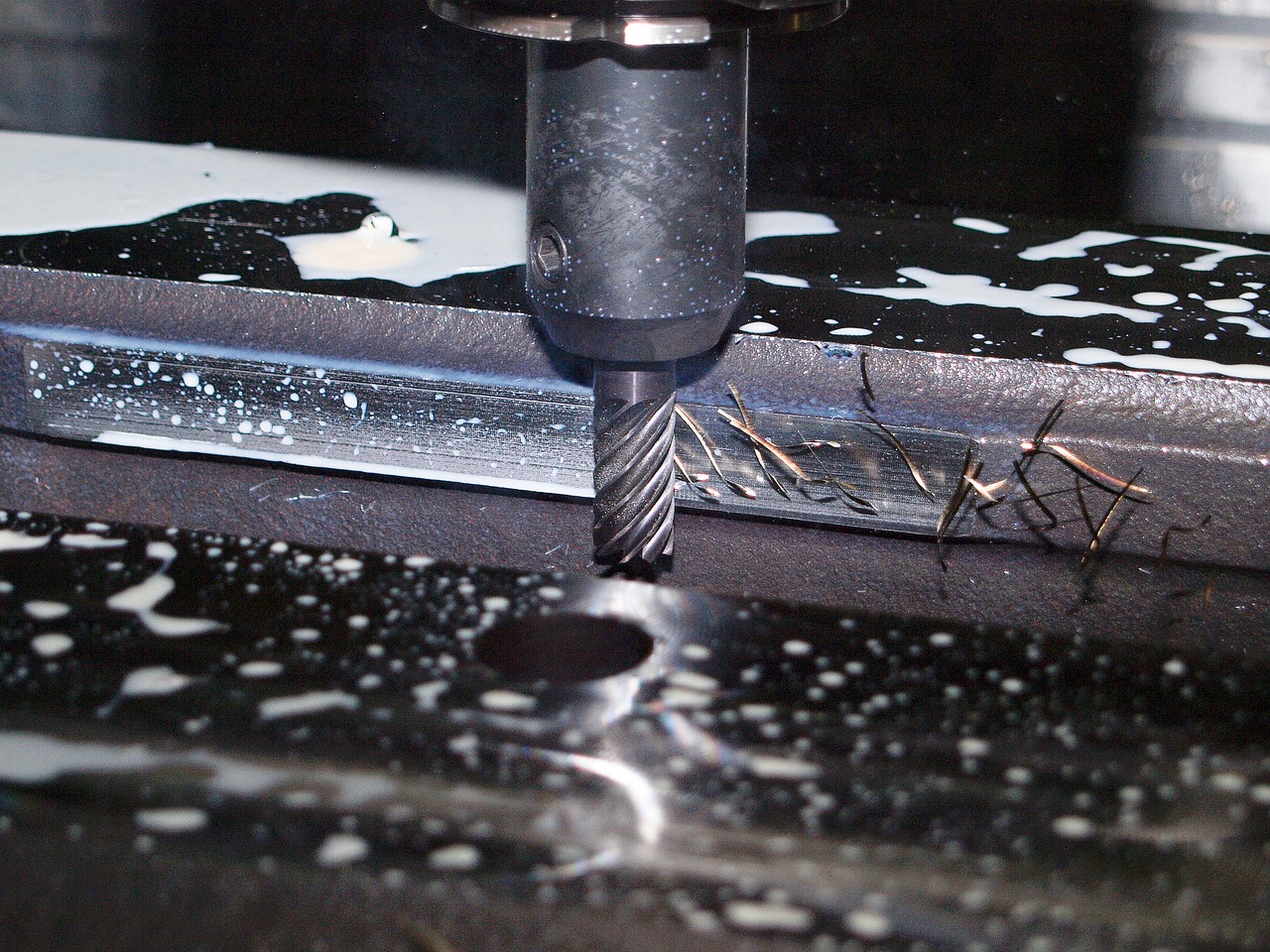

What is CNC machining

CNC machining is a computer-controlled manufacturing process that uses cutting tools to remove material from a workpiece and create a finished part. This process is highly accurate and can produce complex shapes and designs with ease. CNC machining is ideal for creating parts with tight tolerances and intricate details and can work with a variety of materials, including metals, plastics, and composites.

Its working principle is as follows:

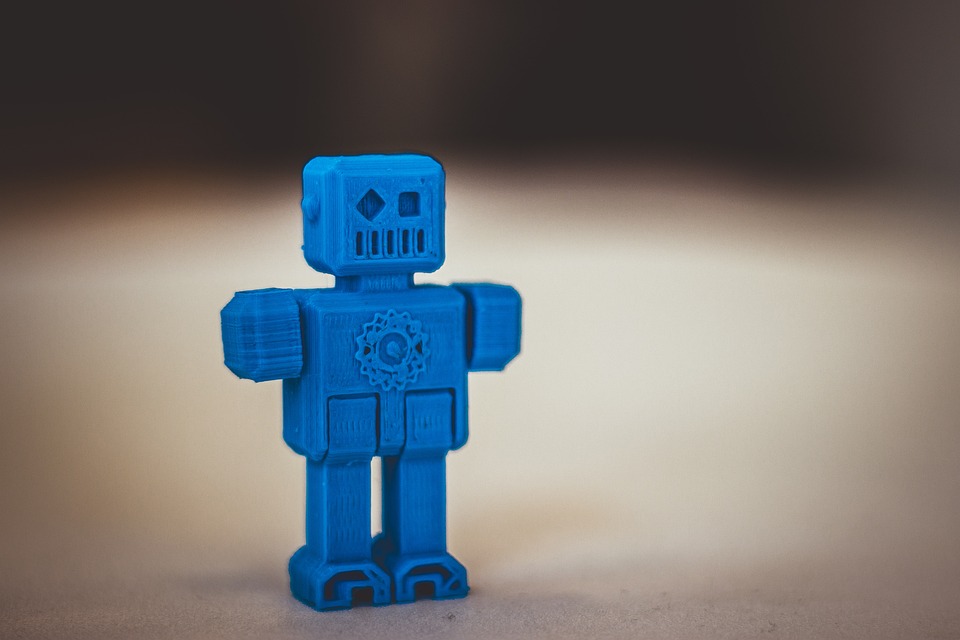

- Firstly, you need a 3D model file that provides a detailed description of the shape and structure of the object you want to print.

- Next, you need to choose the printing materials, such as plastic, metal, etc. These materials are processed into powder or fine filaments for use in printers.

- Secondly, the printer will print out the various parts of the object layer by layer according to the instructions in the model file. An object formed by stacking layers of thin sheets.

- Finally, after printing is completed, some post-processing may be required, such as polishing, coloring, etc., to make the object more perfect.

What is 3D printing

3D printing, also called additive manufacturing, is a process of creating physical objects from digital models by adding material layer by layer. It’s used for rapid prototyping, customization, and making complex shapes in various industries.

Its working principle is as follows:

- Firstly, you need a CAD or CAM software to establish a digital model or machining path for the workpiece. This model or path should have all the dimensions, shapes, and processing requirements of the workpiece, etc.

- Then, you convert this model or path into code that CNC machine tools can understand, a process commonly referred to as post-processing or programming.

- Finally, you input the code into the CNC system of the CNC machine tool. The controller of the machine tool will read these codes and operate various parts of the machine tool, such as the spindle and cutting fluid system, according to the instructions.

The advantages of CNC machining

- Processing complex CNC parts

- High yield and low cost

- Multiple material options

- Strict tolerance (+/-0.005mm)

- Rapid delivery of CNC parts within 3 days

The purpose of CNC machining

| Industry | Concrete content |

| Aerospace | Engine components, landing gear parts,Aviation turbine engine, etc |

| Automobile | pistons and cylinder heads, transmission case, etc |

| Medical treatment | Surgical tools, orthopedic implant lamps, Dental Instruments,etc |

| Electronic product | Circuit boards, casings, etc |

| Military and National Defense | Weapon components, communication equipment parts, etc |

The advantages of 3D printing

- Iterative design and prototyping

- Cost-effective for low volume production

- No upfront tooling costs

- Complex Geometries

The purpose of 3D printing

| Industry | Concrete content |

| Construction | Additive welding, powder bonding, etc |

| Medical care | Personalized prosthetics, hearing aids, etc |

| Aerospace | Non critical or older aircraft components, etc |

| Automobile | Racing, etc |

The commonalities between Cnc machining and 3D printing

- They make 3D products based on 3D models

- They all have a high degree of flexibility and customization

- They do so by following instructions from a compute

- They all have a certain degree of diversity in material select

The difference between Cnc machining and 3D printing

| CNC machining | 3D Printing | Attribute |

| Reduced material manufacturing technology | Additive Manufacturing Technology | Work technology |

| High machining accuracy and surface quality, especially in the field of metal processing. The machining dimension accuracy can reach between d0.005 and 0.01mm, or even higher | Overall, it is still lower than CNC machining. Its surface quality may be relatively rough and requires post-treatment to improve | Precision and surface quality |

| Suitable for various materials, including metal, plastic, wood, glass, etc | The main materials currently used are plastics, metal powders, ceramics, etc. Although the types of materials are constantly increasing, they are still relatively limited compared to CNC machining | Material selection |

| The cost is relatively high, but the production efficiency is high. Especially for large-scale production, CNC machining has significant cost advantages | Low cost, especially for small batch or personalized customized products. But its production efficiency is relatively low, especially when printing large-sized objects | Cost and efficiency |

| The stroke is large and the processing range is wide. The machining range of the gantry machine tool can even reach a range of two to three meters for the entire piece | The processing range is relatively small, generally not exceeding 600mm. If it is larger than this size, it will need to be disassembled for printing, and the cost will also increase accordingly | Processing scope and dimensions |

| Programming software is relatively complex and requires professional personnel to operate. Programming and operational experience have a significant impact on the machining quality of parts | Most 3D printing slicing software is easy to operate and get started with. Even laymen can quickly master it under professional guidance | Programming and Operations |

| There are various post-processing options, including grinding, oil spraying,powder coating, electroplating, screen printing, etc., which can meet the needs of different industries | There are relatively few post-processing options, generally including polishing, sand blast, deburring, etc | Post processing |

When to consider choosing CNC machining or 3D printing

- When you need high precision and high surface quality:CNC machining can provide very high precision and surface quality, especially in metal processing. If you need to manufacture precision parts or require highly smooth surfaces, CNC machining is a better choice.

- When you need rapid prototyping or small batch production:3D printing technology can quickly generate product prototypes and even be directly used for small batch production. It can produce complex shaped parts at a lower cost and time, making it very suitable for rapid iteration and testing design.

- When you need to handle large parts:CNC machining machines have a wide range of travel and can handle large parts. If you need to process parts with larger dimensions, CNC machining is a more suitable choice.

- From the perspective of cost-effectiveness: In large-scale production, CNC machining can achieve high efficiency, high output, and higher cost-effectiveness; In small batch or personalized customization production, 3D printing can reduce mold and tool costs, quickly respond to design changes, and have higher cost-effectiveness.

- When you need to process special materials:CNC machining is suitable for various materials, including metals, plastics, wood, etc. If you need to process any of these materials, CNC machining is a great choice,Of course, it’s also possible consider 3D printing,although the material selection for 3D printing is relatively limited, it can also handle some special materials, such as metal powders, ceramics, etc. If you need to process these special materials and 3D printing can meet your needs, then it is also a feasible choice.

- When you need to quickly modify the design or make personalized customization: 3D printing technology can quickly adapt to design changes and customize according to your needs. If you need to frequently modify designs or create unique products for each customer, 3D printing is a good choice.

- When you focus on environmental protection and sustainability:3D printing may be more environmentally friendly in terms of material usage and energy consumption, as it reduces waste and waste generation. If you are concerned about environmental protection and sustainability, 3D printing may be a better choice.

Why choose Longsheng

Accurate, reliable and efficient! We focus on providing customers with excellent precision CNC machining services. Longsheng ensures the quality of your CNC machined parts with ISO 9001:2015, ISO 9001:14001 and IATF16949 certified quality management systems.With advanced 4 and 5-axis CNC machining centers. Our precision CNC machining provide rapid prototyping, small batch machining and high volume production. By choosing our precision CNC machining manufacturer, you will receive high-quality, customized parts, fast delivery, and competitive prices. We will cooperate with you to provide excellent CNC machining solutions for your project.At the same time, you can go to our official website check out our rich library of images, which showcases the precision prototypes and CNC parts we process.

Regarding 3D printing services,We provide you with rapid prototyping and customized parts production. Why choose us for online 3D printing services?

- We have the ability to handle multiple materials, and we can provide professional solutions no matter what material of parts you need to process.

- Provide customized solutions based on customer design requirements and specifications to ensure that parts meet their unique needs.

- We provide competitive prices and cost-effective solutions to ensure that customers gain the greatest advantage in cost control.

- We have efficient production processes and flexible production plans, which enable us to timely deliver customer orders and meet urgent project needs.

Conclusion

Through this article, we have learned about the related content of CNC machining and 3D printing, including their concepts, advantages, uses, similarities, differences, and the appropriate way to manufacture parts in what scenarios. Sometimes, the two can also be combined for prototyping and mold production, combination manufacturing, personalized customization, etc. In practical situations,When choosing 3D printing or CNC machining, it is necessary to comprehensively consider multiple factors such as design complexity, material selection, accuracy requirements, and cost. In practical applications, flexible selection can be made based on the characteristics and requirements of the product. For example, for prototype products with complex designs that require rapid verification, 3D printing can be chosen; For parts that require high precision and mass production, CNC machining can be chosen. In addition, according to the actual situation of the production line, 3D printing and CNC machining can be combined to achieve more efficient and flexible production methods.

FAQs

What are the alternative solutions for 3D printing and CNC machining?

Injection molding: can be seen as an alternative to both, especially suitable for large-scale production.

Will 3D printing be cheaper than CNC machining?

This depends on various factors, such as model complexity, material selection, machining accuracy, and production quantity. Generally speaking, 3D printing may be cheaper for small batch, customized, or complex structured products; For large-scale production, CNC machining may be more economical.

Can 3D printing replace CNC machining?

3D printing is unlikely to completely replace CNC machining. Both have advantages in precision, material selection, processing range, and are suitable for different production needs.

Which is better between Cnc machining and 3D printing?

CNC machining Advantages: high precision, high quality, wide material selection, suitable for large-scale production,additionally, its disadvantage is thatHigh cost, long production cycle, and potential material waste.

3D printing Advantages: rapid prototyping, customized production, and the ability to manufacture complex structures,additionally, its disadvantage is relatively poor accuracy and surface quality, limited material selection, and unsuitable for large-scale production

To sum up,CNC machining and 3D printing each have their own advantages and application scenarios, and the choice of technology depends on specific product requirements and production conditions

Resource

Effect of 3D Printing Technology on 3C Product Manufacturing