CNC machining and vacuum forming are two popular manufacturing techniques that have revolutionized the production industry. In this article, we will explore the benefits and applications of both techniques, and how they can help businesses achieve their manufacturing goals.

CNC Machining

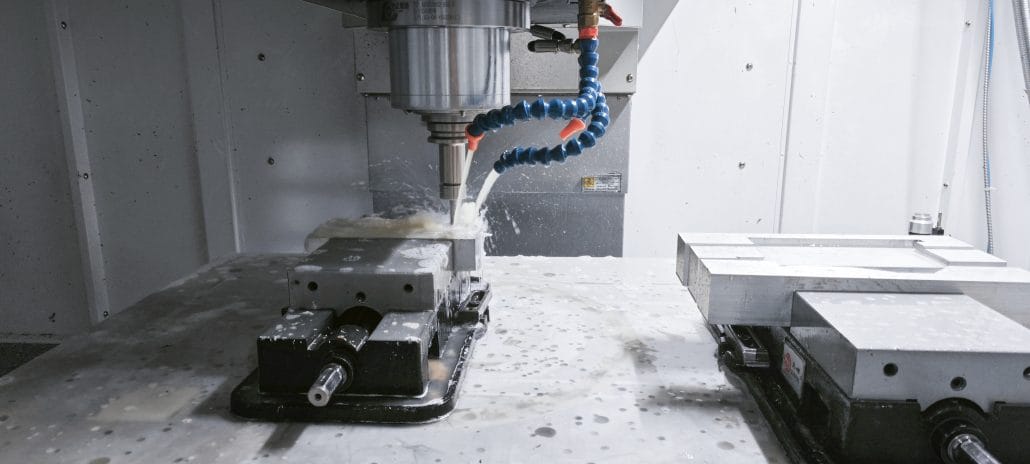

parts machining, or Computer Numerical Control machining, is a process that utilizes computer software to control machine tools to produce high-quality parts with precision and accuracy. This technique is used to manufacture complex shapes, prototypes, and finished products for various industries, including aerospace, automotive, medical devices, and more.

The benefits of CNC machining include:

- High accuracy and precision

- Quick turnaround time

- Ability to produce complex shapes and parts

- Consistency in quality and performance

- Reduced labor costs and increased productivity

Vacuum Forming

Vacuum forming is a manufacturing process that uses heat and vacuum to form a sheet of plastic into a 3D shape. This technique is commonly used to produce plastic parts, packaging, and custom products for various industries, including retail, signage, and automotive.

The benefits of vacuum forming include:

- Cost-effective manufacturing

- Quick turnaround time

- Ability to produce large and small parts

- Flexibility in design and customization

- Reduced tooling costs

Applications and Integration

The combination of CNC machining and vacuum forming can provide an efficient and cost-effective solution for manufacturing complex parts and products. By utilizing CNC milling machining to produce molds and tooling, businesses can create customized vacuum-formed parts with precision and accuracy.

This integration is commonly used for producing signage, retail displays, and custom products for various industries. The ability to produce high-quality parts in a shorter amount of time provides businesses with a competitive edge in the market.

Conclusion

CNC machining and vacuum forming are two manufacturing techniques that offer a wide range of benefits and applications. By understanding the advantages of both techniques and how they can be integrated, businesses can achieve their manufacturing goals efficiently and effectively. With the increasing demand for high-quality products, CNC machining and vacuum forming will continue to play a vital role in the manufacturing industry.