This article briefly introduces some basic information about mechanical workshops, including their history, concept, composition, tools, types, advantages, influencing factors, processes, and impact on the industry, in order to better help you understand the knowledge of mechanical workshops.

History of Mechanical Workshop

- Before the Industrial Revolution in the 19th century, components were manufactured in local workshops in small cities, towns, and villages. After the Industrial Revolution, it helped many new machines enter the world, enabling manufacturers to produce clothing, ships, household goods, and tools more quickly. Soon after, factories established their own mechanical workshops.

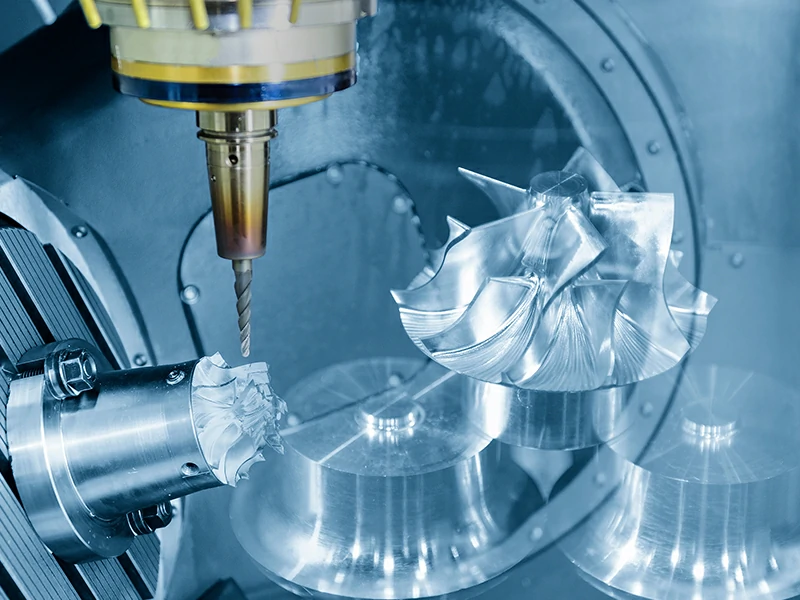

- Until the early 20th century, mechanical workshops were driven by mechanical belts driven by steam engines. Later, electric motors took the lead. With the development of electronic technology, CNC technology has been introduced into mechanical workshops, achieving automation.

- Today, electricity, computers, and robots drive our machining tools. This largely eliminates the possibility of human error. Now, machine workshops can quickly process high-quality tools and components for major manufacturers.

What is a mechanical workshop?

- The mechanical workshop or engineering workshop is the center of mechanical processing (a type of reduced material manufacturing method). Whether it’s a room, a building, or the entire company, skilled mechanics will use machine tools and cutting tools here to process parts.

- In other words, a mechanical workshop is just a place, location, building, company, or room where mechanical processing is carried out. Mechanical processing refers to cutting raw materials to convert them into the desired size and shape.

- These parts are mainly made of materials such as metal or plastic, and occasionally also made of materials such as glass or wood. The scale and form of mechanical workshops vary, ranging from small enterprises (such as processing workshops) to designated areas within factories (tool rooms or production areas), and ultimately these parts are sold to other manufacturing industries, such as the automotive industry, aviation industry, power generation industry, or shipbuilding industry.

What is the composition of a mechanical workshop?

- Milling machine

- Metal lathe

- Multi tasking machine

- Processing center

- Grinding machine

- Drilling machine

- Welding machine

- Testing equipment

Tools in the mechanical workshop

| TOOL | CONTENT |

| Cutting tools | Cutting tools include end mills, drills, and turning tools made of high-speed steel or hard alloys. These cutting tools are used for cutting, shaping, and removing materials from workpieces. |

| Manual tools | This tool includes a wrench, hammer, and screwdriver, which are essential tools for manual adjustment and assembly tasks in the workshop. |

| Measuring instruments | This includes precision tools such as calipers, micrometers, and gauges. They ensure accurate measurement of the dimensions and tolerances of the machined parts. |

| Ties and pipe tape | Because they can help you move, fix, and secure structures. Ties and duct tape are rarely used together as a small helper to ensure that your structure remains intact. |

| Electric tools | Electric tools are electric or pneumatic driven tools, such as drills and saws. It is used for various cutting and forming tasks to improve efficiency. |

| Work clamping device | This tool includes pliers, chuck, and fixture. They are used to firmly secure the workpiece during processing operations. |

| Deburring tool | Deburring tools are crucial for removing burrs and smoothing the edges after machining. They can ensure safety and improve the quality of finished parts. |

| Coolant system | This system is used to maintain the integrity of cutting tools and workpieces during the machining process. Can extend tool life and prevent material deformation. |

The type of mechanical workshop

Universal processing

- If you need traditional machining, almost any machining workshop can provide assistance. These services include production design prototypes, equipment maintenance, and even small-scale production of products.

- The tools required for general mechanical processing include ordinary lathes, shaft milling machines, and turret milling machines. You can also find horizontal boring and milling machines, as well as surface grinders and cylindrical grinders. With these tools, the mechanical workshop can manufacture prototypes and parts that meet your customization requirements.

CNC machining

- Nowadays, most of the best mechanical workshops offer CNC machining, which is much more advanced than traditional machining. CNC stands for computer numerical control, which means that all machining tasks are completed by computer tools.

- The addition of computers in the mechanical workshop has completely changed mechanical processing in many aspects:

- CNC machining has achieved a high degree of automation, and all other machining processes except for blank clamping can be completed by CNC machine tools. By combining automatic loading and unloading methods, CNC machining has become a fundamental component of unmanned factories, effectively reducing operator labor and improving working conditions. Production time can be shortened by weeks or even months.

- More precise production of parts and prototypes. In CNC machining, CAD (Computer Aided Design) is commonly used for design. Then input the design into the CNC machine’s computer, so that the machine can cut and shape raw materials according to the precise specifications specified in the design.

- Complex shapes can be perfectly crafted. Some product designs are almost impossible to manufacture using traditional machinery or handicrafts. You need a true genius to create them, and not many mechanics possess this skill. But with computers, everything has become much easier.

- You can use CNC machining to manufacture items made from different types of materials. It can be used for different metals, such as steel, aluminum, or bronze, and even for silver or gold, expanding the application range of mechanical processing.

Customized machining plant

Customized mechanical workshops are craftsmen in mechanical processing who specialize in manufacturing unique customized components to meet specific customer requirements. These workshops typically engage in unique or small-scale production, prioritizing precision and attention to complex details. Skilled mechanics in custom mechanical workshops are adjusting their processes to meet the needs of individual customers and professionals. They are highly skilled and able to flexibly handle various materials and complex designs.

Advantages of Mechanical Workshop

| ADVANTAGE | CONTENT |

| High safety | Mechanical production can significantly reduce the risks on the production site and protect production workers from harm |

| efficiency | Utilize advanced machinery and technology to simplify production processes and shorten delivery times |

| customized | Customize products according to specific requirements to meet unique design and functional requirements |

| high-precision | Mechanical production can ensure that each product has the same size and quality standards. The products produced are more precise, reducing errors in the manufacturing process |

| costing | By implementing detailed management, such as energy savings in lighting, air conditioning, computers, and the rational use of electricity in production machinery, energy costs can be significantly reduced |

The influencing factors of choosing a mechanical workshop

- Work quality: Gain a deep understanding of the factory’s ability to produce parts that meet your specifications. View their performance records, certifications, and how they handle quality control.

- History and work experience: You won’t really want to choose a newly established mechanical workshop unless it has years of experience since its establishment. What you need are people who have been in the industry for many years, so you can be sure they know what you are doing. Experienced mechanics are more likely to complete projects on time and within budget because they know effective processes

- Turnaround time: Time is money, especially in fast-paced industries. Check if the store can deliver quickly within the project deadline

- Technical capability and equipment: Ensure that the workshop is equipped with the correct tools required for the project, from CNC machine tools to precision instruments.

- Customer service and communication: Good communication and customer service are key to a smooth work relationship. Confirm that the store responds quickly and is willing to work closely with you

- Cost effectiveness: While cost is not the only determining factor, it is crucial to ensure that their services are competitively priced and bring true value to your investment

- Additional services: Understand if the store provides additional services, such as finishing work, assembly assistance, or design assistance – these additional small services may make a significant difference

Mechanical processing technology

Mechanical processing is the process of removing materials from workpieces to manufacture precision objects or parts. The following is the main process of a mechanic cutting and subtracting materials in a mechanical workshop.

| TECHNOIOGY | CONTENT |

| Turning | Turning is a machining process that uses rotating workpieces as the main method of making contact between metal and cutting tools. Lathe is the main machine tool for turning machining |

| Milling | Milling uses a rotating cutting tool to press the cutting edge onto the workpiece. This is the most widely used tool and technology in the machining workshop |

| Drilling | Drill holes using rotating tools to create new holes or improve existing holes. Drilling is most commonly done using a drilling machine, but sometimes drilling tools are connected to compatible lathes or milling machines for drilling |

| Reaming | Reaming is a process that uses rotating cutting tools to smooth existing holes on a workpiece. This is a cutting process for removing materials, with the main purpose of making the hole wall flat |

| Surface Treatment | Surface treatment of finished products, such as chrome plating, galvanizing, spraying, etc., to improve their corrosion resistance and appearance quality |

The impact of mechanical processing on the industry

| INDUSTY | EFFECT |

| car | In the world of automobiles, the mechanical workshop is an unknown hero. They can improve assembly efficiency, reduce human errors, ensure standardization of automotive quality, and also remotely control the stamping workshop to reduce safety accidents and protect the safety of operators |

| Medical equipment | The medical field cannot do without mechanical processing workshops. They have made significant contributions to the production of medical equipment and devices, with precision machining at its core. They ensure high standards of construction in medical device workshops, maintain a dust-free and sterile environment, and prevent microbial contamination |

| aviation industry | Aerospace engineering requires perfection, and mechanical workshops are the craftsmen who ensure perfection. Mechanical processing can improve the efficiency and quality of mechanical assembly, such as the automation of complex processes such as aircraft body assembly |

| Power generation industry | Realize comprehensive automation supervision, management, and control of the power generation process to ensure efficient operation of the power plant. Real time dynamic monitoring of the operating status of mechanical equipment, feedback on abnormal states, and improvement of comprehensive automation efficiency in power plants |

Why choose Longsheng?

Because Longsheng has a good mechanical workshop, our manufacturing factory is equipped with advanced production lines that can handle various materials, including metal, plastic, and composite materials. In CNC machining, we have advanced 4-axis and 5-axis CNC machining centers. Our precision CNC machining provides rapid prototyping, small batch processing, and large-scale production. In addition to CNC machining, we also offer injection molding, sheet metal processing, 3D printing, post-processing, and more. We sincerely invite you to our official website to learn about the services you want. With over 15 years of manufacturing experience, we always adhere to the pursuit of excellent quality and provide you with impeccable results.

conclusion

You will find that the mechanical workshop is not only a warehouse for storing equipment, but also a place close to life. It can be used in medical equipment, automotive industry, aviation industry, and other places, bringing convenience to people’s lives. It also has an irreplaceable position and role in modern manufacturing industry. If you are looking for a trustworthy mechanical workshop, Longsheng is the ideal choice for your manufacturing project. As a reliable and skilled supplier of rapid prototyping and production services, we can provide high-quality, high-precision, and reasonably priced products for machined parts, regardless of the quantity.

FAQs

What types of materials are commonly used in mechanical workshops?

Mechanical workshops usually use materials such as metal and plastic. However, they can also process other materials such as glass or wood according to specific requirements.

What does a mechanic do?

Mechanists use tools such as lathes, milling machines, and grinders to produce parts, instruments, and tools. Mechanists work in mechanical workshops, using blueprints, sketches, or computer-aided design (CAD) to create precise objects for machines and mechanical objects.

Is it difficult to become a mechanic?

Becoming a mechanic poses certain challenges, but the level of difficulty depends on various factors, including personal interests, background, learning attitude, and level of effort. You need to master certain knowledge of mathematics, physics, and mechanical engineering, and apply these knowledge to practice. You also need to have rich practical experience, participate more in practical projects, and have certain skills and qualities. You need to persevere and continuously make efforts.

What is mixed processing?

Mixed processing combines additive processing and subtractive processing techniques. This process completes two or more processing processes with different mechanisms on the same equipment. This can reduce material costs and the time spent on individual projects. The disadvantages of mixed processing are high setup costs and the need for significant investment in installing new technologies in the machining workshop.

Resource

Design-to-fabrication automation for the cognitive machine shop