What is Precision Metal Stamping?

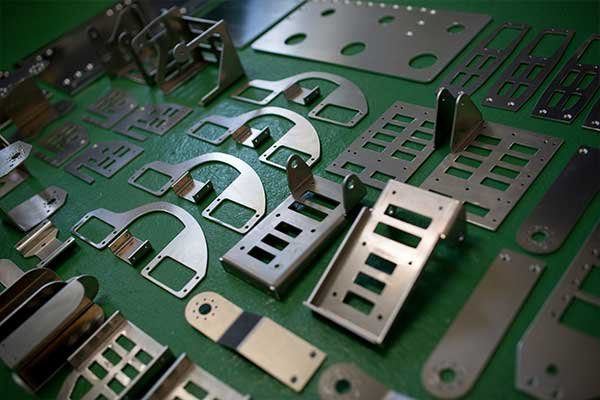

Precision metal stamping is a manufacturing process that involves the use of a stamping press to create parts from sheet metal. The process is called “precision” because it allows for high levels of accuracy and repeatability, making it an ideal solution for creating complex or intricate parts.

In precision metal stamping, a sheet of metal is inserted into a stamping press, which then uses a tool and die set to shape the metal into the desired part. The tool and die set is made up of a punch, which applies pressure to the metal, and a die, which holds the metal in place and shapes it.

One of the biggest advantages of precision metal stamping is that it allows for the creation of parts with a high degree of consistency. Because the process is automated, it is possible to create large quantities of parts that are virtually identical. This consistency is particularly important in industries such as aerospace, automotive, and medical, where precision and quality are paramount.

Another advantage of precision metal stamping is that it is a cost-effective manufacturing process. Because the process is automated, it is possible to produce parts quickly and efficiently, which can result in significant cost savings. Additionally, because the process is highly accurate, there is less waste, which further reduces costs.

Precision metal stamping is used to create a wide range of parts, from small components such as connectors and brackets, to larger parts such as automotive body panels. The process can be used with a variety of metals, including steel, aluminum, and copper, and can be used to create parts with a range of thicknesses and shapes.

In conclusion, precision metal stamping is an important manufacturing process that allows for the creation of high-quality, consistent parts. Its accuracy, efficiency, and cost-effectiveness make it an ideal solution for a wide range of industries and applications.

6 Types of Metal Stamping Processes

Metal stamping is a process that is used to create intricate patterns or designs onto metal sheets. It is a popular manufacturing technique that is used in a wide range of industries, including automotive, aerospace, and electronics. There are six main types of metal stamping process. Let’s take a closer look at each of them.

- Blanking: Blankings are the basic components of metal stamping. They are flat metal sheets that are cut or punched into a specific shape. The process of blanking involves creating a die, which is a tool that is used to punch the metal sheet into a specific shape.

- Piercing: Piercing is a process that is used to create holes in metal sheets. The process involves creating a die that has a sharp edge. The die is then used to punch a hole into the metal sheet.

- Bending: Bending is a process that is used to create curved or angled shapes in metal sheets. The process involves using a die that has a specific shape to bend the metal sheet into the desired shape.

- Drawing: Drawing is a process that is used to create complex shapes in metal sheets. The process involves using a die that has a specific shape to stretch the metal sheet into the desired shape.

- Forming: Forming is a process that is used to create three-dimensional shapes in metal sheets. The process involves using a die that has a specific shape to press the metal sheet into the desired shape.

- Coining: Coining is a process that is used to create intricate patterns or designs on metal sheets. The process involves using a die that has a specific shape to stamp the metal sheet into the desired shape.

In conclusion, metal stamping is a versatile manufacturing technique that is used to create a wide range of products. There are six main types of metal stamping processes, including blanking, piercing, bending, drawing, forming, and coining. Each of these processes has its own unique advantages and disadvantages, and the choice of process depends on the specific application. If you are interested in learning more about metal stamping, please sign up for our newsletter to receive the latest updates and insights on this fascinating topic!

Select Metal Stamping Materials to Consider

Metal stamping is a process that involves using a machine to cut and shape metal into different forms. This process can be used to create a variety of products, from car parts to jewelry. However, choosing the right material for metal stamping is essential to ensure the final product is strong, durable, and aesthetically pleasing. Here are some factors to consider when selecting the best metal stamping material.

Strength and Durability

One of the most important factors to consider when choosing a metal stamping material is its strength and durability. This is especially important if the final product will be used in a high-stress environment, such as in the automotive or aerospace industries. Metals such as stainless steel, aluminum, and titanium are known for their strength and durability, making them great choices for metal stamping.

Corrosion Resistance

Another important factor to consider when choosing a metal stamping material is its resistance to corrosion. Metals that are exposed to moisture, chemicals, or other corrosive substances can quickly deteriorate, leading to the failure of the final product. Stainless steel is an excellent choice for metal stamping as it is highly resistant to corrosion, making it ideal for use in harsh environments.

Aesthetics

In addition to strength and durability, the final appearance of the metal stamping product is also important. If the product will be visible to customers, it is important to choose a material that looks attractive and professional. Metals such as brass and copper are great choices for decorative metal stamping as they are highly malleable and can be easily shaped into intricate designs.

In conclusion, choosing the right material for metal stamping is essential to ensure the final product is strong, durable, and aesthetically pleasing. Stainless steel, aluminum, titanium, brass, and copper are all great choices for metal stamping, depending on the specific needs of the project. If you need metal stamping services, be sure to choose a company that has experience working with a variety of materials and can help you select the best one for your project.

Metal Stamping: The Pros and Cons

Are you in need of metal parts for your business or DIY project? If you are, then you might want to consider metal stamping. This process is becoming more popular nowadays because of its advantages. However, like any other manufacturing process, it also has its disadvantages. In this article, we will discuss the pros and cons of metal stamping to help you decide if it’s the right option for you.

The Advantages of Metal Stamping

- High Efficiency – Metal stamping is a quick and efficient process. It allows you to produce a large number of parts in a short amount of time. This is perfect for those who need to meet tight deadlines.

- Consistent Quality – Metal stamping machines are designed to produce consistent parts every time. This means that you don’t have to worry about variations in the finished product.

- Cost-effective – Metal stamping is a cost-effective process because it can produce a large number of parts in a short amount of time. This means that you will be able to save money on labor costs and material costs.

- Versatility – Metal stamping can produce parts in various sizes, shapes, and thicknesses. This means that you can create parts that are tailored to your specific needs.

The Disadvantages of Metal Stamping

- High Initial Cost – The initial investment for metal stamping equipment can be high. This means that it may not be the best option for those who only need a small number of parts.

- Limited Design Flexibility – Metal stamping machines are designed to produce parts with simple designs. This means that you may not be able to create complex parts with this process.

- Lead Time – Metal stamping may take longer than other manufacturing processes. This means that you may need to wait longer to receive your finished parts.

In conclusion, metal stamping has its advantages and disadvantages. However, if you need a large number of parts in a short amount of time and at a cost-effective price, then metal stamping may be the right choice for you. At [Company Name], we offer top-quality metal stamping services that are perfect for your business or DIY project. Contact us today to learn more!

The Future of Metal Stamping: Why You Need Our Service

Metal stamping has been around for centuries, but as technology advances, so does the future of metal stamping. In the past, metal stamping was a manual process where workers would use a hammer and chisel to create intricate designs on metal sheets. However, with the invention of machines and computer software, metal stamping has become more precise and efficient.

So, what does the future hold for metal stamping? Well, the possibilities are endless. With the advancement of 3D printing, metal stamping can now create complex designs that were once impossible to produce. And with the use of robotics, metal stamping can be done with even greater precision and speed.

But why should you choose our metal stamping service over others? Well, for starters, we have over 30 years of experience in the industry. Our team of experts knows the ins and outs of metal stamping and can provide you with the highest quality products. Plus, we have state-of-the-art equipment and software that allows us to create even the most intricate designs with ease.

But we don’t just offer high-quality products. We also offer exceptional customer service. We know that every project is unique, and we work closely with our clients to ensure that their needs are met. We are dedicated to providing our clients with the best possible experience, from start to finish.

And let’s not forget about the cost. We offer competitive pricing without sacrificing quality. We understand that budgets are tight, but that doesn’t mean you have to sacrifice quality for affordability. With our metal stamping service, you can have both.

In conclusion, the future of metal stamping is bright, and our service is here to help you make the most of it. With our experience, expertise, and dedication to quality, you can trust us to provide you with the best possible products and service. So why wait? Contact us today to get started on your next metal stamping project.

Frequently Asked Questions About Metal Stamping

Do you have questions about metal stamping? Don’t worry, you’re not alone. We’ve compiled a list of frequently asked questions to help you better understand this process and how it can benefit you.

What is metal stamping?

Metal stamping is a manufacturing process where a metal sheet is transformed into a desired shape or form using a stamping die. The die is made up of two parts, the punch and the matrix, which work together to cut or shape the metal. This process is used to create a wide range of products, from small parts to large components.

What materials can be used for metal stamping?

Metal stamping can be done on a variety of materials, including aluminum, brass, copper, stainless steel, and carbon steel. The type of material used will depend on the desired outcome and the specific requirements of the project.

What are the benefits of metal stamping?

Metal stamping offers several benefits, including high precision, repeatability, and cost-effectiveness. It also allows for the creation of complex shapes and designs that would be difficult or impossible to achieve using other methods.

Can metal stamping be customized?

Yes, metal stamping can be customized to meet the specific needs of your project. Our team of experts will work with you to understand your requirements and design a custom stamping die that will produce the desired results.

How long does the metal stamping process take?

The length of time required for metal stamping will depend on the complexity of the project and the size of the production run. Our team will work with you to provide an accurate timeline for your project, so you can plan accordingly.

How can I get started with metal stamping?

Getting started with metal stamping is easy. Simply contact us to discuss your project and get a quote. Our team of experts will work with you to design a custom stamping die and produce the parts you need.

In conclusion, metal stamping is a powerful manufacturing process that can be used to create a wide range of products. If you have any questions or would like to learn more about how metal stamping can benefit your project, don’t hesitate to contact us. We’re here to help!