In the manufacturing industry, sheet metal fabrication plays a vital role. Because it is widely used in a variety of industries, such as automotive, electronics, construction, etc., it is very important to understand the basic concepts of sheet metal working.

Sheet metal fabrication is a process that involves cutting, bending, and shaping thin sheets of metal to create a wide range of products. This manufacturing process is used across various industries, including construction, automotive, aerospace, and electronics. Sheet metal is a versatile material, and this process can transform it into anything from automotive parts to electronic enclosures.

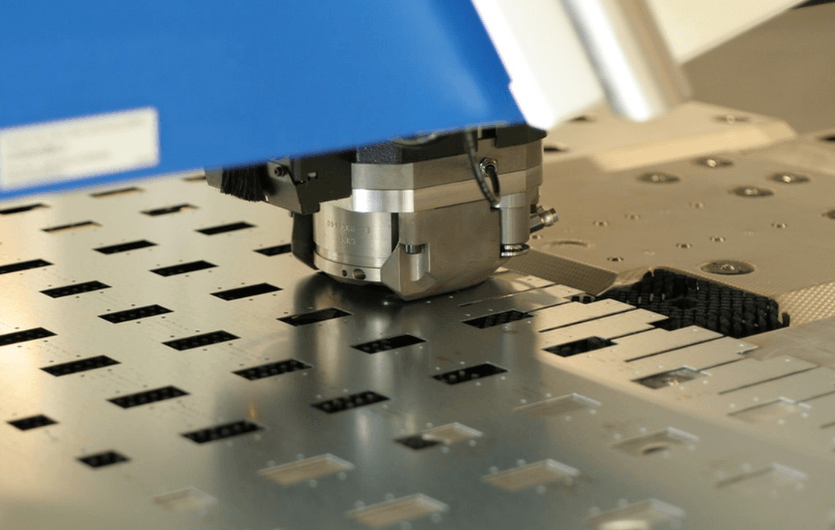

Traditional sheet metal fabrication usually uses hand tools and equipment. However, modern machining technology has achieved the efficiency and precision of automated and online CNC machining. These technologies have made sheet metal fabrication faster and more convenient, thus occupying an important position in the manufacturing industry.

Sheet metal fabrication can produce a variety of different shapes and sizes. These products include car and motorcycle casings, building materials and furniture. In addition, sheet metal fabrication can also manufacture metal parts for electronic products, equipment and instruments.

The Process of Sheet Metal Fabrication

The sheet metal fabrication process involves several steps:

1. Design

The first step in sheet metal fabrication is designing the product. This involves creating a blueprint or a 3D model of the product using computer-aided design (CAD) software. The design process is crucial because it determines the final product’s functionality and appearance.

2. Cutting

Once the design is finalized, the sheet metal is cut to the required size and shape using specialized cutting tools such as lasers, plasma cutters, or water jets. The choice of cutting tool depends on the thickness and type of metal being used.

3. Bending

The next step is bending the sheet metal to the desired shape. This is done using press brakes, which apply force to the metal, creating the desired angle or curve. The precision of the bends is crucial, and specialized tools are used to ensure that the angles are accurate.

4. Welding

If necessary, the sheet metal components are welded together using techniques such as TIG or MIG welding. Welding is essential because it creates a strong and durable bond between the metal sheets. The welding process requires skilled labor and specialized equipment.

5. Finishing

Finally, the sheet metal product is finished by sanding, polishing, or painting it. The finishing process is essential because it improves the product’s appearance and protects it from rust and corrosion.

Benefits of Sheet Metal Fabrication

Sheet metal fabrication offers several benefits, including:

Versatility

Sheet metal can be cut and shaped into a variety of shapes and sizes, making it ideal for a wide range of products. The versatility of sheet metal allows manufacturers to create products that meet specific requirements.

Durability

Sheet metal is strong and durable, making it ideal for products that need to withstand wear and tear. The durability of sheet metal ensures that products last longer, reducing the need for frequent replacements.

Cost-effectiveness

Sheet metal fabrication is a cost-effective manufacturing process, as it does not require expensive molds or tooling. The process of sheet metal fabrication is also highly efficient, reducing production time and labor costs.

Customization Sheet Metal Fabrication

Sheet metal fabrication allows for customization, as products can be designed to meet specific requirements. Manufacturers can create products that meet unique specifications, ensuring that they meet their customers’ needs.

Conclusion

Sheet metal fabrication is a crucial process in modern manufacturing. It offers numerous benefits and is used across a wide range of industries. By understanding the process of sheet metal fabrication, you can make informed decisions about your manufacturing needs. Whether you need a prototype or a large-scale production run, sheet metal fabrication is a reliable and efficient manufacturing process.