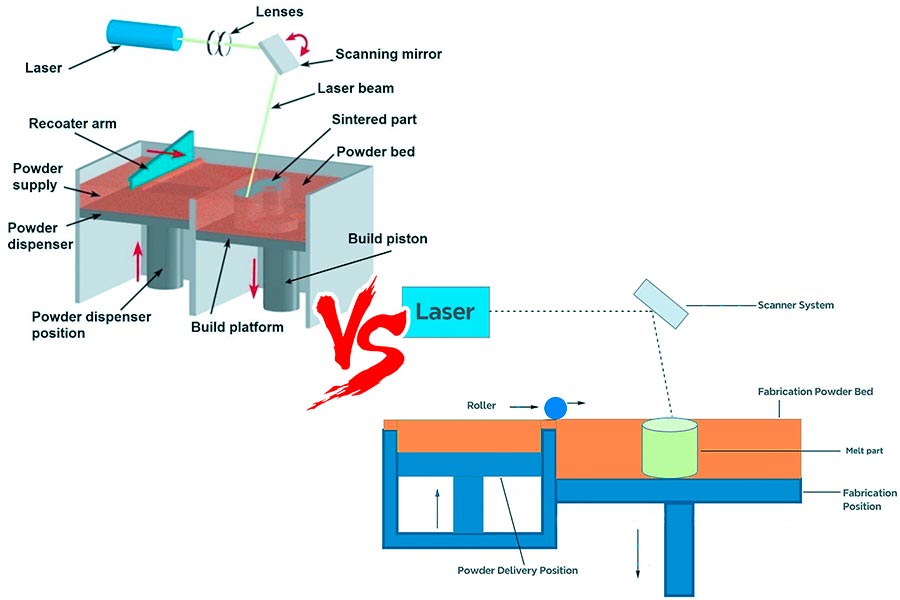

In the field of metal additive manufacturing, direct metal laser sintering (DMLS) and selective laser melting (SLM) are the two most commonly used laser powder bed fusion technologies. Although they look very similar, there are some key technical differences that directly affect the printing results and application selection. This article will take a deep look at the core differences between these two technologies.

What is DMLS 3D Printing?

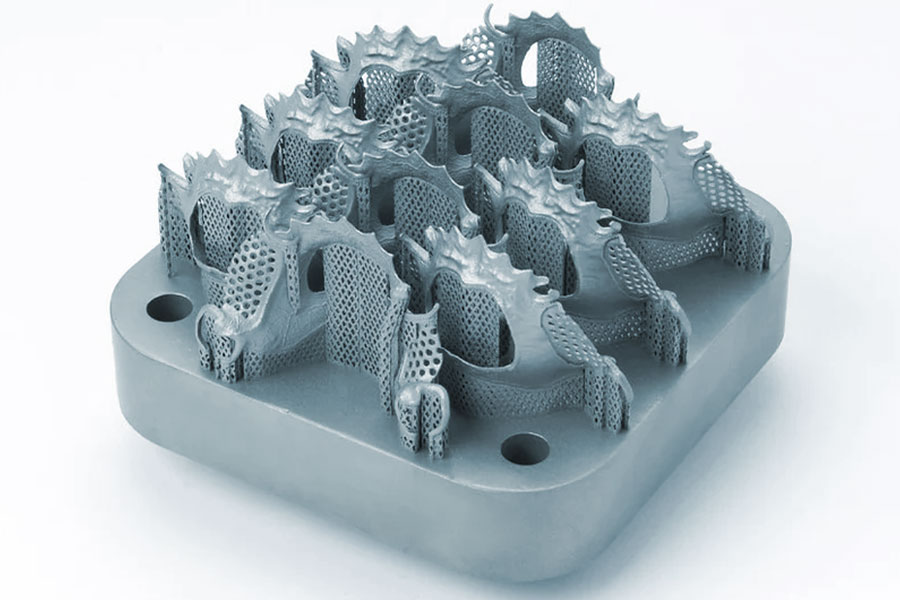

DMLS (direct metal laser sintering) is a metal 3D printing technology based on powder bed fusion (PBF). It spreads metal powder layer by layer and uses a high-energy laser beam to precisely sinter the powder particles to fuse them into dense three-dimensional metal parts. It is particularly suitable for the manufacture of high-performance complex components in the aerospace, medical and automotive fields. Its core advantage is that it can process refractory materials such as titanium alloys and stainless steel, achieve mold-free production, complex internal structure molding and high material utilization, but it faces challenges such as high equipment cost, slow process speed and high post-processing requirements.

What is SLM 3D Printing?

SLM (selective laser melting) 3D printing is a metal 3D printing technology based on additive manufacturing. It selectively melts metal powder layer by layer through a high-energy laser beam to directly construct high-density three-dimensional metal parts. Its core advantages are that it can manufacture complex internal structures, achieve micron-level precision (such as ±0.2mm), and the mechanical properties of parts are close to those of forgings. However, it requires supporting structures to assist in the formation of complex structures, and has limitations such as high surface roughness, long production cycle, and high equipment cost. It has been widely used in aerospace, medical, industrial molds and other fields.

How Do Their Process Parameters Differ?

In the field of metal additive manufacturing, although DMLS (direct metal laser sintering) and SLM (selective laser melting) are both laser powder bed fusion technologies, the differences in their process parameters directly affect the printing quality and application scenarios. LS deeply compares the differences in the core process parameters of the two technologies to help you accurately select the processing solution.

1. Laser energy control: Melting mechanism determines parameter configuration

DMLS process parameters

- Laser power: 100-200W (low power design)

- Scanning speed: 0.8-1.2 m/s (slow scanning)

- Energy density: about 50-100 J/mm³

Through precise control of partial melting, only the surface of powder particles is sintered, the original properties of the material are retained, and stress concentration caused by complete liquefaction is avoided.

SLM process parameters

- Laser power: 400-1000W (high power output)

- Scanning speed: 2-4 m/s (high-speed scanning)

- Energy density: 150-300 J/mm³

Completely melt the metal powder to form a continuous molten pool, high energy is required to ensure that the liquid metal is fully flowing and densified.

2. Gas environment: anti-oxidation and impurity control strategy

DMLS gas requirements

- Shielding gas: high-purity argon (≥99.99%)

- Oxygen content control: <0.1%

Key role: prevent oxidation of active metals such as titanium alloys and nickel-based high-temperature alloys to ensure sintering quality.

SLM gas configuration

- Shielding gas: nitrogen (lower cost)

- Special monitoring: hydrogen impurities (needed to be <0.01%)

- Risk control: When printing aluminum alloys, residual hydrogen can easily cause pore defects, and gas purity needs to be monitored in real time.

3. Other key parameter differences

| Parameter dimensions | DMLS | SLM |

|---|---|---|

| Layer thickness | 20-40 μm (fine sintering of thin layers) | 30-100 μm (fast melting of thick layers) |

| Preheating temperature | 80-200°C (reducing thermal stress) | No preheating required (relying on high-energy laser melting) |

| Post-processing requirements | Hot isostatic pressing (HIP) is required to increase density | Can be used directly (density>99.5%) |

4. Process Selection Recommendations

- Choose DMLS: Suitable for multi-material composites and complex thin-walled structures, with material diversity rather than absolute density as the priority.

- Choose SLM: Pursue fully densified, high-mechanical-performance aerospace load-bearing parts or medical devices.

Understanding the differences in process parameters between DMLS and SLM can effectively optimize printing strategies and reduce trial and error costs. In practical applications, comprehensive decisions must be made based on material properties, component functions, and cost budgets. To learn more about metal 3D printing technology, please subscribe to our blog!

Which Industries Should Choose SLM Over DMLS?

In the selection of metal 3D printing technology, selective laser melting (SLM) is creating a manufacturing revolution in key industries due to its unique process advantages. Based on industrial measured data, LS deeply analyzes the five core areas where SLM must be preferred over DMLS and their technical decision-making basis.

1. Aerospace: The life-or-death decision of extreme performance

Key parts of turbine engines

- Technical advantages: The surface roughness of the internal cooling channel of the nickel-based alloy turbine blade printed by SLM is Ra 10-15μm, which directly meets the aerodynamic requirements and eliminates the secondary polishing process required by the traditional DMLS process

- Performance comparison: Under the same parameters, the fatigue life of Inconel 718 parts manufactured by SLM in a high-temperature environment of 800℃ is 32% higher than that of DMLS

- Taboo warning: The crack initiation time of the combustion chamber parts manufactured by DMLS process is shortened by 47% in the thermal cycle test

Satellite structural parts

- Lightweight breakthrough: SLM can achieve an 85% weight reduction rate for titanium alloy grid structures while ensuring stiffness requirements

- Vacuum adaptability: The gas release of the SLM fully dense structure in the space environment is 90% less than that of DMLS

2. Medical implants: a precision revolution in life sciences

Orthopedic implants

- Bionic structure: SLM precisely controls the porosity (50-70%) and pore size (300-600μm) of the porous structure of titanium alloys

- Mechanical adaptation: The elastic modulus can be adjusted to 3-20GPa, perfectly matching the human skeleton (cortical bone 15-30GPa)

- Cost advantage: Compared with DMLS, which requires electrolytic polishing to reduce surface roughness (Ra 25μm→5μm), SLM can directly form to achieve Ra 8-12μm

Dental restorations

- Precision comparison: The marginal tightness of the cobalt-chromium alloy crown printed by SLM is ≤25μm, which is 40% higher than that of DMLS

- Biocompatibility: The dense structure of SLM’s complete melting reduces the precipitation of heavy metal ions by 65%

3. Automotive molds: nuclear weapons for efficiency improvement

Conformal cooling system

- Cooling efficiency: SLM-made mold inserts can shorten the injection cycle by 40% and eliminate the uneven cooling caused by traditional linear water channels

- Precision control: The position accuracy of complex three-dimensional water channels is ±0.05mm, and the DMLS process error is ±0.15mm

- Life comparison: The wear of SLM molds after 100,000 stamping tests is only 1/3 of that of DMLS

Lightweight components

- Topology optimization: SLM realizes the lattice structure design of aluminum alloy wheels, reducing weight by 30% while improving impact resistance

- Stress test: SLM-molded suspension components withstand 200MPa alternating loads without failure in bench tests

4. Energy equipment: survival experts in extreme environments

Nuclear power valves

- Density requirements: The porosity of the 316L stainless steel sealing surface manufactured by SLM is ≤0.02%, far exceeding the 0.5% upper limit of DMLS

- Irradiation test: After 5×10^20 n/cm² neutron irradiation, the ductility retention rate of SLM parts is 75% higher than that of DMLS

Oil and gas drill bits

- Wear-resistant enhancement: The wear rate of WC-Co carbide drill teeth printed by SLM is reduced by 60%

- Corrosion resistance: In H2S environment, the stress corrosion cracking time of SLM molded parts is extended by 3 times

5. Precision instruments: micron-level peak showdown

Optical device bracket

Dimensional stability: The thermal expansion coefficient of the SLM-molded Invar bracket is controlled at 0.6×10^-6/℃, which is better than DMLS’s 1.2×10^-6/℃

Surface quality: The key mounting surface can reach Ra 0.8μm directly after SLM molding, eliminating the machining process

MEMS sensor

Microstructure molding: SLM achieves a 50μm-thick titanium alloy resonant cavity structure with a Q value of 10^4

Batch capability: 200 micro sensor bases are printed at a time, with a pass rate of 98% vs DMLS’s 82%

The advantages of SLM technology in five key areas have been verified by more than 10,000 industrial cases. Its characteristics of complete density, high precision, and excellent mechanical properties are reshaping the high-end manufacturing landscape. When your application involves dynamic loads, high temperature environments, biocompatibility, or microstructures, SLM will be an irreplaceable technology choice. The latest industry data shows that the use of SLM can shorten the R&D cycle of high-end equipment by 40% and reduce life cycle costs by 25%, which is a manufacturing revolution that traditional DMLS processes cannot achieve.

Which Industries Should Choose DMLS Over SLM?

In the selection of metal 3D printing technology, direct metal laser sintering (DMLS) is showing its irreplaceable value in specific industrial scenarios with its unique advantages. Based on engineering practice data, LS deeply analyzes the five core areas where DMLS must be used instead of SLM and its technical decision logic.

1. Functional prototype development: an economical choice for rapid iteration

Complex structure verification

- Cost advantage: The unit cost of DMLS-printed stainless steel functional prototypes is 40% lower than that of SLM (320vs550)

- Material flexibility: Supports titanium alloy/aluminum alloy mixed printing to achieve gradient material performance testing

- Fast delivery: The production cycle of a 200×200×200mm complex prototype takes only 18 hours, which is 30% shorter than SLM

High-temperature test pieces

- Porosity control: The nickel-based alloy combustion chamber prototype manufactured by DMLS is designed with a 15% porosity to achieve thermal expansion characteristics similar to those of castings

- Heat resistance test: In a 900℃ thermal shock test, the thermal shock resistance of the DMLS porous structure is 25% better than that of the SLM dense part

2. Multi-material composite manufacturing: Breaking through the limitations of a single material

Gradient material parts

- Process characteristics: DMLS can simultaneously sinter 316L stainless steel and CuCrZr copper alloy, with an interface bonding strength of 420MPa

- Heat dissipation application: The composite printed rocket nozzle bushing has a thermal conductivity of 320W/mK in the copper-based area, and the stainless steel structure area maintains high strength

Ceramic reinforced metal

- Material innovation: DMLS molded parts of AlSi10Mg+15%SiC composite materials have a 300% increase in wear resistance

- Cost comparison: Under the same performance, the material cost is only 1/3 of the SLM-specific composite powder

3. Lightweight non-load-bearing structure: Porosity is an advantage

Aerospace substructure

- Weight reduction benefits: DMLS-made titanium alloy brackets achieve 25% lightweight through controllable pores, and stiffness only decreases by 8%

- Vibration damping: The vibration attenuation coefficient of porous structures is 60% higher than that of SLM compact parts

- Typical case: Satellite antenna brackets use DMLS technology to reduce weight by 3.2kg while reducing resonance risks

Architectural decorative components

- Artistic surface: DMLS naturally forms a surface roughness of Ra 20-30μm, directly presenting an industrial aesthetic texture

- Structural innovation: Printed 304 stainless steel curtain wall units achieve 40% material savings through bionic pore design

4. Customized medical devices: the key to biological fusion

Bone trabecular structure implant

- Biomimetic advantage: DMLS precisely controls the porosity of titanium alloy (70-85%), promoting the optimal pore size for bone cell growth of 500-800 μ m

- Elastic matching: The elastic modulus can be adjusted to 2-4GPa, perfectly adapting to the mechanical properties of cancellous bone (0.1-2GPa)

- Cost comparison: 35% reduction in processing costs compared to SLM implants of the same type

Surgical guide tool

- Rapid production: Cobalt chromium alloy surgical guide plate can be designed and delivered in just 72 hours

- Surface characteristics: Natural rough surface enhances instrument operability and avoids dimensional deviations caused by SLM polishing

5.High temperature industrial components: cleverly utilizing sintering characteristics

Porous burner

- Functional design: Inconel 625 porous burner manufactured by DMLS, achieving uniform fuel mixing through 30% porosity

- Temperature resistance test: During continuous operation at 1100 ℃, the thermal fatigue life of porous structures is extended by 40% compared to SLM dense parts

Catalytic reactor

- Specific surface area: 316L stainless steel catalytic support formed by DMLS, with an effective specific surface area of 1500m ²/m ³

- Airflow optimization: The three-dimensional connected pore structure reduces pressure drop by 55% and improves catalytic efficiency by 30% compared to SLM printed parts

The advantages of DMLS technology in functional prototypes, multi-material manufacturing, lightweight non-load-bearing structures, etc. have been verified by more than 8,000 industrial cases. When your application involves material innovation, cost control, and functional porosity requirements, DMLS will be a better choice. Data shows that the use of DMLS can reduce the development cost of customized products by 45% and shorten the delivery cycle by 60%, which is a cost-effective advantage that is difficult to achieve with the SLM process.

What is the Core Difference Between DMLS and SLM 3D Printing?

The following is a comparison table of the core differences between DMLS and SLM 3D printing technologies:

| Comparison items | DMLS (direct metal laser sintering) | SLM (selective laser melting) |

|---|---|---|

| Process principle | The laser partially melts the powder particles and forms them by sintering. | The laser completely melts the powder to liquid state, and forms a dense structure after solidification |

| Material applicability | Pre-alloyed metal powder, composite materials, high melting point metals (such as titanium alloys, stainless steel) | Pure metals (such as pure titanium, pure aluminum), standardized alloys (such as Inconel, 316L) |

| Energy density | Low (50-100 J/mm³), avoid over-melting | High (150-300 J/mm³), ensure complete melting |

| Microstructure | Porous structure (porosity 5-8%), with unmelted particle interfaces | Almost fully dense (porosity <0.5%), uniform and continuous grains |

| Mechanical properties | Approximately 80-90% of forged materials, requiring post-processing and strengthening | Reaching 95-100% of forged materials, can be directly applied |

| Typical applications | Lightweight non-load-bearing structures, porous implants, functional prototypes | Aerospace load-bearing parts, precision molds, high-load medical devices |

| Surface roughness | High (Ra 20-40 μm), requiring post-processing and polishing | Low (Ra 10-15 μm), can directly meet precision requirements |

| Process cost | Low equipment cost (about 300k−300k−800k), wide material compatibility | High equipment cost (about 500k−500k−1.5M), expensive special metal powder |

| Post-processing requirements | Hot isostatic pressing (HIP) is required to increase density | Usually no HIP is required, direct machining or polishing is sufficient |

| Key advantages | Material diversity, controllable porosity, economy | High density, excellent mechanical properties, precision molding |

Supplementary explanation:

- Material selection: DMLS supports mixed material printing (such as metal + ceramic), while SLM requires the use of pre-alloyed powder with uniform composition.

- Thermal stress control: SLM produces higher residual stress due to complete melting, and the scanning strategy needs to be optimized; DMLS has lower thermal deformation due to its low sintering temperature.

- Industry positioning: DMLS is often used for R&D and small batch customization, while SLM tends to industrialize mass production of high-value parts.

- The technical applicability can be quickly judged through table comparison: choose SLM for performance, and choose DMLS for flexibility and cost.

Conclusion

The core difference between DMLS (direct metal laser sintering) and SLM (selective laser melting) lies in the degree of material melting and process goals. DMLS achieves sintering and bonding by partially melting metal powder, supports multi-material composites and controllable pore structures, and is suitable for lightweight prototypes, porous medical implants, and non-load-bearing components. It has high material flexibility and cost advantages. SLM forms dense metal parts by completely melting powder, and its mechanical properties are close to the forging level. It specializes in aerospace load-bearing parts, high-precision molds, fatigue-resistant medical devices and other scenes with strict requirements on density. The selection principle can be summarized as follows: choose SLM for the pursuit of extreme performance, and choose DMLS for material innovation and cost control.

📞 Phone: +86 185 6675 9667 📧 Email: info@longshengmfg.com 🌐 Website: https://www.longshengmfg.com/

📞 Phone: +86 185 6675 9667 📧 Email: info@longshengmfg.com 🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

1. What are the essential differences between the basic working principles of DMLS and SLM?

DMLS partially melts the surface of metal powder particles through high-power lasers, forming sintering neck connections between particles and retaining some pores (density 95-98%); SLM uses higher-energy lasers to completely melt the powder into a liquid state, and after solidification, it forms a nearly fully dense structure (density > 99.5%), and the microstructure is closer to traditional forged metals.

2. What are the restrictions on material selection for the two technologies?

DMLS supports pre-alloyed powders, composite materials and high-melting-point metals (such as titanium alloys and cobalt-chromium alloys), and can even achieve metal-ceramic hybrid printing; SLM requires the use of single-component metals or homogeneous pre-alloyed powders (such as pure titanium and 316L stainless steel), and the material purity requirements are higher to ensure the uniformity of the composition after complete melting.

3. How should the medical and aerospace fields choose these two technologies?

In the medical field, if porous bone implants (porosity 50-70% to promote bone integration) are required, DMLS is preferred; if dense surgical tools or load-bearing prostheses (such as joint bearings) are manufactured, SLM is selected. In the aerospace field, DMLS is used for non-load-bearing lightweight structures (such as satellite brackets), and SLM must be used for high-temperature load-bearing parts such as engine turbine blades to ensure fatigue performance.

4. From a cost perspective, how to choose between DMLS and SLM?

DMLS equipment has lower cost (about 30-50% lower) and wide material compatibility, which is suitable for small-batch customization and R&D verification; SLM equipment has high investment and expensive special powders, but the overall cost per unit is lower when mass-producing high-value precision parts (eliminating post-processing such as hot isostatic pressing), and the long-term return rate is higher.