Among the major metal joining techniques, MIG welding (metal inert gas welding) and TIG welding (tungsten inert gas welding) are two pillars with distinctive natures. MIG welding, from its inherent merit of continuous wire feeding efficiency, is proficiency in welding medium and thick plates with high-speed performance, which is efficiency. TIG welding, from its inherent merit of precise control over the arc, is unavoidable to weld thin-walled material, high-precision joint, and join dissimilar metals.

The cost of error is high: Applying MIG welding to thin parts in the wrong way will most likely result in burn-through and distortion, while trying to apply TIG welding to thick plates for long welds will lead to low efficiency, prohibitively high costs, and even weld failure. It is therefore imperative to have a clear understanding of the fundamental differences between the two processes, including mode of operation, appropriate materials, facility of use, and economy.

This article will delve into these basic differences and discover how high-end welding machines are leveraging technological innovation to achieve the maximum potential of both processes.

A Detailed Comparison Of MIG And TIG Welding Core Concepts

| Comparison Dimensions | MIG Welding (Metal Inert/Active Gas Welding) | TIG Welding (Tungsten Inert Gas Welding) |

|---|---|---|

| Working Principle | Concurrent wire feeding as electrode + weld pool: The welding wire is automatically and continuously fed into the arc zone, acting as both filler metal (melting to supply the weld) and electrode (conductor). An inert gas (Ar/He) or an activated gas (CO₂, O₂ mixture) is used to shield the weld pool and the arc from atmospheric contamination. | Non-melting tungsten electrode: The electrode is a rod of high-melting-point tungsten. The arc is melted between the workpiece and the tungsten electrode but is not melted by the tungsten electrode. Optional filler wire: A fill-in wire can be fed into the weld pool, or no filler wire at all (self-melting). Shielding is achieved with pure inert gas (primarily Ar/He). |

| Operational Difficulty | Easy to Use (Semi-Automatic): Operation is relatively simple. The main tasks are controlling the welding gun angle, travel speed, and position. Wire feeding is automatic and can usually be operated one-handed. The learning curve is relatively gentle. | High Difficulty (Requires Two-Hand Coordination): The operation is complex and requires a high degree of skill and two-hand coordination: one hand holds the welding torch to precisely control the arc length and angle, while the other hand (if necessary) feeds the filler wire evenly and steadily. This method requires extremely high arc stability and weld pool observation and control. The learning curve is steep. |

| Applicable Materials | Steel, Aluminum, Stainless Steel (Pulse Required): Widely used for carbon steel, low-alloy steel, and stainless steel. The pulse function is often required when welding aluminum and aluminum alloys to achieve a stable arc and good penetration. It is less suitable for reactive metals such as magnesium and titanium (which require extremely high shielding) and copper alloys (which require excessive heat input). | All Metals (Aluminum, magnesium, titanium, and copper alloys are particularly preferred): The shielding effect is excellent, the heat input is controllable, and it can weld almost all metals. It is particularly adept at welding aluminum and aluminum alloys, magnesium alloys, titanium alloys, copper and copper alloys, and nickel-based alloys, which require high purity and precise thermal control. Stainless steel welds are also excellent. |

| Optimal Thickness | Medium to thick plate (≥1.5mm): Due to its high deposition efficiency and welding speed, it is particularly suitable for welding medium to thick plate. Thin plates are prone to burn-through. | Thin Plate/Precision Parts (0.5mm and up): The arc is focused and the heat is precisely controlled, making it ideal for welding thin plates, precision parts, and small components, effectively preventing burn-through. |

| Welding Speed | Fast (up to 7 m/min): Continuous wire feeding and high deposition efficiency make this a highly efficient welding method, particularly advantageous in high-volume production. Maximum speeds can reach several meters per minute. | Welding Speed: Slow (Requires Precise Arc Control): The welding speed is relatively slow. Precise control of the arc and weld pool is required, and manual wire feeding also limits speed. It is typically used where high quality is more important than efficiency. |

| Weld Bead Quality | Good (Possible Spatter): Good weld strength and density are achieved. However, spatter may occur (especially when using active gases), and the weld surface is not as smooth and aesthetically pleasing as TIG. Penetration depth is typically “mushroom-shaped.” | Excellent (No Spatter, Beautiful): The weld is highly pure, has good internal quality (few impurities, minimal porosity), and has an aesthetically pleasing, uniform, smooth appearance with no spatter. It offers excellent penetration depth (finger-shaped penetration) and a minimal heat-affected zone. It is the preferred choice for high-quality, high-standard welding. |

| Equipment Cost | Medium-low: The equipment is relatively simple, primarily consisting of a welding machine, wire feeder, welding gun, and gas cylinder/supply system. The overall investment cost is lower than TIG. | Medium-high: The equipment is generally more complex and sophisticated, with higher costs for the welding machine (especially those with high-frequency arc ignition and pulse functions), water-cooled welding gun, and foot-operated controller (for current adjustment). |

| Typical Applications | Automotive bodies, pipelines, steel structures, heavy manufacturing, shipbuilding, rail vehicles, and mass production: applications requiring high efficiency and welding of medium-to-thick plates. | Aerospace, nuclear industry, food/pharmaceutical equipment, pressure vessels, precision instruments, art decoration, pipeline root welding, and thin plate/dissimilar metal welding: applications requiring the highest quality, precise control, thin plate welding, and reactive/difficult-to-weld metals. |

Why Trust This Guide? LS Engineers’ Hands-on Experience

Over my more than 20 years of experience with welding processes, equipment stability and reliability and precise process adaptation have directly determined project success or failure. Equipment changes and parameter adjustments repeated on numerous occasions waste not just time, but also debase weld quality and consistency. I know this pain point intimately.

Things turned for the better when we created and commissioned our next-generation MIG/TIG dual-function welder. The core strength of this equipment lies in its ability to actually resolve day-to-day challenges for welders. The smart parameter memory function allows me to switch between welding steel and aluminum with a single click, without having to constantly change settings, reducing my workload by half. Its sophisticated gas flow control technology accurately reduces weld porosity and improves inherent quality. Especially in the dynamic surroundings of outdoor job sites, welder’s built-in real-time voltage fluctuation compensation technology is a stabilizing force par excellence, delivering highly stable arc output regardless of power grid fluctuations, effectively guaranteeing weld uniformity. Since adopting the LS solution wholesale, the rework rate for welds on a number of projects has fallen by over 40% on average, and this has made me see for myself that “reliability is the true essence of efficiency.” This reliability is not only achieved through our standard equipment but also through the ability to customize solutions for complex challenges. We provided them with a full TIG solution last year when they were a manufacturer of new energy vehicle battery trays. They experienced recurring thermal cracking and deformation during the welding of their aluminum shells. Our LS group conducted in-factory testing and ultimately developed a solution of a high-frequency pulsed TIG power supply to precisely regulate heat input, a high-accuracy water-cooled welding gun to offer stable performance over the long term, and an optimally innovative Ar+He gas blend. This combined solution delivered short-term benefits: heat input was reduced by 35%, weld penetration uniformity was raised to an impressive 98%, and lastly, a zero-leakage product. This project saves the customer’s rework cost over 2 million RMB annually and once again demonstrates the extensive experience of LS technology in resolving the most severe welding issues.

As an engineer who has personally participated in the design and implementation of such solutions, I am intimately familiar with the technology depth and underlying understanding of customer issues that are involved with LS. The expertise offered here, distilled from millions of actual uses, is worth your trust.

Comparison Of Core Principles And Working Methods

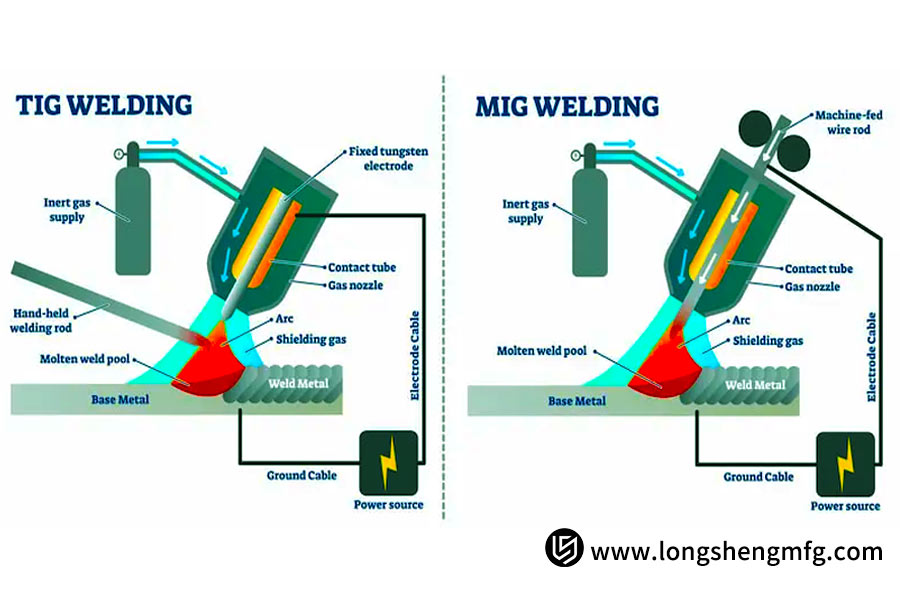

In fusion welding, the core principles and operating methods of MIG (metal inert gas welding) and TIG (tungsten inert gas welding) differ significantly.

| Comparison Items | MIG welding | TIG welding |

|---|---|---|

| Electrode | Continuously fed consumable welding wire (also serving as filler metal) | Non-consumable tungsten electrode |

| Wire Feed Method | Automatic continuous feeding by the wire feed mechanism within the welding gun | The welder holds the welding torch while manually feeding the filler wire with the other hand |

| Arc Initiation Location | Between the continuously fed welding wire (electrode) and the workpiece | Arc Initiation Location: Between the tungsten electrode (electrode) and the workpiece |

| Shielding Gas | Inert gas (Ar/He) or activated mixed gas (e.g., Ar+CO₂) | Pure inert gas (Ar, He, or Ar/He mixture) |

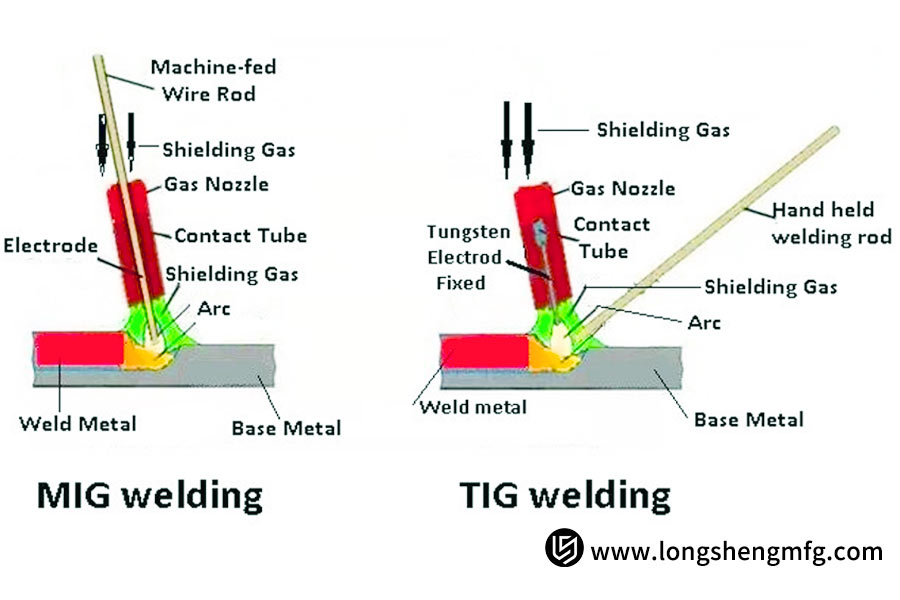

- MIG welding: The basic principle is to use a wire continuously fed as a consumable electrode, which melts into filler metal. An arc between the wire and the work to be welded and an inert or reactive mixed gas (MAG) protects the weld pool and arc area from air contamination. Its operation is highly automated, and wire feeding is continuous and stable.

- TIG welding: The basic principle is to use a high-temperature non-consumable tungsten electrode to initiate and maintain the arc, producing a molten pool between the electrode and the work. The filler wire is manually fed by the welder’s free hand into the molten pool as and when needed. The welding process is always tightly shielded by pure inert gas. Its operation relies more on welder skill and precise control of heat input.

MIG is all about the constant feeding of a wire as electrode and filler, generally with a mixture of shielding gases, and its use is fairly automated. TIG, on the other hand, relies on a non-consumable tungsten electrode to create the arc, with filler wire added manually and relying on pure inert gas shielding, requiring more operator skill. The choice between these two processes depends on specific application requirements.

Major Equipment Part Differences: MIG And TIG welding

MIG welding (metal inert gas welding) and TIG welding (tungsten inert gas welding) exhibit significant differences in their major equipment parts, which directly determine their respective process features and applicable conditions in turn.

Major Equipment Part Difference Comparison Table:

| Key Components | MIG Welding | TIG Welding |

|---|---|---|

| Power Supply Characteristics | Constant Voltage (CV) | Constant Current (CC) |

| Gun Structure | Wire Feeder (Integrated Wire Feeder + Gas Hood) | Tungsten Electrode Holder (No Wire Feeder) + Independent Wire Feeder (Optional) |

| Shielding Gas System | Commonly used: Ar + CO₂ (steel), Ar (aluminum) |

Required Inert Gas: Pure Ar or He

|

Power Supply:

- MIG welding: A constant voltage (CV) power supply is used. The output voltage remains constant, and the current varies automatically with the variation of the wire feed speed and stickout length. This provides a stable arc length and is therefore appropriate for automatic or semi-automatic wire feeding.

- TIG welding: Uses constant current (CC) power source. Output current is maintained constant (hand or foot pedal adjustable), and arc voltage is a function of arc length. This allows the welder to accurately control heat input and weld pool, is quite insensitive to changes in arc length, and is well suited to fine manual work.

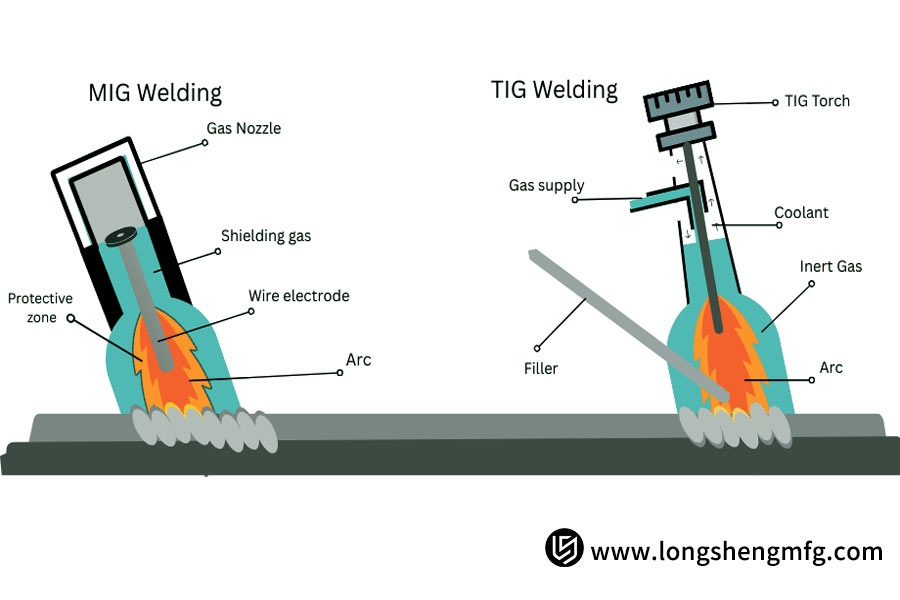

Welding torch

- MIG welding torch: A contact tip, a shielding gas nozzle, and an internal wire feed mechanism are contained in a gun that feeds the wire automatically and continuously from the gun body, through the contact tip, and into the arc zone. A gas hood channels shielding gas to cover the weld pool.

The central part of a TIG torch is the tungsten electrode holder. Its primary function is to hold and pass current to the tungsten electrode, and provide shielding gas via the nozzle. It doesn’t feed wire by nature. Filler metal (wire) is typically hand-fed by the operator in front of the weld pool (similar to gas welding) or fed via an independent wire feeder (automatic or semi-automatic).

Shielding Gas System:

- MIG welding: The choice of gas is relatively free. Ar + CO₂ mixtures (e.g., C25) are generally used to weld low-alloy steel and carbon steel; pure Ar is used everywhere to weld aluminum, magnesium, copper, and their alloys. Ternary gas mixtures (e.g., Ar+CO₂+O₂) or Ar+He are sometimes used to create some special effects.

- TIG welding: An inert shielding gas (pure Ar, pure He, or combination of Ar+He) is required. Reactive gases (e.g., CO₂ and O₂) will contaminate, oxidize, and burn the hot tungsten electrode, thereby causing arc instability. Pure Ar is employed most commonly, with He or combinations of Ar/He in processes that require increased heat input for penetration (e.g., heavy aluminum and copper).

The fundamental differences between MIG and TIG welding in power supply mode (CV vs CC), central welding torch operation (integrated wire feeding vs tungsten electrode clamping + independent wire feeding) and shielding gas requirements (flexible mixing vs strict inertness) significantly reflect the different working fundamentals and usage position of the two processes.

Operating Techniques And Learning Curve: MIG And TIG Welding

The choice of welding method directly impacts the difficulty and learning curve of operation. The following is a key comparison of MIG and TIG welding techniques and learning curves:

| Welding Method | Technique Learning | Curve |

|---|---|---|

| MIG | Easy to get started, suitable for long straight seam/fillet welding, requires control of welding gun angle and travel speed. | It is relatively gentle and easy to master. |

| TIG | Highly difficult, requiring coordination of the welding torch, filler wire, and foot pedal (current control), suitable for fine shaping welding. | It is steep and requires more practice. |

MIG welding or metal inert gas welding is convenient to use, and the continuous wire feed system makes it inexpensive to learn. It is optimally suited for making long straight welds and fillet welds. Its success is based on maintaining the torch angle and travel speed consistently.

TIG welding, or tungsten inert gas welding, requires extremely high operator skill, requiring precise hand coordination (torch and filler wire handling, respectively) and appropriate foot control (manipulating a foot pedal to modulate the welding current carefully). This independent control over the filler metal and heat source makes it unavoidable for thin sheets, complex joints, and precise welds needing very aesthetic output (“sculpting welding”). It also creates a much steeper learning curve.

Briefly, MIG welding, by virtue of its ease of operation, facilitates easy learning and rapid production, while TIG welding, despite its higher learning burden, is an indispensable process for achieving optimum weld quality and versatility. Both are the backbone of modern welding technology.

Material Suitability And Weld Quality: MIG And TIG Welding

Proper choice of welding process is crucial in assessing material compatibility and weld quality. Due to their special nature, MIG and TIG welding both have some advantages in terms of material compatibility, efficiency, and weld quality.

Comparison of Material Suitability and Weld Quality of MIG and TIG Welding

| Features | MIG Welding (GMAW) | TIG Welding (GTAW) |

|---|---|---|

| Advantageous Materials | Carbon steel, thick aluminum plates, mass-produced stainless steel parts | Thin plates (<3mm), stainless steel, aluminum, titanium, and copper alloys |

| Applicable Plate Thickness | More suitable for medium and thick plates | Particularly effective for thin plates |

| Weld Quality | High efficiency and fast deposition rate; may cause spatter and slag | Clean, slag-free welds, high aesthetics, and precise formation |

| Main Disadvantages | Requires high spatter control and is prone to burn-through in thin plates | Relatively slow welding speed, requires high operator skill, and is costly. |

MIG welding: Because of the continuous wire feeding and high deposition rate, it is of tremendous advantage in welding carbon steel, aluminum plates of considerable thickness, and stainless steel components where high-efficiency mass production is required. Though considerably higher productivity is obtained, spatter generated during welding must be controlled, and the appearance of welds is not likely to be as good as when TIG welding.

TIG welding: Utilizing a non-melting tungsten electrode and shielding with inert gases, it produces very clean, oxidation-free welds. Most ideally suited for those applications where the ultimate in weld purity and appearance is required, e.g., welding thin stainless steel sheets, aluminum, titanium, and copper alloys. With its controlled heat input, it gives very good control when welding ultra-thin materials. On the negative side, it has lower welding speeds, demands more operator skill, and tends to have higher overall costs.

Therefore, choosing MIG or TIG welding based on the material type, thickness, and specific requirements for efficiency and weld quality is the path to optimizing welding results.

Productivity And Cost-Effectiveness Analysis: MIG And TIG Welding

Productivity and cost-effectiveness are key trade-offs when choosing between MIG (metal inert gas welding) and TIG (tungsten inert gas welding).

Overview of the Productivity and Cost-Effectiveness Comparison of MIG and TIG Welding

| Analysis Dimensions | MIG Welding | TIG Welding |

|---|---|---|

| Productivity High | High-speed continuous welding, high deposition rate | Low: Slow welding speed |

| Economy – Labor | Excellent: Low labor costs (high degree of automation) | Disadvantage: High reliance on labor, high skill requirements, and high costs |

| Economy – Materials | Average: Spatter may cause some material loss | Excellent: Material savings (precise filler wire, minimal spatter) |

| Economy – Post-Processing | Average: Extensive spatter cleanup may be required | Excellent: Minimal post-processing (clean and aesthetically pleasing welds) |

| Applicable Scenarios | Mass production, medium and thick plates, long welds, high efficiency requirements | Precision welding, thin plates, dissimilar metals, high-quality appearance requirements |

Production Efficiency:

- MIG: Its most significant virtues are its continuous high-speed welding and deposition of metal at high rates. Ongoing, automatic feeding of the wire keeps the arc burn constant, so MIG is particularly well adapted to long welds and to applications where large quantities of filler metals are required. This lowers welding cycles dramatically in production in quantity, increasing overall throughput.

- TIG: The operation is non-stop (with repeated arc initiation, arc extinction, and wire addition), resulting in relatively slower welding rates. Deposition rates are also lower in the sense that the operator must manually and precisely control wire addition. It results in weld length or filler volume per unit time being considerably smaller than with MIG.

Economics – Labor Cost:

- MIG: Labor efficiency is lower. Its semi-automatic or automated mode (automated wire feeding) reduces the need for continuous manual operator ability, and having one operator operate multiple stations or extended weld time is made possible, making it to be of high labor efficiency.

- TIG: Very labor-intensive and costly. Welding ability is highly dependent on operator hand-eye coordination and focus. A good TIG welder is a long time to train and quite costly. Its slower rate also takes more man-hours to achieve the same amount of work.

Economy – Material Cost

- MIG: Material efficiency is relatively low. There is normally some spatter generated during welding (specifically in short-circuiting transfer mode), and this results in waste wire and shielding gas. While this can be kept to a minimum by optimising parameters, the loss is generally higher than for TIG.

- TIG: Substantial savings in material. With a particular filler wire process, the welder is able to precisely control the amount of wire added, creating virtually no spatter. This becomes particularly important when welding expensive materials (e.g., stainless steel, aluminum alloys, and specialty alloys), really conserving raw material expense.

Economy – Post-processing Cost

MIG: Spatter often needs to be stripped away (grinding and chipping) from the face of the weld. In use where appearance is a factor, spatter removal has additional labor and time expense.

TIG: There is minimal post-processing. The process is free from dirt, with smooth, clean, and aesthetically pleasing welds that typically require little or no cleaning. The process is suitable for applications where excellent weld appearance standards are required (e.g., food-grade equipment, show parts, and precision instruments).

MIG: It is the preferred choice for high productivity application and low total cost (specifically for mass production, welds of long lengths, and welding medium-thick plates). The economic benefits are largely quantified in terms of speed and labor economy.

TIG: It is economical when material costs are important (valuable materials), when high weld quality, cleanliness, and finish are required, and thin plates or precise parts welding. Its value is material saving, reduced post-processing, and high quality at the cost of increased labor cost per piece.

MIG is applied in high-volume, high-speed manufacturing with low costs of labor, whereas TIG is applied where the application requires material savings, tighter control, and good appearance.

Typical Application Scenarios: MIG And TIG Welding

In the manufacturing industry, MIG (metal inert gas welding) and TIG (tungsten inert gas welding) are two widely used arc welding technologies with distinct characteristics, each suited to different applications.

Overview of Typical Applications of MIG and TIG Welding

| Welding Method | Typical Applications | Key Selection Criteria |

|---|---|---|

| MIG | Automotive chassis, steel structures, pipeline welding, heavy machinery manufacturing | High efficiency, high deposition rate, suitable for medium and thick plates, easy automation, and adaptable to various welding positions. |

| TIG | TIG Aerospace components, food-grade stainless steel piping, precision instruments, artistic metal sculptures, thin-walled container repair | High-quality welds, precisely controlled heat input, clean and spatter-free welds, suitable for thin plates and dissimilar metals, and aesthetically pleasing welds. |

Common uses of MIG welding:

- Automotive frame: High strength, high efficiency, and good fatigue strength are required in welding. The high welding speed and high deposition rate of MIG are ideal for high-volume production on automotive assembly lines for consistent steel of varying thicknesses to be joined.

- Steel structures: There are numerous long welds and medium-thick plates (e.g., H-beams, I-beams, columns, and trusses) used. MIG’s high deposition rate and efficiency greatly speed up construction, and its excellent penetration and strength meet structural requirements of buildings.

- Pipe welding: Particularly suitable for welding and prefabrication on the site of long-distance pipelines (oil, gas, and water). MIG (particularly its variations such as flux-cored arc welding (FCAW)) can weld in various positions (horizontal, horizontal, vertical, and overhead) with high efficiency and relatively good on-site environmental adaptability.

- Heavy machinery manufacturing: Uses like excavators, cranes, farm machinery, and mining equipment. These equipment have heavy-duty structural components and numerous, long welds with high strength and some toughness requirement. MIG has high efficiency and deep penetration properties, which are beneficial for the welding of thick plates and to meet load-carrying requirements of heavy-duty equipment.

Certain common applications of TIG welding are:

- Aerospace components: Such components require extremely high weld quality, cleanliness, tensile strength, high-temperature resistance, and uniformity (e.g., aircraft engine components, fuel lines, and fuselage structural components). TIG precisely controls the heat input to avoid material degradation with a spatter-free, clean welding process. This provides repeatable, high-quality welds on difficult-to-weld materials such as aluminum alloys, titanium alloys, and heat-resistant alloys.

- Stainless steel tubing food-grade: These components require completely smooth, flawless welds that are resistant to corrosion, easy to clean, and prevent bacterial growth. Slag and spatter are eliminated with TIG welding, which leaves beautiful, clean welds perfect for the stringent hygiene requirements of the food, drug, and beverage industries.

- Precision components: These components involve welding tiny components and thin-walled parts (like sensor enclosures, precision valves, and optical instrument bases). TIG’s concentrated arc and tightly controlled heat input readily prevent thin plate distortion and burn-through, making precise, solid welds.

- Metal Sculpture: For applications in which high weld appearance and more delicate expression are desired (for example, stainless steel and aluminum alloy sculpture), TIG welders are able to control the weld pool as with a brush, creating smooth, even, almost mark-free welds or welds with deliberate decorative features, meeting artistic work requirements.

- Thin-Wall Container Repair: Thin-walled components such as stainless steel water tanks, chemical tanks, and heat exchangers require very precise control of heat to avoid burn-through or excessive deformation. TIG welding’s low heat input and precision make it the ideal process for this type of repair.

Its high deposition rate and efficiency have earned MIG welding the status of workhorse for mass production of heavy- and medium-plate in the heavy machinery, construction, piping, and automotive industries. TIG welding’s superior quality of weld, heat control, and visually pleasing clean weld cannot be substituted in sensitive, high-end applications such as thin-wall repair, aerospace, precision manufacturing, food and pharmaceuticals, art, and precision optics.

FAQs

1. Should a beginner learn MIG or TIG first?

For beginners, it’s strongly recommended to start with MIG (Metal Inert Gas Welding) because it’s relatively simple to operate and allows for quick mastery of basic arc control skills, including wire feed stability, weld pool management, and arc maintenance. Once this foundation is established, progress to TIG (Tungsten Inert Gas Welding), which allows for more refined techniques like precise heat input control and high-quality weld appearance. This approach is suitable for complex or high-quality workpieces, avoiding the frustration of prematurely acquiring challenging techniques.

2. Is MIG or TIG better for welding aluminum alloys?

When welding aluminum alloys, if the workpiece thickness exceeds 6 mm (thick plate), MIG welding is recommended for improved efficiency and productivity, making it suitable for mass production. For thinner plates (typically less than 6 mm) or where high quality is required and the risk of burn-through and deformation is minimized, TIG welding is preferred because it provides more precise heat control, ensuring weld integrity and aesthetics. This is particularly effective for precision components or decorative applications.

3. Can TIG welding be performed without filler material?

Yes, TIG welding can utilize a “self-melting” process in specific circumstances, such as thin plate butt welding. This process eliminates the need for filler material, with the weld formed by the base metal itself melting. This makes it suitable for simple connections that don’t require additional strength reinforcement. However, in most practical applications (such as those involving gaps, requiring improved mechanical properties, or requiring aesthetics), filler wire must be added to improve weld strength, toughness, and appearance, and to avoid potential weld strength defects.

4. How does the LS system solve the wire feeding challenge for aluminum MIG welding?

The LS system integrates a dual-drive push-pull system and a specialized U-groove wire guide to effectively address wire feed blockages caused by soft aluminum wire. The dual-drive system provides synchronized push and pull forces, optimizing wire feeding stability. The U-groove design reduces friction and guides the wire smoothly, ensuring a continuous and reliable welding process, significantly improving the quality and efficiency of aluminum MIG welding.

Conclusion

The fundamental difference between MIG and TIG lies in electrode usage and process objectives. MIG is an efficiency-oriented “productivity tool,” irreplaceable in mass production thanks to its automatic wire feeding and high tolerance. TIG, on the other hand, is a quality-oriented “precision paintbrush,” making it the preferred choice for welding high-quality materials and aesthetically pleasing welds through precise heat input control. Understanding material properties, thickness requirements, and quality objectives is fundamental to selecting a scientific welding method.

Whether you pursue ultimate efficiency or exceptional quality, LS welding solutions offer professional support. Our intelligent welding machines are compatible with MIG, TIG, and MMA processes and feature an expert parameter database and remote diagnostics system. Contact the LS technical team today for a free welding process assessment and trial weld service. Empower your manufacturing competitiveness with technology!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.