“Have you ever printed a model with a complex internal structure, but accidentally damaged the exquisite finished product in the last step – removing the support? The frustration of failing at the last hurdle is a nightmare that every 3D printing enthusiast and engineer wants to avoid.”

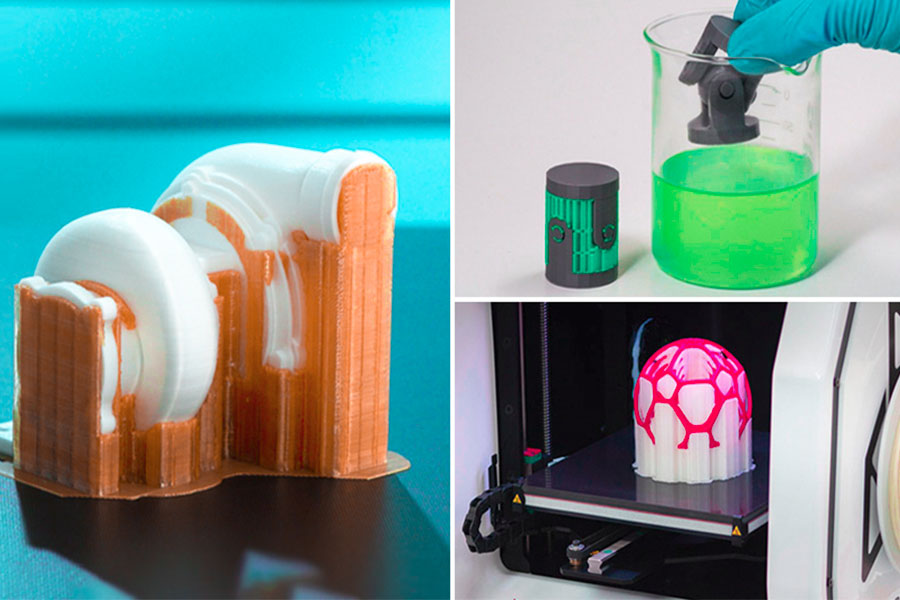

For 3D printing players, support structures are both saviors and potential “invisible killers”. They help the suspended parts to be successfully formed, but may bring disaster when they are removed – at the least, they will leave a rough cross-section, or even directly break key details. What’s even more frustrating is that some supports seem to be “integrated” with the model, and even if you use all the tweezers, pliers and patience, you may still ruin the results of hours or even days of printing.

But there are solutions. By optimizing support settings, choosing the right materials, and mastering scientific removal techniques, you can say goodbye to the era of “violent support removal”.

To save you time, here is a quick overview of the core conclusions.

Summary of core answers

| Support material | Dissolving medium | Dissolving principle | Most suitable main material |

|---|---|---|---|

| PVA (polyvinyl alcohol) | Water (Water) | The hydroxyl group (-OH) in the PVA molecular chain forms hydrogen bonds with water molecules, making it gradually dissolve and disperse in water | PLA, PETG, Nylon (hydrophilic or compatible materials) |

| HIPS (high impact polystyrene) | Limonene (Limonene) | HIPS is a non-polar polymer. Limonene (citrus solvent) as a non-polar solvent can penetrate and dissolve its molecular chain | ABS, ASA (non-polar materials) |

This guide will take you deep into these two amazing dissolving support materials, explain the science behind them, and provide a clear decision framework for when and how to use water-soluble support materials, and how this affects the final price of your 3D print.

Here’s What You’ll Learn

🔍 Why do PVA/HIPS filaments magically dissolve?

A Quick Decision Framework → Determine in 60 seconds whether your project should be supported by PVA or HIPS (based on material, dissolution conditions, and cost).

A comparison of the three dissolution principles → Why does PVA “disintegrate” in water while HIPS needs limonene? In-depth analysis from molecular polarity, hydrogen bonding, solvent compatibility.

The three-step method to overcome the difficult-to-dissolve support → Warm water soaking strategy for stubborn PVA residue, and safe cleaning process for HIPS after dissolution.

Real cases in LS printing workshop → How to realize “zero-damage” dismantling of cardiac artery models for medical teaching and lightweight ABS frames for drone fuselages.

FAQ → What is the difference between PLA and PVA? What is a water-soluble resin? What does “wet filament” mean? How to use water-soluble support material correctly? –Pitfalls that even experienced users may step on.

“After reading this article, you will no longer rely on luck and brute force to remove bracing, but instead use the scientific method to achieve the magical effect of ‘bracing automatically disappears’ like a professional engineer!”

Why should you trust this guide? Practical experience from LS 3D printing experts

At LS’s 3D Printing Workshop, we push the limits of manufacturing every day. As a service provider specializing in custom 3D printing and manufacturing, we offer high-precision printing solutions to customers in the medical, architectural, and industrial design fields. From internal runners for bionic medical devices, to complex overhangs for architectural models, to hollowed-out designs for lightweight industrial parts – geometries that are difficult to achieve with traditional processes are where our 3D printing technology comes in.

All of this is made possible by our in-depth knowledge of soluble support materials such as PVA and HIPS. Not only do we know how they dissolve, but more importantly, we have accumulated a whole range of optimization experience to ensure that the support structure is both solidly formed and easily removed to avoid damaging fine features. For example:

- PVA Moisture Proofing Practical Tips:

It must be sealed and stored dry (humidity <30%) before printing, otherwise it will lead to extrusion instability and loss of support strength due to moisture absorption (wet filament).

A constant temperature drying oven or real-time heated moisture-proof feeding system is used in printing to avoid PVA absorbing air moisture during the printing process. - Efficient pairing of HIPS with limonene:

The use of a temperature-controlled ultrasonic cleaner (40-50°C) during dissolution dramatically reduces the dissolution time of HIPS supports (from hours to 30 minutes).

For large ABS parts, we will design support chunking strategies to ensure structural strength while reducing solvent usage and costs. - Customized economic solutions for our customers:

For short-term display models, we prefer to recommend low-cost PLA + easy-to-peel supports;

For functional metal-plated parts, we use HIPS supports + post-treatment polishing to ensure surface finish.

This experience, accumulated from thousands of print failures and optimizations by our team, is the core reason why LS’ 3D Printing Workshop has become a trusted supplier to the industry. We don’t just sell prints – we provide a complete chain of manufacturing knowledge from design to post-processing.

(Small question interaction: What famous “rollover” scenes have you encountered when removing supports? Welcome to leave a message, our engineering team will give you targeted answers!)

How to choose the right dissolving support for your complex model: a simple decision framework

PVA and HIPS are not interchangeable options. Which one you choose depends entirely on the ‘host material’ you are printing your model with. It is a simple matter of chemical matching.

Step 1: Determine your main printing material

Question: Is the main printing material you use PLA, PETG, Nylon, or ABS, ASA?

- Decision path:

If using PLA / PETG / Nylon → Select PVA for the support.

Why? The printing temperature of PVA is compatible with these materials and it is soluble in water, which does not have any effect on these primary materials.

Applicable scenarios: Medical models, precision gears, porous structures, and other PLA / PETG prints that require high-precision support.

If ABS / ASA is used → Select HIPS as the support.

Why? The printing temperature of HIPS matches perfectly with ABS / ASA, and limonene, which dissolves HIPS, is completely harmless to ABS / ASA.

Applicable Scenarios: ABS/ASA prints that require high strength support such as automotive parts, high temperature resistant housings, industrial grade functional parts, etc.

Step 2: Evaluate your equipment and post-processing capabilities

Question:Do you have a dual/ multi-jet 3D printer?Are you comfortable handling organic solvents (e.g. limonene)?

- Decision Path:

Yes, with dual nozzles and easier to handle with water → PVA is ideal.

- Advantage: water dissolution is safe, easy and low cost for home studios or educational institutions.

- Caution: PVA absorbs moisture easily and needs to be stored dry or it may clog the nozzle.

Yes, there are dual printheads and don’t mind using limonene → HIPS is the only professional choice for printing complex parts in ABS.

- Advantage: smooth surface after dissolution, no residue, especially suitable for demanding industrial grade parts.

- Caution: Limonene has a citrus odor and needs to be operated in a ventilated environment and stored properly (flammable).

No, single printhead printers only → Consider peelable supports (e.g. Breakaway) or optimize model design to reduce support dependency.

Pro-Tip:

“When you ask our LS3D Printing Workshop for a quote on a complex 3D printed part, our engineers will first confirm the main material and structure of the model, and then recommend the best support solution for you. This is the first step to ensure a successful print and control 3D printing costs.”

Choosing the right dissolving support only requires two steps: first look at the main material (PVA for PLA/PETG/Nylon, HIPS for ABS/ASA), then look at the equipment (dual nozzles are a must, and the solvent handling capacity determines the feasibility). With the right match, the support can be easily dissolved, the model is perfect and intact, and the 3D printing cost can be optimized.

In-depth analysis: the scientific principles of two types of “dissolving supports”

Today, we will not talk about those high-sounding theories, but will talk about two particularly practical “dissolving support” materials in 3D printing – PVA and HIPS. They are like magicians, holding the model firmly during printing, and “disappearing” without a trace after printing. The key lies in their unique “dissolving” principles. If you understand this, you can play with complex models and avoid many pitfalls!

1.PVA (Polyvinyl Alcohol) – Magic of Water (PVA Filament)

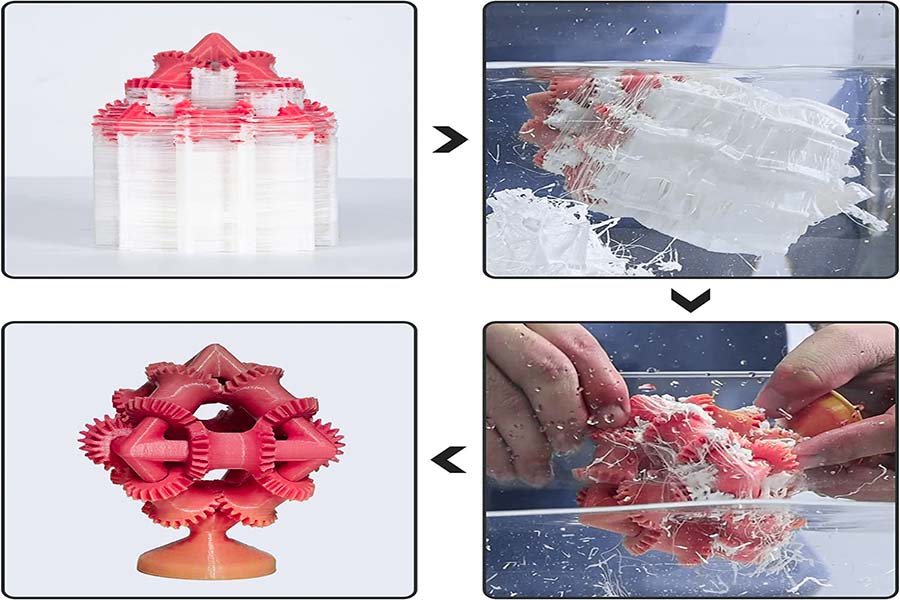

- The Science: Why does PVA love to “dissolve” in water? The secret lies in its molecules! It is full of “little grabbers” (professionally called hydroxyl groups, -OH) that are particularly fond of water molecules. Water molecules, themselves also a little “small magnetic” (hydrogen bonding). These two meet on the “sympathetic”, holding particularly tight. As a result, an army of water molecules swarmed up, hard to break up the molecular chain of PVA, macroscopically we see it “dissolved”. Isn’t that why it is the best water-soluble support material?

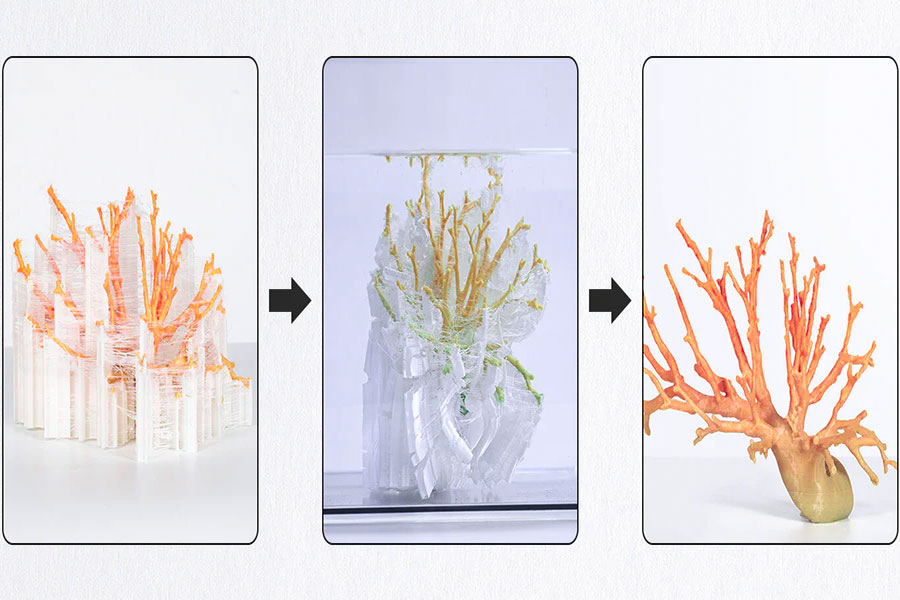

- Key application: Think of models that are particularly delicate, with lots of nooks and crannies, such as delicate miniature buildings, intricate works of art, or medical devices that require incredibly smooth interior walls. When printing a subject in PLA, the PVA support fills these complex voids perfectly. Finished? Soak it in water! The PVA dissolves, leaving you with a clean PLA body, with no support scars to be found.

- Challenge and response: PVA is great, but it has a “natural enemy” – humid air! Why? Remember its water-loving “little grabbers”? In the air, it will also try to grab the moisture in the air. The result? Printing wire becomes soft, sticky, and even plugged, drawn, and the print quality is miserable. So, **which kind of wire is the most afraid of moisture, the most favorite “water”? It is PVA!

Our team’s blood and tears:

Seal! Seal! Sealed! It’s important to say it three times. When not in use, PVA spools must be kept in a sealed bag with enough desiccant.

Before printing, dry it! Even if you keep it sealed, it’s best to dry it again in a drying oven (usually 50-60°C for a few hours) before using it to get rid of any moisture that may have been sucked in. This step will greatly improve the success rate of printing!

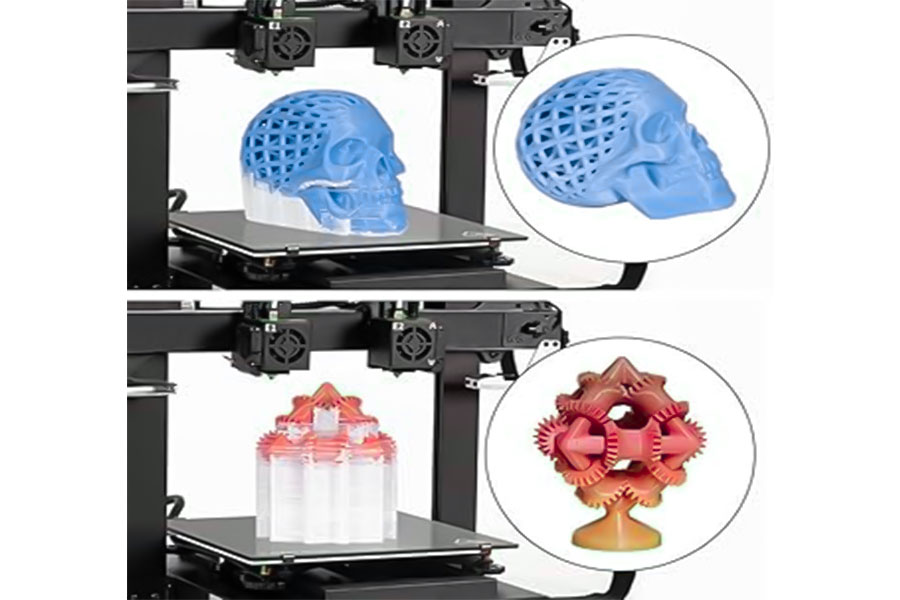

2. HIPS (High Impact Polystyrene) – Limonene is its “nemesis”!

- The science: Why is HIPS dissolved by limonene (a solvent derived from citrus fruits)? It’s a classic chemical principle – “like dissolves like”. In layman’s terms, this means that “one family recognizes another”; HIPS and ABS are both members of the polystyrene family, and their molecular structures are similar in that they are both “oily” and non-polar in nature. Limonene is also a natural non-polar solvent. Therefore, when limonene meets HIPS, just like oil can dissolve oil-based handwriting, it can easily penetrate into the HIPS molecules apart and dissolved. While ABS is also a “family”, but structurally more stable, limonene can not help it (or dissolve very slowly).

- Key application: HIPS supports come in handy when you need to print functional ABS parts. For example, engineering prototypes with complex clips, or mold inserts with delicate cooling channels inside, ABS itself is difficult to print (prone to warping and cracking), and using HIPS as a support, it adheres exceptionally well to the main body of the ABS, providing a super-stable support platform that effectively fights warping. After playing soaked in limonene solution, HIPS support dissolved and disappeared, leaving the complete ABS parts.

- Engineer’s View of the Advantage: HIPS has a particularly great thing going for it: it’s also a pretty good printing material in its own right! And because it is a “close relative” of ABS, the bond between the HIPS support layer and the ABS body layer is very good when printing, with the layers sticking together very firmly. This means that the support structure itself is very strong and reliable and will not easily collapse during the printing process, which is essential to ensure the success of printing complex ABS parts.

PVA dissolves in water by being “hydrophilic” and specializes in complex supports for PLA; HIPS dissolves in limonene by “recognizing” (similarly soluble) and is a good partner for complex ABS parts. The key to using them well is to understand the principle of their dissolution, and targeted to do a good job of protection (PVA moisture) and the choice of the right dissolving agent. Master these two points and you have a 3D printer in your hands that unlocks more possibilities!

Practical case analysis: from complex design to perfect finished product

Theory should ultimately serve practice. At LS, we know that the value of innovation lies in implementation. Through advanced soluble support technology, we help customers break through the limitations of traditional 3D printing and turn designs that were once considered “impossible to print” into reality. The following are two typical cases that show how we solve industry problems through the combination of material science and precision technology.

Case 1: Heart Artery Model for Medical Teaching – When Precision Meets Transparency

Challenge

A medical education organization needed to create a fully transparent PETG heart model containing an intricate network of arterial vessels, with the smallest vessel having an internal diameter of only 0.8mm. traditional support techniques could not meet the needs because:

- Manual removal of the support would damage the delicate vascular structure

- Remaining traces of the support can affect the pedagogical value of the model.

- The internal channels must be completely clear to ensure the accuracy of fluid dynamics experiments.

Solution

We use an industrial-grade dual-jet 3D printer with a precision temperature control system:

- Main body material: Medical grade transparent PETG to ensure high light transmission (>92%) and biocompatibility.

- Support material: High purity PVA water-soluble wire, optimized dissolution rate for microstructures.

- Post-treatment process: Models are immersed in a constant temperature water bath at 35°C, combined with directional water circulation technology to ensure complete dissolution of the deep supports

Results

After 24 hours, all the internal PVA supports were completely dissolved, leaving behind a crystal clear, perfect teaching model with a clear internal structure, which is absolutely impossible to achieve with traditional support methods.

Case 2: Lightweight ABS Frame for UAVs – When Strength Meets Complex Geometry

Challenge

A startup team focusing on high-performance UAVs designed a topologically-optimized ABS airframe with features including:

- Ultra-thin reinforcement (0.3mm) with honeycomb openwork structure

- Required to withstand 12G impact loads while reducing weight by 40% compared to conventional structures

- Manual removal of supports resulted in over 30% scrap rate

Solution

We used a HIPS-ABS dual material printing system combined with a chemical post-treatment process:

- Main body material: carbon fiber reinforced ABS for improved flexural strength.

- Support material: modified HIPS for selective dissolution in D-Limonene solution.

- Precision cleaning: Gradient solvent immersion and ultrasonic assisted cleaning to avoid stress damage

Results

The HIPS was completely dissolved, revealing an ABS frame with a complete structure and smooth surface without any scratches or breaks. This successful prototype helped the customer quickly move to the next round of functional testing. This project is the best embodiment of the value of our customized 3D printing services.

Why are these cases noteworthy?

These projects testify to our full-link capabilities from design to finished product:Material innovation: customized formulation of medical PVA and industrial HIPS

Process breakthrough: temperature/chemistry synergy to control dissolution precision

Industry value: helping customers shorten R&D cycles and reduce trial-and-error costs

“True technology makes complexity simple.” –This is exactly what LS continues to address. If you have an “impossible to print” design, contact us for a free manufacturability evaluation.

FAQ – Answers to all your questions about Dissolvable Supports

1. What is the difference between PLA and PVA?

PLA (Polylactic Acid) is a common 3D printing material with high hardness and good print stability, which is suitable for making the main structure of the model. While PVA (Polyvinyl Alcohol) is a water-soluble support material with a softer texture, specially used as a dissolvable support in dual-head printers, which can be paired with PLA to simplify the printing and post-processing of complex models.PLA requires mechanical removal of the support, whereas PVA only needs to be dissolved by soaking in water, resulting in a smoother model surface.

2. What are water-soluble resins?

Water-soluble resin is a special resin used for light-curing 3D printing (e.g. SLA/DLP) that can be cleaned with water or a mild solvent after printing, eliminating the need to manually remove the support structure. It is functionally similar to the PVA support material used in FDM printing, but is suitable for resin processes, reducing post-processing time and improving the surface quality of fine parts, and is particularly suited to the needs of high-precision, complex structure printing.

3. What does “wet filament” mean?

“Wet filament” refers to 3D printing consumables (especially hygroscopic materials such as PVA, nylon, etc.) that have absorbed moisture due to exposure to a humid environment. Wet filament can cause problems such as bubbling, spattering, pulling or clogging when printing, which can seriously affect the print quality. To avoid this problem, it is recommended that moisture-absorbent wires be stored in a dry box or sealed bag and dried before use (e.g. PVA at 50°C for 4-6 hours).

4. How to use water-soluble support materials correctly?

The use of water-soluble support materials (e.g. PVA) requires the following points: firstly, make sure the material is dry to avoid wet filament problems; secondly, use a dual-nozzle printer with the right temperature (usually 190-210°C) and pumping parameters; after printing, immerse the model in ambient water and leave it to stand for 12-48 hours until the support is completely dissolved, during which time it can be gently stirred or changed to accelerate the dissolution. For complex structures, high-speed dissolving PVA can be used to improve efficiency.

5. Is there a recommended brand of water-soluble support?

Common brands of high-quality water-soluble supports on the market include Bambu Lab, Creality, and PolyMaker, etc. Bambu Lab’s PVAs are widely available and dissolve quickly; Creality’s PVAs are more cost-effective and suitable for beginners; and PolyMaker’s PolyDissolve series is known for its low residue and stability. PolyMaker’s PolyDissolve series is known for its low residue and stability. When choosing, you need to consider compatibility with the main printing material and prioritize products with moisture-proof packaging. Professional 3D printing service providers often test multiple PVAs against equipment performance to ensure optimal support.

Conclusion

PVA and HIPS support materials are more than just consumables. They are key technologies to unlock complex geometries, achieve seamless surfaces, and turn disruptive designs into reality.

If your design is difficult to manufacture due to its complex structure, don’t compromise. Our LS team of 3D printing experts are proficient in a variety of advanced support technologies. Upload your design file now and let us provide you with professional manufacturing solutions and transparent 3D printing quotes!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.