CNC milling machining is considered one of the strategic technologies in manufacturing complex and precision parts, but among many suppliers and alternative technological choices, the right option is not an easy choice. Besides, information barriers most often expose you to the risk of project delays and uncontrolled costs. Herein lies the great challenge-to match general knowledge and ordinary machining plants with your specific needs for precision, efficiency, and reliability.

In that respect, this guide is your personalized decision-making tool-not just for deep-diving into the core technology but also for showing how, through advanced equipment, knowledge in material science, and forward-looking DFM analysis, LS Manufacturing ensures that your designs reach optimum cost and quality. The only way these informed choices could be made is if we comprehend deeply why CNC milling has become the cornerstone of modern manufacturing.

Quick Reference Table: CNC Milling Core

| Module | Core Content Summary |

| Technical Essence | The process used is computer-controlled, precision cutting generally utilized for very complex and high-precision pieces. |

| Core Benefits | Extremely high precision and repeatability, suitable for a wide range of needs: from prototyping to mass production. |

| Design Key (DFM) | The first step in cost control and quality assurance is to optimize the designs to include internal corner fillets and correct wall thickness. |

| Key to Success | Selection of a partner with state-of-the-art equipment, professional DFM capability, and a strict quality system is very important. |

CNC milling machining is the core of ingenious design development from blueprint to the actual product. The quality supplier will contribute to optimizing the design and reduce the risk by providing far-sighted DFM analysis, transferring technical strength and quality systems, guaranteeing that the project attains the best balance in cost, time, and quality, and therefore lays a solid foundation for ensuring the success of your product.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

We deeply understand the processing characteristics of various materials and strictly abide by standards put forth by National Association for Surface Finishing(NASF) for process control. Parts we process in critical structural components for the aerospace industry are connected to flight safety, while precision implants manufactured in the medical device industry contribute directly to patient health.

Our group has finished tens of thousands of very complicated workpieces using 5-axis CNC technology in the past decade. In this process, very rich experience is gathered, starting from high speed cutting of titanium alloys to preventing thin wall aluminum alloy parts from deforming for meeting the requirements of Aluminum Association(AAC).

It crystallizes practical wisdom from successes and lessons learned so as to help the reader avoid certain pitfalls we went through ourselves. You will not find textbook theory here, but truly reliable professional knowledge, proven through cutting and polishing.

Why has CNC milling become the core technology for manufacturing complex parts and precision molds?

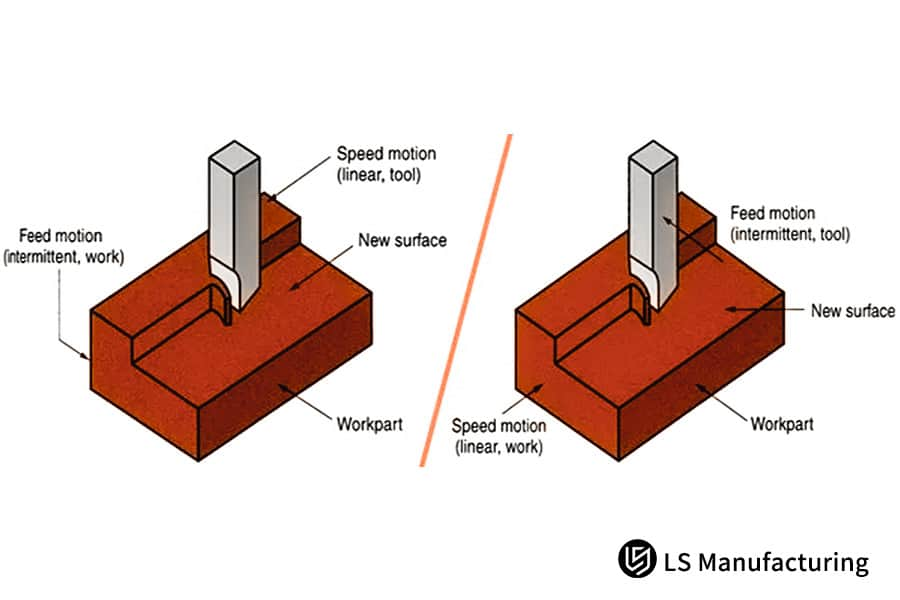

Essentially, CNC milling has become a core technology for complex parts and precision molds because its disruptive advantages allow it to comprehensively outperform traditional methods in precision, efficiency, and flexibility. This stems from the CNC milling working principle, which translates the answer to what is CNC milling?—computer-controlled material removal—into the versatile CNC milling application seen today. A CNC milling machine’s superiority is reflected in these key dimensions:

- High Precision and Complexity: Thanks to the the CNC milling working principle, it can easily achieve micron tolerances and complex geometrical features by controlling with extreme and superior precision, moving a tool in three-dimensional space by means of digital programs. Be it precision cavities on a mold or difficult-to-reach curved surfaces on a part, they can be machined in one go and in highly consistent fashion.

- Good material adaptability: From common aluminum alloys and steel to engineering plastics and high-temperature alloys, CNC milling can process everything efficiently. Furthermore, the wide applicability extends the range of CNC milling application, which can meet demanding requirements in the aerospace and consumer electronics industries.

- High automation and consistency: This equipment can run unmanned for an extensive period of time once set, ensuring high repeatability for each part produced in batches, hence greatly improving production efficiency and quality stability.

In all, it integrates digital design seamlessly into physical manufacturing. Its high precision, extraordinary capability for processing complex-shaped objects, wide adaptability of material processing, and automatic production in a stable way established its irreplaceable core position in modern manufacturing.

3-axis, 4-axis and 5-axis facing: how to select the most economic milling solution for your project?

Knowing the types of CNC milling forms the very basis of making the right choice. A suitable solution of CNC milling affects the cost per part, the whole production cycle, the fixture costs, and quality of the final product. Below is a table comparing the main characteristics of three different solutions that will help you establish a framework for selection in no time.

| Axis Type | Core Capabilities and Applicable Scenarios | Economic Analysis |

| 3-Axis Milling | There are planes, holes, and simple cavities in the work part. Only one surface is machined at a time. | For very simple geometric parts, lowest equipment and programming costs make 3-axis milling the first choice. |

| 4-Axis Milling | The machine type includes a rotary table used in the machining of features on the sides of cylinders or box-shaped parts requiring multi-angle indexing. | 4-axis milling stands between 3-axis and 5-axis milling in cost and efficiency. However, it is preferred since it combines cost-effectiveness. |

| 5-Axis Milling | Can simultaneously machine such complicated spatial surfaces as impellers and precision molds, completing multiple surfaces in one setup. | Highest hourly cost, but it reduces setup time, improves accuracy of the part, and is more economical for complex parts. |

The LS Manufacturing engineering team can offer professional analysis for free on how to choose a CNC milling solution. Based on your drawing and production volume, we would recommend the most optimized and economical solution among various types of CNC milling, so that every penny of your budget creates value to the maximum extent.

From Drawing to Finished Product: What are the main ingredients constituting a successful CNC milling operation?

Behind every successful CNC milling operation is a strong, standardized process. Confirmation is made at LS Manufacturing that everything-from data to finished product-is under control through standardized workflows that balance quality and efficiency with cost. There are some key steps involved in successful machining; these are clearly identified in the table below.

| Key Steps | Core Task Summary |

| CAD Model Review & DFM Optimization | The model review by the engineers and subsequent optimization are based on DFM principles for better manufacturability and cost control. |

| CAM Programming and Path Planning | The process by which 3D models are converted into CNC code and an efficient toolpath and cutting parameters are assigned. This would act as the “brain” of the CNC milling operation. |

| Precision clamping and tool setting | Customizing a robust clamping scheme for the workpiece and precisely setting the machining datum are the physical foundations for ensuring the accuracy of the entire CNC milling process. |

| Cutting and Online Inspection | Perform the machining program, during which online measurement for critical dimensions in real-time should be done, ensuring control in the machining status. |

| Final Quality Inspection and Post-processing | Special equipment will be used for full-dimensional final check after the processing; surface treatment and other post-processing will be carried out according to the requirements. |

LS Manufacturing puts every collaboration into this extensive CNC milling process system. That ensures the precision and reliability of every single CNC milling operation. It consistently guarantees the consistency and traceability in mass production of your project and thus perfectly changes from drawing to finished product.

LS Manufacturing : Lightweight Solution Five Axes Milling for Aerospace Titanium Alloy Bracket

In the high-end manufacturing field, combining extreme design with reliable manufacturing is a core challenge. The following typical LS Manufacturing milling case fully demonstrates how we solve highly complex problems in aerospace component machining through advanced processes.

Customer Challenge

The task of development of a critical bracket for its new engine has been undertaken by the aerospace equipment manufacturer. The core requirement to be met by the customer was huge weight reduction, coupled with structural strength and fatigue performance. This part is made from high-strength titanium alloy, with a complex, conformal, lightweight cavity. Traditional 3-axis machining cannot replicate its intricate structure, and work-hardening tendency for titanium alloy is very high; hence, machining stress is very easily liable to cause excessive deformation and is highly risk-prone.

LS Manufacturing Solution

Our professional 5-axis CNC machining solution was developed by our team. We used the capability of a 5-axis CNC center to clamp the part once and precisely machine a system of multi-angle holes and an internal cavity with complex shapes, effectively avoiding repeated clamping errors. We adopted the dynamic milling strategy for titanium alloy and applied specialized tooling to effectively suppress vibration and deformation. Before machining, optimization of parameters was executed by cutting simulation software and pre-control of machining stress.

Results and Value

Eventually, a 25% weight reduction was achieved with the titanium alloy bracket. All mechanical performance tests were passed the very first time, and batch production consistently yielded more than 99.5%. The customer gained great confidence in passing the most rigid airworthiness certification, and LS Manufacturing won the title of “Core Supplier” for this outstanding performance.

This project of aerospace component machining epitomizes LS Manufacturing’s strength in meeting the cutting-edge challenge. Success can only come from deep integration between material properties, advanced equipment, and process parameters, as demonstrated by this LS Manufacturing milling case.

Smarter If your project faces such challenges, please consult with our technical experts now for your free Design for Manufacturability analysis service!

How can scientific design for manufacturability maximize the value of CNC milling?

In a highly competitive market, the cost and quality of a product are decided mainly during the design phase. Scientific design for manufacturability, or DFM, plays the main role in the process of CNC milling cost control. With the view to deeply integrating your design intent with the best manufacturing process, the professional DFM analysis service offered by LS Manufacturing adds value in these ways:

Geometry optimization to increase machining efficiency

Our engineers will analyze such features as internal fillets, cavity depth, and thin-walled structures. For example, replacing unnecessary right-angle internal angles with internal fillets that can be machined with standard tools avoids the use of expensive special tools and reduces tool change time; rationally standardizing wall thickness avoids deformation caused by uneven cutting forces. These optimizations directly reduce machining time and tool wear.

Optimizing tolerances to achieve a balance between quality and cost

Not all features require micron-level tolerances. Through DFM analysis, we differentiate between critical mating dimensions and general functional dimensions, recommending relaxed tolerance requirements in non-critical areas. This significantly reduces reliance on high-precision machine tools and finishing time, a key step in controlling the cost of precision CNC milling while ensuring the core functionality of the product.

Preventing potential defects and improving yield

Assessing and mitigating issues such as stress concentration at sharp corners and vibrations caused by insufficient rigidity before machining reduces trial-and-error costs and scrap rates at the source, ensuring a smooth and stable production process.

The DFM analysis value—bringing manufacturing knowledge to the R&D stage—is fundamental to reducing complexity, shortening cycles, and improving yield. Choosing LS Manufacturing as your manufacturing partner means gaining a strategic ally committed to creating maximum value for you through technological optimization.

How does LS Manufacturing ensure that every milled part comes out perfect?

Flawless does not happen by accident in precision manufacturing but is an outcome of strenuous and traceable system engineering. The LS Manufacturing quality system involves all the people in the commitment to high-precision CNC milling. We understand that superior quality is not determined in final inspection but instead permeates every stage, from material receipt to product delivery.

- Source Control: We set up a strict mechanism for the certification and traceability of raw materials. Thus, every single blank must come from qualified suppliers whose material reports and mechanical properties meet the standard to lay a reliable foundation for high-precision CNC milling from its source.

- Process Monitoring: For example, probes installed on machine tools for processing are used for real-time, on-machine inspections after key processes. This enables them to find micron-level deviations in dimensions right away and quickly make the proper corrections, rather than manufacturing defective products. This represents the principle of preventative control within our LS Manufacturing quality system.

- Terminal Verification: All products must be fully dimensionally inspected by precision CMM after completion. The test data is compared with the 3D model to generate an authoritative inspection report to ensure that 100% of each dimension and tolerance meets the requirements of the drawing.

Our quality fortress is built on three lines of defense: prevention, control, and verification. That depends not only on advanced equipment to carry out tests but also on standardized processes that are deeply rooted in quality awareness at every employee’s level. By means of this comprehensive LS Manufacturing quality system, pledges of quality become reliable performance in every high-precision CNC milling part and win your long-term trust.

Can LS Manufacturing provide seamless support from prototyping to mass production?

The challenging leap from prototype to mass production requires mastering core technologies like CNC milling. Understanding how does CNC milling work—a process of precise, computer-controlled material removal—explains its vital role in guaranteeing consistency. While many companies face risks of quality fluctuations and delays at this stage, LS Manufacturing’s core competency is providing a smooth, reliable one-stop service that seamlessly covers the entire process from prototyping to mass production.

Our seamless support system reflects itself in the following key aspects

Standardization and scalability of processes: In addition to ensuring rapid sample delivery, the most appropriate machining processes, tooling solutions, and fixture designs are deeply analyzed and solidified during prototyping. The “process file” established for the prototype is a gold standard for subsequent mass production, which means guaranteeing absolute stability of quality at scale.

Proactive capacity and supply chain assurance:

We have a flexible production line layout with enough equipment capacity and are able to pre-allocate resources according to your mass production plan. In the meanwhile, the supply chain system of raw materials is stable, making sure that there is consistency in material property, continuity from prototyping to mass production, and no risk of any material shortage.

Dedicated project management and full-process collaboration

You are supported by a project manager from the first prototype onwards, who takes care of internal resource coordination and planning for the smooth transfer and consistent implementation of all technological requirements and quality measures with respect to the transition from prototyping to mass production, thus offering you an effective and transparent window for communication.

As your hands-on partner from incubation to mass production, LS Manufacturing ensures a seamless scale-up. The precision and scalability of LS Manufacturing CNC milling are foundational to this. Our one-stop manufacturing service, with its fully integrated system, eliminates the prototype-production gap entirely, guaranteeing consistent quality and on-time delivery as you grow.

What does choosing LS Manufacturing as your CNC milling partner mean?

Precision manufacturing means that in choosing a supplier, you are literally choosing the “fate” of your project. It is never about just buying a service; it is about bringing a reliable CNC milling partner into your project. In-depth analysis will reveal that the core reasons for choosing LS Manufacturing are rooted in our commitment to creating value for you beyond the machining itself. Working with us will ensure:

- Deep empowerment by a team of technical experts: We offer a complete range of technical support-from manufacturability analysis to process optimization-through professional experience to help customers minimize risks and optimize costs, turning the manufacturing process into value creation.

- Systematic reduction of project risks: With a comprehensive quality control system and transparency of the project management process, we will be able to assure our clients that everything is under control-reducing uncertainties like fluctuation in quality or delays in delivery.

- The essence of enhanced supply chain resilience: With a stable production capacity and a mature supply chain system, we can assure our clients of reliable supplies that guarantee a smooth transition from prototyping to mass production for long-term stability.

With LS Manufacturing, clients are working with a strategic partner for whom their success is the most important goal. We provide not only precision parts but also predictable results of projects due to professional collaboration. That is the main reasons for choose LS Manufacturing-let us be your most reliable CNC milling partner in creating competitive and high-quality products.

FAQs

1. How long will it take for LS Manufacturing to provide a quote once the 3D drawings are supplied?

We know how crucial efficiency is for projects. Once we have your 3D drawings, we can provide you with a proper quotation-including a preliminary manufacturability analysis-in less than 4 business hours. For more complex projects, an answer including scheduling will be provided in no more than 8 hours, which allows our customers to make fast decisions and push projects at full speed.

2. My design may not be the most suitable for milling; would you like to give optimization suggestions?

Absolutely, a free DFM or Design for Manufacturability analysis is part of our service offering. We have engineers who will provide specific suggestions to optimize your design to control cost without deformation and thus ensure functionality, which will help improve quality and optimize the manufacturing cost for customers.

3. How does LS Manufacturing protect my design intellectual property?

Safeguarding the intellectual property of our clients is our business lifeline. Ever since the first interaction, confidentiality agreements are something to which we completely adhere. Transferred and stored documents are via an encrypted system where access is strictly controlled so that at all times your design data remains safe, without any chance of leakage.

4. Is there a minimum order quantity for the CNC milling service?

We offer highly flexible services without any restriction on the minimum quantity of the order. Whether that is a single-piece prototyping or mass production, we put in all our expertise to meet your requirements at every stage, from R&D verification to mass production in the marketplace.

5. What type of materials have you handled? Have you handled aluminum, stainless steel, and titanium alloys?

We can process different engineering plastics, aluminum alloys, stainless steel, titanium alloys, high-temperature alloys, and so on. With rich experience in processing aerospace, medicine, and other areas to optimize the process according to the material properties, we can put forward professional advice on material selection.

6. How do you ensure consistent part quality during mass production?

A comprehensive SPC system is applied to ensure real-time monitoring of a production line, guaranteeing every part’s critical dimension in each batch is within tolerance. This process control method ensures high consistency and ultra-high yield rates from the source for large-scale production.

7. Will an urgent project be able to be expedited in its production?

Yes. We have a fast-response channel that can flexibly allocate the resources for urgent orders, give priority to manufacturing, and fully ensure your urgent delivery needs to help you fight against some unexpected time pressures in projects.

8. How do I start my first CNC milling project cooperation?

It is very easy to start cooperation with us. You just need to upload your CAD files directly onto this page, and our project manager will immediately contact you to kick off the whole process: from technical review and DFM analysis to accurate quotation, housing you through the whole collaboration.

Conclusion

Only expert partners can unlock this powerful capability of CNC milling technology-with deep process knowledge, advanced equipment platforms, and rigorous quality systems. Equipped with abundant multi-axis precision machining experience, exact cognition of the properties of hundreds of materials, and end-to-end quality standards, LS Manufacturing ensures your design transforms from blueprint into an ultra-reliable product. Far beyond the traditional function of a supplier, we are a strategic driver for your product’s success.

Let our expertise safeguard your creative vision. We invite you to click the button below to contact our experts immediately and obtain a professional solution that includes DFM optimization advice and transparent cost analysis, taking the first step towards efficient collaboration!

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.