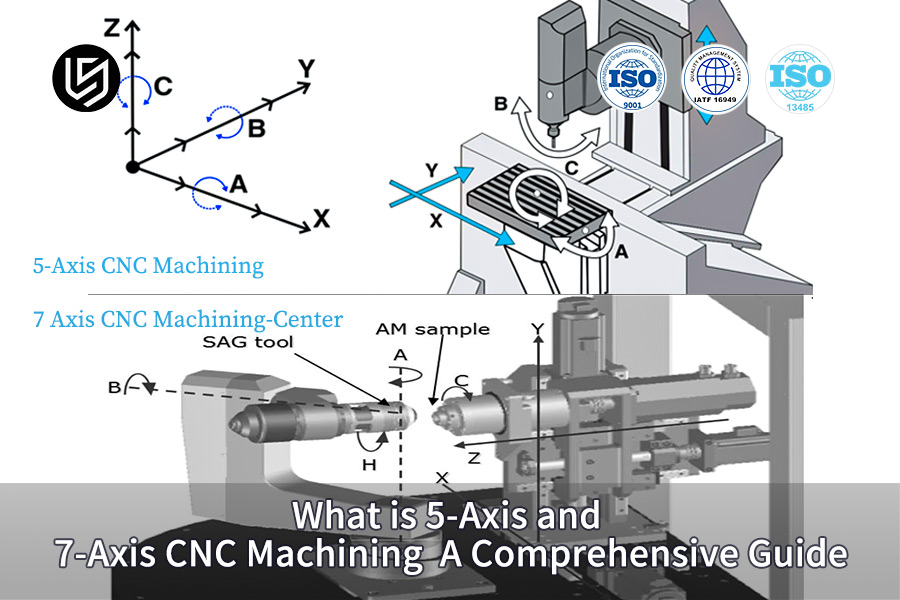

5-axis and 7-axis CNC machining technologies are key to solving the challenge of high-precision manufacturing of complex components. Traditional 3-axis machine tools, due to insufficient machining freedom, often require multiple clamping operations, leading to accumulated errors and extended cycle times. The fundamental problem lies in the technological limitations imposed by the number of machining axes.

5-axis and 7-axis technologies add rotary axes and linkage control, respectively, for the complete machining of polyhedra and complex curved surfaces in one clamping. Then, what exactly is the difference between 5-axis and 7-axis machining? The following will clearly explain the technical route and selection with practical case studies.

Quick Reference Table for 5-Axis and 7-Axis CNC Machining Technology

| Module Classification | Core Content Summary |

| Technical Definition | 5-axis: XYZ linear axes + 2 rotary axes; 7-axis: 5-axis plus 2 additional auxiliary motion axes |

| Degree of Freedom | 5-axis can machine 5 surfaces, while 7-axis has more complicated trajectories and multi-workpiece collaborative machining. |

Applicable Scenarios |

5-axis: impellers, molds, and other complex curved surfaces; 7-axis: aerospace structural parts, large molds. |

| Comparing Accuracy | 5-axis positioning accuracy ±0.01mm; 7-axis repeatability accuracy ±0.005mm. |

| Equipment Cost | A 5-axis system investment is moderate, whereas a 7-axis system is more expensive, costing 40%-60% higher. |

| Programming Complexity | 5-axis requires professional CAM software; 7-axis requires higher-level path planning. |

| Processing efficiency | 5-axis machining saves clamping times; 7-axis parallel machining of two workpieces is possible. |

| Typical Applications | 5-axis: Medical device moulds, 7-axis: Aero-engine blades. |

5-axis technology can be applied to most parts with complicated curved surface topographies, enabling the machining of 5 surfaces in one clamping, with great improvement in accuracy and efficiency. 7-axis technology can add two auxiliary motion axes on the basis of the 5-axis system, which can be more suitable for processing ultra-large workpieces and some complicated scenes requiring multi-workpiece collaboration.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

With more than fifteen years of experience in 5-axis and 7-axis CNC machining, LS Manufacturing provides high-precision machining solutions for aircraft engine blades, orthopedic implants, and lithography machine parts to the leaders in the aerospace, medical, and precision optics industries.

Our technology system is designed in strict accordance with OSHA equipment safety specifications and EPA green manufacturing standards. Intelligent vibration suppression systems are mounted on our 5-axis machining centers, while the 7-axis equipment has realized a recycling rate of more than 95% for cutting fluid.

It also shares multi-axis synchronization strategies and chatter suppression methods certified by aerospace AS9100D and medical ISO 13485 systems. Using these methods, readers will understand how to avoid common multi-axis machining pitfalls and will be able to perform precise manufacturing of high-value-added parts.

How Does 5-Axis CNC Machining Work?

What is 5-Axis CNC Machining? It is the core technology for modern precision manufacturing. Much more than simple cutting, it’s a complex ballet of motion choreographed precisely by numbers. In general, the essence of this technology is that 5-axis CNC machining represents the final solution for the machining of complex parts and achieves the ideal goal of “one-time clamping.” Its working principle and core value are mainly reflected in the following 3 aspects:

Multi-Axis Linkage and Dynamic Machining

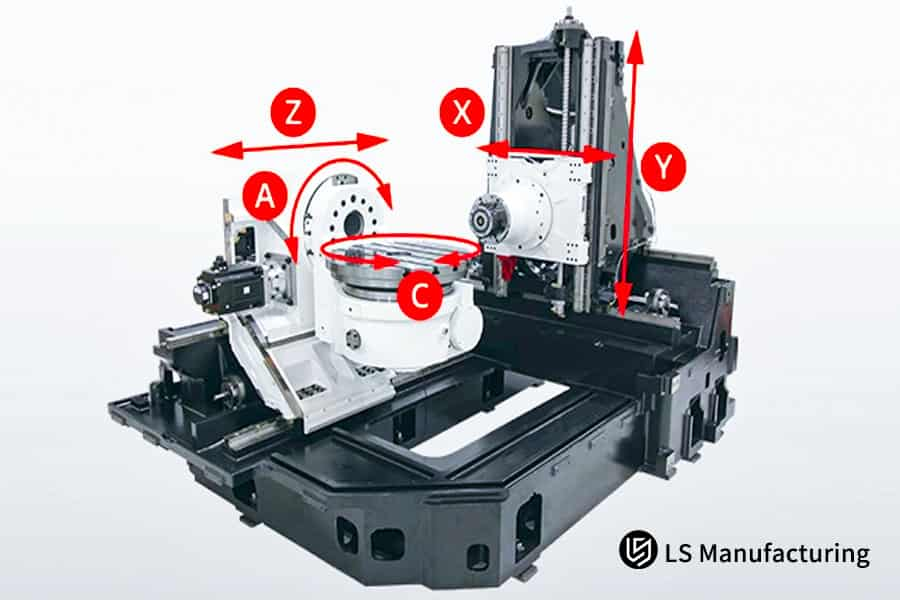

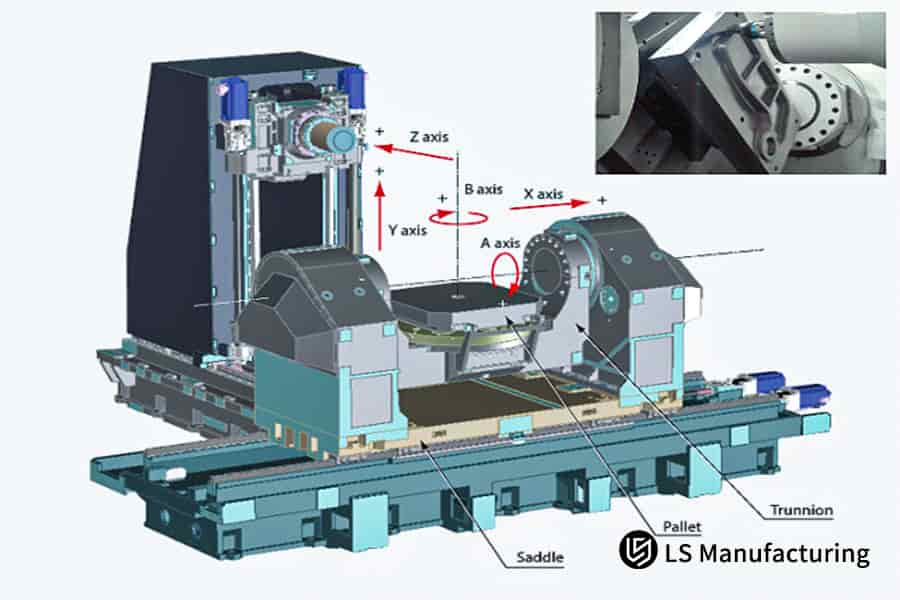

A 5-axis machine tool adds two rotary axes, usually the A/C axes or the B/C axis combination, in addition to the 3 linear axes of X, Y, and Z. During the operation, these 5 axes are not moving independently but are precisely linked under the control of a CNC system, ensuring that during the whole movement, the tool maintains the best cutting angle with the workpiece surface to efficiently machine complex spatial surfaces. The disruptive value of “one-time clamping”:

This is the central benefit of 5-axis technology

While conventional machining must have multiple clamping operations to change the machining surfaces, the 5-axis machine tool, by means of rotating the worktable or tool head, can complete most of the machining on 5 sides of a workpiece in one clamping. In doing this, it completely eliminates the accumulated errors caused by repeated clamping and greatly improves the overall precision and positional accuracy of the parts.

Simplification and effectiveness improvement:

There is no need to design and manufacture complicated special fixtures. Moreover, time saving on multiple clamping and debugging greatly simplifies the whole process of production. Meanwhile, shortening the tool and using side edges for effective cutting improves machining efficiency and surface quality, prolonging tool life.

Briefly, it means that 5-axis CNC machining fosters flexibility and precision in machining by concurrently moving several axes. It completes the integral manufacturing of complicated workpieces, with “one-time clamping,” which shortens the production cycle while its extremely high precision makes it an indispensable tool in high-precision fields such as aerospace and medical devices.

What are the advantages of 7-axis CNC machining over 5-axis?

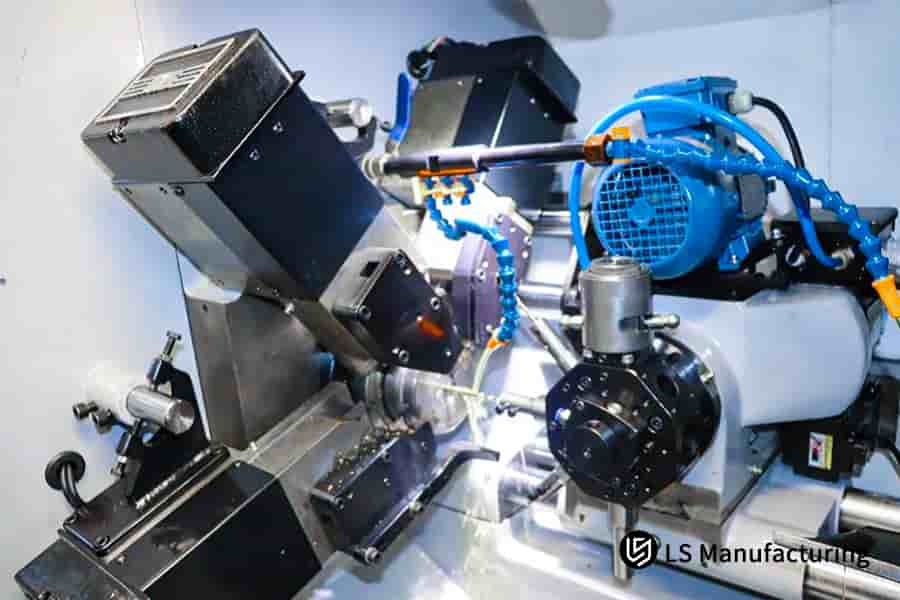

7-axis CNC machining represents a great step and improvement in the process of multi-axis CNC machining. The advantages will not lie in pursuing higher theoretical precision but in overcoming physical-space limitations and poor kinematics of 5-axis machine tools, especially in special scenarios involving the large and complex parts machining. The advantages come mainly from the following 3 key dimensions:

Machining Capability for Ultra-Large or Irregularly Shaped Workpieces

In general, the size and weight of a workpiece are limited by the worktable for 5-axis machine tools. By allowing the workpiece and tool to move collaboratively-such as adding two movement axes to the 5-axis system or introducing robot collaboration-a typical 7-axis system is able to machine giant components far beyond the travel range of the worktable, such as aircraft wing spars and big marine propellers.

Extreme Flexibility to Avoid Tooling Interference

For parts with deep cavities, complicated internal cavities, and features distributed compactly, collision can easily happen to the tool, tool holder, and tooling fixture. The 7-axis system provides more motion axes for more selectable approach angles and motion paths for tools, enabling them to bypass obstacles and reach the machining areas that are forbidden for 5-axis machine tools.

Generating Optimized Continuous Machining Paths

For very complicated spatial surfaces, 7-axis CNC machining can plan toolpaths that are much smoother and more effective than 5-axis machining. This will not only contribute to keeping more stable cutting loads and improving the quality of the surface but also protect the tool and extend its life by optimizing tool posture and avoiding extreme cutting angles in critical areas.

7-axis is not designed for and never intended to replace 5-axis machining; instead, it’s a very important complement to its functionality, mainly serving specific industries like aerospace and energy equipment. It solves the “impossible tasks” that 5-axis machine tools face in terms of physical scale, spatial obstacle avoidance, and path optimization.

5-Axis vs 7-Axis Machining: Core Differences and Selection Guide

Understanding the difference 5-axis vs 7-axis CNC will better arm you with the information to make the right decision in selecting a multi-axis machining solution. How choose 5-axis machining or decide to upgrade to a more complex solution has a direct impact on the success or failure of the project. Based on LS Manufacturing’s experience in multi-axis CNC machining services, here is a clear comparison and selection guide for you.

| Comparison Dimensions | 5-Axis Machining | 7-Axis Machining |

| The main axes count is 3 linear axes | X/Y/Z + 2 rotary axes: A/C or B/C. | This is typically based on 5-axis machining with the addition of a workpiece movement axis or a robotic arm. |

| Machining Flexibility | Extremely high, can be used to machine complex-curve surfaces in a single setup. | Highly capable of handling ultra-long strokes or extreme obstacle avoidance conditions. |

| Typical Applicable Workpieces | Complex parts, like aerospace components, impellers, and precision medical devices. | Ultra-large structural parts; workpieces with deep cavities or dense interference. |

| Overall Cost | Generally low equipment costs combined with low programming and labor costs; very good value. | Very high equipment costs with high programming/debugging costs; solution for certain intractable problems. |

| Programming Difficulty | Complicated requires professional CAM software experience. | Extremely complicated requires advanced simulation and post-processing, which is at a very high technological threshold. |

| Core Value | High precision, single setup, simplified process. | Overcomes the physical limitations of 5-axis machining, enabling ultra-large or extremely complex structure machinings. |

For most complex metal or plastic parts, 5-axis machining can provide the best balance among precision, efficiency, and cost. Only when your workpiece is extremely large or has an extreme tooling obstacle avoidance requirement is a 7-axis solution necessary.

What are the fundamental values of switching to multi-axis machining?

Adopting 5-axis machining technology has now become a major move for modern manufacturing to enhance its core competitiveness. The advantages are directly reflected in the following 3 quantifiable dimensions: reduce costs and improve accuracy, thus providing customers with a considerable return on investment. Specific comparative advantages are given below:

| Advantage Dimensions | Specific Manifestations and Quantifiable Benefits |

| Precision Quality | Mill several surfaces with one setup and completely avoid repeated positioning errors to raise the product yield to a new level. |

| Time and Cost | This would decrease the set-up time by more than 90%, greatly reduce investments in dedicated tooling fixtures, consequently shorten the production cycles, and reduce unit costs. |

| Design Freedom | Implement integrated machining for complicated structures, reduce parts and assembly steps, and optimize product performance and reliability from the very beginning. |

All the advantages of 5-axis machining interlink to a value system. It maximizes Return on Investment through improvement of quality, cost savings, and liberation of design. This is not just an upgrade of process, but a strategic choice to help companies move from “manufacturing” towards “intelligent manufacturing.”

Which industries and parts are best suited for multi-axis machining?

The LS Manufacturing 5-axis machining capability is deeply integrated into the high-precision industries and transforms the manufacturing challenge into a competitive advantage for many of our clients. The main concentration fields are aerospace parts machining and medical device machining. Some of the most typical application industries and part types are listed as follows:

- Aerospace: Parts in this field tend to be made of materials which are difficult to machine, such as titanium alloys and high-temperature alloys, with complicated configurations and extreme demands for weight and reliability. By using 5-axis machining centers, the machining of parts such as impellers and casings, which have complicated curved surfaces and deep cavities, can be done in one setting with accuracy, including meeting extremely high mechanical performance and aerodynamic efficiency.

- Medical Devices: Medical implants, especially for knees and hip joints, demand a very high degree of conformation to human anatomy and extremely high surface finish requirements. Our technology enables the efficient machining of materials such as medical-grade titanium alloys and PEEK to create complex skeletal biomimetic structures and provide high-precision parts for surgical robot end effectors.

- Automotive Industry: Turbocharger cores are of complex shapes and have excellent dynamic balance to improve efficiency in engines. Multi-axis machining offers high precision in blade profile accuracy, rapid prototyping, and functional testing, hence considerably shortening the developmental cycle.

- Energy Equipment: Whether for the impeller in a gas turbine or the integrated valve body of a hydraulic system, these have complex internal flow channels and spatial curved surfaces. Multi-axis technology avoids tool interference, which enables the integral molding of those parts, reduces assembly steps, and improves the overall equipment reliability.

LS Manufacturing 5-axis machining has ample experience with projects in many of these fields and has profound comprehension regarding the particular standards of quality and performance requirements for those areas. It also provides comprehensive solutions for customers from process planning to precision manufacturing, making sure every part is of top-notch performance and reliability.

How Does 5-Axis Machining Overcome the Challenges of Aero-Engine Impellers?

In the field of aerospace manufacturing, the machining of engine impellers has always been considered the most challenging job in precision manufacturing. These parts need not only to withstand the most adverse working environments but also to meet high aerodynamic performance criteria. Our cooperative project with an aerospace technology company perfectly illustrates how 5-axis machining technology can turn apparently impossible manufacturing challenges into successful engineering cases.

Client Challenge

In the development of a new generation of aero-engines, this company was facing a thorny technical problem: the impeller prototype needed to use high-strength titanium alloy materials with controlled blade thickness within 0.8 mm and flow channel profiles that were complex and varied. Using traditional 3-axis machine tools in manufacture alone meant not only that the necessity for multiple re-clamping produced obvious tool marks on the blade surface but also consistently led to failing dynamic balance tests. These problems caused interference that seriously affected the accuracy of aerodynamic performance testing and resulted in product development being nearly a month behind schedule.

LS Manufacturing Solution

The engineering team developed a systematic solution to address this challenge: First, we adopted an imported 5-axis machining center from Germany, equipped with a Renishaw probe for precision positioning; second, we employed multi-axis linkage programming technology to realize continuous and coordinated movement between the tool and workpiece; simultaneously, we developed a dedicated fixture system to ensure the stability of the thin-walled blades during machining. With regard to the machining parameters, after testing the process time and time again, we eventually came up with an optimal combination of cutting parameters-for instance, 0.08mm feed per tooth and 8000rpm spindle speed.

Results and Value

After precision machining, the final impeller prototype achieved good results: the surface roughness of the blade was controlled within Ra0.8μm, and the profile error of the flow channel was not more than 0.05mm. What is even more commendable is that the dynamic balancing test passed with less than 0.5g·mm/kg on the first try. These excellent performances shortened the development cycle from the original 14 working days to 4 working days and gave our customer a valuable market advantage.

This success story fully demonstrates the irreplaceable advantages of 5-axis machining technology in addressing complex manufacturing challenges related to aerospace parts. At the same time, by offering creative process solutions and sophisticated machining techniques, we helped clients not only to overcome technical bottlenecks, but more importantly to establish a replicable set of precision manufacturing standards.

Customize your multi-axis machining solutions and start your project now!

What are the major capabilities to consider in selecting a multi-axis machining supplier?

Success or failure of a project depends on how to choose a 5-axis machining supplier. As a customer, you want to work with a professional partner who is able to anticipate and mitigate risks and ensure final quality. The capability of LS Manufacturing 5-axis machining is built based on continuous investment in these key dimensions below. There are four core capabilities worthy of focus when choosing a supplier:

Hardware Equipment and Basic Precision Assurance

The supplier should be equipped with high-precision 5-axis machining centers, including but not limited to German DMG MORI and Japanese Mazak brands. It should have comprehensive equipment maintenance and precision calibration records that can lay a physical foundation for ensuring micron-level machining accuracy and long-term stability, directly determining the upper limit of part dimensions.

Advanced CAM programming and process simulation capabilities

Complex 5-axis machining depends on advanced Computer-Aided Manufacturing software and professional programming engineers. More importantly, suppliers need to apply specialized simulation software that comprehensively checks the toolpaths for the anticipation and avoidance of any possible collisions among a tool, spindle, workpiece, and fixture. That is very important to guarantee safety during machining and the first-pass success of it.

Specific Material Area Process Experience Database:

Different materials such as titanium alloys or high-temperature alloys commonly used in aerospace, or implant-grade materials within the medical field require quite different cutting parameters, tools, and cooling solutions. Whether the supplier has a mature machining database and successful case studies for materials in your industry is a very important factor in not making you a “guinea pig.”

Systematic Quality Control and Certification:

Check the supplier’s certification for ISO 9001 Quality Management System or AS9100 for aerospace. That would indicate that their quality control system would be a traceable, reproducible, systematic process rather than dependent on individual craftsmen, so batch products will be consistent and reliable.

In short, a qualified 5-axis machining supplier means finding a reliable value chain for your product. LS Manufacturing continuously builds its core advantages in these four dimensions to ensure every customer’s complex part requirements find strong support here, all the way from technical feasibility to commercial success.

What is the cost structure of multi-axis machining? How to optimize it?

Basic understanding of 5-axis machining cost structure is the basis of effectively controlling cost and maximizing value. The optimization of machining cost is all about bringing cost control forward to design and process planning. LS Manufacturing is committed to helping you find optimization opportunities through professional free DFM analysis services. Its cost structure and optimization strategies mainly include the following 3 aspects:

Pre-programming and process planning costs

It is a major cost element only associated with multi-axis machining. Only intricate CAM programming, simulation, and optimization can be extremely time-consuming for professional engineers. The way to optimize is early collaboration with suppliers, adopting DFM to optimize part design, such as standardizing corner radii and avoiding deep cavities and narrow grooves, which highly simplifies the complexity of programming and machining difficulties.

Amortisation Costs of High-Precision Equipment and Specialised Tooling

High-value machinery, such as 5-axis machining centers, is very expensive; likewise, very expensive specialized tooling is required for certain materials, such as titanium alloys. The optimization must make use of the process experience of the supplier in picking the most cost-effective tooling solution and extend tool life by optimizing the cutting parameters to decrease the unit cost.

Unit Machining Time and Post-Processing Costs

While 5-axis machine tools have higher time rates, their ability to complete multiple processes in a single setup significantly reduces the total machining time and also eliminates the costs of secondary setups, specialized tooling, and subsequent assembly. This is where optimization should fully exploit this advantage by reducing the number of parts through integrated design that lowers the overall manufacturing costs.

By actively communicating with your machining partners during the design phase and leveraging their experience for DFMA (Design-Factor Analysis), you will often be able to achieve tremendous improvements in machining efficiency with huge cost savings even from minor design changes.

What is the workflow in LS Manufacturing from drawings to finished product?

Turning your design ideas into top-class precision parts needs a strict, transparent, and well-efficient system process. This comprehensive guide to CNC machining is intended to clearly illustrate the whole LS Manufacturing service process and give you absolute transparency into each and every step of the process. Our process design is centered on ensuring project controllability, reliable quality, and smooth communication, finally providing you with a worry-free collaborative experience. The six key phases that constitute our end-to-end service process are as follows:

- Requirements Analysis and Accurate Quotation: Once we receive your 3D drawings and technical requirements, we will immediately conduct a process review and send a quotation, transparently detailed, within 2 hours with the price and delivery time clearly specified.

- Free DFM (Manufacturability) Analysis: Our engineers perform proactive DFM analysis and provide written optimization proposals to help customers improve the manufacturability of the design, reduce possible risks, and cut down unnecessary costs.

- CAM Programming and Machining Simulation: Efficient and safe toolpaths are then created using advanced CAM software by the professional engineers at the company. Additionally, 100% collision checks using simulation software are conducted to ensure faultless machining.

- Precision Machining & Online Inspection: Machining of the workpiece is done on the 5-axis machining center. Probes and other equipment are used by operators for online inspection of critical dimensions to supervise quality in real time.

- Final Quality Inspection and Report Issuance: The full-dimensional check of all the fully machined parts will be carried out on the CMM. Shipment will be made with a complete Quality Inspection Report for data traceability.

- Protective packaging and on-time delivery: Qualified parts will be cleaned and rustproofed, then properly packed to ensure safe transportation and delivery to clients within the timeline agreed upon.

This standardized process means integrated quality control for us in LS Manufacturing. It is not only about machining but also about cooperation on the pre-processing stage and quality assurance after processing. To our mind, process transparency is a solid base for trust; with such an approach, we can guarantee that every project you take up will turn out just as you expect.

FAQs

1. What is the MOQ of 5-axis machining?

LS Manufacturing fully understands various needs at each stage in product development. We support anything from single-piece prototypes to small batches without rigid MOQ restrictions. These flexible production lines are designed to give flexible support to your innovations while ensuring the same quality, whatever the quantity.

2. What is the typical lead time for 5-axis machining?

The delivery cycle for common complex parts is about 5 to 10 business days. However, this may vary with geometric complexity, size of the part, and the present production schedule. We shall issue a formal delivery commitment indicating exact dates upon receiving your drawings.

3. How do you cope with tool interference when machining?

We use advanced CAM software with full-path cutting dynamics simulation, which means 100% simulation of the machining process in the programming phase. In this way, all imaginable collision risks between tools, tool holders, and workpieces or fixtures for machining safety can be pre-identified and optimized by us.

4. Whether a strict tolerance of up to ±0.01mm is guaranteed or not?

Absolutely, top-of-the-line 5-axis machine tools fitted with fully closed-loop linear encoders and integrated Renishaw online measurement systems ensure stable tolerances as low as ±0.01mm or even more stringent. Confirmation of key dimensions is given in final CMM reports.

5. Does my product design require 5-axis machining?

It depends on the geometry of the part. Please upload a 3D model so our engineers can perform a manufacturability review. It is free of charge. We will recommend the best machining solution-3-axis, 3+2-axis, or 5-axis linkage from a techno-economic point of view to achieve maximum return on investment.

6. What do you do to safeguard the intellectual property?

Information security is our lifeline. An NDA can be signed in advance for every project before the commencement of the said project. Afterwards, the whole production process will be transferred to a controlled and isolated network environment where electronic and physical data are processed under proper procedures to ensure absolute security for your design.

7. Besides metals, is 5-axis machining possible for plastics or composite materials?

Of course, we machine a wide range of engineering plastics including PEEK and PEI, carbon fiber-reinforced composites, as well as other non-metallic materials. We can optimize cut parameters and the clamping scheme based on material properties to meet the special needs of industries such as aerospace and medical.

8. How do I get started with a first 5-axis machining project?

Very simple: You only need to upload your 3D design files through our website or email. A professional project manager will be assigned to contact you with preliminary process analysis, transparent quotation, and clear follow-up steps within 2 hours after the receipt of your files.

Conclusion

5-axis and 7-axis CNC machining represent the core technologies in today’s precision manufacturing industry. Their value far exceeds that of “machining”; these technologies are an essential means to drive product innovation, enhance performance, and win in market competition. Hopefully, this 5-axis CNC machining guide will be helpful to you.

Your complicated design deserves the best in manufacturing solutions. Free yourself from technology selection hassles-just click here to upload part drawings now and get a free technical solution and competitive quote courtesy of the expert team at LS Manufacturing. Let us apply our experience to protect your creativity.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.