In the arena of modern product development,

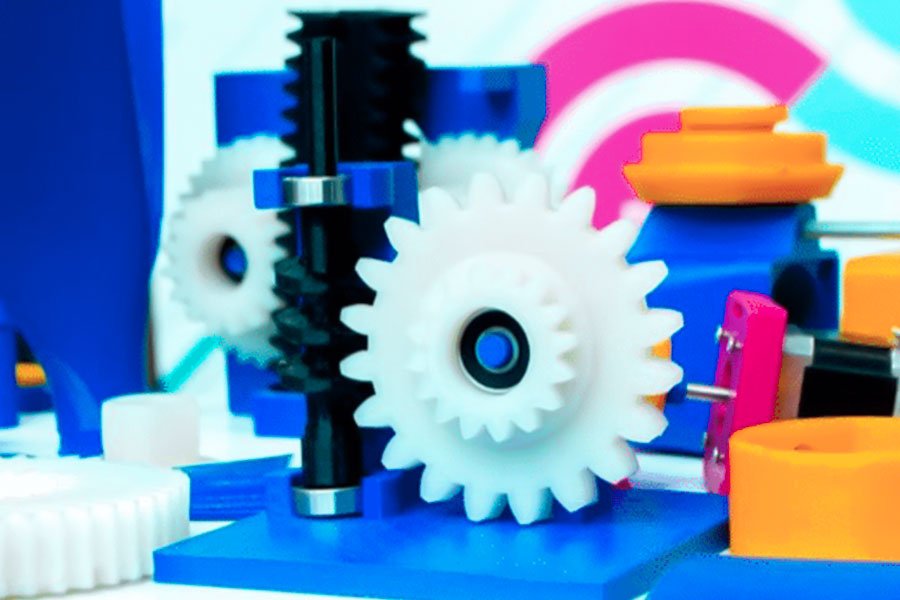

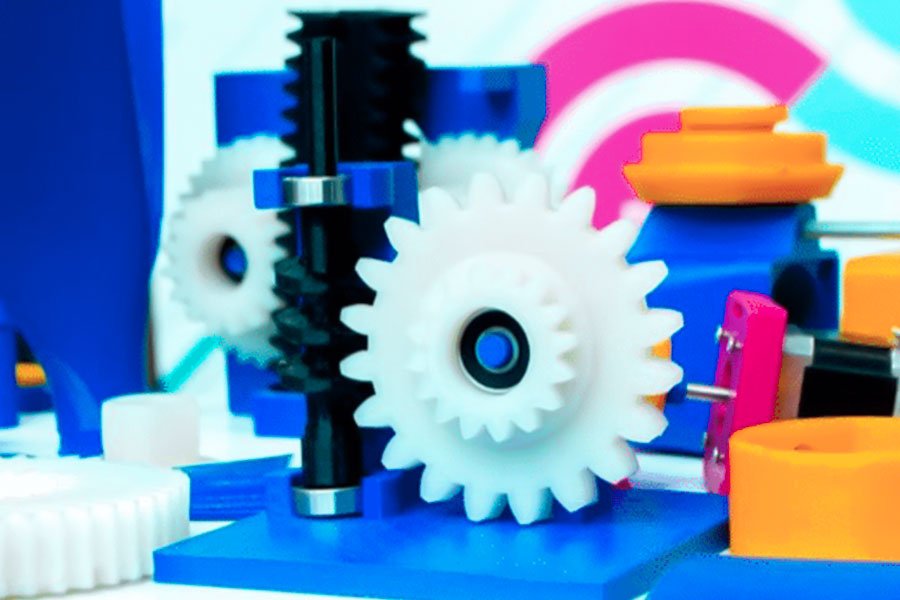

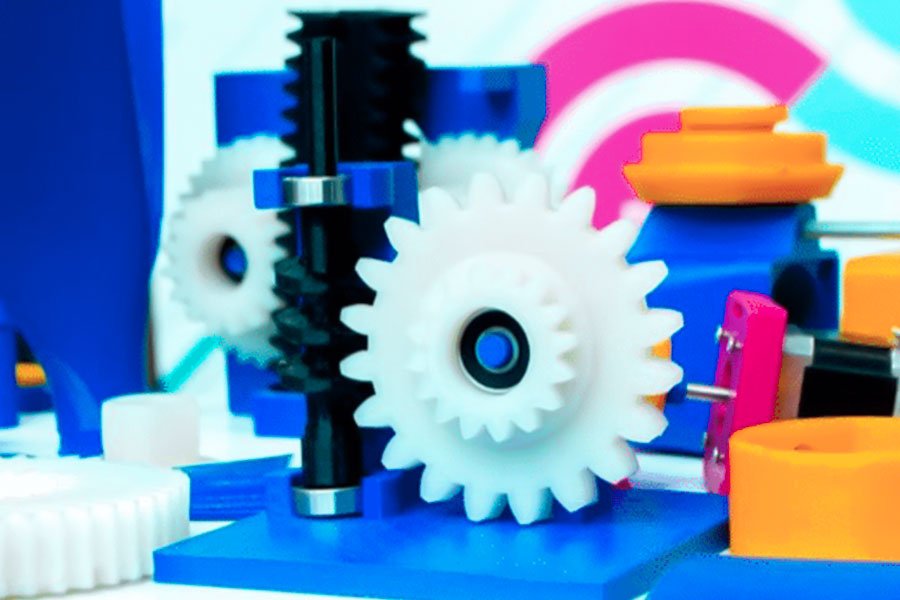

ABS and PLA are undoubtedly the two most dazzling “star players” in thermoplastics. Whether it is the spools stacked next to desktop 3D printers or the roaring

injection molding molds in the factory, they are everywhere. However, if you regard this duel as a simple multiple-choice question of picking a roll of

3D printing filament, you will greatly limit your engineering vision. For product designers and engineers who are truly committed to going from concept to market, the choice between ABS and PLA is far from a battle of filaments.

It is a strategic decision that runs through every key link from prototype verification to final mass production.

So, which material is “better”? This is an engineering trap in itself. In the pursuit of excellent products, “better” is an illusory pseudo-proposition; “more suitable” is the essence of engineering decisions. What is your core need? Is it to create a rugged and durable shell that can withstand rough drops and repeated impacts, or to quickly iterate and low-cost to produce a visual prototype to show the appearance and function? Will your product eventually need to be

mass-produced in millions through efficient injection molding processes? The answers to these questions are the real key to clearing the fog and selecting materials.

In order to help you transcend the simple “good and bad” debate and quickly focus on

the essential needs of engineering applications, we have sorted out the core differences between

ABS and PLA from a professional perspective.

Engineering Material Comparison: ABS vs PLA

| Engineering properties |

ABS (Acrylonitrile-Butadiene-Styrene) |

PLA (Polylactic Acid) |

Key points for engineering material selection |

| Mechanical strength and toughness |

High toughness, excellent impact resistance. It can yield and absorb energy under stress and is not easy to break. |

High rigidity, low toughness, and significant brittleness. Poor impact resistance, easy to break brittlely under impact or stress concentration. |

- ABS: Suitable for functional parts, shells, buckles, and tool handles that need to withstand impact, drop, repeated stress, or require toughness.

- PLA: Suitable for static display models, low-stress structural parts, and occasions with high rigidity requirements but no toughness requirements.

|

| Heat resistance |

High (HDT ~95-105°C). Able to withstand high ambient temperatures or short-term temperature rise. |

Low (HDT ~55-60°C). Rapidly softens and deforms at high temperatures and loses its load-bearing capacity. |

- ABS: Can be used in warm environments (such as automotive interiors, electronic equipment housings), parts that need to withstand certain working temperatures or post-processing (such as hot assembly).

- PLA: Only suitable for room temperature or low temperature environments. Parts in direct sunlight inside the car or near heat sources will fail.

|

| Manufacturability (3D printing) |

High requirements: requires heated bed (>90°C), closed chamber (anti-warping), and precise temperature control.The printing smell is obvious. |

Very friendly: no heated bed is required (or low temperature is sufficient), and it can be printed in an open environment. The printing smell is slight or absent. The fluidity is usually better. |

- PLA: The first choice for rapid prototyping, proof of concept, educational use, and desktop printing. Fast iteration and low equipment requirements.

- ABS: More professional equipment and experience are required, but the finished product is closer to the final industrial part performance. Warping is the main challenge.

|

| Manufacturability (injection molding) |

Extremely mature: good fluidity, thermal stability, wide process window, one of the main materials for injection molding. |

Specific requirements: low heat deformation temperature and possible crystallization behavior (for specific grades) require optimized process (mold temperature, cooling). |

- ABS: King of mass production, cost-effective and reliable performance.

- PLA: Suitable for injection molding products with bio-based requirements, but requires targeted process adjustments, and is generally not as mature and cost-effective as ABS.

|

| Post-processing capabilities |

Excellent: easy to grind, drill, and tap; can be perfectly smoothed with acetone vapor to obtain a similar injection molding gloss; good paint adhesion. |

Limited: can be sanded, drilled, and painted. Cannot be smoothed with acetone (does not dissolve). Other chemical smoothing methods have limited or challenging effects. |

- ABS: Post-processing is a huge advantage. It can achieve extremely high surface quality and is ideal for final appearance parts or high-precision assembly parts.

- PLA: The surface treatment effect is limited, it is difficult to achieve the smoothness of ABS, and it is more suitable for prototypes or internal parts with less demanding surface requirements.

|

| Ultraviolet (UV) resistance |

Poor: Long-term exposure to UV will cause significant yellowing, surface powdering, and brittleness. |

Poor: UV will accelerate the breakage of molecular chains, resulting in embrittlement and strength loss, and may also discolor. |

- Both are not suitable for long-term outdoor exposure applications. If outdoor use is necessary, it is necessary to:

- Add UV stabilizers (special grades).

- Use protective coatings/paints.

- Consider replacement or protection during design.

|

| Environmental protection and safety |

Petroleum-based. Theoretically recyclable, but the actual recycling chain is complicated (requires classification and cleaning). Releases VOCs such as styrene during printing, requiring good ventilation. |

Bio-based (usually derived from corn and sugarcane). Industrial composting is degradable (requires specific facility conditions). Basically non-toxic and odorless during printing (but ventilation is still recommended). |

- PLA: More environmentally friendly in the prototype stage (low carbon footprint, renewable resources, degradation potential), and safer to operate.

- ABS: The recycling system is more mature (especially in the field of injection molding), but it depends on the recycling infrastructure. Strict attention should be paid to ventilation and air filtration during printing.

|

| Material Cost |

Medium |

Low |

- PLA: Usually the lowest-cost entry-level choice, especially for high-volume prototype iterations.

- ABS: Slightly more expensive, but cost-effective in mass production due to its excellent overall performance and processability.

|

Here’s What You’ll Learn:

- A Concrete Decision-Making Handbook: Allows you to select ABS or PLA from the application scenario (impact resistance, heat resistance, aesthetic appearance, mass production) within 60 seconds.

- Comparative Study of Core Five Performances: Compare thoroughly the main differences in toughness and rigidity, heat resistance, manufacturability (printing and injection molding), post-processing effects and environmental properties, and explain how they influence the real performance of parts.

- Professional solutions to solve ABS printing problems: Master the three parameters to succeed in 3D printing ABS (hot bed, closed mode, ventilation), avoid warping and odors under control.

- The secret to obtaining perfect surface finishing: Describe only ABS’s “ace” post-processing technology-acetone vapor smoothing, how to obtain a smooth surface equivalent to injection molding without cost.

- Real-world prototype case study to mass production: Through a whole drone controller development project, it shows how strategically apply PLA and ABS (injection moulding and 3D printing) during different stages (concept validation -> functional validation -> small batch production) to finally achieve product launch.

- A step-by-step guide to materials that you cannot afford to miss: Get the concrete application conditions of “necessarily choose PLA” and “ABS is top class” nailed down so you regret not doing so.

- Resolution of the most frequent FAQs misleading engineers and designers: e.g., “Is ABS really better than PLA?”, “Is smell of printed ABS toxic?”, “Can PLA be injection molded?”, “Does transfer molding require redesign?”, providing ultimate and actionable answers.

Let us proceed a bit further in this age-old war of materials and find the best-fit “plastic partner” for your project.

Toughness And Rigidity – ABS vs. PLA

| Features |

ABS (Acrylonitrile-Butadiene-Styrene Copolymer) |

PLA (Polylactic Acid) |

| Core Features |

Toughness |

Rigidity |

| Key Ingredients |

Butadiene (Rubber Phase) |

Lactic Acid-Based Polymer (High Crystallinity Tendency) |

| Impact Resistance |

Excellent – Absorbs impact energy |

Poor – Brittle, easy to break |

| Deformation Behavior |

Bends and deforms when subjected to force, but not easy to break |

Resist deformation when subjected to force, and directly breaks when reaching the limit |

| Typical Applications |

Functional parts, housings, buckles, items that may fall |

Display models, decorative parts, static items that require precise shapes |

ABS’s toughness:

- ABS’s rubber phase is composed of fine rubber particles distributed throughout the plastic matrix. The rubber particles are similar to an infinite number of tiny “shock absorbers”. Upon impact, they can absorb and dissipate energy via deformation of themselves, inhibiting crack growth quickly.

- Metaphor: ABS parts are similar to Lego blocks. It can be plugged and replugged repeatedly (simulating stress cycles), and can also “bounce” or flex without shattering if dropped (simulating impact) due to its resilience, just like the same is difficult to destroy for Lego blocks.

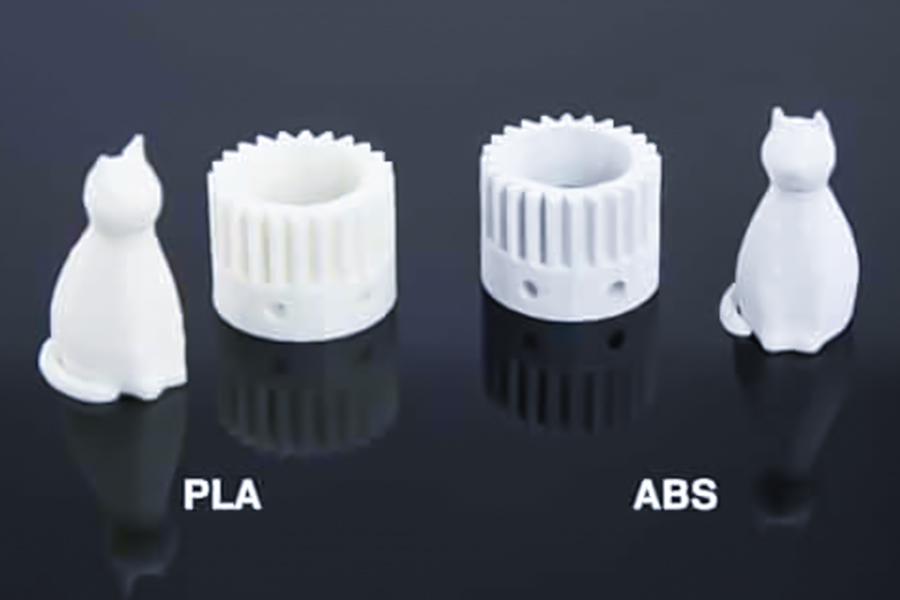

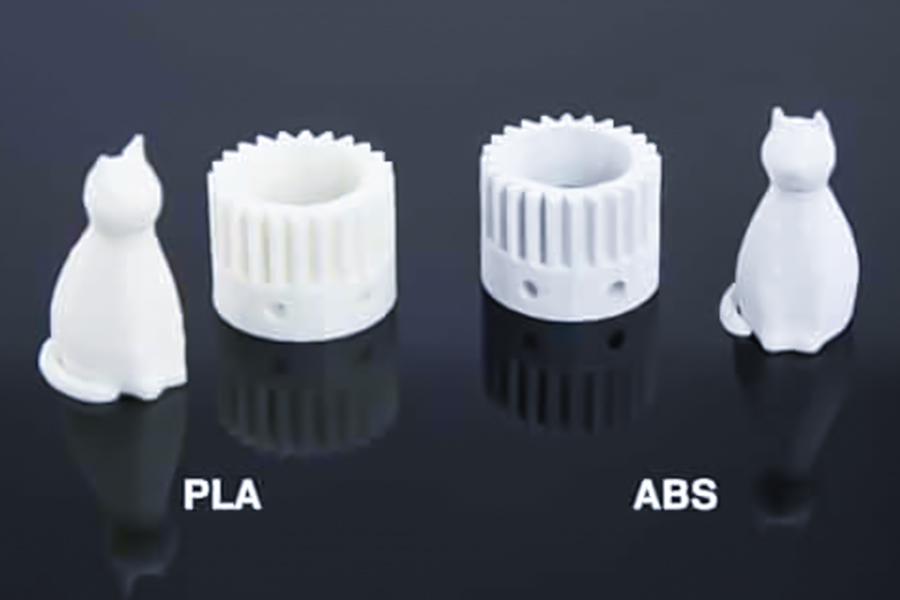

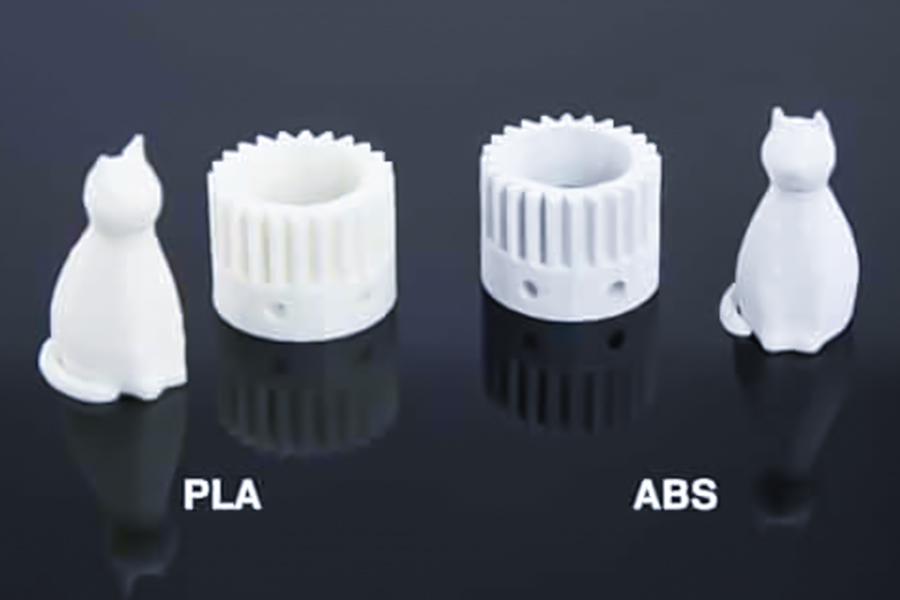

PLA’s Rigidity:

- PLA molecular chains are extremely isotropic and tend to form crystalline domains with ease, hence PLA possesses extremely high hardness and stiffness. This makes prints from PLA dimensionally stable and non-warping (when cooled down), and hence ideal for making display models or ornament pieces that have to maintain precise shapes, fine details, and are not loaded.

- But all this inflexibility and no rubber stage also mean brittleness. If it is impacted or loaded beyond its tolerance level, it does not yield to deform and absorb energy as ABS does, but fractures outright.

Engineering inspiration: On the above basis, if your parts need to withstand repetition of stress (such as snap-fits) or falling might be an issue, ABS is safer because it can absorb shock by toughness and avoid fatal failure.

Whenever impact toughness to withstand impact (e.g., snap-fits or dropped parts) is needed by the application, employ ABS; when static rigidity in terms of having some set shape is necessary to have, employ PLA – the former is strong and can withstand drops, but the latter is stiff and can break.

High Temperature Survival: ABS vs. PLA

| Features |

ABS (Acrylonitrile-Butadiene-Styrene) |

PLA (Polylactic Acid) |

| Heat Deflection Temperature (HDT) |

High (usually in the range of 90°C – 105°C) |

Low (usually in the range of 50°C – 60°C) |

| Upper Continuous Use Temperature Limit |

Up to ~80°C or higher |

Usually below ~55°C |

| Heat Performance |

Can maintain shape and rigidity at higher temperatures |

Soften and deform at lower temperatures |

| Direct Sunlight Tolerance |

Good, more resistant to UV aging |

Poor, easy to become brittle and deform after long-term exposure to sunlight |

| Typical High Temperature |

Applications Automotive interior parts, electronic equipment housings, tool handles |

Indoor models, low-temperature displays, short-term products |

- The heat deformation temperature difference (HDT): HDT is a measure of the temperature at which a material begins deforming significantly under stress. As seen from the above table, ABS’s HDT is much higher than PLA’s. This means that under the same external stress (even the material’s weight) and temperature, PLA will sag, bend, or deform permanently sooner and to a larger degree than ABS.

- Test of real-world scenarios:

- Car dashboard phone stand: In the summer sun, the air in an enclosed car can quickly be more than 60°C, and even approach or exceed 70°C. In such a situation, the PLA stand will quickly turn soft and deformed, and no longer function to hold the phone steadily in place, or even shatter into pieces. The ABS stand, with its higher HDT and heat resistance, will still maintain structural strength and be able to function in the same way.

Enclosure of electronic device: As the internal components of the device (e.g., the CPU, power supply) operate, heat is produced and the local housing temperature rises. The PLA enclosure can become softened and deformed irreversibly with frequent heat. This can affect the structural integrity, heat conductivity, or main function of the enclosure of the device. The ABS enclosure can endure the working temperature more and ensure long-term stable operation of the device.

From the survivability viewpoint of hot conditions, ABS is a reliable choice since it has much higher heat deformation temperature and heat resistance, whereas PLA cannot meet the demand due to its low heat resistance limit.

Equation Of Manufacturability: From Print Bed To Mold

Redirecting

prototypes from 3D printing to mass production by

injection-molding, material selection is not an automatic transposition. The processing disparity between ABS and PLA well dramatizes the fundamental difference in “manufacturability.”

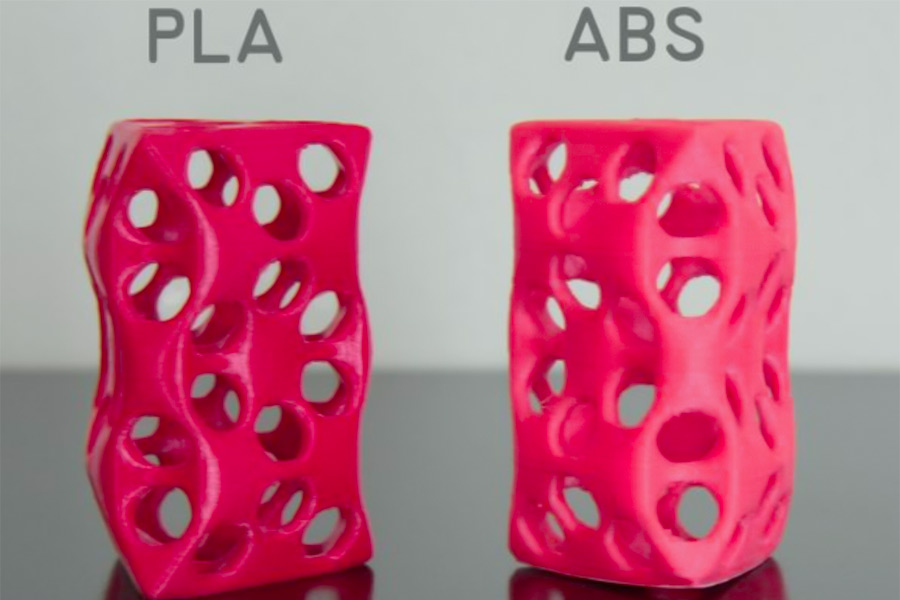

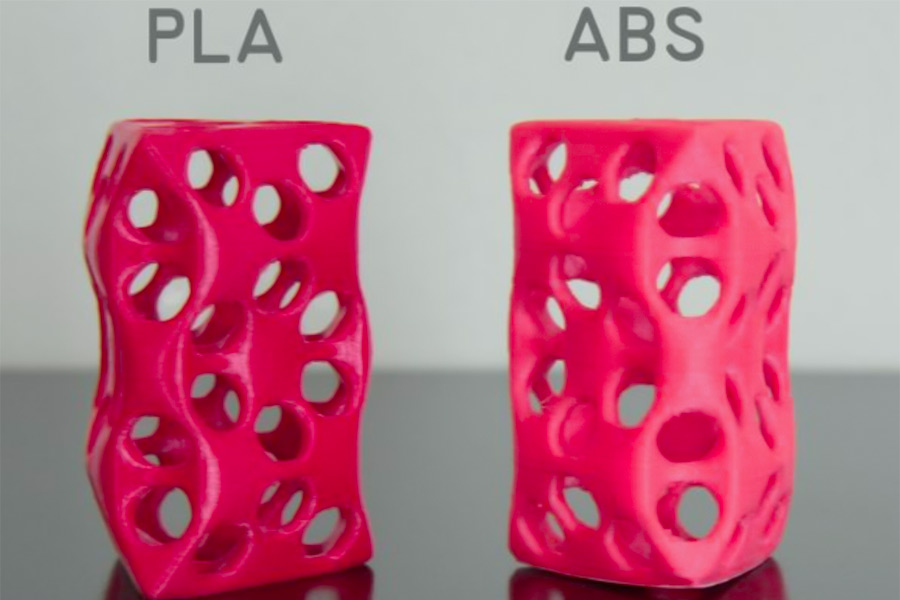

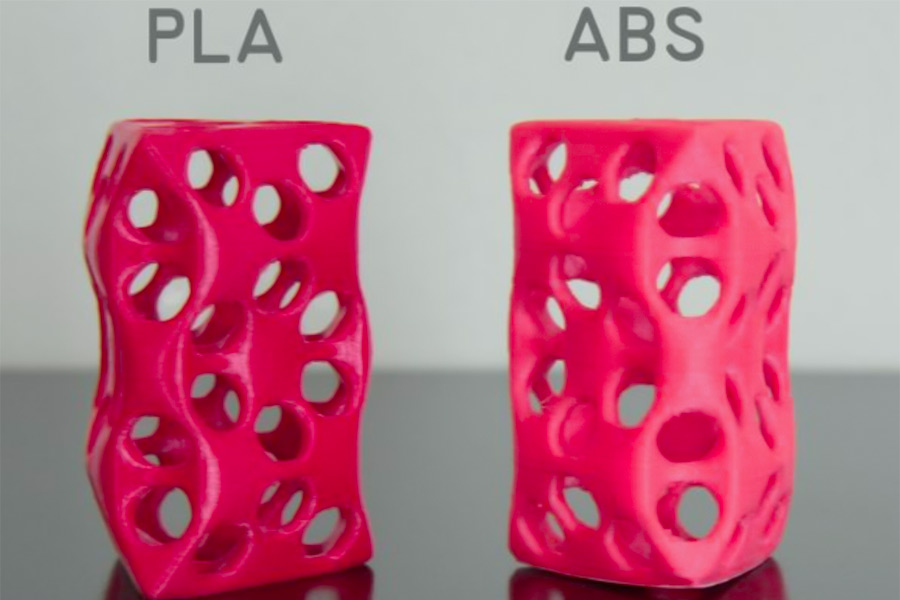

1.3D printing: the environmental sensitivity challenge

ABS: is a “hard to serve” model. Its severe shrinkage requires heating the print bed (~110°C) and isolating the environment to combat the terrible warping distortion of the model edge. In contrast, high-temperature printing releases VOCs such as styrene, which requires a large ventilation system, increasing cost and complexity to equipment.

PLA: It may be called the “friendly ambassador” of home desktop printing. A room temperature print bed is okay, environmental closure is not needed, VOCs release is extremely low, it is almost plug-and-play, and it possesses very good adaptability to laboratory environments.

2. Injection molding: the process maturity division

ABS: In

injection molding technology, it is an “old-timer” with a long application time (tens of years of use) and extremely mature technology. Its high melt fluidity and wide process window (temperature, pressure) guarantee that it possesses excellent molding stability. Its stable shrinkage (~0.5%) is easy to compensate for, and it possesses a high yield rate, which makes it an insured foundation for mass production.

PLA:

Injection molding applications are a bit specialized and more challenging. Its crystallization behavior is extremely sensitive to mold temperature (usually >60°C), and low-temperature molds lead to brittleness and uneven crystallization. Drying conditions of the raw material are strict (water content <0.025%), and even minute amounts of water are responsible for degradation, bubbles, and strength loss, significantly increasing the challenge and cost of process control.

From mold to print bed, material behavior is dramatically different. ABS is “troublesome” to print, but becomes a “stable foundation” in injection molding; PLA is print-conducive, but injection molding requires strict tuning. Understanding this collection of “manufacturability equations” – the amplification and constraint of material properties by process – holds the key to crossing the prototype-to-production gap successfully. When selecting material, process maturity and stability for mass production must rank above prototyping ease.

Achieving Ultimate Results: Post-Processing

If the prototype seeks to have the appearance and feel of mass-produced items, post-processing is the answer.

ABS material, by nature, possesses the “trump card” of 3D printed appearance enhancement, while PLA is severely limited.

1. ABS’s trump card: acetone vapor smoothing

Principle and effect: ABS prints, when exposed to a controlled acetone vapor environment, are slightly dissolved at the surface layer, the molecules re-flow and mix, the layer pattern and step effect are eliminated, and the

surface finish can be close to the injection molded article if processed well.

Benefits: cheap, time-efficient, and effective, suitable for functional models, show models or some end-use parts with high gloss or precise streamlined appearance.

Key points: Ambient temperature, vapor concentration and exposure time must be precisely controlled and the procedure must be performed in a well-ventilated area away from sources of fire.

2. Shortcomings of PLA: Problems of traditional techniques

Chemical smoothing issue: PLA is very resistant to regular organic solvents and does not have the ability to achieve a chemical vapor smoothing effect similar to ABS.

Mainly rely on physical methods

Grinding: very common but labor and time-consuming, difficult to handle complex cavities or fine details, excessive grinding may damage features or cause surface deformation.

Filling and painting: filling the defects and layers with fillers and then coating with paint can improve appearance uniformity and color but incur process and cost, and the paint surface may not be wear-resistant.

Other investigations: There are specific smoothing solutions for PLA, but the result is less effective and efficient than that of the ABS-acetone system, the cost is higher, and the safety demands are more stringent.

For 3D printed prototypes that require super smooth and traceless surfaces, ABS with acetone vapor smoothing is an ideal combination with better efficiency and effect. PLA prints rely mainly on grinding and spraying to improve their looks, and cannot obtain the same level of chemical smoothing effect. In selecting printing materials, if the final appearance requirements are in the first place, the advantages of ABS post-processing are the decisive factor and it is a sharp tool for appearance prototype polishing.

Green Debate: Biodegradable Or Recyclable

| Features |

PLA (polylactic acid, a typical biodegradable plastic) |

ABS (acrylonitrile-butadiene-styrene copolymer, a typical recyclable plastic) |

| Source of raw materials |

Bio-based (renewable resources such as corn starch and sugar cane) |

Petroleum-based (fossil fuels) |

| Core environmental attributes |

Biodegradable under industrial composting conditions |

Mature and efficient recycling system (recycling code #7 most common materials) |

| Degradation/recycling conditions |

Strictly rely on industrial composting facilities (high temperature, high humidity, specific microorganisms) |

Rely on existing plastic recycling sorting and processing processes |

| In normal environments |

Degradation is extremely slow (similar to traditional plastics, which may take hundreds of years and produce methane in landfills) |

Does not degrade, but can be recycled to reduce landfill and new material production |

| System maturity |

Industrial composting facilities are scarce and the collection and treatment system is not perfect |

Recycling infrastructure is widely mature and the treatment technology is stable and reliable |

| Ideal application scenarios |

Disposable, short-lived items that can be collected for industrial composting (such as specific tableware, packaging, prototypes) |

Durable, long-lived items that can enter the recycling stream (such as electronic product casings, Lego blocks, automotive parts) |

1. PLA’s “halo” and reality: conditionality of biodegradation

Halo: Bio-based feedstocks decrease some carbon footprint; biodegradable under certain industrial composting conditions (high temperature, high humidity, microorganisms).

Reality: Very slow breakdown in nature or landfills (centuries or even decades). Key bottleneck: Commercial composting facilities are few and collection infrastructure is weak. Reality:

- The majority of PLA ends up in landfills, degrades slowly and may produce methane.

- Mixing into mainstream recycling flows will contaminate recycled material.

- Conclusion: Its ecological advantages are highly vulnerable to the poor back-end processing infrastructure.

2. ABS’s pragmatic solution: The reliability of an experienced recycling system

Original state: Petroleum-based, non-biodegradable.

Advantages: Experienced and efficient recycling system (recycling code #7 most widespread materials):

- Gathers widely (electronic waste, some consumer products).

- Sorting and recycling technology is experienced, producing quality recycled ABS (rABS).

- Market demand is stable, forming a recycling-regeneration chain.

- Value: Substantially lower primary resource consumption and carbon emissions (vs. production of new material), and lower waste to landfills.

Conclusion: While petroleum-based, its well-established recycling system in practice effectively minimizes environmental effects, particularly for long-life items.

3. Scenarios dictate the choice

Disposable, short-life model/tests/products (and can facilitate industrial composting): PLA is superior.

Items that need usage for long durations, durable and recyclable: ABS boasts more utilitarian environmental advantages.

PLA is applied for simple disposal in short time (composting needs to be guaranteed), and ABS is preferable for use over long periods and recyclability.

Case Study: Prototyping A Drone Controller

I am Longsheng, a designer at LS. By taking the example of the newly successfully delivered drone controller, I will explain how to make strategic selections of manufacturing processes and materials with respect to the product development stage objectives to achieve efficient and dependable mass production.

Phase 1: Ergonomics and layout verification (concept verification)

Objective: Quickly validate handle grip comfort and physical button layout logic.

Plan and implementation: Use

PLA 3D printing because it prints quick and is cost-effective. It can iterate 5 versions of design within a week, and size accuracy can facilitate testing support and revision.

Outcome: By iterating quick and gathering customer feedback, optimal appearance design and button layout are locked in.

Phase 2: Structure and durability testing (functional prototype)

Goal: Expose the structural strength and durability of the controller to test, chiefly simulate daily drops and cyclic life of major moving pieces.

Plan and action: Use

ABS 3D printing, which has good toughness and impact strength, can replicate final product plastic behavior, and perform drop and buckle opening and closing fatigue tests on the prototype.

Results: The weakness of the initial design buckle’s strength was disclosed, and concentrated reinforcement optimization was led to avoid potential failure risks during mass production.

Phase 3: High-performance and quality production (small batch production)

Objective: Deliver the order of the first 10,000 units, enhance unit cost, increase production efficiency, and ensure product consistency and surface finish.

Strategy and implementation: On the basis of optimization of the

3D model in the first two processes, shift to ABS injection molding, and make special

injection molds by designing and manufacturing them.

Outcomes: Injection molding is satisfactory, the cost is significantly reduced, the production process is smooth, the product size is consistent, the structural intensity is high, the surface is clean, and it is suitable for listing.

Conclusion: Success is the outcome of strategic decisions

This project can reflect the serial process to developing hardware products. In LS, we completely realize there is no “universal” manufacturing process. Concept validation is done with PLA 3D printing, functional validation is done with ABS 3D printing, and injection molding for mass production; the goals of each process are diverse, which determines the processes and materials to be utilized; rapid iteration and rigorous testing in the early prototype phase are the most crucial features of successful mass production and cost reduction. The LS team is not only proficient in technology, but also full life cycle strategic thinking and practical capabilities, which can guide scientific planning of development courses and make optimal decisions. If you require any hardware product development, please ask the advice of the

LS team to customize the development strategy.

When Should You Absolutely Choose PLA?

Absolute situations for choosing PLA:

(1) Rapid, low-cost prototyping and display

When the basic requirement is to immediately verify the appearance, size or ornamentation effect rather than functional strength. PLA is easy to print (almost no warping), with a high rate of successful prints, a

smooth finish, and vivid colors. It can produce concept models, demo samples or packaging models with excellent visual effects at the lowest cost and quickest speed.

(2) Instructional, artistic and construction models:

When visual performance, simplicity of operation, safety and cost are most critical.

PLA printing has a mild smell and is non-toxic (safe in classrooms/homes). It can easily be post-processed and painted, has high color texture range (wood grain, stone grain, transparent, etc.), and is cost-effective. It is the number one choice for educational demonstrations, art models, and architectural scale models.

(3) Low strength, household desktop items

When making decorations, storage items, small tools or toys stored in a room at room temperature, not carrying loads, and not exposed to heat. PLA is strong enough to support such items, can show excellent appearance, feel and dimensional stability, and lowest printing cost and easiest.

(4) Single or small batch molds/fixtures:

When quick and affordable temporary auxiliary devices are needed to be made. For example, injection molds to cast several batches of resin, silicone, or low-melting-point substances (such as chocolate), or alignment fixtures. PLA is inexpensive per unit and easy to print repeatedly and quickly. Its short-term mechanical strengths and thermal resistance (<60°C) usually suffice.

When Is ABS The Unbeatable Choice?

ABS plastic is the choice one in the following uses:

(1) When excellent impact resistance and toughness are required:

When the part must absorb impact, pressure or persistent vibration (e.g., auto interior panels, dashboard components, luggage, sporting goods, tool cases), ABS is the choice one due to the excellent toughness contributed by its butadiene content, which may be useful in suppressing brittle fracture.

(2) Parts of good-quality appearance and surface treatment:

For items to be electroplated, vacuum coated, sprayed or silk-screened (e.g., car grilles, buttons, consumer electronics housings, home appliance panel), ABS possesses superior smoothness, adhesion and processing stability, and can be produced with high gloss, metallic feel or intricate color effects.

(3) Consumer electronic product housings and structural components:

In residential appliances such as TVs, monitors, routers, keyboards, printers, etc., ABS has balanced strength, rigidity, dimensional stability, easy to process, and good appearance processability, and is a mature product with very high cost performance.

(4) Requirements for large-scale injection molding production

ABS has good fluidity, wide process window, and excellent heat stability, enabling it to be very suitable for efficient and mass production

injection molding. Its mature process conditions and supply chains reduce the cost and risk of manufacture.

Brief summary of main strengths

The single most critical competitiveness of ABS is “balance” – it provides suitable impact resistance (toughness), stiffness, process flowability,

surface finish/dressability and similar economical cost. If your application situation requires attention to all these properties at once, especially where particular requirements on impact resistance, surface quality and large-volume production exist, ABS is generally the safest, economic and best-established first choice material.

FAQs

1.Is ABS really stronger than PLA?

That would be a function of how “strong” is being defined. ABS does outperform PLA in impact resistance and toughness (ability to absorb sudden impact without breaking apart). But PLA will be stiffer than ABS (ability to withstand indentation of the surface or flexing). Therefore, ABS would be more suitable if parts will need to withstand impact or bending, but PLA will do when a stiffness with not much force is needed.

2.Is printing ABS hazardous to breathe?

ABS does release volatile organic compounds (VOCs) when melting, such as chemicals like styrene. Prolonged exposure to these gases in a poorly ventilated location can be detrimental to health. Therefore, it is strongly recommended that good ventilation conditions be maintained while printing with ABS, preferably in an enclosed printer with air filtering or exhaust system.

3.Can you injection mold PLA?

Yes, we can injection mold PLA. Please note, though, that PLA has special requirements for temperature control of the mold and cooling time in injection molding, and its heat deformation temperature is lower, and long-term strength is typically worse than ABS. For high-strength mass production jobs with high heat resistance and cost demands, we usually recommend ABS or other engineering plastics.

4. Do I need to re-engineer when shifting from 3D printing to injection molding?

Most likely. Injection molding process does have specific demands, e.g., demolding angle, uniform wall thickness, avoidance of over-thick areas, etc., which are typically overlooked in

3D printing design. We will provide free manufacturability analysis (DFM), identify problems and propose modifications (e.g., raised draft angle, alteration of wall thickness, inclusion of ejector pin locations, etc.) to make the design suitable for mass production at high efficiency.

Conclusion

“Is ABS better than PLA?” The answer to this one is far from a simple yes or no. PLA, with its ease of use and environmental-friendliness, is rightfully a “creative accelerator” – it speeds up prototype verification and idea demonstration faster than ever before, and is an excellent partner for products 0 to 1. ABS, with its remarkable strength, toughness, heat resistance and post-processing, is a reliable “industrial workhorse” – it’s a superb foundation to build end-products that will survive harsh application environments, meet professional standards, and ultimately win the market.

It’s not just a question of

material selection, it’s the critical choice points within your product life cycle: are you content to merely rapidly prove out your ideas, or do you insist on creating a durable product that can truly withstand the test of the marketplace over a long period of time?

Whatever your answer to the former or the latter, the next step requires expert insight.

Upload your CAD file now! Not only will you get a swift and

accurate quote on injection molding (ABS or PLA) or 3D printing, but also expert guidance from real manufacturing experts throughout the entire product lifecycle. Let us help you pick the most suitable “engine” for your imagination, whether accelerating prototype iteration or driving your product to success!

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:

https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and

types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking

quotes for parts are responsible for defining the specific requirements for those parts.

Please contact to our for more information.

Team LS

This article was written by various LS contributors.

LS is a leading resource on manufacturing with CNC machining,

sheet metal fabrication,

3D printing, injection molding,metal stamping and more.

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/