Some time back, the question of “can stainless steel be 3D printed” was the industry’s hot potato. Today, the technology limitations have been surmounted, and metal additive manufacturing (AM) has grown from being a lab prank to a useful tool for engineers, inventors, and designers to solve complex structural issues and accelerate iteration. But with technical feasibility no longer the determining issue, the question “How much does 3D printing stainless steel cost?” has quickly become the all-overriding consideration before a project can begin, replacing “Is it possible?” as the pivotal idea.

This is far from a simple number. Compared to the open-and-shut expenses of desktop FDM plastic printing, metal AM’s cost profile, specifically stainless steel printing, is orders of magnitude more complex. It has a number of interdependent factors like the material itself, operation of equipment, post-processing operations, design optimization, part complexity and volume, batch size, and service provider strategy. Simple online quoters tend to fall down here; even a minor change in design or alteration of post-processing requirements can significantly alter the final cost.

Identification of these cost drivers is the foundation of sound project decision and effective budget control. In this article, we will review systematically the true cost structure of stainless steel 3D printing to allow you to prepare your next breakthrough project.

Components of Cost Estimates for 3D Printing

| Cost Components | Estimated Range (USD) | Key Influencing Factors |

|---|---|---|

| 1. Material Cost (Powder) | $50 – $120 / /kg | Part volume, required support structures |

| 2. Print Time (Machine Hours) | $10-$40/hour | Part height, complexity, and printing technology |

| 3. Post-Processing and Labor | $50-$1,000+/batch | Heat treatment, support removal, surface preparation (sandblasting/polishing) |

| 4. One-time Setup/Programming Fee | $50-$300/order | Print file preparation, build chamber layout optimization |

Here’s What You’ll Learn:

- A Transparent Cost Structure Formula: Unravelling the four key variables (materials/printing time/post-processing/setup fees) that constitute the cost of 3D printing stainless steel, dispelling the common myth that “size determines price.”

- Four Key Design Parameters: Show how part volume, complexity, print orientation, and post-processing requirements account for a huge component of the bottom-line price, allowing you to correctly estimate your costs.

- The Overall Cost Comparison of DMLS vs. Binder Jetting: Quantifying how different technologies impact cost, from machine time, material usage, through post-processing difficulty.

- The Hidden Economic Advantages of Outsourcing: In comparison to the tens of millions of dollars spent on machinery of an industrial standard, why professional rapid prototyping services are the budget-friendly solution for 95% of companies.

- Real-World Case Study: Drone Bracket: Discover how topology optimization merged three components of CNC into a single piece of DMLS-printed material that achieved a 40% weight reduction and 5-day delivery breakthrough.

- Frequently Asked Questions (FAQs): Dispelling myths like “Can home printers print stainless steel?” and “Is the cost per kilogram accurate?” and providing hands-on cost-saving tips.

Now, don the engineer’s hat and take us through actual cost justification of 3D printing stainless steel and maximize the return on each dollar invested.

Why Print Stainless Steel in 3D?

| Advantages | Traditional manufacturing (e.g., CNC machining, casting) | 3D printing stainless steel |

|---|---|---|

| Geometric freedom | Limited: Difficult to machine complex cavities, lattices, organic shapes, and deep, narrow features | Extremely high: Easily implement internal lattices, conformal cooling channels, and complex organic structures |

| Lightweighting potential | Limited: Often relies on subsequent subtraction or simple design, resulting in low material utilization | Excellent: Topology optimization preserves material only where stress is applied, achieving optimal strength-to-weight ratio |

| Component integration | Low: Complex products require multi-part manufacturing and assembly, increasing cost and risk | High: Multiple parts can be designed and printed as a single, integrated component, reducing assembly |

| Iteration speed | Slow: Long mold/tooling preparation and processing cycles (weeks to months) | Fast: Driven by digital files, functional metal prototypes can be obtained in days |

| Core value | Mature, potentially lower costs for high-volume production | Design freedom, rapid innovation, functional integration, on-demand production |

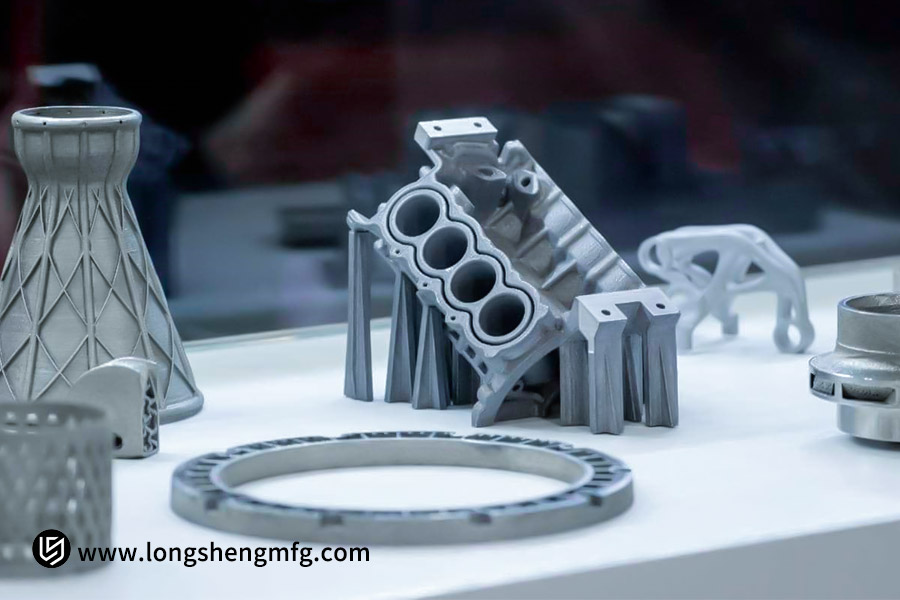

A Revolution in Geometric Freedom:

Liberating itself from the traditional design restrictions of subtractive (CNC) or homogeneous material (casting/forging) production.

Core Value: Developing internal lattice structures (energy absorption, heat dissipation, weight savings), conformal cooling channels (independently raising mold efficiency by orders of magnitude), highly complex organic biomimetic shapes, or embedded fluid channels—all impossible or economically infeasible to make by traditional methods.

The Summit of Lightweight Design:

Coupled with topology optimization algorithms, the software models stress conditions dynamically.

Core Value: To put material in only in critical load-carrying routes, thus removing redundant areas. This creates never-before-seen strength-to-weight ratios, mission-critical to saving weight in aerospace, transportation, and high-performance machinery.

Component Consolidation Simplifies Manufacture

Parts that had formerly required several discrete individual components (machined, welded, bolted, etc.) can now be redesigned and printed in a single, more integrated, more complex part. It decreases assembly stages, connector cost, and failure points, making the product easier to supply chain logistically and more trustworthy.

Facilitate faster development with faster iteration:

Abolish the time-consuming steps such as mold making and intricate tool setup, and proceed directly from digital models to parts.

Core Value: Functional stainless steel components are printed and delivered in days, not weeks or months, for testing and validation.

This dramatically speeds up development times to allow market feedback and design optimization.

The inherent value of 3D-printed stainless steel is to bypass the limitations of design, achieve functional integration, and bring innovative designs to unprecedented velocity, reversing the development and production cycle of complex, high-performance metal components.

The 4 Key Drivers That Increase Your Cost

Comparison of the Four Key Drivers That Additive Manufacturing Costs

| Influencing Factors | Primary Cost | Driver Cost Impact |

|---|---|---|

| Part Volume and Weight | Directly increase metal powder and other raw material consumption | High |

| Design Complexity | Increases support material consumption, increases print time, and increases post-processing labor | High |

| Print Orientation and Height | Z-axis height dominates print time; orientation affects efficiency | Medium-High |

| Post-Processing Requirements | Additional steps (e.g., heat treatment, finishing) increase labor and resource investment | Variable (can be very high) |

Part Size and Weight:

Material usage is the main driver of increasing cost. Larger and heavier parts require more metal powder or other print materials, and this is the most self-evident cost factor.

Design Complexity:

Overhangs: These require enormous support structures, not only consuming more material but, more importantly, incorporating much more labor and effort in removing support in post-processing.

Complex, thin-walled/finned details: These typically require slower print speeds to guarantee quality and accuracy, increasing total print time, machine size, and energy cost.

Build Orientation and Height:

Cost is most closely tied to print time, which is most closely tied to the part Z-height (time to create layers).

Orientation can significantly impact Z-height and support requirements. Optimizing orientation (e.g., orienting long parts flat rather than vertical) can significantly reduce print time, minimize supports, and overall reduce cost.

Post-Processing Requirements:

The number and nature of post-processing operations are significant considerations that will have a huge impact on cost.

Basic processing (e.g., support material removal, sandblasting) is relatively inexpensive. Advanced processing (e.g., stress-relief heat treatment, CNC machining of critical sizes, and complex surface finishes/coatings) can significantly contribute to labor costs, equipment fees, and consumables.

The rising cost of additive manufacturing is primarily due to the material usage, wasteful printing times due to complexity of design and print orientation, and extra labor and resource input that goes into the different post-processing treatments required to obtain final specifications.

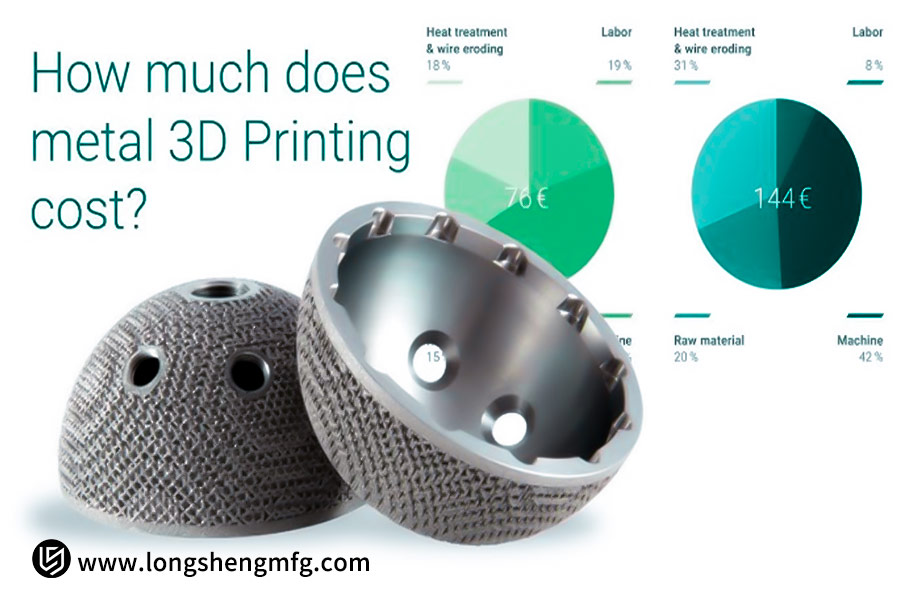

The Core Cost Formula That You Need to Know

| Cost Factor | Definition | Is it primarily affected by part size? | Impact Explanation |

|---|---|---|---|

| Material Cost | The cost of raw materials used to manufacture a part | Yes | Larger parts, thicker walls, and more solid sections require more material. |

| Machine Time | The cost of equipment (3D printer, CNC machine, etc.) runtime. | Partially | Size affects this time, but complexity (supports, fine features) has a greater impact. |

| Post-Processing Cost | The cost of manual operations or additional processing required after printing/machining. | Usually No | Depends on the process selected (sanding, staining, painting, assembly, etc.) and labor time. |

| Fixed Setup Fee | A fixed base fee charged per order or batch. | No | Covers fixed administrative costs such as file processing, machine preparation, and basic quality inspection. |

Core Cost Formula:

Total Cost ≈ (Material Usage × Material Unit Price) + (Print/Process Time × Machine Hours) + Post-Processing Fees + Fixed Setup Fee

Material Cost:

Calculation: Actual weight or volume of the part times material unit price.

Key Point: Material unit prices vary greatly (plain PLA vs. engineering-grade nylon vs. metal powder), and material selection has a direct impact on this cost. Part geometry (volume, density) is the largest contributor.

Machine Hours:

Formula: Machine time to produce the part multiplied by machine/service hourly rate.

Important Fact: Time is more than size but a function of geometry complexity (overhangs have additional support time), print/processing strategy (toolpath, layer thickness, infill density), print speed, and number of parts printed in parallel (smearing cost). Small complex parts can take longer and cost more than large simple parts.

Post-Processing Costs:

Calculation Basis: Generally a set or fee-per-piece/per-hour based on character of post-processing process and duration of labor involved.

Key Factor: Variable by size. The cost is highly dependent upon client’s specific specifications (e.g., fine sanding, special color paint, plating, assembly, custom packaging, etc.). Different processes (e.g., manual sanding vs. automatic dyeing) have immensely different prices.

Fixed Setup Fee:

Calculation Basis: Level rate per batch or order.

Key Point: This is the cost of handling an order on the service provider side, review and correction of documents (if required), initial machine preparation (material change, calibration), overall cleaning cost, and minimum management fees. Small or large, this fee is usually remitted when an order is placed. With a single small lot or single small parts, this fee probably represents a fine percentage of the overall cost.

The price for the complete rapid prototyping service, online or offline, is not merely dependent on component size but on material utilization, production time (dependent on size and complexity), customer-specific post-processing, and fixed operating costs to be incurred. Geometry is just one of the cost drivers.

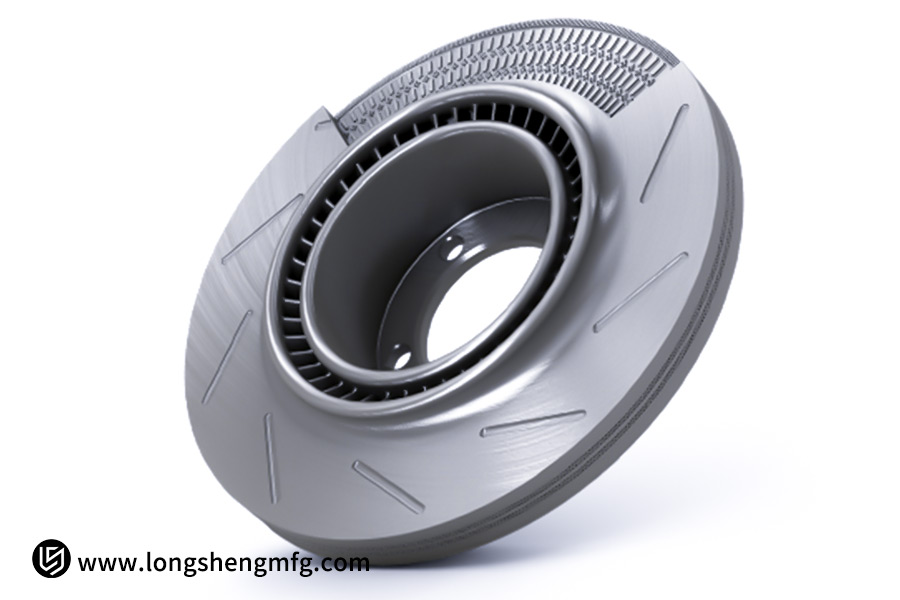

DMLS vs. Binder Jetting: How Technology Selection Impacts Cost

The difference in the technical approach between DMLS and binder jetting directly determines their respective cost drivers in metal additive manufacturing, greatly affecting the final part cost.

Comparison of DMLS and Binder Jetting Costs

| Features | Direct Metal Laser Sintering (DMLS/SLM) | Binder Jetting |

|---|---|---|

| Core Cost Drivers | High laser cost, low print speed, inert gas | Low printhead cost, high print speed, sintering energy consumption |

| Equipment/Machine Hours | Very high (precision laser system, high maintenance) | Relatively low (low inkjet printhead cost) |

| Print Speed | Slow (point-by-point melting) | Very fast (layer-by-layer binder jetting) |

| Raw Material Cost | High (specialized spherical metal powder) | Relatively low (cheaper powders available) |

| Post-Processing Costs | High (support removal, stress relief heat treatment) | Moderate (debinding, sintering, possible metal infiltration) |

| Material Utilization | High (most unmelted powder is recyclable) | High (most unbound powder is recyclable) |

| Dimensional Accuracy/Shrinkage | High accuracy, controlled shrinkage | Significant shrinkage, compensation required, accuracy challenges |

| Cost Advantages of Scale | Limited incremental production cost reduction | Small batches significantly reduce unit cost |

| Best Use Cases | High-precision, high-performance functional parts, complex prototypes | Small-batch production parts with simple geometry, prototypes |

Equipment and Machine Hours

DMLS: High laser system cost and slow printing → Extremely high machine hourly costs

Binder Jetting: Low inkjet head cost and fast printing → Moderately reduced machine hourly costs

Material Costs

DMLS: Requires high-purity spherical powder → High material cost

Binder Jetting: Low-cost powders + binder use → Low cost of materials

Post-Processing Expense

DMLS: High complexity of support removal + heat treating → High post-processing expense

Binder Jetting: High debinding/sintering energy consumption + shrinkage compensation → Moderate post-processing expense (yet with accuracy risks)

Scale Benefits

DMLS: Difficult to scale speed → Little cost benefit in batch size

Binder Jetting: High-speed printing + nested packing → Significant unit cost benefits for small batch sizes

In general, complex functional parts that pursue ultimate precision and performance generally need to bear the prohibitive cost of DMLS, while low-production volume needs with relatively simple geometries can more significantly benefit from the huge unit cost savings of binder jetting.

Service vs. Buying a Printer: A Cost-Benefit Analysis

Faced with the hundreds of thousands or even millions of dollars that industrial metal 3D printers command, most businesses today are resorting to professional service providers to acquire customized rapid prototyping, which is more cost-effective and rational.

Cost-Benefit Comparison Overview:

| Comparison Items | Purchasing an Industrial Metal 3D Printer | Using Customized Rapid Prototyping Services |

|---|---|---|

| Equipment-Related Costs | High purchase price + depreciation + maintenance + space | Zero Cost (No equipment ownership costs) |

| Materials and Processes | Requires custom-built environment + expensive trial-and-error parameter exploration | Professional Environment + Proven Processes (Eliminates trial-and-error costs) |

| Flexibility | High fixed costs, resulting in significant waste when utilization is low | Use as needed, pay per project (frees up resources) |

- Eliminate the substantial equipment ownership costs: Organizations completely remove the hefty initial acquisition cost, ongoing depreciation, routine maintenance costs, and assigned location rental or building costs of industrial-strength metal 3D printers.

- Transfer professional material and process know-how: Service providers provide a controlled environment for the storage and handling of materials, as well as an experienced staff of engineers and an extensive database of process parameters, essentially removing the expensive material and time-consuming trial-and-error process development burden on clients.

- Have full flexibility: With a pay-as-you-go arrangement, firms pay for only that time when the service is used. This suits best project-based, small-order, or infrequent needs, avoiding the enormous wastage of resources by idle equipment.

For most firms, accessing their metal 3D printing prototyping needs fulfilled from a professional service organization is the most cost-effective choice, reducing investment risk significantly, improving utilization of resources, and obtaining high-quality result in a timely manner.

Case Study: Prototyping a Drone Bracket

Client Challenge:

A startup drone firm we worked with was in a time-sensitive requirement for a light yet high-strength customized bracket for its core camera gimbal system. Their initial idea was a traditional CNC machining approach, where they machined three separate pieces and then welded them together. This resulted in a weight in the finished component well over the design specification as well as a long production cycle, severely affecting their product development schedule.

LS Solution:

We moved fast to remedy the client’s issues and intervened:

- Design Optimization: Our team of engineers utilized topology optimization technology to reorganize the initial design. This led to the three previously constructed parts being merged into one, more streamlined geometry, eliminating much redundant material.

- Advanced Manufacturing: We selected Direct Metal Laser Sintering (DMLS) additive manufacturing, printing the part in 316L stainless steel. This technology is ideal for the manufacture of high-performance metal parts with complex internal geometries or integrated design, free from traditional tooling.

Achievements and Value:

- Substantial Performance Enhancement: The last working metal prototype bracket weighed 40% less than the initial design without compromising on rigidity. Primary mechanical attributes, including strength, were enhanced by a similar percentage of about 25%. This directly impacted and improved the payload and flight capabilities of the drone.

- Faster Development Rate: From the time the customer had put up the last optimized drawings to the time the customer had a functional testable metal prototype, it took only five days. This significantly accelerated the customer’s iteration and verification cycle.

- Total Cost Advantage: While the cost of one proof ($450) was higher than typical CNC machining, we eliminated the outrageous cost of mold development and enjoyed an incredibly quick delivery time. More specifically, we saved the customer a significant amount of time to market, dramatically increasing market opportunity and product development productivity. The value delivered was far greater than the difference in one-off manufacturing expense.

Key Insight

This case study fully shows how LS, through collaborative design optimization (topology optimization) and advanced metal additive manufacturing (DMLS) capacities, helps customers address the inherent tradeoffs of lightweighting, high strength, and fast delivery, providing solid support for effective development of innovative products.

FAQs

1. How much more expensive is 3D printing stainless steel than plastic?

The cost of 3D printing stainless steel is significantly greater than printing with plastic, and the actual difference depends on the material in question. Compared to high-performance engineering plastics like ULTEM, stainless steel printing usually costs 5 to 20 times more, and for general-purpose plastics like PLA or ABS, it can be hundreds of times more costly. This is mainly due to the costly equipment required for metal printing (e.g., laser melting systems, which cost hundreds of thousands of dollars), a gas inert atmosphere, high-cost metal powders, and expert post-processing (e.g., heat treatment and finishing). Plastic printing, though, uses inexpensive FDM or SLA printers, which are simple to work with. Hence, stainless steel printing is better for industrial mass production compared to individual projects, with the cost variation being largely caused by equipment investment, material rarity, and power usage.

2. Can I print stainless steel using my home 3D printer?

Not by a long shot. Domestic 3D printers are generally optimized for plastic materials (like PLA or ABS) and are not capable of working with stainless steel or metals in general. Metal 3D printing takes specialized machinery, like selective laser melting (SLM) machines, and has to be done in an isolated chamber supplied with an inert gas (like argon) to ensure there’s no oxidation and explosion hazard. It demands high-powered lasers (in the order of kilowatts), accurate temperature control, and careful safety protocols. The machinery is costly and calls for professional certification. Attempting to print at home not only will not succeed but also poses extreme safety risks, such as fire or toxic dust. Therefore it must be done only in industrial-grade facilities.

3. How can the cost of 3D printing stainless steel be reduced?

Design optimization is a significant cost-saving measure: removing material from solid components to save on material use (e.g., honeycomb structures), reducing support structures to save on post-processing time, selecting optimum print orientation to save on surface defects and support requirements, and tolerating in non-critical areas to avoid unnecessary finishing. Batch printing of multiple parts also distributes equipment costs. The application of simulation software to predict potential issues (e.g., distortion) allows for the choice of low-cost technologies such as binder jetting. Cooperation with print service bureaus to fine-tune parameters (e.g., layer thickness and laser power) and recycling powder from wasted powder can also reduce costs by as much as 20-50% in total.

4. What is the cheapest metal 3D printing process?

In low-volume manufacturing, steel materials (such as 17-4PH stainless steel) made by binder jetting tend to be the lowest-cost per-part. The process deposits a binder to bind metal powder together into shape and sinters to form a solid material. The process is rapid and effective with less investment equipment needed than laser melting processes (such as SLM) and excellent material usage efficiency and ability to fabricate complex geometries. Other cost-effective techniques are wire arc additive manufacturing (WAAM), but binder jetting is the cheapest because of its batch nature, low post-processing needs, and wide applicability (e.g., car parts). It costs only a few dollars per cubic centimeter to make it suitable for prototyping and low-volume production.

Conclusion

The cost of 3D printing stainless steel is dynamic, depending on your design, technology choices, and post-processing requirements. Rather than being obsessed with a fixed “price per kilogram,” view it as a strategic investment. Its true value lies in the design freedom, development speed, and improved product performance it brings you.

Stop guessing about the cost of your next rapid prototype part. Leave the complex calculations to LS! Upload your CAD file to our intelligent quoting platform now, and you’ll receive a detailed, transparent 3D printed stainless steel quote in seconds. Experience the speed and excitement of bringing complex prototypes to life!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

As a Newbie, I am always browsing online for articles that can benefit me. Thank you

At this time it seems like BlogEngine is the best blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?