Material selection in engineering design and fabrication ever determines the performance, cost, and life of the product. Between the other two most prized materials in the market today for enhanced corrosion resistance and strength, respectively, with light weight and heat transmission, come stainless steel and aluminum castings. The options, however, inevitably oblige the decision-makers to make the choice. Do you make it for the strength and hardness of the structure or reduce the weight and enhance the economy in production? It goes beyond the technical properties but determines to a large degree the competitiveness in the market for the product and the mode of its application. The subsequent article will provide a thorough analysis of the inherent merits and de-merits of each, providing logical reasons for the resolution of this perennial dilemma.

Stainless Steel vs. Aluminum Casting Core Performance Quick Reference

| Performance Indicators | Stainless Steel Castings | Aluminum Castings |

| Strength/Structural Performance | Excellent: Offers extremely high strength and hardness, with excellent load-bearing capacity, wear resistance, and deformation resistance. | Fair/Good: High specific strength (strength/density ratio), but lower absolute strength and hardness than stainless steel, making it susceptible to deformation. |

| Corrosion Resistance | Excellent: Demonstrates excellent corrosion resistance in natural atmosphere, fresh water, and various harsh chemical media, requiring no additional surface treatment. | Good: Forms an oxide film in air, providing good atmospheric corrosion resistance, but is susceptible to pitting corrosion in harsh environments such as chloride ions, often requiring enhanced surface treatment. |

| Lightweight (Density) | Poor: High density (~7.8 g/cm³) and heavy weight, making it unsuitable for lightweight design. | Excellent: Extremely low density (~2.7 g/cm³), weighing only about one-third that of stainless steel, making it a preferred choice for lightweighting. |

| Cost | High raw material prices; demanding casting processes (high melting point, slightly poor fluidity), resulting in relatively high processing costs. | Low raw material prices; excellent casting performance (good fluidity, low melting point), high production efficiency, and more advantageous overall manufacturing costs. |

- Briefly, no material is possible to be totally perfect; only the best available alternative can be obtained. To have total structural strength, durability, and corrosion resistance in case weight does not become an issue, stainless steel is to be utilized.

- If reducing weight, light weight, and cost-effectiveness are your priorities the most and you are willing to sacrifice corrosion resistance in processing points, then aluminum casting is a sensible option.

Why Trust This Guide? Practical Experience of LS Experts

The LS staff have extensive working experience in the food machinery sector. LS specialists possess significant experience in material science and always provide customers with the proper material selection solutions in accordance with strict hygiene standards, corrosive environments, and cost savings, taking into account optimal equipment functioning and its lifespan.

While operating a customer application of food grade screw conveyor (LS series), corrosion of the sauce and easy cleanability was experienced by the customer. LS experts strongly recommended 304 stainless steel throughout the entire line. Its superior-than-food-grade corrosion protection, stain resistance, and ease of cleaning and disinfection is more than adequate to withstand acidic environments and sanitation processes, significantly improving equipment reliability and customers’ production performance. All this clearly demonstrates LS’s proven and reliable, field-validated scientific material selection logic. If you do have material selection questions or concerns, feel free to contact us at LS.

What Are The Unique Characteristics And Applications Of Stainless Steel Castings?

In the inner spaces of industrial production, material choice has a direct influence on both product performance and lifespan. Stainless steel castings, with all their full complement of high-end properties, are today prime prime components in a wide range of demanding applications. They are not commodity metal products, but the ultimate manifestation of engineering and materials science unification.

1. Advanced mechanical and chemical properties

Their main advantage is basically in their advanced mechanical and chemical properties. The most characteristic property of stainless steel castings is their optimum possible combination of high strength and superior corrosion resistance. What it means is that stainless steel castings can withstand considerable loads and impacts and are resistant to corrosion from various media, e.g., water, chemicals, and acid-containing atmospheres, significantly enhancing equipment life. In addition to that, they also exhibit fine wear resistance, withering and dimension stability even under harsh abrasion conditions, and enhanced high-temperature resistance, withering strength and oxidation resistance under high-temperature conditions, and therefore less inclined to deform or fail.

2. Challenging applications

Due to this, stainless steel castings find use in almost all industries requiring utmost reliability. It is used in shipbuilding to create seawater corrosion-resistant propeller components, pumps, and valves. Its corrosion resistance, sterilizability, and non-toxicity have established it as a dependency for food processing equipment and medical devices in applications such as mixing tanks, surgical instrument holders, and implants. In addition, in applications relating to energy and chemicals, stainless steel castings are used in piping systems, pumps, and valves for sealing, strength, and stability for long-term use under harsh operating conditions.

- In brief, stainless steel castings with everywhere characteristics of high strength, resistance to corrosion, wear resistance, and high temperature resistance have taken the pivotal position in the high-grade equipment manufacturing industry.

- It is generally a valuable and best choice when used in application where a product requires to be strong, tough, and clean simultaneously.

What Are The Priceless Benefits Of Aluminum Castings? Where Are They Used?

In the modern industrial pursuit of lightness and energy efficiency in design, aluminum casting with its perfect combination of strengths has been an invaluable and vital contributor. It not only represents lightness but is equally concerned with performance and economic benefit, providing fundamental material bases for innovation and progress in numerous industries.

Ultimate lightweight and excellent functionality

Its critical advantages are mainly summarized in its ultralightweight and superior performance. The most excellent feature of aluminum casting is its extremely low density, weighing around one-third that of steel. This has a great role in reducing equipment weight in general and in improving energy efficiency. Besides this, its excellent thermal and electrical conductivity allow it to be the first option for manufacturing heat dissipation components. In terms of process, the higher fluidity of aluminum alloy melts provides a capability to replicate complex and detailed mold cavities with high accuracy for casting thin-walled castings with complex structures and fine surfaces.

Unmatched cost-effectiveness

Another significant advantage is its greater cost-effectiveness. Compared to other cast metals, aluminum castings are more expensive economical raw material and production-wise. Their reduced melting point reduces energy consumption, and their increased casting properties reduce subsequent processes by hugely improving the efficiency of production and keeping overall production costs low.

Different applications

Due to this, castings of aluminum are heavily utilized where weight sensitivity is required and effective heat dissipation is needed. In automotive, it is extensively utilized for producing engine blocks, transmission cases, and wheel hubs and attains the objectives of weight reduction and energy efficiency. In aviation, its ultimate mission of lightweighting is its first choice for such safety-critical structural components. It is also very much applied to electrical enclosures (e.g., router and motor enclosures), heat exchangers, and other light mechanical components.

- Briefly speaking, aluminum castings, with their unparalleled lightness, outstanding performance, and affordability, have become the “lightweight engine” of modern production.

- It remains still a favorite material of designers in applications that demand weight reduction, heat dissipation, rapid prototyping, and cost savings.

Stainless Steel Castings vs. Aluminum Castings: Core Performance Comparison

The following table visually compares the core performance differences between stainless steel castings and aluminum castings, providing a clear reference for your design selection.

| Performance Dimensions | Stainless Steel Castings | Aluminum Castings |

| Density and Weight | High (~7.8 g/cm³), heavy. | Very Low (~2.7 g/cm³), lightweight advantages. |

| Strength | Very high, excellent strength and hardness, good load-bearing capacity and wear resistance. | Low (but high specific strength), low absolute strength, prone to deformation. |

| Corrosion Resistance | Excellent, resistant to atmospheric and chemical media corrosion, no additional treatment required. | Good (resistant to atmospheric corrosion), but requires surface treatment for harsh environments. |

| Heat Resistance | Excellent, maintains performance at high temperatures | Poor oxidation resistance, strength drops sharply at high temperatures, prone to deformation. |

| Cost | High, both raw material and casting processing costs are high. | Economical, low raw material costs, low energy consumption, and high efficiency in the casting process. |

| Processing Difficulty | Difficult, high melting point, requiring higher casting and machining requirements. | Easy, good fluidity, low melting point, easy to cast complex parts, and good machinability. |

- The choice between stainless steel and aluminum castings ultimately depends upon your application requirements.

- For applications in which great strength, toughness, corrosion resistance, and high-temperature capability are a requirement, and weight is not a consideration (such as in heavy machinery, chemical valves, and medical devices), stainless steel is a safe bet.

- For those applications where lightweighting, weight reduction, cost control, and high-rate production (such as automotive parts, aerospace parts, electrical enclosures) are of primary concern, aluminum castings offer irreplaceable advantages.

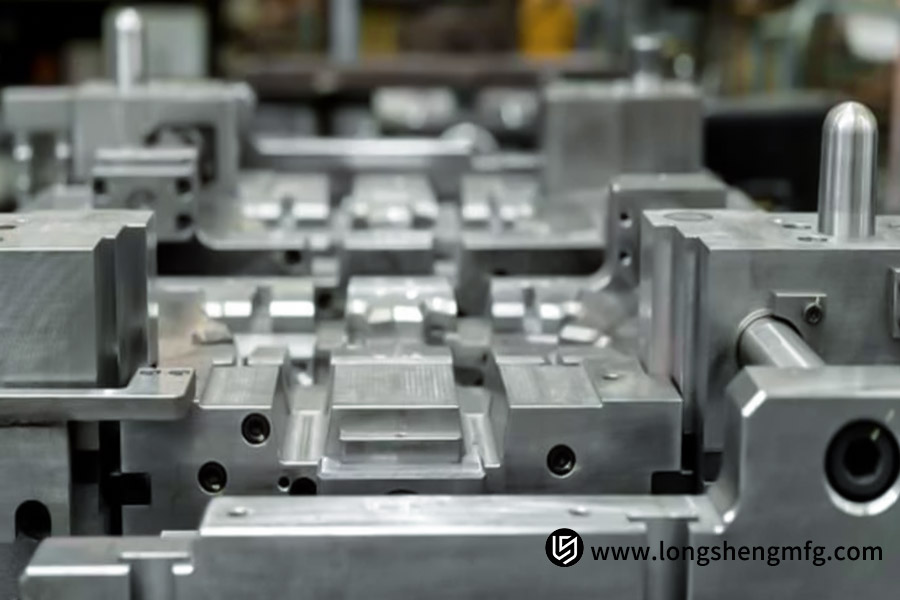

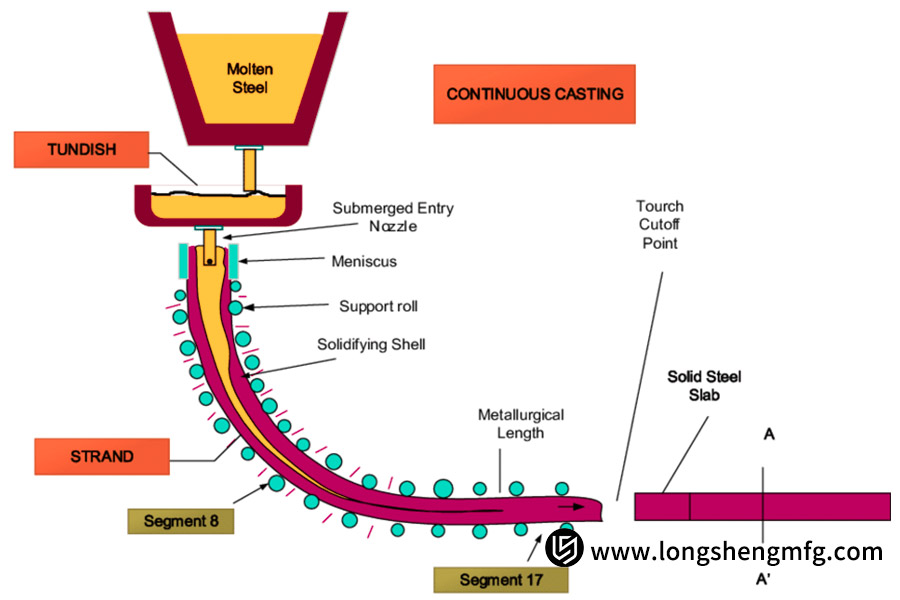

How Are Manufacturing Processes For Stainless Steel And Aluminum Castings Different?

Due to their distinct material properties, the manufacturing processes of stainless steel and aluminum casting differ considerably. The differences have a direct bearing on use of production energy, cycle time, and final cost, and understanding them plays an important role in making sound economic and technical decisions. Essential process differences are primarily manifested in the following three aspects:

| Process Dimensions | Stainless Steel Casting | Aluminum Casting |

| Melting Temperature | Extremely High (approximately 1500-1600°C) | Lower (approximately 600-700°C) |

| Mold Requirements | High, requiring thicker, heat-resistant mold materials | Relatively low, resulting in longer mold life |

| Shrinkage Control | Higher shrinkage (approximately 2.0-2.5%) is prone to shrinkage cavities and porosity, requiring a complex feeding system | Relatively low shrinkage (approximately 1.3-1.5%) provides better casting dimensional stability |

Melting Temperature

The melting point of stainless steel is high and consequently has a greater energy demand (e.g., utilization of medium-frequency furnaces), more heat-resistant melting equipment, and more stringent safety practices. This naturally increases the production cost and depreciation of equipment. In contrast, aluminum’s very low melting point greatly decreases the melting consumption of energy, lowering production cost energy and rate of production.

Mold Requirements and Shrinkage

The hot molten stainless steel results in more thermal shock and corrosion in molds (especially in sand molds), shortening mold life and increasing mold cost. Its higher liquid and solidification shrinkage requires more complicated and accurate riser and chill systems for shrinkage feeding, or internal defects are extremely probable to be created. This increases not only the process design complication but also increases the follow-up cleaning and inspection workload. Aluminum casting is much less stressful in this regard. Its high fluidity and low shrinkage make it better suited to mass producing thin-walled intricate parts with greater yields at reduced runs.

- Overall design is the key to stainless steel casting technology, and the main problem of controlling high temperature and high shrinkage is the core. Its cost model relies on energy consumption and complex process control.

- Aluminum casting, on the other hand, has a process with the attributes of high efficiency, energy conservation, and molding ease, and is furthermore cost-biased in the direction of raw material price and scale of economy. This fundamental distinction in the process forms the foundation for the ultimate cost and usage difference between the two.

How Do I Choose The Best For My Project?

The choice between stainless steel and aluminum castings isn’t a definitive list of pros and cons; it’s an apples-to-apples match based on your project’s inherent requirements. The proper choice can deliver peak performance, reduce expenses, and extend equipment life.

Stainless steel castings

If your project emphasizes structural integrity, durability, and versatility in high-specialized environments, stainless steel castings are the safer bet. If your application is faced with high-pressure, high-abrasion, or highly corrosive environments (chemical process equipment, offshore facilities, and food process streams), or stainless steel’s exceptional high-temperature properties meets high-temperature requirements, utilize stainless steel by all means. It assures complete reliability and excellent product life. The initial cost is higher, but overall lifecycle cost may be lower.

Aluminum castings

If your design focuses on lightweighting, efficient heat removal, and cost effectiveness, aluminum castings offer superior advantages. For uses in which weight reduction is required to increase efficiency or performance (such as automotive and aerospace parts), or for uses in which the high thermal conductivity of aluminum is required to cool (such as enclosures for electrical devices and heat sinks), aluminum castings are superior. Its relatively low price also makes it superior for high-volume applications.

- In brief, there is no “best material,” only the best available option. We strongly recommend that you inform our LS team of experts of your specific application conditions, budget, and goals.

- With years of experience in material selection and numerous industry success stories, LS can provide you with a professional technical assessment and custom, optimum solution.

- Call an LS expert today to make a smart, tried-and-true decision for your project!

Stainless Steel vs. Aluminum Castings: Upfront Cost vs. Long-Term Value

Choosing between stainless steel castings and aluminum castings is more than a unit-cost comparison. Complete cost analysis must consider total cost of ownership (TCO) over the entire life cycle of the product, integrating the initial cost with all the recurring operating expenses. Below is the analysis from different perspectives. As a point of comparison intuition, I’ve constructed a TCO comparison chart:

| Cost Dimensions | Stainless Steel Castings | Aluminum Castings | Long-Term Value Orientation |

| Raw material costs | High. Prices of alloying elements such as nickel and chromium fluctuate significantly (significantly influenced by global supply and demand), resulting in a high proportion of raw material costs. | Relatively low. Aluminum raw material prices are generally lower than stainless steel, but are also subject to market fluctuations. | Aluminum castings (lower initial material costs)

|

| Production efficiency and energy consumption | Low. High melting temperatures (approximately 1500-1600°C) result in high energy consumption, higher casting and machining requirements, and potentially longer production cycles. | High. Low melting points (approximately 600-700°C) provide excellent casting properties (good fluidity), high production efficiency, and greater ease of mass production. | Aluminum castings (higher production efficiency, high output per unit time)

|

| Lifespan and maintenance costs | Extremely low. Excellent corrosion and wear resistance ensures a longer lifespan in harsh environments, eliminating the need for frequent replacement or maintenance, reducing downtime. | Potentially higher. Particularly in corrosive or abrasive environments, surface treatment or earlier replacement may be required, adding additional costs and maintenance. | Stainless Steel Castings (Significant Advantage)

|

| Scrap Value | Stainless steel, due to its alloy value, is highly recyclable and has a high salvage value. Moderate. | Aluminum can also be recycled, but its value is generally lower than that of stainless steel. | Stainless Steel Castings (Higher Salvage Value)

|

| Initial Investment | The unit price is generally higher, and mold and process requirements may be more complex. | The unit price and mold costs are generally relatively low, making it easier to control initial budgets. | Aluminum Castings (Lower Initial Investment)

|

Understanding Total Cost of Ownership (TCO):

- While aluminum castings have advantages in terms of initial investment and production efficiency, durability in the long run is not likely as good as stainless steel.

- Although stainless steel generally means higher raw material and front-end processing cost, its longer service life, minimal maintenance requirements, and high end-of-life recycling value can help to offset the average cost over the entire lifecycle in most applications, perhaps even being more cost-effective in the long run.

LS Precision Manufacturing Case Study: Why Use Stainless Steel Castings with a Food Machinery Customer?

The client’s challenge

One food equipment business was faced with the issue of selecting a material for the impeller, a critical component of their new mixer equipment. The client requested an impeller that could withstand repeated high-temperature and high-pressure cleanings and resist corrosion from various food ingredients (such as flavorings and acids).

The initial aluminum casting solution in question had glaring faults in use:

- It was prone to corrosion in harsh cleaning processes, causing the formation of aluminum oxide powder on the surface, posing hygienic and safety risks of food contamination.

- It also experienced poor wear resistance, reduced service life, and frequent replacement downtime, significantly causing major interruptions in the continuity and efficiency of the production line.

1. LS provides a breakthrough solution

Faced with the customer’s dilemma, the LS technical team went beyond simple material replacement and conducted extensive operating analysis and material science evaluation. We firmly realized that in this use with extremely challenging requirements for hygiene, security, and durability, the performance limits of aluminum castings had been reached and a more durable material was necessary.

Accordingly, LS pioneered the idea and utilized 316 stainless steel as the casting material for the agitator impeller. 316 stainless steel contains molybdenum (Mo) that has superior corrosion resistance to chlorides and resistance to acids and alkalis compared to standard 304 stainless steel and is thus ideally suited for chemical attack by a large range of food additives and cleaning agents. Meanwhile, its own intrinsic high strength, high wear resistance, and excellent oxidation resistance ensure that the parts are able to retain their dimensional stability and smooth surface finish under long usage periods, completely satisfying food-grade hygiene and safety standards.

2. Superior value and performance for customers

This material advancement advantageously benefited the customer in both short-term and long-term benefits:

- Double Lifespan: The 316 stainless steel casting blades have a considerably longer life compared to the customer’s current aluminum casting solution, eliminating the hassle and procurement cost of frequent replacements.

- Sustaining Safety: The risk of food contamination due to material corrosion is essentially eliminated, giving the safety and conformance of the finished product.

- Improving Efficiency: Maintenance down time due to component damage is significantly reduced, enabling the customer’s production line to run continuously and in a steady manner and improving overall production efficiency.

Ultimately, LS’s technical ability and customer-first way of thinking not only rectified a part problem but also made the customer’s product inherently more competitive by virtue of proper material selection, establishing the customer’s high trust.

Environmentally Speaking, Is Stainless Steel Or Aluminum More Sustainable?

Recyclability

Both stainless steel and aluminum, from the viewpoint of recyclability, are excellent in environmental performance. Both these materials are infinitely recyclable without loss of their important properties and, thus, are good candidates in a circular economy. Stainless steel can have up to 60%-90% recycled content and aluminum is similarly highly recycled. This high level of recyclability significantly reduces virgin extraction of minerals, which reduces the environmental footprint.

Recycling energy consumption

Aluminum is definitely more advantageous in recycling energy consumption. Recycling aluminum production uses only about 5% of the energy of virgin aluminum, and that is huge energy saving. For stainless steel recycling, while it is also conserving around 75% of energy, its actual energy consumption remains greater. That is primarily because stainless steel possesses a higher melting point and therefore requires more energy in melting and processing. Yet it is worth stressing that recycling for both material uses far less energy than virgin production, and constitutes major environmental gain.

A life cycle

Both from a life cycle point of view have pluses. High corrosion resistance and durability of stainless steel give it a long lifespan in hostile environments, sometimes lasting decades. This longevity leads to less replacement and reduced use of resources. On the other hand, the lightweight nature of aluminum gives it dramatic environmental benefits during usage, particularly in the transport sector, where it can significantly reduce the use of fuel and carbon emissions.

In summary, both alternatives are quality and sustainable:

- Stainless steel is more apt to applications where long life and high durability are required, and the environmental benefits over its entire lifecycle are more pronounced.

- Aluminum has benefits in applications where lightweighting and recyclability are paramount.

The ultimate choice must be based on some application requirements, keeping in mind the entire lifecycle impact of the material to arrive at the most ecological-friendly option. Both materials fully meet the environmental and ESG requirements of modern production and are major materials for facilitating green development.

What Are The Main Things To Consider When Designing Stainless Steel Or Aluminum Castings?

Successful casting design begins with an adequate understanding of the character of the material and how particularly they will perform when cast. Because of the distinctive physical and metallurgical characteristics of stainless steel and aluminum castings, the LS staff, with extensive hands-on experience, offers the following basic design rules.

Aluminum casting design

When castings are designed in aluminum, the properties of solidification and mechanical strength are critical factors to be considered. Aluminium alloy molten metal possesses excellent fluidity, but shrinkage on solidification is relatively large, while strength and stiffness are inferior to steel. Therefore, structural reasonableness holds paramount importance. The principal rule is to provide a good uniform and minimum wall thickness (normally recommended not below 1.5-2.0mm). An overly thin wall thickness can easily lead to poor filling or cold shut, whereas an overly thick wall thickness can easily create flaws like internal shrinkage.

In providing equal wall thickness with added component rigidity, effectively placed ribs are instrumental. Reinforcement ribs consistently enhance the section modulus, significantly enhancing part strength and deformation resistance at minimal material weight, preventing warping and facilitating easy metal filling. This is the key to achieving a balance between light and high-performance aluminum castings.

Stainless steel casting design

Conversely, the most significant challenge in stainless steel casting design is how to control high shrinkage stresses and defects. Stainless steel has a high melting point, large solidification shrinkage, and large thermal expansion coefficient. Hot spots have a tendency to form in the heavily sectioned regions or in irregularly shaped junctions with non-uniform wall thicknesses, which leads to heavy defects such as shrinkage cavities, porosity, and thermal cracking.

Therefore, the golden rule of design is that there should be an even thickness distribution of walls. Smooth, rounded corners for transitions for all wall thicknesses are necessary to avoid sharp corners, thus stress concentration, ensuring sequential solidification. For unavoidable heavy sections, feeder heads must be strategically located at the design phase to ensure adequate replenishment of metal. This is vital in maintaining casting density.

- In brief, good casting design is an art that incorporates material science, casting techniques, and structural mechanics.

- Whatever material you choose, LS’s engineering staff, with its wealth of technical know-how, can provide you with a one-stop solution depending on your product’s functional requirement, from suggesting the material to structure optimization and process implementation.

- Your design is thus made not only feasible but also the optimal compromise of performance, cost, and reliability.

FAQs

1. Is stainless steel casting always more expensive than aluminum casting?

Generally, yes. The initial cost of stainless steel castings is relatively higher than that of aluminum castings. However, when stainless steel is viewed from the “lifecycle cost” perspective, its improved corrosion resistance, abrasion resistance, and extended service life frequently significantly reduce maintenance, replacement, and downtime costs. Therefore, in hostile environments, its economic benefit over the long term could even be more.

2. Is the structural requirement fulfilled by the strength of aluminum castings?

Yes. Although pure aluminum is low in high-strength, through optimal design (e.g., rationally designed reinforcing ribs and uniform wall thickness) and high-strength alloys (e.g., A356/T6), its specific strength (strength-to-density ratio) may be equivalent to or even higher than that of some steels. After T6 heat treatment (artificial aging and solution treatment), aluminum castings’ internal grain size is hardened, tensile strength, hardness, and toughness greatly improving. This is sufficient to obtain lightweight structural components such as automobile suspensions and aerospace brackets’ level of mechanical performance, weighing against weight reduction and load performance.

3. If corrosion resistance is the issue at hand, what does one employ?

The choice is based on the environment involved. Stainless steel (especially 316 molybdenum-containing grades) performs best in high-temperature, high-humidity, aggressive acid, alkali, or chloride environments (e.g., chemical, marine, food processing industries). It possesses a natural passivation coating for constant protection without additional treatment. Aluminum castings form an aluminum oxide coating in air environments, but they have poor resistance to pitting corrosion. Surface finish of anodizing and spray coating is required for additional protection in salt-spray or wet conditions. Therefore, the least costly choice for severe applications is stainless steel, and the least costly choice for mild environments is aluminum with surface finish.

4.Can LS offer custom casting for both types of castings?

Yes. LS Precision Manufacturing has large twin-material casting capability: with medium-frequency melting furnaces, high-accuracy mold production lines, and heat treatment workshops, it can handle stainless steel and aluminum alloy castings. Depending on your application situation (e.g., pressure resistance specifications, corrosive conditions, and weight reduction targets), our company will present a one-stop solution starting from material selection and structural simulation optimization (to prevent shrinkage and distortion), followed by precision casting (silica sol/water glass process), and surface treatment, achieving the best balance between performance and cost.

Conclusion

In considering aluminum castings versus stainless steel castings, there is always no “single best” solution. The real decision is a total trade-off among performance requirements, cost concerns, and process requirements. You have to make a choice of whether strength and resistance to corrosion are more critical than cost and lightness, or balance between the two. Each of the materials demonstrates its specific worth in unique circumstances.

We strongly invite you to consult your specific application conditions, budget, and goals with the LS engineering staff. With decades of long-term experience in material applications and well-documented casting processes, we conduct free professional selection analysis and customized solutions for supporting you in making the most scientific and economical choice. Contact us today to begin your project optimization process!

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Your blog is a true hidden gem on the internet. Your thoughtful analysis and engaging writing style set you apart from the crowd. Keep up the excellent work!

It?¦s actually a nice and useful piece of info. I?¦m glad that you just shared this useful information with us. Please keep us up to date like this. Thank you for sharing.

Thank you so much for your appreciation! I’m glad the information was helpful. I will definitely keep updating and sharing more useful content.

Good write-up, I’m regular visitor of one’s web site, maintain up the nice operate, and It’s going to be a regular visitor for a long time.

Hi! I could have sworn I’ve been to this site before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be bookmarking and checking back often!

This actually answered my drawback, thank you!

Hi , I do believe this is an excellent blog. I stumbled upon it on Yahoo , i will come back once again. Money and freedom is the best way to change, may you be rich and help other people.