Do you hope to reduce your costs of developing products by at least one-half? In the more and more competitive marketplace, R&D costs control and speed to first-to-market have become essential corporate imperatives. Rapid prototyping technology is the ultimate enablement of excellence at doing so. Rapidly converting digital designs into physical prototypes, it helps teams cycle rapidly through multiple loops of validation of the design, test of assembly, and capture of user feedback before facing the expensive task of mold building.

Not only do these drastically lower the expense of last-stage revisions and rework due to design iteration, but they also drastically compress the development cycle, effectively eliminating show-stopping high risks of scaling up large-volume production. How accurately does rapid prototyping save costs? What processes and methods maintain it? This article has an intimate inside focus on the analysis. To save your time, below are the article’s key points at-a-glance.

Quick Reference: Choose Your Tap at a Glance

| Core Question | Sentence Summary |

| What is it? | It uses technologies like 3D printing to quickly transform designs into physical prototypes |

| Why does it save money? | It reduces mold costs, modification costs, and time, significantly reducing trial-and-error costs upfront. |

| What methods are available? | SLA (high precision), SLS (high strength), CNC (high strength and high precision), and vacuum casting (small batches). |

| What is the process? | Design → Manufacturing → Testing → Iterative Optimization, a repetitive cycle. |

| Real Results? | As demonstrated in the LS case study, 350,000 yuan in direct mold modification costs was successfully saved. |

| What about performance? | Performance and accuracy are incredibly close to the final part, sufficient for functional testing. |

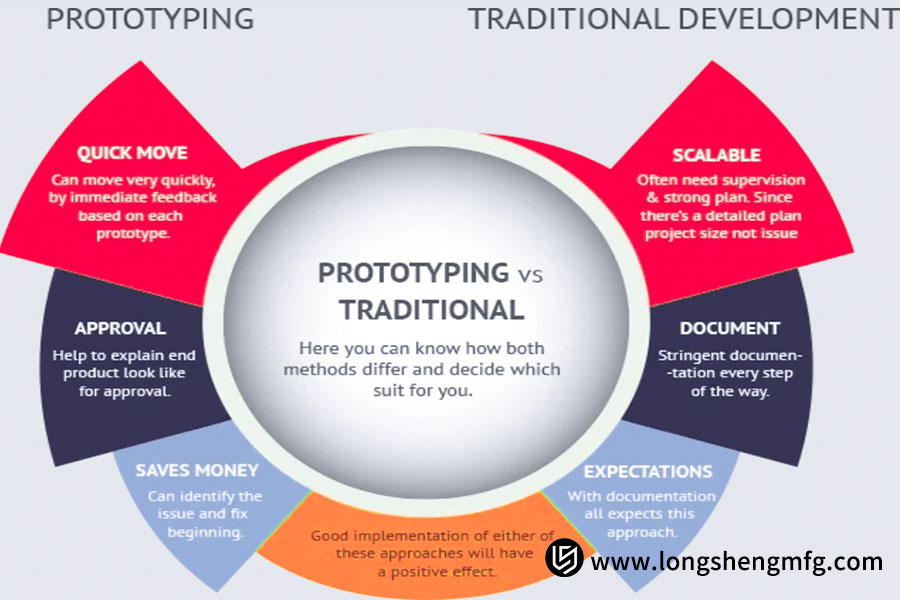

Rapid prototyping technology has fundamentally changed the high-cost, long-cycle traditional development model through pre-verification, accelerated iteration, and risk avoidance. It is the core strategy and tool for achieving the goal of saving up to 50% in development costs.

Why Trust This Guide? Leveraging LS Experts’ Practical Experience

Having over two decade’s experience with rapid prototyping, our factory as seasoned engineers of LS Precision Manufacturing prides itself on incorporating the latest processes as follows: industrial 3D printing processes (such as SLS nylon sintering), vacuum molding and CNC precision machining, and 3D scanning and other test technologies and constructing an efficient test system. We are also used to product development costs pain points and are dedicated to assisting customers in identifying design defects prior to developing mold with active technical risk test verification and thus cutting development costs by up to 50%. Such a function and technical integrative ability form the foundation of our safe advice.

In our real case study, an auto parts project had gone many rounds of rapid prototyping prior to mass production. In doing so, our precise prototypes clearly defined an error of design of the structure—one which would have resulted in improper assembling if the mold had gone for production immediately according to that mistake. Through our observation of the prototypes and suggested corrections, the client managed to improve its design prior to mold production and thereby save on mold modification costs of up to ¥350,000 and weeks-long project backlogs.

That has made it clear for us that rapid prototyping is not merely the technology itself, but rather a strategic decision.

What Is Rapid Prototyping?

Suppose you employ computer-aided design for your new product and instead of needing weeks for mold, you have a sturdy, usable component part in days or hours—rapid prototyping. It is indeed a superhighway and it “prints” ideas in digital format as tangible products. It actually uses state-of-the-art technologies such as 3D printing also called additive manufacturing and CNC machining also called subtractive manufacturing, skipping the expensive mold-constructing process of mass production and quickly translating drawings into reality.

The magic of rapid prototyping is that it really does change the pace of product development. It allows one to cycle instantly through “design-test-learn-revise.” One may want to check appearance and feel, assembly structure, or functional performance, and it can all be done without being committed to full runs of production. With the power of verifying and iterating on the spot, the risk and expense of last-minute rework because of design flaws are greatly diminished.

- Rapid prototyping refers to the combination of computer technologies which quickly build physical prototypes.

- It is not new technology–it is new thinking regarding how products are made.

- Through the rapid and recurrent transformation of ideas into products, teams are able to bypass much development risk, realize considerable time and cost savings, and capture truly low-risk effective innovation of products.

Why Is Rapid Prototyping Considered A Cost-Cutting Tool? Where Exactly Do These Savings Occur?

Rapid prototyping is cost-effective because it sidesteps the most costly and uncontrolled cost of development at three primary elementary levels.

1. Avoiding expensive mold revisions

Molds are generally left behind or completely re-designed for design changes in conventional development, with tens or hundreds of thousands of yuan per cycle costs. Rapid prototyping doesn’t use molds and can provide multiple design iteration in low-cost experimentations. For instance, in 3D printing, one could make a prototype with a few hundred or a few thousand yuan, saving significantly against the mould cost of easy tens of thousands of yuan.

2. Significantly shortens development cycles and reduces time costs

It would usually take weeks for traditional mold-making, and design issues make the entire schedule take numerous times longer. Rapid prototyping technology creates concrete replicas within hours to days, which speeds the “design-verification-revision” loop by orders of magnitude. The products hit the market earlier, which saves development staff time and money and catches market windows and possible profit simultaneously.

3. Early verification avoids catastrophic losses later

Not every structural, assembly, or functional problem is valued until there are real physical pieces in front of you. By enabling mass test and fix of any possible shortfalls prior to investment for economies of scale, quick prototyping sidesteps the incalculable expenses of scrap lots, product recall, and even brand harm through design errors.

- Rapid prototyping is a very cost-effective strategic investment.

- It substitutes low-cost early test-and-trial with end-stage high-cost rework, and enables exact savings in tooling, time, and risk.

- It enables organizations to manage development costs and reach the marketplace sooner and, thus, is a vital cost-saving tool.

What Are The Common Rapid Prototyping Methods?

Rapid prototyping is not a single technology but a set of technologies chosen at various times for product requirements. There are now the following mainstream processes, each with its strengths and appropriate for different application scenarios and levels of development.

SLA

SLA cures with laser beams and has the ability of building with smooth surfaces and fine details. It excels best with building with building concept models and show prototypes with good looks. It scores poorly on the fact that the material tends to become brittle and not typically ideal for rugged functional use.

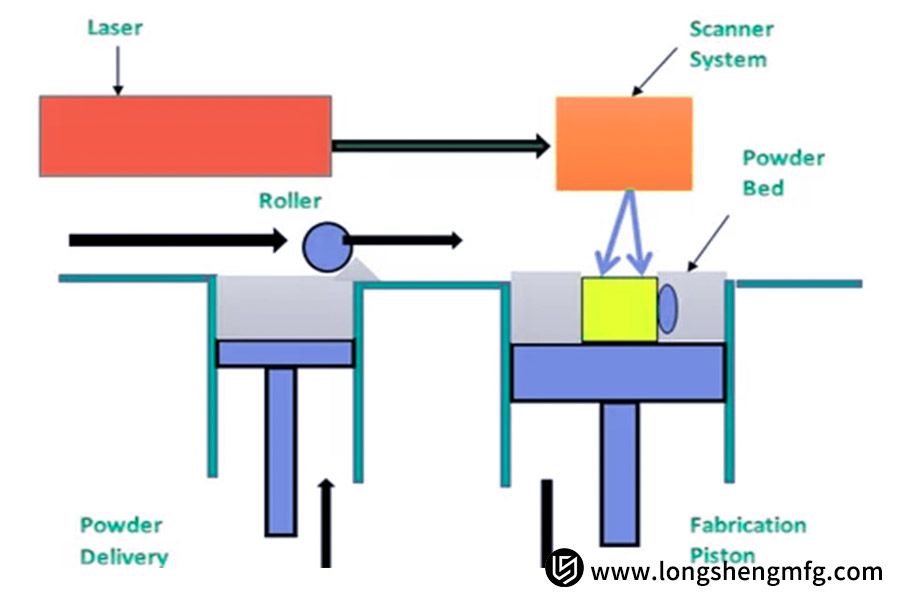

SLS

SLS accumulates its products layer by layer through laser fusion of powder materials like nylon. Its biggest advantages are extremely good mechanical properties, isotropy, and lack of support structure. It is ideally suited for functional testing, assembly check, and low-batch production of complex structural components.

CNC machining

CNC (CNC Machining) is the subtractive manufacture of parts from solid stock material with the help of precise machine tools. CNC machining service can machine any engineering plastic and metal type and can produce hard and precise prototypes with performance almost equal to end-production part. CNC machining service is used widely for functional verification of mold mastering and high-load.

Vacuum casting

Vacuum casting (silicone casting) provides an economical low-volume replication technique where in a finished prototype with a silicone mold and casting material like polyurethane is cast into the mold. It can rapidly produce 10-50 replicas which are functionally and visually identical to the injection-molded component. It is ideal for low-volume trial production, marketplace demonstration, and user test and evaluation and far less expensive than the development of a steel mold. The following table contrasts the two procedures clearly:

| Method | Technology Type | Suitable Part Type/Stage | Key Advantages |

| SLA | Additive Manufacturing | Appearance verification, demonstration models | High surface quality, fine detail |

| SLS | Additive Manufacturing | Functional testing, complex structural parts | High strength, no support required, assembly-ready |

| CNC Machining | Subtractive Manufacturing | High-precision, high-strength functional parts | Wide range of materials, extremely high precision and strength |

| Vacuum Casting | Replication Process | Small trial runs (10-50 pieces) | Low cost, fast turnaround time, and a wide selection of materials |

- Finally, your end-objective of choice–appearance verification, functional test, or constrained-batch test production–dictates your selection of rapid prototyping technique.

- There are no one-technology-solves-all solutions for all; there is wisdom in learning the strengths and weaknesses of each technique and merging them and accordingly with project stage. Maximizing time and cost savings comes from this prudent strategy.

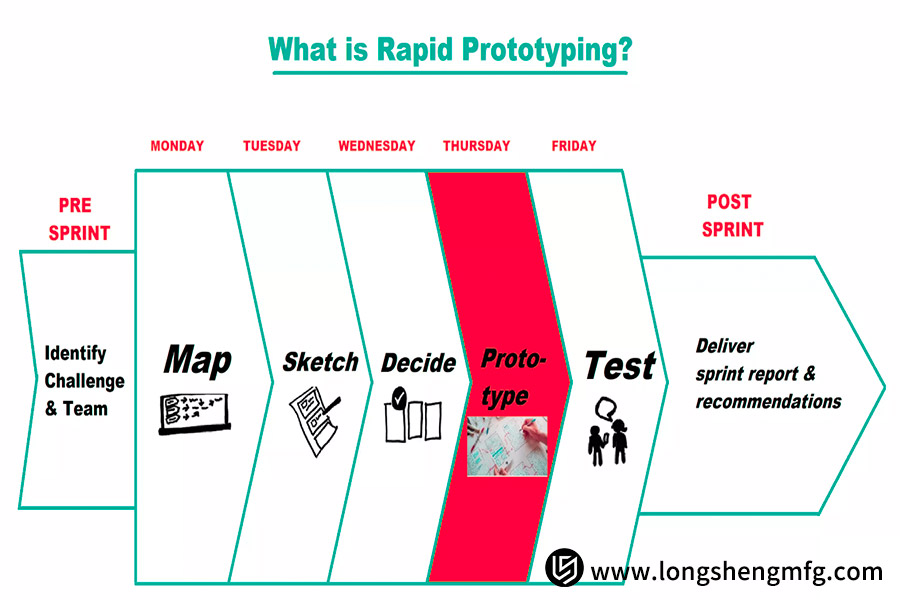

What Does A Complete Rapid Prototyping Process Look Like?

A quick and effective rapid prototyping method involves far more than just “printing out a model”; it is also a very integrated multi-discipline system. A standard process would involve five basic steps for effective transfer from computer-aided conception, via data preparation, and on to physical verification.

1. 3D model design:

It starts from product designing and preparation of 3D model. Product design and export of the same in standard format like STL or STEP is done using commercial CAD software – either SolidWorks or UG. Design quality at this stage has direct impact on the prototype’s success.

2. Data preparation:

Then comes data preparation and process selection as the second most important step. Technicians prepare the programme or slice the 3D model file using application-specific software. Selecting the ideal process (e.g., SLA, SLS, or CNC) depending on the final use of the prototype (either for presentation purposes or testing of function), required material, cost, and timeline is an important decision for the selection of cost and efficiency.

3. Manufacturing:

Manufacturing stage comes as the third stage. The equipment gets started on the basis of data that has been pre-processed. From layer by layer on the 3D printer to precise cutting on the CNC machine, it is an extremely automated process which allows for one to produce an actual component from hours to days.

4. Post-processing and verification:

Post-production serves to perfect the quality of the prototypes. This may include the removal of support structures, painting, silkscreen printing, even sub-processes like vacuum molding and assembly, to achieve the appearance or feel of the prototype as close to the intended final product as possible.

5. Inspection and feedback:

Final step is inspection and feedback. Completed products are checked for functional verification, assembly, or dimensional correctness and any challenges that are thus found are traced back to the design team. The design can be quickly changed and improved on the basis of measured data so that the subsequent, improved cycle of manufacture may start.

- In short, entire rapid prototyping process represents the cycle of the “design-manufacturing-verification-optimization.”

- Under highly effective and well-coordinated cooperation, it rapidly and with calculable predictability transforms ideas into tangible value.

- Not only do development times significantly decrease, but also, through early risk checking, companies save huge late-stage costs. It is a fundamental process of the new products development.

LS Precision Manufacturing Case Study: How Did It Save A Client 350,000 RMB In Mold Modification Costs?

1. Client challenge:

A state-of-the-art hardware producer made a state-of-the-art housing for a smart home control module. The housing must fit snugly several circuit boards, pieces for heat dissipation, and connectors, and must be extremely accurate in both outer gaps and inner structure. Because the internal structure is of very advanced technology, the producer feared the assembly relationship and internal heat dissipation of the numerous internal details, and computer simulation could not guarantee it completely. Were they to commit mold production all at once, design failure would cause enormous monetary and time costs.

2. Limitations of traditional solutions:

Regular procedures of the industry usually include direct mold production from finished designs. The mold of this project with around 350,000 yuan spent four or five weeks on construction. In situations of structural interference or heat dissipation difficulties during mold trial, the mold could have to undergo serious revisions or have to be scrapped. Not only did each of these revisions incur tens of thousands of yuan of additional costs, it also incurred at least two or three weeks of project delays. For start-ups, this kind of risk and expenditure became almost intolerable.

3. LS’s innovative solution:

LS team put forward the new method: step-by-step prototyping. SLA technology was first implemented on the rapid production of an exterior prototype for validation of the design of form factor and assembly relationships. A functional 1:1 prototype with internal structure, clip design, and positions of heat dissipation holes was made with CNC precision machining. Three rounds of physical assembly tests and thermal tests on the circuit board found three structural interference risks and one key defect of heat dissipation design, which were removed. During the process, the client only paid less than 10,000 yuan for producing costs of the prototypes, achieving quick iteration and optimization of design.

4. Final results and value demonstrated:

According to the measurement data and the revision recommendation of LS, the client finished all of the revisions of the design prior to mold making. Ultimately, the mold worked out well during the preliminary test, sparing the probable 350,000 yuan of mold scraping and revision costs which would have been incurred for future revisions. In addition, the development cycle of the products narrowed for six weeks from the original schedule, securing the first-mover advantage on the market for the client. This real case completely illustrates the very necessary value of rapid prototyping: “Minimizing investment while avoiding significant losses” and indicates the capability and rich practical experience of the LS team.

What Kind Of Performance And Precision Can Rapid Prototype Parts Achieve?

The majority of individuals still have the impression that rapid prototypes are rough models. The technology of rapid prototyping eliminated such a constraint a long time ago. The precision and performance of components produced by rapid prototyping are now as good as completed mass-production components, so they actually serve the very critical function of functional verification.

1. Surface quality:

From the surface quality aspect, with advancing technologies, prototypes can attain very high surface accuracy. As an illustration, SLA –cured pieces subsequently fine grinding andspraying can attain surface roughness of Ra 0.6-1.6μm with appearance and feel nearly as good as injection-molded pieces, good enough for the majority of presentation, review, and marketing use.

2. Dimensional accuracy:

Dimensional precision of the standard industrial-grade 3D-printing technology (e.g., SLS and SLA) is usually ±0.1%, while precision CNC machining can be as low as ±0.025mm or more precise. Prototyping in its current form is perfect for application on assembly verification, that is, testing part fit, and determining interference problems well ahead of time.

3. Mechanical properties:

Most thrilling of all is the leap of mechanical properties. With current capability, SLS-processed PA12 parts are remarkably robust and durable with properties comparable to injection-molded PA parts. One can machine the prototype directly from engineering materials with real properties like POM, PC, aluminum alloy, and even stainless steel and perform aggressive functional, durability, and thermal tests with exact precision mimicking the finished part environment with extreme conditions.

4. Subsequent small-batch remolding capabilities:

Furthermore, by secondary processing like vacuum remolding (silicone remolding), available high-precision prototypes can be easily replicated into dozens to hundreds of small-batch products in a brief span of time. Remolded products can replicate the material characteristics of different plastics like ABS, PP, and soft rubber, hence completely fulfilling the requirements for small-batch trial production, clinical trials, and market pre-production, as well as realizing optimal conversion from “prototype” to “product.”

- In short, the rapid prototyping today far exceeds the definition of “prototype.” Through its finer surface finish, precise dimensional accuracy, strong mechanical properties, and versatile small-batch production, it has become the best and most stable vehicle between design and mass production.

- To select rapid prototyping means not only selecting a production process, but selecting an efficient, low-risk product development process.

FAQs

1. How much can rapid prototyping save compared to traditional mold development?

Rapid prototyping achieves mainly the economies of mold adaptation or write-off with design iteration. The average mold development adaptation costs tens of hundreds of thousands of yuan. Rapid prototyping, with dozens of examples of iteration, accomplishes one-tenth or less times of mean methods of economies. In mean cases, the method can save customers on average 30%-50% of overall development costs and shorten development time from years or years and months, and attain the function of the role of “low-cost trial and error, high-efficiency optimization.”

2. Besides saving money, what other benefits does rapid prototyping offer?

Not only do costs significantly decrease with prototyping rapidly, build times are also materially reduced, so products rapidly reach the marketplace. By enabling physical models, it greatly enhances supplier and customer and team communications and minimizes rework due to miscommunications. In addition, functional, assembly, and user testability are greatly enabled at an earlier stage, significantly increasing end-product quality and longevity.

3. Which rapid prototyping method should I choose?

Rapid prototyping technology selection is an overall evaluation of the specific needs of the product, preferred material properties, project budget, and timeline. Optical inspections are possible with SLA, functional validations with SLS or CNC, and miniproduction with vacuum casting, for instance. We suggest that you begin with getting in touch with the LS engineering team, which will give an overall technology choice solution suited to your project’s specific properties, balancing quality, economics, and productivity.

4. What rapid prototyping services does LS offer?

LS has all of the plastics and metals rapid prototyping technologies in its portfolio: stereolithography (SLA), selective laser sintering (SLS), CNC precision machining, and vacuum casting. We do it all–from design review and prototyping right through post-processing and low-volume production. We are able to assist customers with the full scope of needs, from proof of concept and functional validation right through low-volume production, and enable simplification of development of products at a single location.

Conclusion

Rapid prototyping technology itself is a strategic investment which will save as much as 50% of products development costs of an enterprise. Checking design with several rounds and risk check at low costs before large scale large production, it will save loss of expensive mold redesign and production halt due to design failure, and thus ensure the level of success and return on investment of large scale large production. That “little investment before preventing large losses” forms the very core of competitiveness of new products development.

If your company is looking for cutting-edge solutions to lower development costs and shorten time to market, it’s time to make the change. Engage the LS professional staff today and receive a complimentary technical consultation and tailored project estimate. We use our professional rapid prototyping services to bring your ideas to market leading advantages more quickly, inexpensively, and with more certainty. Your success begins with this consultation.

📞 Phone: +86 185 6675 9667

📞 Phone: +86 185 6675 9667

📧 Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

you are truly a just right webmaster The site loading speed is incredible It kind of feels that youre doing any distinctive trick In addition The contents are masterwork you have done a great activity in this matter

Superb blog! Do you have any hints for aspiring writers? I’m planning to start my own blog soon but I’m a little lost on everything. Would you propose starting with a free platform like WordPress or go for a paid option? There are so many options out there that I’m totally overwhelmed .. Any suggestions? Thank you!

Terrific post but I was wanting to know if you could write a litte more on this topic? I’d be very grateful if you could elaborate a little bit further. Thank you!

Thank you for your encouragement and specific suggestions! The direction you mentioned is very valuable, and I will consider adding more details in future updates. Are there any specific areas you are particularly interested in? I would be happy to hear your further thoughts.

Youre so cool! I dont suppose Ive read something like this before. So nice to find someone with some unique thoughts on this subject. realy thanks for beginning this up. this website is one thing that is needed on the internet, someone with somewhat originality. helpful job for bringing one thing new to the web!

I will immediately clutch your rss as I can not to find your e-mail subscription hyperlink or e-newsletter service. Do you’ve any? Please allow me realize so that I could subscribe. Thanks.

You can contact my email (info@longshengmfg.com)

Pingback: LS Manufacturing: 40% Faster Product Development With Rapid Prototyping