When developing a part manufacturing strategy, the choice of the optimal process among precision CNC turning and CNC milling is the most critical decision for the majority of design engineers and purchasing managers. It directly affects final product quality, production cost, and delivery lead time. With complex machining requirements, the wrong process choice can easily lead to issues like low material utilization, failure to maintain tolerances, and secondary clamping errors.

The key to an informed decision is a detailed understanding of the difference between CNC turning and milling. As your process partner, LS Manufacturing, with years of experience, is committed to providing professional process analysis.

LS Manufacturing will carefully examine your part geometry, material properties, precision requirements, and batch size to allow you to correctly pair the optimum process route, ultimately streamlining manufacturing costs and significantly improving product quality. To save you time, here’s a quick overview of the core conclusions.

Precision CNC Turning vs. CNC Milling Core Quick Reference

| Comparison Dimensions | CNC Turning | CNC Milling |

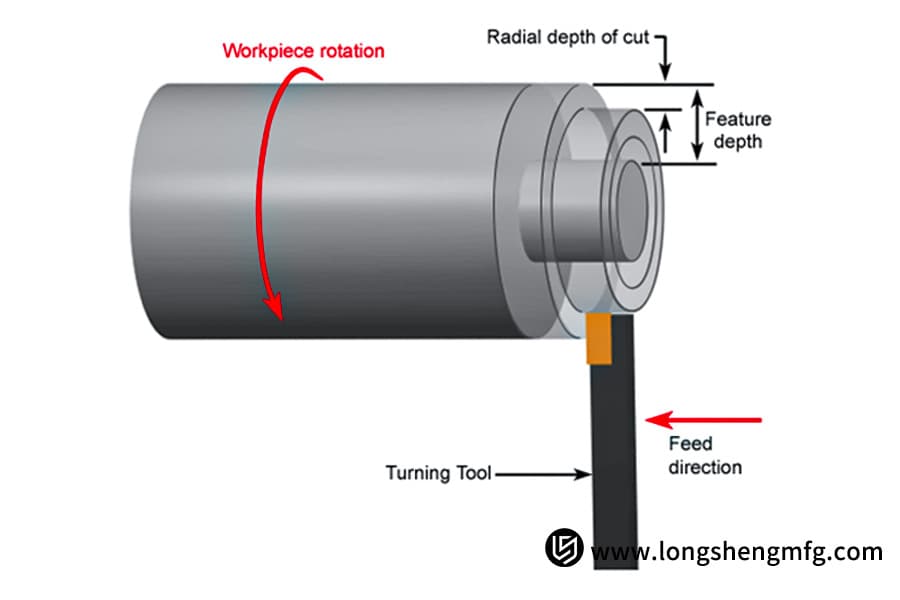

| Core Principle | Workpiece rotates, tool moves linearly | Tool rotates and moves, workpiece is stationary |

| Spindle Movement | Workpiece clamped on the spindle rotates | Tool clamped on the spindle rotates |

| Geometry | Excels at rotating parts (axisymmetric) | Excels at complex contour parts (asymmetric) |

| Typical Applications | Shafts, screws, bushings, flanges | Housings, brackets, molds, cavities |

| Advantages | Superior machining efficiency, good concentricity, and fine surface finish for rotating parts | Very high geometric flexibility, with the capability of machining complex features |

| Limitations | Difficult to machine non-circular features and complex curved surfaces | Relatively low productivity for machining pure rotating parts |

The choice between precision CNC turning and CNC milling fundamentally depends on part geometry. Turning is suitable for round parts, achieving efficient and high-accuracy machining through rotation; while milling is suitable for square or complex-shaped parts, achieving geometric complexity through multi-axis tool motion.

The experts at LS Manufacturing suggest: Many complex parts actually require a combination of two processes (turn-milling) for optimal production. We’ll go over the most cost-effective and efficient flow process based on your own design.

Why Trust This Guide? Real-World Experience from LS Manufacturing Experts

This guide’s decision-making logic is informed by LS Manufacturing’s over a decade of experience with hands-on precision machining. Not only do we possess industry-leading CNC lathes and multi-axis milling centers, but we also have an intimate knowledge of how to push the trade-offs of the two processes in accordance with various material properties, precision tolerances, and batch requirements.

For example, LS Manufacturing once helped a medical device customer analyze the basic component. The main shape of the part was a stainless steel shaft with a custom-shaped flat surface. CNC milling alone would be too costly, and turning alone would not be able to shape it.

Our experts ultimately produced a hybrid process solution: “Precision CNC turning on the main body, with secondary direction milling on the flat area.” This solution, maintaining Class 10,000 cleanroom levels of manufacturing, lowered the unit price by over 30% for the customer.

LS Manufacturing does not only perform the machining but also gets involved on the design aspect. Based on our extensive expertise in CNC turning and milling and our extensive library of case studies, we translate your specifications into effective and economical manufacturing solutions.

How to Choose Turning or Milling Based on Part Geometry?

The initial move toward a right choice for a particular part is grasping the difference between milling and CNC turning. The fundamental idea behind this selection procedure is the systematic detection and assessment of the geometric characteristics of the part.

1. Identifying Symmetry of the Main Shape:

Parts having a general round, cylindrical, or sleeve form and a clear axis of revolution (i.e., a fully defined profile following a 360-degree rotation around the axis) are most suitable for CNC precision turning. For these “body-of-revolution” parts, such as shafts, sleeves, and flanges, rotary machining on a lathe efficiently and accurately ensures the dimension and finish of features such as the outer diameter, internal bore, end faces, and tapers, and is the only means of achieving optimum concentricity and roundness.

2. Analyze Feature Distribution:

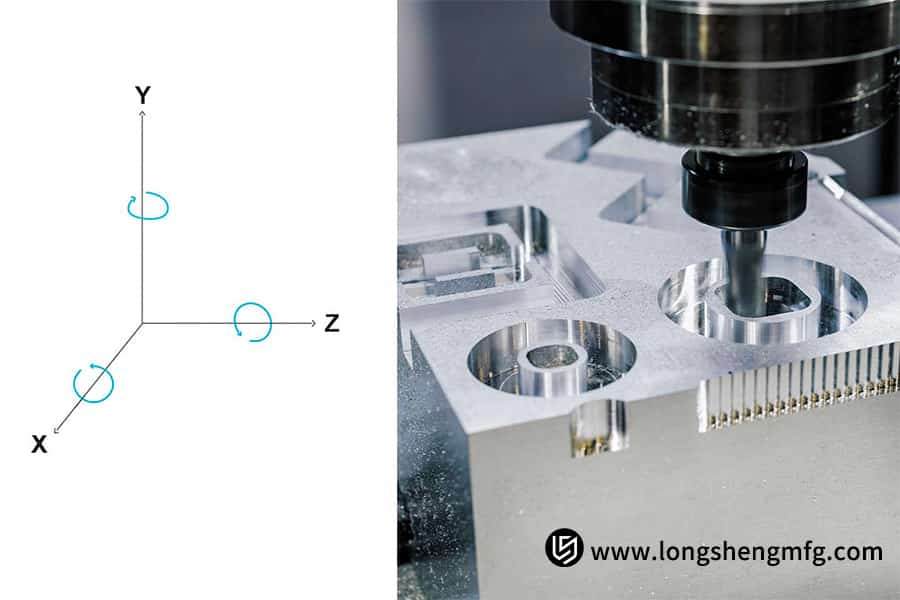

When the part body is box-shaped, rectangular, or of complex, irregular form and its prominent features (e.g., planes, cavities, bosses, threaded holes) are directed in different spatial directions, CNC milling flexibility is increasingly advantageous. The milling cutter, through multi-axis connection, can approach the workpiece from any direction and machine such features as walls, grooves, and three-dimensional curved surfaces, which cannot be done by a single turning operation.

3. How to Choose Between Turning and Milling:

The first answer is “look at the shape.” If you grasp the general principle of “turning for rotating bodies, milling for polyhedra/complex contours,” you can complete the initial screening of most processes. For parts that feature both significant rotating bodies and localized unusual features, consider a turn-mill hybrid process, which completes the entire process in a single setup to achieve both efficiency and accuracy.

LS Manufacturing’s process team is experienced in performing this thorough analysis to ensure the best process route. Contact us today to schedule a free analysis and consultation.

How does turn-mill hybrid achieve the one-step molding of complex parts?

For complex parts with rotational features and special-shaped structure combined (e.g., flanges with radial holes or shafts with flatten sections), traditional sequential machining is faced with cumulative error and efficiency bottleneck caused by multiple clamping. CNC milling machines are the ultimate solution to this problem.

1. Complete all processes in one clamping:

The nature of milling technology is to integrate the function of a multi-axis milling machine and a precision lathe into a single machine. With single clamping, the workpiece can undergo turning, milling, drilling, and tapping operations in succession or even all together without inter-machine transfer. This essentially eliminates datum conversion errors caused by multiple clampings.

2. Extremely Improved Positioning Accuracy and Machining Efficiency:

As all datums are integrated, the relative position precision of various features on the part (such as the perpendicularity of holes and end faces, and the coaxiality of special-shaped structures and outer diameters) is well guaranteed. Besides, through integrated processing, CNC milling machine services greatly reduce setup time and the number of fixtures, thereby significantly shortening the overall part manufacturing cycle.

LS Manufacturing employs the latest equipment and high-end programming expertise to deliver completed intricate parts in one shot with greater accuracy and shorter lead times, giving you a vital advantage in precision manufacturing.

Utilizing LS Manufacturing’s CNC turning-milling service is to entrust complicated, multi-process machining to a highly coordinated “integrated manufacturing cell.”

Why is turning essential for precision shaft parts?

In the manufacture of high-precision transmission components, the operation of the normal rotating parts, such as bushings and shafts, is critical. When should CNC turning be favored over milling? For these parts, the answer is clear: high-precision CNC turning offers unmatched advantages in efficiency, precision, and consistency.

1. Superior Material Removal Efficiency and Economy:

Turning combines workpiece rotation and the tool’s steady feed to create continuous, effective cutting. On bar stock, turning can machine extensive quantities of stock in the shortest path and least time, quickly generating external diameters, steps, and grooves. Compared to milling with multiple small cutters to “carve” a cylindrical shape, turning offers improved economics in material removal rate and tooling cost.

2. Unparalleled Geometric Tolerance Control:

Key quality characteristics of shaft parts, such as concentricity of individual shaft sections, end-face runout of critical shoulders, and overall cylindricity, all rely on the stability of the workpiece at the center of rotation. Turning allows multiple sections of the outside diameter along with end faces to be machined in a single setup with a common datum. This is handy for maintaining micron-level geometric tolerances, which is difficult to achieve with multi-setup milling.

3. Consistent Surface Finish:

Turning, under optimum cutting parameters, results in uniform and continuous chip removal and provides a consistent, high-quality surface finish. This uniform surface texture is critical to ensure the service life and reliability of shaft components that must be precisely aligned with bearings and seals.

If efficient and high-precision machining of rotational components is your top priority, precision CNC turning is the unbeatable choice. It offers the optimal blend of technical and economic benefits for these components.

Precision CNC lathes and specialized processes from LS Manufacturing ensure that every axis provides optimum rotational accuracy and high performance.

How can milling achieve high-precision machining of complex mold surfaces?

In mold making, complex cavities, fine textures, and contoured surfaces are the rule, and this is the area where CNC turning and milling are most different. Faced with the geometrical challenges of these non-rotary workpieces, multi-axis CNC milling, with its unrivaled universality, is the path to high-precision molding.

1. Multi-axis linkage, conquering free-form surfaces:

Molds for products such as mobile phone casings and automotive interiors often feature sculptural free-form surfaces. Five-axis CNC machining enables the milling cutter to approach the workpiece at the optimum angle at all times, achieving precise tangential machining.

This not only ensures surface finish and precision, but also avoids interference between the tool and the workpiece. It is possible to machine vertical features such as inclined corners and deep ribs in a single setup, achieving both accuracy and efficiency.

2. Dedicated Strategies for Deep Cavities and Narrow Grooves:

Molds often feature deep cavities, thin-walled features, and narrow grooves, placing extremely high demands on machining stiffness and chip removal. Our engineers utilize specialized CAM programming and apply efficient strategies such as layered spiral cutting and plunge milling.

Combined with long-neck tools and internal coolant technology, they effectively control cutting forces and heat, ensuring stable dimensional tolerances and protecting the integrity of thin structures even when machining deep cavities.

When your top priority is the development of complex three-dimensional forms, multi-axis milling is the unavoidable choice. Proper application of CNC machining technology is the bridge between design creativity and high-precision molds.

LS Manufacturing, with its extensive mold experience, offers full milling services for all your requirements, from complex electrodes to large mold cores, with every surface precisely engineered.

How can cost analysis models be used to optimize process decisions?

In choosing a process, the direct comparison of unit costs can be deceptive. Scientific choice must rest on a complete cost model covering equipment, labor hours, and material use. Especially for high investments such as the cost of CNC mill-turn machines, it is important to quantify their value over the long term.A good cost analysis model must contain the following essential components:

| Cost Dimensions | Specific Composition | Influence on Process Choice |

| Equipment and Labor Costs | Machine tool depreciation, floor space, operator time. | Time per piece can be minimized and cost per piece can be distributed by high-speed CNC machining operations. |

| Tooling and Material Costs | Purchase of tooling, tool wear and replacement, cutting fluid, and material scrap rate. | Tool wear can be reduced and material can be conserved by optimized processes with near-net-shape builds. |

| Secondary Operation Costs | Setups, post-processing, quality inspection, and scrap rate. | These costs are significantly reduced by minimizing setups and, hence, a key advantage of mill-turn machines. |

Selecting the perfect CNC machining process involves more than just the numbers on the quote. The challenge is to compute the total cost of ownership. Although CNC mill-turn machines are more expensive than single-function machines, the secondary operation savings created by reducing setups and processes can pay for themselves quickly in complex parts and medium- to large-sized lots.

LS Manufacturing’s experts will help you create a custom cost model and use data to decide on the most cost-effective way to manufacture.

LS Manufacturing Case Study: How does milling-turning innovate medical implant machining?

In high-value, difficult parts manufacturing like medical implants, even a slight defect in the process route can directly impact patient safety and treatment outcome. The following real-case example shows how LS Manufacturing applied CNC milling-turning machine tools to help a partner solve precision machining problems and achieve a significant breakthrough.

1. Customer Dilemma:

One well-known manufacturer of medical devices produced a stainless steel implant holder. The part featured a complex structure, including high-precision rotary contours and a number of asymmetric positioning surfaces.

The original “turn first, then mill” sequential machining process resulted in cumulative errors due to multiple clamping operations, so verticality and positioning of important positioning surfaces were highly unstable. The product qualification rate was 78%, significantly impacting order delivery and quality management system certification.

2. LS Manufacturing Solution:

We provided professional CNC milling-turning machine tools to resolve this bottleneck. The solution’s essence is as follows:

- With the workpiece clamped once, precision CNC turning is used first to complete all machining of the external diameter, internal bore, and end faces with high efficiency, absolute uniformity of the datum system.

- Next, with the same machine, a multi-axis milling head machines all contoured positioning surfaces and threaded holes with accuracy.

- An online measuring system incorporated in the machine provides real-time detection and compensation of important dimensions so that all significant features achieve a stable machining accuracy of ≤0.01mm.

3. Results and Value:

The implementation of the integrated turning-milling solution basically addressed the issues of the customer. Product qualification rate was enhanced significantly from 78% to 99.5%, and cycle time was reduced by 60%.

More importantly, the solution achieved excellent dimensional stability and perfect process control, providing the customer with solid data and process support to sail through the rigorous medical device quality management system certification with ease and gain the long-term trust of the end market.

This example shows that for the components of medical devices that require both rotary precision and complex features, the choice of a hybrid machining solution that couples precision CNC turning and multi-axis milling is far more than a simple process substitution; it is a strategic manufacturing improvement.

How does milling reduce the manufacturing cost of complex parts?

Though CNC mill machines are more expensive than single-function machines, their “one-setup, complete machining” paradigm can significantly reduce the total manufacturing cost of complex parts in a variety of ways. What follows is a point-by-point contrast:

1. Significantly Reduced Tooling and Site Costs:

Traditional, sequential machining requires different sets of dedicated fixtures and worktables for different processes, i.e., turning, milling, and inspection. One CNC milling machine, however, integrates all the functions, reducing dedicated tooling by over 90% along with equipment footprint and logistics costs.

2. Directly Reduced Labor and Work-Hour Costs:

The second important economic advantage of milling is automatic, “unattended” machining. Several machines can be tended by one operator. Once the part blank is fixtured, the machine automatically executes all turning, milling, drilling, and tapping operations. It reduces average machining time per part by more than 50%, directly reducing expensive labor content and work-in-process inventory.

3. Save hidden costs by improving yield rates:

Multi-clamping can very easily lead to dimensional variation and rejected components. Mill-turn technology, through delivering constant benchmarks, regularly raises product yields to over 99.5%, immediately avoiding scrap loss, rework time, and additional risk costs associated with variable quality.

When evaluating a CNC mill-turn machine’s worth, don’t just consider the initial investment but the total savings in tooling, labor, yield rate, and production cycle. When dealing with complex parts, the total cost of manufacture of a mill-turn solution is typically over 30% lower than sequential machining, with a guaranteed payback period.

LS Manufacturing will be delighted to provide you with a detailed cost study and proof of its financial viability.

What key technical indicators should be included in a supplier evaluation system?

In selecting a precision manufacturing partner, the equipment list by itself does not qualify to determine their true capabilities. A good supplier rating system must include the following key quantitative values to make sure your partner of choice possesses the capability of making high-quality products.

1. Equipment Capabilities and Technological Advancement:

- Key Technical Equipment: Identify key equipment brand, model, quantity, and age, such as CNC turning and milling machines.

- Precision and Stability: Document key parameters such as positioning accuracy, repeatability, and spindle runout of key equipment, and request recent inspection reports.

- Process Coverage: Determine if the supplier has end-to-end capabilities, from the CNC machining processes to post-process (e.g., heat treatment and surface finishing).

2. Process Experience and Engineering Support:

- Team Professional Qualifications: Describe the usual industry background of the programming and core process engineers with particular emphasis on successful case studies in your industry (e.g., medical devices, aerospace).

- Process Optimization Capability: Verify if the supplier is able to provide complete process analysis reports showing insight into CNC machining process selection, tooling design, and cutting parameter optimization.

- Issue Response Mechanism: Verify the presence of formalized Engineering Change Request (ECR) and rapid issue resolution process.

3. Quality System and Continuous Improvement Capabilities:

- Certification System: Whether the company has obtained international quality system certifications such as ISO 9001, IATF 16949, or AS9100.

- Process Control: Online inspection equipment penetration rate, first-article inspection pass rate, and key processes’ CPK process capability index.

- Data Traceability: Whether detailed inspection and production records of data are generated, with full traceability of significant dimensions from raw material to end product.

The quality of a good supplier is not only in providing CNC turning and milling machine services, but in coordinating equipment, experience, and systems to provide to you stable and reliable end-to-end solutions.

These controls have been rigorously tested by LS Manufacturing. You are invited to audit us with an open and transparent mind and become your long-term strategic partner.

How can DFM be used to optimize processes and improve efficiency and quality?

Placing manufacturing feasibility analysis in the early design stage is the key to optimizing efficiency and quality. LS Manufacturing’s innovative collaborative analysis technique aims to optimize designs at their essence and create an efficient and reliable basis upon which to base further precision CNC turning or other CNC machining procedures.

1. Feature Optimization, Design for Manufacturing:

LS Manufacturing engineers examine the 3D model of the product in a systematic manner in order to identify and recommend optimization of features that are adverse to machining. To mention an example, they recommend rounding off internal sharp edges with a standard tool radius rather than the additional cost and vibration that employing specialized tooling will generate.

Standardizing thread specifications and even out complex surfaces can significantly improve CNC machining process reliability and tool life.

2. Process Integration, Streamlining Manufacturing:

Based on the optimized design, LS Manufacturing then examines the optimal process path to achieve these goals. This includes determining which of the features can be used in precision CNC turning and which can be used in milling, and examining process combining to reduce setups. The goal is to develop highly integrated, smooth process planning that practically reduces production steps and decreases lead time.

Successful manufacturing begins with excellent collaboration. LS Manufacturing’s Design for Manufacturing (DFM) services essentially put our extensive years of manufacturing know-how at the center of your product design strategy.

By working up-front with our experienced staff, you acquire not just a manufacturable design but a completed, optimized solution for optimum cost, efficiency, and quality.

FAQs

1. Is turning-milling economical for small batches of complex parts?

Absolutely. Turning-milling completes all machining operations in a single setup, which reduces tooling investment and repositioning time by a significant amount. It is well suited for small-lots trial manufacture and R&D proof of principle. Although the higher per-hour machining cost, overall efficiency improvement, reduced scrap rate, and shortened production cycle increase its overall cost somewhat relative to traditional multi-step processes, its overall cost is superior because it is an economical solution for breakthrough projects.

2. How do you determine whether a part is more suitable for turning or milling?

The most essential factor is geometric properties. Axisymmetrical rotating parts (shafts and sleeves, for instance) can be machined with turning, which can best ensure cylindricity and concentricity. Multi-directional properties, complex surfaces, or box-type structures, however, must be milled. LS Manufacturing provides expert process analysis services. We help customers scientifically determine the optimal process route through feature recognition and cost simulation, executing quality and cost optimization.

3. What level of precision can be achieved with mill-turn machining?

Mill-turn machining erases datum transformation errors in one clamping operation with very high overall accuracy: positional accuracy is typically ≤ 0.015mm, surface finish is Ra0.8μm or better, and geometric tolerances such as concentricity and perpendicularity are very precisely maintained. Combined with online measurement and compensation systems, this accuracy can meet the requirements of most precision parts on a routine basis and is therefore the method of choice for highly advanced integrated parts.

4. What preparations are required to transition from traditional machining to mill-turn machining?

Process re-engineering, upgrading the programming systems, and operator training are needed. LS Manufacturing offers end-to-end technology migration solutions such as process solution optimization, CAM programming system installation, and specialized skill training to assist businesses in transitioning to a smooth efficient combined manufacturing model and realize the overall potential of mill-turn machining in quality, efficiency, and cost in a short span.

Conclusion

To precision machining, scientific process decision-making is key to optimizing costs, quality assurance, and minimizing delivery times. Regardless of whether standard precision CNC turning and milling or complex CNC turning and milling machine services are in the mix, it requires process knowledge and field expertise.

LS Manufacturing, with its wide equipment capabilities and experienced engineering analysis team, is committed to being your best manufacturing advisor to ensure that every part is matched with the optimum process route for optimal value.

Contact LS Manufacturing today! Forward your part prints or your questions today, and the staff of process specialists at LS Manufacturing will provide you a free, personalized “Manufacturing Process Optimization Plan.” The plan will include detailed process analysis, cost analysis, and delivery projections, providing you with a total, accurate, and effective manufacturing solution.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.