When a micrometer-level manufacturing flaw might make or break a revolutionary medical device, with what sort of manufacturing partner would you want to be associated? In medicine, the pursuit of precision, safety, and reliability has no end. This is precisely why medical CNC turning technology has become an overarching process—it is not only the basis of achieving the ultimate heights but also the first line of defense for managing risk.

LS Manufacturing is precisely this kind of partner. Not only do we install the technology, but serve as the risk managers for your project, too. We employ our professional medical grade CNC turning machinery, the rigorous ISO 13485 quality system, in-depth knowledge of biocompatible materials, and significant experience delivering millions of safety components to world-class customers. To save you time, here’s a quick overview of the core conclusions.

Medical CNC Turning Core Quick Reference Table

| Core Dimensions | Key Overview |

| Process Definition | Precise machining technology controlled by computers for the manufacture of high-standard medical components. |

| Safety Core | Patient safety ensured by ultimate accuracy, biocompatibility of the materials, and complete traceable quality system. |

| Materials Challenges | Biocompatible materials (e.g., titanium alloys) are difficult to machine, and special processes are needed to ensure their safety and performance. |

| Quality Cornerstone | ISO 13485 certification is a mandatory milestone, ensuring that the manufacturing system complies with medical device regulations. |

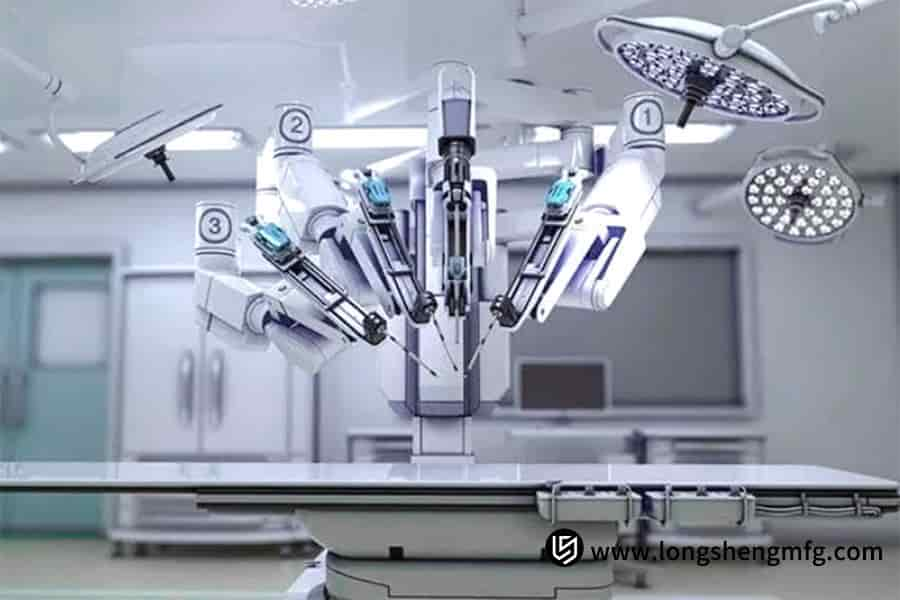

| Applications | Widely utilized in precision components such as orthopedic implants, cardiovascular devices, surgical robots, and drug delivery systems. |

| Core Strengths | It has higher standards and more rigid controls on precision, material, environment, and quality systems than conventional turning. |

| Supplier Selection | Its technical capabilities (precision), quality certifications, material competence, success cases, and traceability systems should be verified. |

Medical CNC turning is far more than “machining”; it is a systems engineering project marrying precision engineering, materials science, stringently regulated rules and regulations, and risk management.

Partnering with a firm like LS Manufacturing, having technical, compliance, and project experience, is the greatest guarantee of successful introduction to the medical device market and patient safety.

Why Trust This Guide? Practical Experience from LS Manufacturing Experts

You are able to trust all insight and norm here, as they are not derived from theory alone, but from actual experience of LS Manufacturing in shipping millions of safe components to top medical customers across the globe.

LS Manufacturing has solved the work hardening issues of titanium alloys firsthand, precision-toleranced micron-level chains for complex orthopedic implants, and mastered dozens of demanding customer and regulatory audits on the ISO 13485 system. All of the challenges described in this document—stable processing of biocompatible materials to ensuring traceability for millions of shipments with zero defects—mirror real issues we face and deal with on a daily basis.

This guidebook is actually a reliable action manual condensed from over a decade of valuable experience committed to medical CNC turning, and its aim is to put you in the market-tested, really workable answers.

What is Precision CNC Turning in the Medical Industry?

Precision CNC turning in the medical field is much more than traditional machining. It is a state-of-the-art manufacturing process exhaustively optimized for the life and health sector, its purpose lying in providing machining solutions with unparalleled precision and unshakeable reliability for high-risk precision medical parts such as implants and surgical instruments. The unique characteristic of medical CNC turning is realized in three respects:

- Real-Time Connection between Accuracy and Safety: Every micron-order dimensional tolerance and surface finish directly affects the long-term implant stability and surgical instrument working accuracy with no room for compromise.

- Done in a Controlled Environment: We place our machining stations in an ISO Class 7 cleanroom, effectively removing particulate contamination and enabling each precision medical component’s inherent cleanliness.

- Entire Verifiable Quality Loop: We extend it from one “machining” operation to an entirely traceable system for material, process, and testing. Every product contains an entire range of production data, so the manufacturing process is entirely verifiable.

Therefore, LS Manufacturing’s medical turning is a verifiable and regulated precision manufacturing process. It combines comprehensively general technologies with medical-grade standards, translating abstract precision requirements into concrete and reliable compliance to patient safety.

How is patient safety assured by medical CNC turning?

Medical CNC turning converts the very principle of patient safety into solid assurance by precision manufacturing technology. It goes beyond conventional machining in that it assures every precision medical component meets the stringent requirements of lifelines through three key dimensions:

1.Final Precision for Functional Reliability:

Micron-level dimensional consistency ensures a perfect fit between implants and the human skeleton and total zero error in transmission of instruments. LS Manufacturing employs end-to-end on-line measurement and rigorous management of tool life to eliminate the chance of functional failure through dimensional variances—this is medical CNC turning’s prime tenet.

2.Enhanced Surface Finish to Eliminate Potential Risks:

For implants and surgical instruments, we achieve a mirror surface finish that effectively inhibits microbial contamination and enables full sterilization. LS Manufacturing maximizes surface quality with a proprietary database of CNC turning process parameters for biocompatible materials, forming a critical physical barrier for patients.

3.Maintenance of Material Integrity to Avoid Long-Term Failure:

Stress concentrations or microcracks are induced by faulty machining, leading to long-term failure of components. Machining of metals such as titanium alloys and PEEK, LS Manufacturing maintains the native mechanical properties and biocompatibility of materials to the maximum extent through optimized cutting paths along with cooling methods, rendering precision medical components stable and safe throughout their lifespan.

It is through exercising systematic control over the three pillars of accuracy, surface integrity, and material properties that LS Manufacturing’s medical CNC turning technology translates the nebulous need for “safety” into measurable and verifiable quality attributes on every part, ultimately build a solid technical bulwark for patient health.

Why is the machining of biocompatible materials so difficult?

In medical CNC turning, machining of biocompatible materials is the greatest technical challenge. Because of the unique properties of such types of materials, their machining process is complex and, as a consequence, affects the ultimate precision performance of medical parts as well as patients’ safety. The greatest challenges are essentially brought about by the properties of the material itself:

1. Extreme material properties:

Taking titanium alloys, cobalt-chromium alloys, and PEEK as examples, they have high strength, high toughness, and low thermal conductivity.Heat generated in machining cannot be dissipated in a timely manner, easily leading to work hardening, microcracks, or thermal damage on the surface of the material, compromising its biocompatibility.

2. Constricted process window:

To maintain material properties, machining must be performed with unique tool geometry, ultraprecise cutting parameters, and biosafe cooling processes. Improper parameter selection may result in burr residue and stress concentration with the risk of long-term implant failure.

Choosing an inexperienced partner is readily likely to create such disastrous flaws. LS Manufacturing, with its experienced database of biocompatible material CNC turning and dedicated procedure libraries, can precisely equate tools and parameters, maintaining cutting forces and temperatures under tight control, allowing machined material to maintain its optimum mechanical properties and biosafety.

It is this deep insight and systemic problem-solving function that enables LS Manufacturing’s medical CNC turning capacity to confidently transform next-generation biocompatible materials into safe and reliable precision medical parts, bypassing technical risks and protecting the core product value for customers.

Why is ISO 13485 certification crucial to medical turning projects?

In the medical manufacturing sector, ISO 13485 certification is not just a qualifying certificate; it’s a quality management and risk control system that covers the whole life cycle of medical CNC turning projects. With an un-certified supplier, your product stands to fail in registration and be recalled from day one.Its underlying principle can be stated in three aspects:

1.Tracing in All Directions:

Such a system requires a complete line of data ranging from warehousing of raw medical material through the production, to final inspection. That is, the origin, processing conditions, and test results of each medical CNC turning part can be traced, providing precious objective proof for product registration.

2.Process Validation and Control:

It entails rigorous validation and continuous monitoring of all primary processes (such as ISO 13485 CNC machining parameters). Here at LS Manufacturing, this not only assures a stable and consistent manufacturing process but also the assurance that all batches of parts that we ship have consistent and reliable quality performance.

3.Managing Market Access Risks:

Big international regulatory authorities (such as the NMPA and FDA) accept this certification as the cornerstone of compliance. Using non-certified suppliers can render your product registration futile since it is not system-supported.

LS Manufacturing’s entire medical CNC turning process falls under this regime. This is not merely issuing customers with a certificate of compliance; it’s a robust assurance of product safety, performance, and fast time-to-market, converting quality control from reactive checking to proactive prevention.

What specific medical components and devices are most suitable for CNC turning?

Medical CNC turning has very wide applications, including almost all the medical conditions with stringent requirements on precision and reliability. Some examples of precision medical components in some of the major application areas are presented below, which unequivocally demonstrate the technology’s unparalleled flexibility:

- Orthopedic Implants: Including complex spinal fixation screws, femoral stems for joint replacements, etc.

- Surgical Instrument CNC Turning: Used to manufacture precision tubing and connectors for endoscopes, scalpel handles, and key transmission parts for robotic surgical systems.

- Drug Delivery Systems: Precision gears, metering valves, and nebulizer nozzles for insulin pumps, for example.

- Diagnostic equipment components: fluid connectors for gene sequencing instruments and precision probe housings for imaging instruments.

From permanently implantable devices to reusable high-end surgical instruments, medical uses of CNC turning demonstrate its importance as one of the keystones of modern medical manufacturing. LS Manufacturing, with its long-standing experience in these areas, is the go-to partner for most major manufacturers for precision medical parts.

What are the core advantages of medical turning compared to conventional turning?

Compared to common turning, meeting general industrial standards, the core importance of medical turning goes much further than “greater precision.” The advantage of CNC turning in medicine is that it has a whole system of technology and quality that ensures the absolute reliability and safety of every part.The above table well illustrates the main disparities between the two:

| Comparison Dimensions | Conventional Turning | Medical CNC Turning |

| Core Goals | Meets functionality, cost priority | Meets safety, risk management priority |

| Regulatory Requirements | Typically no mandatory system requirements | Mandatory compliance with medical quality systems such as ISO 13485 |

| Manufacturing Consistency | Allows for some batch-to-batch variation | Seeks very low batch-to-batch variation that ensures consistency in bulk production |

| Traceability | Generally only to the previous batch | Full traceability, all parts back to the raw material batch and machining conditions |

Therefore, medical CNC turning is more than a sophisticated technology. In the experience of LS Manufacturing, there is a process procedure that transforms a general technology into an organized and verifiable manufacturing process.

This is precisely the advantage of CNC turning in medicine and the worth that we provide to our customers—defining uncertainty in the manufacturing process.

How does LS Manufacturing solve precision component challenges for a leading global orthopedic company?

When a leading international orthopedic business had a market launch held up due to production issues delaying a high-tech titanium alloy spinal fusion device, they turned to us. Their vendor’s yield was plateaued at 85%, and extreme dimension variations not only increased costs but threatened product registration attempts.

1. Client’s Dilemma:

Their existing suppliers were facing extreme difficulties: the thin-walled components were prone to deformation during manufacture, and there was no dimensional consistency in the critical positioning features that resulted in component fit gaps well beyond design tolerance, finally leading to the product yield rate getting entrenched at 85% with no improvement ever. Not only did this raise unit costs substantially, but it also generated clinical problems through inability to assure batch-to-batch stability, significantly complicating the market launch of the new product.

2. LS Manufacturing Solution:

Faced with this issue, our LS Manufacturing Medical Turning Specialist Team acted promptly:

- We started, leveraging our deep materials knowledge and adherence to the ISO 13485 CNC machining system requirements, by conducting a process root cause analysis and utilizing specialty fixtures to the fullest as well as precision cutting parameters.

- Subsequently, in an ISO Class 7 cleanroom environment, we utilized multi-axis precision lathes with high-pressure cooling technology to offer machining stability and integrity of precision medical parts. We also used 100% fully automated optical inspection that enables real-time monitoring and 100% traceability of production information.

3. Results and Value:

Through process innovation in analysis and rigorous quality control, we were able to successfully increase the client’s yield rate for the project from 85% to 99.8%, and decrease the overall delivery cycle by 40%. More importantly, the complete and auditable traceability documentation package we provided extensively helped the client pass the first-time FDA approval process, ultimately allowing them to successfully bring their new product to market and build a long-term strategic partnership with us.

This illustrates how LS Manufacturing medical turning capability is more than precision machining. With technical expertise and rigorous control, they solve customers’ toughest mass production problems and minimize compliance risks, truly becoming a trusted strategic partner.

What key capabilities must be considered when selecting a medical turning supplier?

Choosing a medical CNC turning supplier is a business decision that is crucial to product success. As industry experts, we recommend that you examine the following four basic capabilities, which work hand in glove with LS Manufacturing’s tried and true system:

1.Foundation of Compliance and Certification:

Suppliers must be up to date with ISO 13485 certification and the corresponding cleanroom level. LS Manufacturing’s entire ISO 13485 CNC machining process is audited vigorously and operates in an ISO Class 7 cleanroom environment, which is a foundation of compliance for your project.

2.Extensive Material Expertise:

Successful experience working with biocompatible materials such as titanium alloys and PEEK is essential. We have assembled a comprehensive medical materials database and process parameter library that enables us to work with material properties at very high accuracy and avoid defects such as work hardening.

3.Measurement and Inspection Capability:

Authoritative measurement equipment such as CMMs and optical measuring machines accurately play a vital role. Our ZEISS coordinate measuring machine and fully automatic optical imaging system ensure absolute authority and objectivity in dimensional reports.

4.Project and Documentation Support:

Suppliers must provide professional project management and complete traceable documentation. Our project team will provide full support throughout the process, offering complete data packages that meet regulatory requirements and directly supporting your product registration.

These four skills taken together constitute the cornerstone of a reliable medical CNC turning supply chain. Not only does LS Manufacturing meet all of these criteria, but they strive for excellence in all of them, with a vision to be your worry-free and reliable manufacturing extension.

Why can LS Manufacturing be your reliable medical turning partner?

Choosing a medical CNC turning partner involves not just technical competency, but comprehension and commitment to the significant needs of the medical market. LS Manufacturing’s reliable partnership is a product of our four principal pillars:

1.Deep Medical Expertise:

LS Manufacturing has been specializing in medical CNC turning for several decades with a deep understanding of the material machining characteristics of materials such as titanium alloys and PEEK and medical standards. This allows us to effectively translate designs into safe and reliable precision medical components.

2.Uncompromising Quality Foundation:

LS Manufacturing is under strict control of the ISO 13485 system, putting quality control at each step from raw materials through to final product. This delivers industry-leading consistency and absolute traceability with each batch of LS Manufacturing medical turning products.

3.End-to-End Support from Concept to Mass Production:

LS Manufacturing offers unbroken integration from rapid prototyping through stable mass production at high volumes, supporting your product from development and clinical testing through to commercialization.

4.Customer-Focused Project Services:

LS Manufacturing boasts an in-house project management team, keeping communication lines open and processes transparent, effectively becoming a reliable extension of your supply chain.

Technological depth, systematic quality assurance, thorough process support, and dedicated service as a whole constitute the value proposition of LS Manufacturing medical turning.

That makes us not only a supplier, but also a trustworthy strategic partner, committed together with you to providing innovative medical technology to patients safely and efficiently.

FAQs

1. What biocompatible materials do you process?

We specialize in precision machining titanium alloys, 316L stainless steel, cobalt-chromium alloys, and polymer material such as PEEK and PEKK. We possess a mature process database and control temperature and stress during processing strictly to prevent an effect on the biocompatibility of the materials.

2. What is your minimum machining tolerance that you can achieve?

Our standard machining tolerance is as high as ±0.005mm, and our critical dimension control capability is as high as ±0.002mm. With our three-gear control mechanism of constant temperature machining, tool precision management, and real-time inspection, we ensure that we are always at the cutting-edge level of medical part precision.

3. Whether you provide services from prototype to volume production?

We provide streamlined services from prototype to mass production. We adopt a three-phased model of control “prototype-trial production-mass production” to ensure process parameters get transferred and optimized throughout the process, allowing customers to quickly introduce their products and ensure consistency of quality.

4. How do you ensure cleanliness and sterility of parts?

We complete processing and packaging in an ISO Class 7 cleanroom, using strict medical device cleaning procedures. We employ dual verification by particle counting and microbial testing to ensure parts cleanliness to implant standards, and provide detailed verification reports.

5. What is the typical production cycle?

Standard sample cycle: 2-3 weeks; mass production: 4-6 weeks. We have a flexible manufacturing system, and we can use expedited channels based on the project’s urgency to lower delivery time without sacrificing quality.

6. Can you provide full traceability documentation?

We rigorously follow the ISO 13485 system and have developed a large traceability system. Each product batch is equipped with a complete “birth certificate,” including material certificates, process parameters, inspection records, etc., fully meeting medical device registration requirements.

7. Besides turning, do you provide any other processing services?

In addition to precision turning, we also provide five-axis machining, grinding, and other process capacity, providing one-stop service for complex medical parts. We are particularly adept at manufacturing implants and surgical instruments comprised of diverse processes.

8. How to Start My First Project?

Just provide us with your 3D drawings, and we will conduct a DFM analysis and provide a complete project proposal within 24 hours. There will be a professional project manager throughout to facilitate easy communication and allow for a swift project start.

Conclusion

Medical CNC turning is an extreme level of integration of precision engineering, safety guarantees, and regulatory compliance, a good foundation for high-end medical device production. Backed by its rich technical strength, thorough quality system, and market-tested success stories, LS Manufacturing is optimally poised to be your most reliable precision manufacturing partner, offering whole-spectrum support for your creative medical projects.

Your next medical breakthrough device deserves equally superior components. Contact us and our medical project experts today for a free DFM (Design for Manufacturability) analysis and a prompt quote. Let’s work together, leveraging credible precision manufacturing capabilities, in making a difference in human health.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.