CNC Milling Services

Experience top-quality CNC milling services from leading milling manufacturers. Our state-of-the-art facility ensures rapid prototyping and production of high-quality plastic and metal parts. With competitive pricing and global delivery in just 3 days.

- Instant milled parts online quotes

- Lead Time as Fast as 3 Day

- Tight tolerance of +/- 0.005mm

- No MOQ 1PC Available

- All uploads are secure and confidential

Custom CNC Milling: Rapid Prototyping

to Custom Production

Achieve high-precision and efficient milling parts machining, from rapid prototyping to customized production, helping you transform designs into complex geometric shapes and obtain customized CNC milling parts that meet your strict requirements.

3 Axis CNC Milling

For producing components with 2D or 2.5D features,3-axis CNC milling is the preferred method for producing simple parts that require precision.

4 Axis CNC Milling

4-axis CNC milling allows for multilateral machining, making it easier to create complex parts with complex geometric shapes.

5 Axis CNC Milling

By tilting and rotating the workpiece,5-axis CNC milling is ideal for creating parts with complex contours, curved surfaces, and freeform shapes.

From CNC Milling Prototyping to Production

CNC machining is very suitable for rapid prototyping and on-demand production. Because it is a highly computerized multifunctional manufacturing process, the following are the CNC services we provide. Whether you need CNC prototype production or mass production, LS Manufacturing CNC parts online provides you with multiple choices.

On-Demand Production

On-demand production allows you to find the perfect match for your unique needs in our precision-driven processes, whether it's rapid prototyping or mass production.

Rapid Prototyping

We have the ability to quickly quote, allowing you to receive prototypes in a short period of time and test prototype parts in a timely manner to bring them to the market.

Bridge Production

Our engineers provide actionable advice for your part design and bridge to production services ensure a smooth transition from design to final product.

Put your CNC Milling parts into production today

- All information and uploads are secure and confidential.

CNC Milling Services Tolerances

Our precision CNC milling services not only cover the CNC milling of individual workpiece, but also cover the entire production cycle, including design, model making, prototyping and mass production. And it can ensure that the CNC parts size is within an acceptable range and effectively fits with other CNC parts.

| Types | Size Tolerance |

|---|---|

| Maximum Part Size |

1300mm × 800 mm × 300mm

51.2 in. × 31.5 in. × 11.8 in. |

| Minimum Part Size |

1mm × 1mm

0.04 in. × 0.04 in. |

| Linear Dimension |

+/- 0.005 mm

+/- 0.0002 in. |

| Hole Diameters |

+/- 0.005 mm

+/- 0.0002 in. |

| Shaft Diameters |

+/- 0.005 mm

+/- 0.0002 in. |

| Lead Time | 3 Business Days |

Materials for Custom CNC Milling Parts

LS Manufacturing diverse materials catalog offers a solution for virtually any project requirement. Whether you need metals, plastics, composites, or specialty materials, you can find the perfect material to suit your needs.

Metals

Plastics

We offer customization based on your specific material requirements. If you need a material not listed here, our team can source and process it to meet your exact needs.

These are just a few examples of the materials we work with. If you have a specific material requirement, please contact us to discuss your needs.

Surface Finishing for CNC Milling Machining

Our surface finishing allows you to customize the appearance and texture of your milling parts. Various textures, colors, and finishes are available to match the aesthetic requirements of your product or brand.

| Category | Description | Material | Color | Texture |

|---|---|---|---|---|

Anodizing

Anodizing

|

Anodizing is an electrochemical process used to enhance the corrosion resistance, appearance, and surface properties of metal parts, particularly aluminum. | Aluminum, Metals | Clear, black, grey, red, blue, gold | Rough, smooth, metallic |

Powder Coating

Powder Coating

|

Powder coating is a popular and environmentally friendly method of applying a protective and decorative finish to various types of metal and even some non-metal surfaces. | Metals | White, Black, RAL and Pantone | Glossy, fine, hardness |

Polishing

Polishing

|

The primary goal of polishing is to create a smooth and reflective surface by removing imperfections, scratches, and irregularities. | Metals | Silver gray | Bright, mirror, silk |

Chromate

Chromate

|

Chromate, commonly known as a chemical thin film, is a conversion coating used as a corrosion inhibitor on aluminum. | Aluminum | Clear/ Slight yellow tint | Satin |

Bead blasting

Bead blasting

|

Bead blasting, also known as abrasive blasting, is a surface preparation technique used to clean, finish, or texture a surface by forcibly propelling small, spherical abrasive materials, called "beads" or "media," at high speeds onto the surface being treated. | Aluminum, copper, stainless steel, steel | N/A | Grainy, slightly matte texture |

As machining

As machining

|

Machining is a subtractive manufacturing process in which a machine tool, typically a cutting tool, removes material from a workpiece to achieve the desired shape, dimensions, and surface finish. | Metals | N/A | Smooth, glossy finish |

Why Choose Us for CNC Milling Service

LS Manufacturing’s CNC milling service is dedicated to achieving the highest levels of precision in the parts and components it manufactures. This precision ensures that your products meet exact specifications, tolerances, and quality standards.

Instant Online Quote

By uploading design files to obtain CNC milling parts quotations, you only need to wait for 2 hours to quickly obtain project cost estimates.

Consistent High Quality

Through continuous analysis of data and feedback, our quality management system ensures that the production process is always in optimal condition.

Fast Lead Time

LS Manufacturing provides solutions to accelerate manufacturing cycles through domestic manufacturing and modern equipment, ensuring timely project delivery.

24/7 Engineering Support

Our engineers provide suggestions based on your project requirements to ensure that your design, material, and manufacturing choices are most suitable for your needs.

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

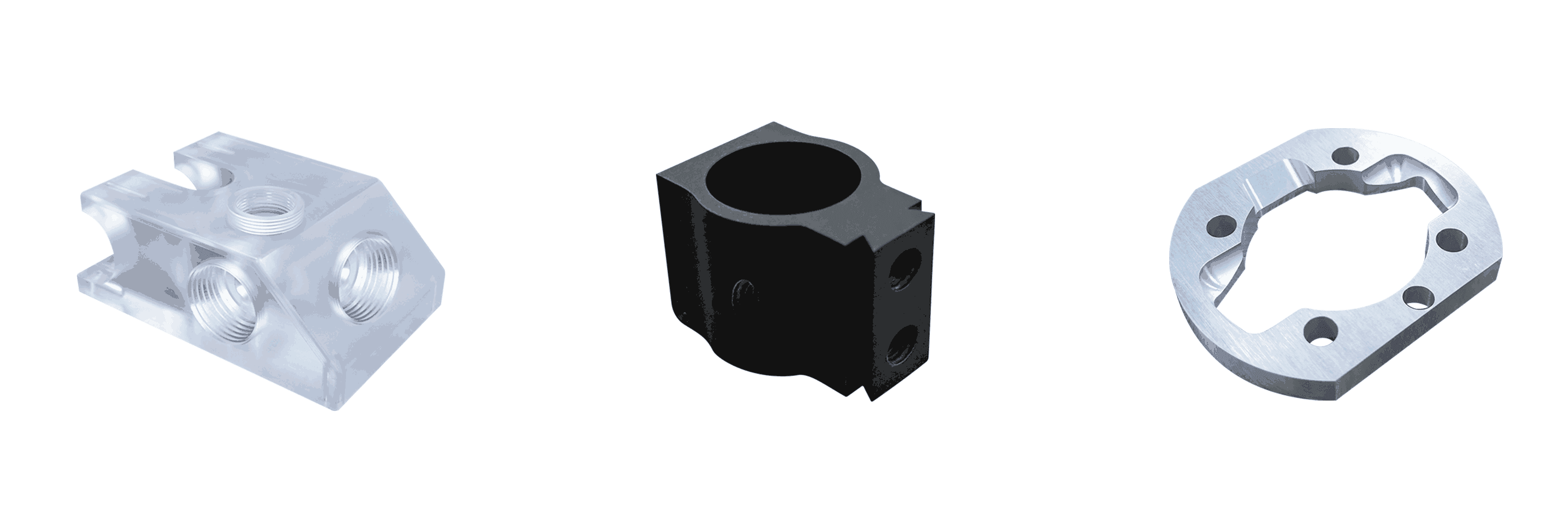

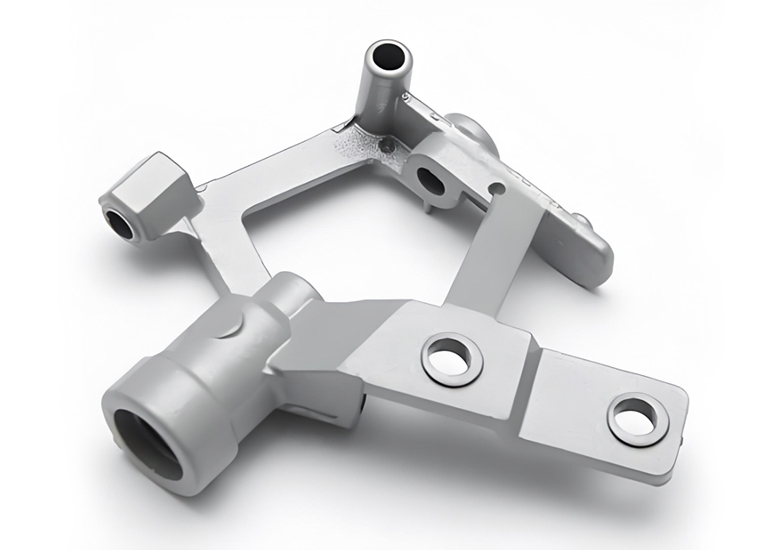

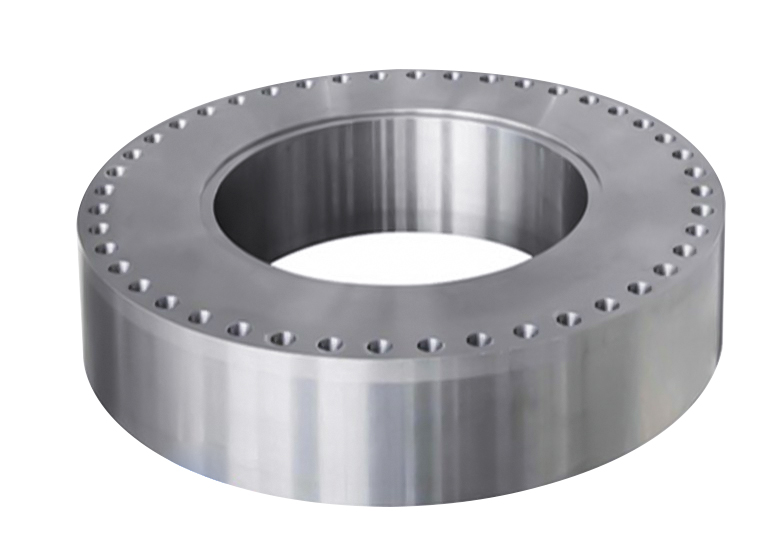

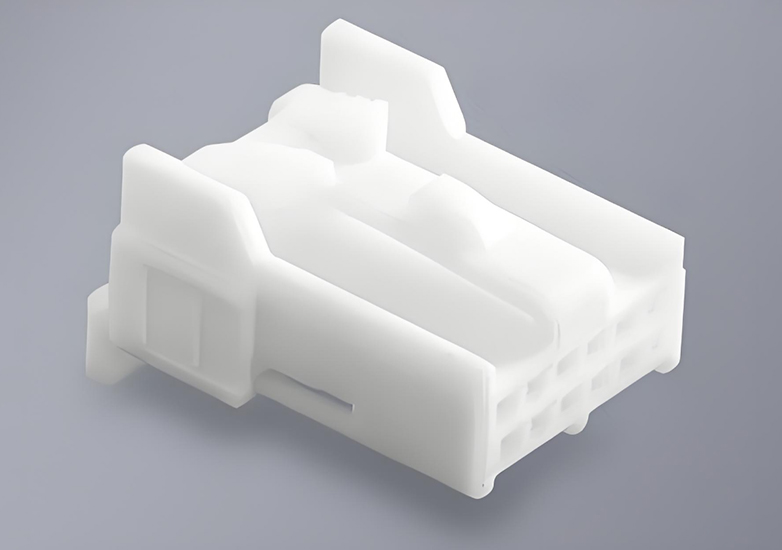

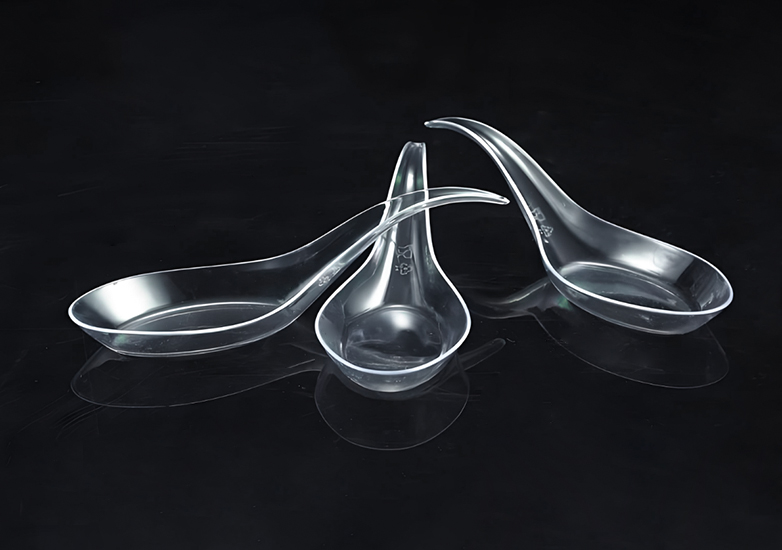

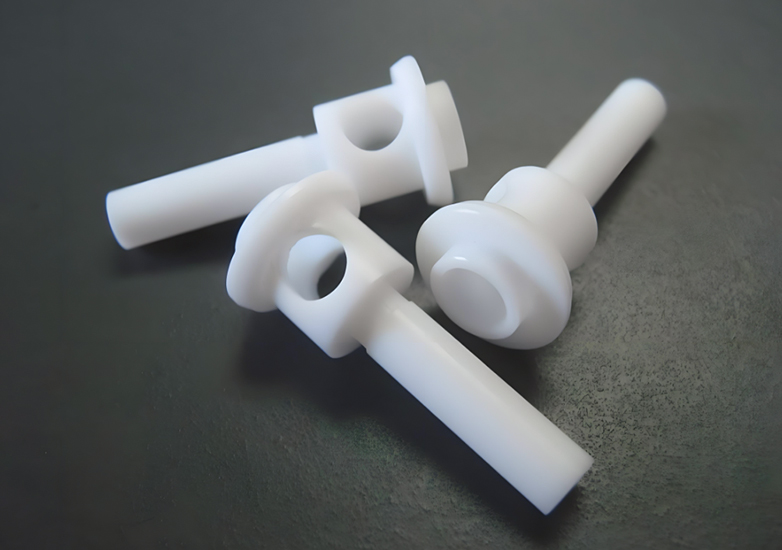

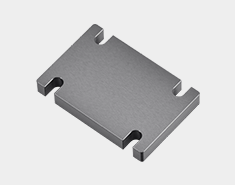

CNC Millied Parts Customer Cases

Our CNC Milling for Various Industrial Applications

Crossing numerous industries, LS Manufacturing uses highly advanced technology, from prototype production to on-demand manufacturing, and then to large-scale production, to ensure the excellent quality and reliable performance of parts, ensuring the success of your project.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

Frequently Asked Questions about

milling Parts Manufacturing

We provide new product developers with engine machining parts suitable for functional testing or final use of engineering -level materials. Get your required CNC machining services support by reading FAQ.

What materials can be used in CNC milling?

CNC milling can be used with a wide range of materials, including metals (such as aluminum, brass, copper, stainless steel), plastics (such as ABS, nylon, polycarbonate), and composites (such as carbon fiber, fiberglass).

What types of parts can be produced with CNC milling?

CNC milling can be used to produce a wide range of parts, from simple shapes to complex geometries. Some common examples of parts that can be produced with CNC milling include brackets, gears, housings, and prototypes.

What types of finishes can you provide?

We offer a variety of finishes, including anodizing, plating, powder coating, and painting. If you have a specific finish requirement, please let us know and we will do our best to accommodate your needs.

How long does it take to complete a CNC milling project?

The time required to complete a CNC milling project depends on a variety of factors, including the complexity of the part, the quantity of parts needed, and the materials being used. We work closely with our clients to provide accurate lead times and ensure timely delivery of all projects.

What is your quality control process?

We have a rigorous quality control process that involves multiple inspections and tests throughout the manufacturing process. We use advanced inspection and testing equipment to ensure that all parts meet or exceed industry standards.

What is your minimum order quantity?

We do not have a minimum order quantity. Whether you need a single part or thousands of parts, we are happy to work with you.

What is your pricing structure?

Our pricing is based on the complexity and quantity of the parts being manufactured. We will provide you with a detailed quote when you submit your order.

Do you offer design assistance?

Yes, we have a team of experienced engineers who can assist you with design and prototyping. We can work with you to optimize your designs for manufacturability and efficiency.

What is your warranty policy?

We offer a warranty on all of our products. If you experience any issues with our products, please contact us and we will work with you to resolve the issue.

How do I submit an order?

You can submit an order by contacting us directly or through our website. We will work with you to ensure that your order is submitted correctly and that you receive the parts you need on time and within budget.

News & Blog

Deep understanding of industry knowledge and real-time updates at any time.

The Ultimate Guide to CNC Milling: Advantages, Limitations & Applications

The Ultimate Guide to CNC Milling Machining: Everything You Need to Know

The Ultimate Guide to CNC Milling Parts: Functions and Components Explained

CNC Milling VS CNC Drilling: Key Differences and Applications

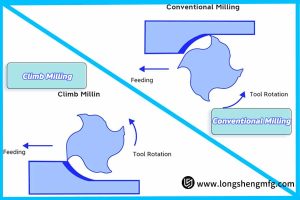

Climb vs. Conventional Milling: A Precision Puzzle That Many Machinists Misunderstand

Aerospace CNC Milling Parts: Everything You Need to Know | LS Manufacturing

Put your parts into production today

- All information and uploads are secure and confidential.