Sheet metal fabrication plays an important role in the manufacturing industry. By using different types of sheet metal fabrication, manufacturers can create a wide range of products such as metal components, enclosures, and brackets. This process is widely used in industries such as automotive, aerospace, construction, and many others. As technology advances, sheet metal fabrication continues to evolve to meet the demands of the industry and produce high-quality products efficiently.

In this article, we will explore What are the benefits, advantages, disadvantages, and use of sheet metal fabrication.

Benefits of Custom Sheet Metal Fabrication

Custom sheet metal fabrication is the process of creating metal products tailored to specific requirements. It is a highly precise and efficient method of producing metal components that meet the exact needs of customers. In this article, we will explore the various benefits of custom sheet metal fabrication.

1. Design Flexibility

Custom sheet metal fabrication allows for greater design flexibility. With the ability to create products tailored to specific requirements, customers can design unique products that meet their specific needs. This leads to more efficient and effective use of resources, reducing waste and improving productivity.

2. Precision and Accuracy

Custom sheet metal fabrication involves the use of advanced equipment and techniques to produce highly precise and accurate products. This results in products that are of superior quality, with tighter tolerances and greater consistency. This level of precision and accuracy is essential for many industries, including aerospace, automotive, and medical.

3. Cost-Effective

Custom sheet metal fabrication can be a cost-effective solution for many businesses. By creating products that meet specific requirements, customers can reduce waste, minimize material costs, and optimize production processes. This leads to improved efficiency, reduced downtime, and lower overall costs.

4. Quality Control

Custom sheet metal fabrication allows for greater quality control. From the design stage to the final product, every step of the process can be monitored and adjusted to ensure the highest quality standards are met. This results in products that are reliable, durable, and consistent in performance.

5. Fast Turnaround

Custom sheet metal fabrication can be completed quickly, allowing for fast turnaround times. With the ability to produce products on-demand, customers can quickly respond to changing market demands and stay ahead of the competition. This is especially important in industries where time-to-market is critical.

In conclusion, custom sheet metal fabrication offers many benefits, from design flexibility to fast turnaround times. By choosing custom fabrication, customers can create products that meet their exact requirements, improve quality control, and reduce costs. If you’re looking for a reliable and efficient way to produce metal components, custom sheet metal fabrication is the way to go.

Disadvantages of Sheet Metal

Sheet metal, despite its many advantages, also has several disadvantages. Some of these disadvantages are:

- Corrosion: Sheet metal is susceptible to corrosion if not properly treated or coated. Exposure to moisture and harsh chemicals can lead to rust, which can weaken the metal and compromise its structural integrity.

- Limited Formability: Sheet metal is not as flexible as other materials such as plastics, which limits the shapes and designs that can be created. This can be a disadvantage in applications where complex shapes are required.

- Difficulties in Joining: Joining sheet metal can be difficult, especially when welding is required. This is because the metal can warp or distort during the welding process, making it difficult to achieve a precise fit.

- Cost: Sheet metal can be more expensive than other materials such as plastics or composites. It also requires specialized equipment and skilled labor to work with, which can add to the overall cost.

- Weight: Sheet metal can be heavy, which can be a disadvantage in applications where weight is a concern.

While sheet metal has many advantages, it is important to consider these disadvantages when selecting a material for a specific application.

Advantages of Metal

Metals are widely used in various industries due to their unique properties. Here are five advantages of metal:

- Strength and Durability: Metals are known for their strength and durability, making them an ideal choice for building structures, machinery, and tools that require high strength and stability.

- Conductivity: Metals are excellent conductors of electricity and heat, making them essential components in electrical wiring, electronics, and heating systems.

- Versatility: Metals can be easily shaped, molded, and formed into various shapes and sizes, making them ideal for creating custom parts and components.

- Resistance to Corrosion: Many metals have a natural resistance to corrosion, making them ideal for use in harsh environments, such as marine or industrial settings.

- Recyclability: Metals are highly recyclable, which makes them a sustainable choice for many applications. They can be melted down and reused to create new products, reducing the need for new raw materials.

Metal is a vital resource in many industries due to its unique properties and advantages.

Several Types of Sheet Metal Fabrication

Sheet metal fabrication is a process of transforming flat sheets of metal into various shapes and sizes. This process is widely used in industries such as automotive, aerospace, construction, and many others. Here are some common types of sheet metal fabrication:

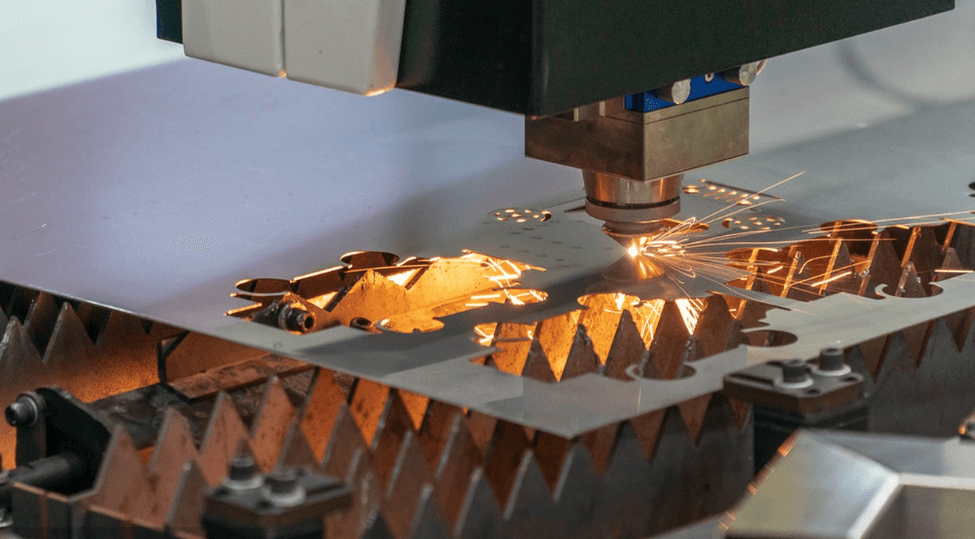

- Cutting: This process involves cutting the metal sheet into the desired shape and size. Cutting can be done using different methods, such as laser cutting, water jet cutting, and plasma cutting.

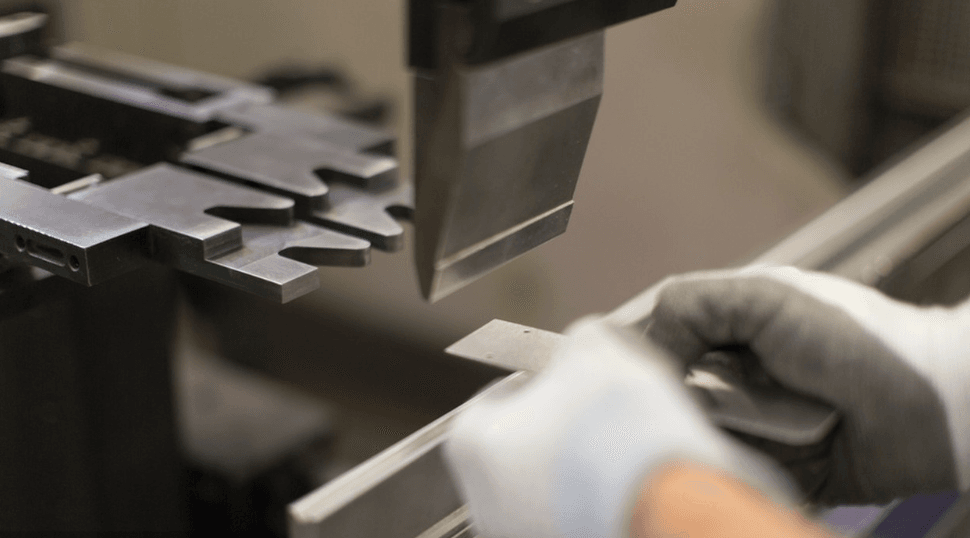

- Bending: Bending is the process of shaping the metal sheet into a specific angle or curve. This process is done using a bending machine, which applies force to the metal sheet and bends it into the desired shape.

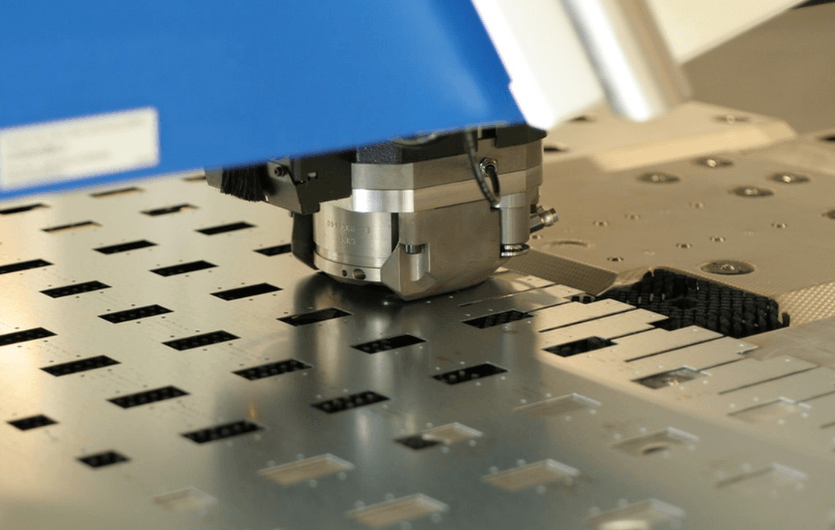

- Punching: Punching is the process of creating holes in the metal sheet. This process is done using a punch and die set, which cuts a hole in the metal sheet when pressed together.

- Welding: Welding is the process of joining two or more metal sheets together. This process is done using a welding machine, which melts the metal sheets and fuses them together.

- Forming: Forming is the process of shaping the metal sheet into a complex 3D shape. This process is done using a press brake, which applies force to the metal sheet and bends it into the desired shape.

Sheet metal fabrication is a complex process that requires specialized equipment and skilled workers. By using different methods of sheet metal fabrication, manufacturers can create a wide range of products that are used in various industries.

The Purpose of Metal Fabricator

Metal fabricators are professionals who specialize in the creation of metal structures and products. Their primary goal is to shape, cut, and join metal pieces to create a finished product. There are many different types of metal fabricators, including those who work with steel, aluminum, and copper.

Metal fabricators are an essential part of many industries, including construction, manufacturing, and engineering. They are responsible for creating a wide range of products, including structural steel frames, industrial machinery, and decorative metalwork.

The role of a metal fabricator requires a high level of skill and attention to detail. They must be able to read technical drawings and understand the properties of different metals to ensure that they create a high-quality product. They also need to have a good understanding of safety procedures and equipment to ensure that they work safely and effectively.

In summary, the purpose of a metal fabricator is to create high-quality metal structures and products using their skills and expertise in metalworking. Their work is essential to many industries and requires a high level of technical knowledge and attention to detail.

Sheet Metal Fabrication Service

At our company, we offer a wide variety of sheet metal fabrication services to meet the demands of our customers. We understand that every project is unique and has its own set of requirements. That’s why we work closely with our clients to ensure that we provide the best possible service and product.

Our team of experienced professionals uses the latest technology and equipment to fabricate sheet metal parts and components. We specialize in both custom and high-volume production runs. We can work with a variety of materials, including stainless steel, aluminum, copper, and brass.

Our sheet metal fabrication services include laser cutting, punching, bending, welding, and assembly. We also offer finishing services such as powder coating, plating, and painting. Our goal is to provide our customers with a complete solution that meets their specific needs.

We pride ourselves on our commitment to quality and customer satisfaction. We believe that our success is directly tied to the success of our customers. That’s why we go above and beyond to ensure that every project is completed on time, within budget, and to the highest standards.

Sheet Metal Fabrication Surface Finishing

Sheet metal fabrication is the process of creating metal structures by cutting, bending, and assembling metal sheets. One of the final steps in the sheet metal fabrication process is surface finishing.

Surface finishing is important to enhance the appearance, durability, and corrosion resistance of sheet metal parts. There are several techniques used for sheet metal finishing:

- Powder coating: Powder coating is a dry finishing process where powder is applied electrostatically and then cured in an oven. It creates a durable and attractive finish with excellent resistance to corrosion, chemicals, and weather.

- Anodizing: Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, and corrosion-resistant finish. It is most commonly used for aluminum parts.

- Plating: Plating is a process where a thin layer of metal is deposited on the surface of the sheet metal part. It provides a decorative finish and improves corrosion resistance.

- Painting: Painting is a common finishing method that provides a wide range of colors and finishes. It is suitable for both indoor and outdoor applications.

- Polishing: Polishing is a process used to create a smooth and shiny surface finish. It is often used for decorative purposes.

In conclusion, surface finishing services is an important step in the sheet metal fabrication process. It enhances the appearance, durability, and corrosion resistance of sheet metal parts. There are several techniques available for finishing sheet metal parts, each with its own advantages and disadvantages. The choice of finish depends on the application and the customer’s requirements.

The Importance of Metal Fabrication

Metal fabrication plays a crucial role in various industries such as construction, automotive, aerospace, and manufacturing. It involves the process of cutting, shaping, and molding metal into different parts and components.

One of the main benefits of metal fabrication is its ability to create custom-made parts that perfectly fit the requirements of a particular project. This ensures that the end product is of high quality and meets the specifications of the project.

Metal fabrication also enables the creation of strong and durable components that can withstand harsh environments and heavy usage. This is particularly important in industries such as construction and aerospace where safety and reliability are critical.

Another advantage of metal fabrication is its versatility. It can be used to create a wide range of products such as structural steel, machine parts, and decorative items. This makes it a valuable process for many different applications.

In addition, metal fabrication helps to reduce waste and improve efficiency. By creating parts and components through the fabrication process, manufacturers can minimize the amount of scrap material generated and optimize the use of raw materials.

Overall, metal fabrication is an important process that contributes to the success of many industries. Its ability to create custom-made, durable, and versatile components makes it a valuable tool for manufacturing a wide range of products.