Can 3D print statues?

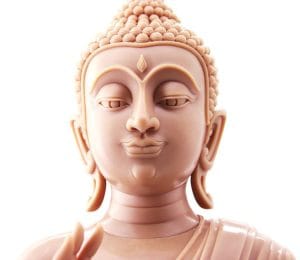

We’ve all seen the replicas of famous statues in our history books, or even in person if we’re lucky enough to have traveled. But have you ever wondered how those statues were made? The process is actually quite fascinating, and it has changed a lot over time. In the past, most statues were carved from stone or wood. But in recent years, a new technology has emerged that has revolutionized the statue-making process: 3D printing. In this blog post, we will explore how 3D printing is changing the statue industry and whether or not it can be used to create accurate replicas of famous sculptures.

Printing technology

The technology for 3D printing has come a long way since it was first invented in the 1980s. Today, there are many different types of 3D printers that use different methods to create three-dimensional objects. The most common type of 3D printer is the fused deposition modeling (FDM) printer.

FDM printers work by melting a plastic filament and depositing it layer by layer to build up an object. This type of printer is well suited for printing statues because it can create complex shapes and detail that other types of 3D printers cannot match.

Another type of 3D printer that can be used to print statues is the stereolithography (SLA) printer. SLA printers work by curing a photosensitive resin with a laser to create each layer of an object. This type of printer is often used for high-precision applications such as dental implants or eyeglass frames.

While both FDM and SLA printers can be used to print statutes

3D printing technology has come a long way in recent years, and it is now possible to print statues using this method. There are several companies that offer this service, and the results can be quite impressive.

The process of printing a statue using 3D technology is fairly straightforward. First, a design is created using CAD software. This design is then sent to a 3D printer, which creates the statue layer by layer.

The material used for the statue can vary, but most companies use plastic or resin. The finished product can then be painted or given a finish of your choice.

If you are looking for a unique gift or piece of art for your home, consider having a statue printed using 3D technology.

, FDM printers are more commonly used because they are less expensive and easier to use than SLA printers.

What can be 3D printed?

3D printing can be used to create many different types of objects. Some common items that can be 3D printed include statues, figurines, and other statuary. In addition to these common items, there are many other things that can be created using 3D printing technology. The possibilities are virtually endless!

The process of 3D printing

3D printing is the process of creating a three-dimensional object from a digital file. The printer reads the file and lays down successive layers of material until the object is complete.

The process of 3D printing is fairly simple. First, a digital file is created using CAD software or another 3D modeling program. This file is then sent to a 3D printer, which reads the file and lays down successive layers of material until the object is complete.

3D printing can be used to create just about anything, from small objects like jewelry to larger objects like statues. In recent years,

3D printing technology has come a long way in recent years, and it is now possible to print objects in a wide range of materials, including metals, plastics, and even human tissue. The process of 3D printing begins with the creation of a digital model of the object to be printed. This model is then used to generate a file that can be read by a 3D printer. Once the file is prepared, the printer creates the object layer by layer, until it is complete.

The advantages of 3D printing are numerous. First, it is an additive process, which means that there is no waste material produced during printing. Second, it allows for the creation of highly customized objects. And third, it is much faster and less expensive than traditional manufacturing methods such as injection molding.

However, there are also some disadvantages to 3D printing. One is that the quality of the final product can be variable depending on the printer and the quality of the digital file. Additionally, some materials are more difficult to print than others, and not all printers are able to print in every material. Finally, there is a risk that 3D-printed objects could be copied and reproduced without permission from the original designer or manufacturer.

3D printing is a process of making three-dimensional solid objects from a digital file. The creation of a 3D-printed object is achieved using additive processes, where successive layers of material are laid down in different shapes.

3D printing is an alternative to traditional manufacturing methods such as machining or casting. It offers a number of advantages over these methods, including the ability to create complex shapes, the ability to print in multiple colors and materials, and the ability to produce objects on demand.

The first step in 3D printing is to create a digital model of the object you want to print. This can be done using CAD software or by scanning an existing object. Once you have your digital model, it needs to be converted into a format that can be read by a 3D printer.

The next step is to choose the material you want to print with. There are many different types of materials that can be used for 3D printing, including plastics, metals, and ceramics. Each type of material has its own advantages and disadvantages, so it’s important to choose the right one for your project.

Once you have your digital model and your chosen material, you’re ready to start printing. The first layer of material is deposited onto the build platform and then cured with UV light or heat depending on the material being used. The next layer is then deposited on top of the first layer and cured in the same way. This process

technology has become increasingly popular and affordable, making it accessible to more people than ever before.

Can 3D print statues?

Yes, you can 3D print statues! There are a few different ways to go about it, but the most common method is to use a 3D scanner to create a digital model of the statue. Once you have the digital model, you can then use a 3D printer to print out your statue.

The advantage of using a 3D scanner is that it allows you to create an exact replica of the statue. This means that you can print out multiple copies of the same statute if you want. The downside is that it can be expensive to purchase a good quality 3D scanner.

If you don’t want to spend money on a 3D scanner, you can also try using photogrammetry. This is where you take multiple photographs of the statue from different angles and then use software to stitch them together into a single 3D model. The advantage of this method is that it’s much cheaper than using a 3D scanner. However, it can be difficult to get accurate results and the process can be quite time-consuming.

The benefits of 3D printing

3D printing is an additive manufacturing technology that creates three-dimensional objects by building them up layer by layer from a digital file. The benefits of 3D printing include its affordability, speed, and versatility.

3D printing is much more affordable than traditional manufacturing methods. It is also faster, as there is no need to create molds or wait for materials to cure. 3D printing is also very versatile, as it can be used to create objects of almost any shape or size.

The drawbacks of 3D printing

3D printing technology is still in its infancy, which means that there are many drawbacks to using it to print statues. First of all, the quality of 3D-printed statues is not yet on par with traditional methods of statue production. The colors may be less vibrant and the overall finish may not be as smooth. Additionally, 3D-printed statues are often much smaller than traditional statues, which can be a problem if you’re trying to create a life-size replica. Finally, 3D printing technology is very expensive, so unless you have a lot of money to spare, it’s probably not worth investing in a 3D printer just to print statues.

Conclusion

Yes, 3D printing technology can be used to create statues. The process is known as direct metal laser sintering (DMLS), and it involves using a high-powered laser to fuse together small particles of metal powder. This technology is often used to create prototypes or small batches of statues, but it can also be used to produce larger quantities.