In precision machining, conventional milling vs. climb milling is a serious quality and efficiency decision. Though based on different principles, machinists generally do manage to blend them into a simpler form, taking only tool wear into account and not a considerable difference in dynamic precision control. For example, conventional milling easily introduces “creep,” the quiet strangulation that restricts the accuracy of machining.

With this problem in mind, LS Manufacturing applies its expertise and customized solutions to help customers accurately specify process bottlenecks. Expediting system stiffness, cutting conditions, and clamping solutions, it converts the theoretical advantage of climb milling and conventional milling into consistent productivity, significantly improving machining quality and efficiency.

This is a story of the climb milling secret and conventional milling accuracy and how LS Manufacturing helps clients gain a winning edge in this valuable practice. To save you time, here’s a quick overview of the core conclusions.

Climb Milling vs. Conventional Milling Core Characteristics Quick Reference

| Feature Comparison | Climb milling | Conventional Milling |

| Cutting Force Direction | Maximum at entry, directed towards worktable, holding workpiece firmly in place. | Maximum at exit, tendency to push workpiece up. |

| Surface Finish | Very good. Chips are thick and then thin, with high cuts and good finish. | Medium. Chips are thick from thin, causing friction and work hardening. |

| Tool Life | Long. Heat of cutting is removed more by the chips, thus less tool wear. | Slip friction and work hardening on first cut enhance tool wear. |

| Heat Effect and Hardening | For machining easily hardened materials like titanium alloys and stainless steel. | This has a tendency to result in surface hardening of the machined surface, affecting subsequent cutting. |

| Applicable Scenarios | Finishing, machining operations with sufficient stiffness of the machine, and stiff clamping. | Roughing, clearance requirement operations, and hardened surface operations. |

- Climb milling is the most widespread method in most modern CNC machine operations, with improved machining quality, increased tool life, and increased productivity.

- Conventional milling is not old-fashioned technology; it shows remarkable toughness when machining work with surfaces that are hardened or soiled, and with very small clearances.

LS Manufacturing employs strict process analysis to help you scientifically select the best milling process according to your unique machine conditions, workpiece material, and machining stage. We then provide you with customized fixture and parameter solutions to achieve theoretical increases in solid and practical real-world productivity.

Why trust this guide? LS Manufacturing’s Practical Experience

LS Manufacturing has decades of precision machining experience. It is not merely the fact that we house state-of-the-art CNC machines but also process experts with deep cutting mechanism knowledge and in-house troubleshooting. LS Manufacturing faces actual machinability challenges on a daily basis in high-reliability markets, ranging from aerospace to medical devices. This translates into the fact that our expertise is not theoretical but the outcome of intense hands-on exposure.

For example, LS Manufacturing recently assisted a customer in overcoming inconsistent surface finish on the side walls of a titanium alloy part. Through process retrospective analysis, we discovered that the customer had improperly used up-cut milling as the final operation to avoid edge chipping. This resulted in tool contact with the hardened surface and consequently contributed to excessive wear and reduced the finish.

Our experts also conducted tests on the rigidity of the customer’s machine tool and concluded conclusively to alter their finishing method to down-cut milling supported by a specialty high-performance miller cutter and cooling setup. The outcome was immediate: surface finish of workpiece was significantly improved, tool life improved by 35%, and cycle time was reduced.

This is precisely the worth that LS Manufacturing provides—extensive machining theory used with specific on-site circumstances to provide you with truly dependable, professional solutions that produce benefit directly.

What are Climb Milling and Conventional Milling?

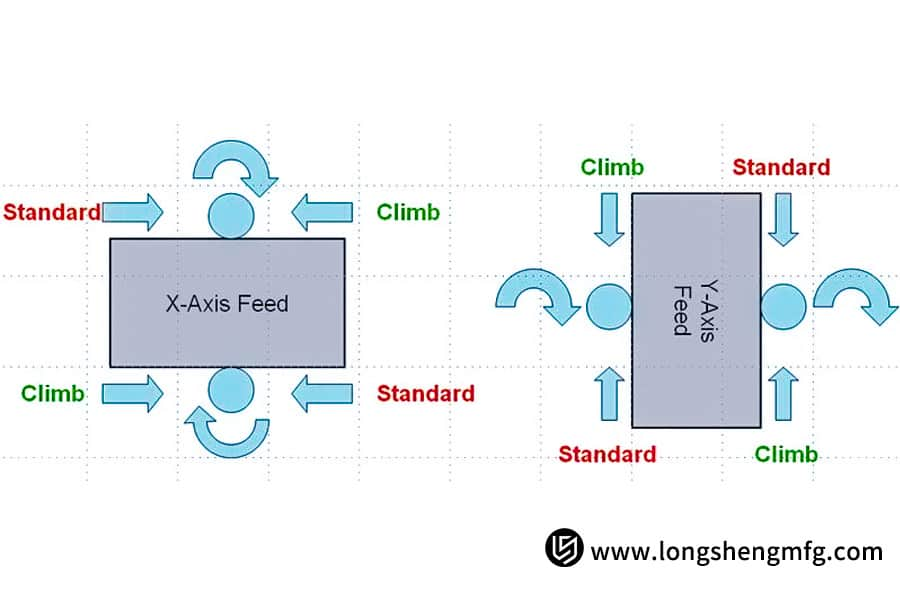

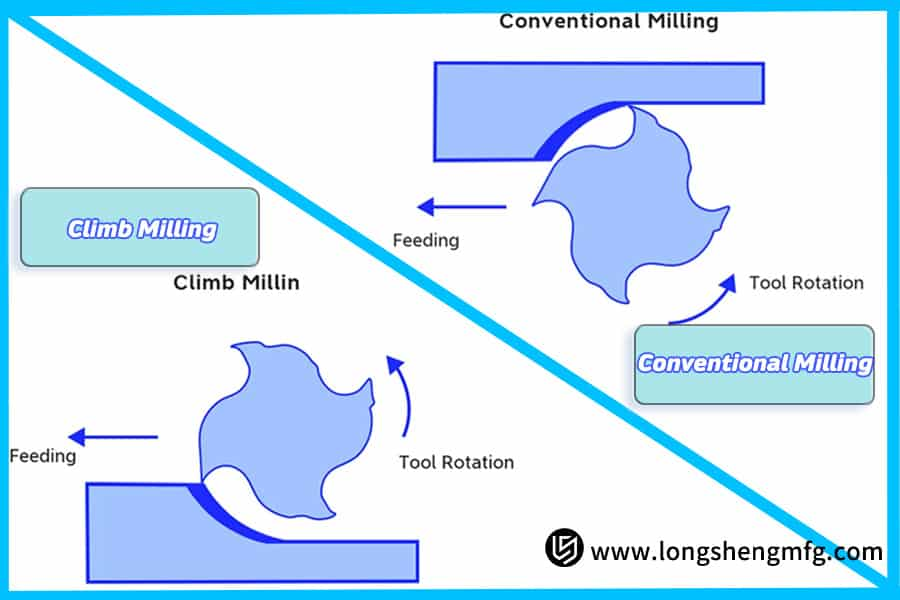

The most elementary kinds of milling are climb milling and conventional milling on CNC milling. The relative difference is the tool rotation direction vs. workpiece feed direction orientation. Comparing climb milling and conventional milling, experience is the foundation of the mastery of efficient and high-precision machining techniques. Especially:

- Climb milling: where tool cutting speed direction and feed direction of workpiece are the same at the point of tangency. Imagine milling cutter teeth “clutching” on workpiece and cutting downwards, gradually decreasing chip thickness from maximum to zero. The process push the workpiece harder on to the worktable, preferring uniform machining conditions.

- Conventional milling: when the direction of feed of workpiece and cutting speed of tool are both reversed on the tangent line. As if the cutter teeth of milling are “facing” the workpiece and cut in the upward direction, the thickness of chip is increased from zero to maximum. Cutting force is in upward direction to push the workpiece.

The most fundamental difference between down milling and conventional milling is relative cutter motion at cutting entrance into work. Such fundamental choice outright determines cutting direction of cutting force and chip flow and directly impacts machining accuracy, surface quality, and tool life.

What are the main differences between Climb milling and conventional milling?

To illustrate climb milling and conventional milling difference, the former is to understand differences in their physical properties while machining, which have direct influences on final machining results. The following compares the precision of conventional milling and down milling based on some basic dimensions.

| Comparison Dimensions | Climb Milling | Conventional Milling |

| Cutting Force Direction | Down, against the worktable, improving workpiece stability. | Develops upward forces that lift the workpiece and influence clamping reliability. |

| Chip Formation | Thick to thin, smooth chip removal. | Thin to thick, prone to friction with machined surface. |

| Tool Life | Longer (up to 40% longer). | Larger wear due to initial friction and work hardening. |

| Surface Quality | Better, with reduced vibration and smoother finish. | Low, vibration-prone, “creeping.” |

1. Cutting Force and Stability:

In climb milling, the cut’s foremost force is in the downwards direction, thrusting the work hard into the worktable forcefully and aiding vibration damping significantly, the root of its precision. In up milling, the direction of the cutting force upwards helps to lift the work out of contact with the worktable. This, more so when the clamping is not hard enough, can cause vibration and have a severe impact on machining stability.

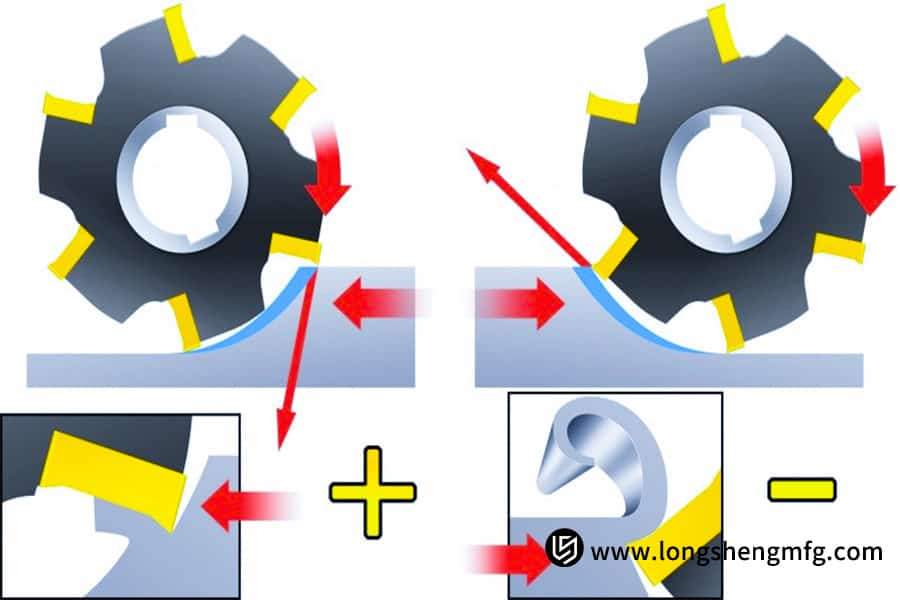

2. Chip and Surface Quality:

The “thick to thin” formation of chips in down milling makes chip removal simple and minimizes friction with the machined surface. In standard milling, the end is ground off rubbing against the hardened layer over a distance prior to cutting from thin to thick chips. This not only wears the tool faster but also has a tendency to easily produce surface roughness and even chatter marks.

3. Tool Life:

Because climb milling avoids high friction and work hardening in the initial phases of conventional milling, the cutting edge remains in a better state with less heat generation, resulting in significantly longer tool life than conventional milling.

The difference between climb milling and conventional milling is fundamentally a conflict between precision and stability.

Comparative precision on conventional vs. climb milling means that, given acceptable rigidity of the machine tool, climb milling with improved load behavior and chip control is significantly better than conventional milling in modern machining processes with high surface quality, high accuracy, and high productivity.

Why does down milling offer higher precision?

Comparison to the conventional, down milling is the mode of preference for finishing since its precise mechanical properties automatically ensure the stability and consistency of machining. Its high-precision benefit mainly comes from three basic mechanisms:

1. Favorable Cutting Force Direction:

When the workpiece is down milled, the cutting force is predominantly downwards, in fact “pressing” the workpiece onto the worktable and fixture. This mechanical mode significantly dampens the workpiece vibration and tool deflection, giving a sound foundation to achieve stable geometric tolerances and dimensional accuracy.

2. Minimized Tool Runout and Initial Slide:

Unlike up-cut milling, in which the cutter must begin at zero chip thickness and then “push” and slide along the workpiece surface, down milling cutters cut directly down from the top chip thickness, like a knife cutting through meat. This process eliminates nasty first-cut friction and work hardening, essentially cutting shock and tool radial runout, and gives precise and reproducible cutting paths.

3. Uniform Load and Thermal Management:

While the chip gets thinner progressively, down milling forces and heat generation become stable and uniform. This avoids micro-deformation and tool wear caused by loading spikes or localized overheating, maintaining the sharpness of the cutting edge and maintaining constant high-quality workpiece surface generation.

Advantages and disadvantages of climb milling need to be examined carefully. Although it is prohibited from being applied for hard-skinned workpiece or vintage machine tool processing, it promises unchallenged physical conditions for ultra-high precision attainment on modern rigid CNC machine tools by enhancing force distribution, reducing vibration, and holding thermal loads steady.

When should climb milling be chosen over conventional milling?

In shop machining, the question of when to employ climb milling is a key process decision for maximizing efficiency and quality. Though selecting climb milling is not absolute, it should be your go-to method whenever the following are the main goals for machining.

1. When pursuing a high surface finish:

For final or finishing machining, down milling must be prioritized. Its “thick to thin” cutting action provides a smooth material separation without friction and scratch on the machined surface by the cutter’s teeth. Critical surface finish comparisons between down milling and conventional milling affirm that down milling provides a smoother and more uniform finish.

2. When machining easily hardened or difficult-to-cut materials:

When machining those materials possessing a work hardening tendency, such as stainless steel and titanium alloys, down milling is to be employed. This is considering that it will allow the tool to remove material from the inside, avoiding the problem of up milling sliding on the hardened surface and improving tool wear, thus providing an assurance of tool life and machining stability.

3. When operating on modern, rigid machine tools:

The full benefits of down milling are dependent upon the stiffness of the machining system. Provided your CNC machine tool has high accuracy, close guideway clearances, and rigid workpiece clamping, down milling is able to utilize full benefit of its stability by the virtue of cutting forces in the downward direction and achieves higher dimensional accuracy and lower vibration.

The choice to use down milling is based on balancing machining objectives and conditions of the system. If your shop is precision machining, working on special materials, and you have a steady machining environment, down milling will yield rich dividends in terms of surface finishing, machining accuracy, and efficiency.

In what situations is conventional milling more suitable?

Although down milling generally has the lead in comparison between normal milling and down milling in terms of accuracy, such a process choice always concerns in-depth consideration. An awareness of the advantages and limitations of down milling helps us fully comprehend the irreplaceable status of conventional milling. In the following typical conditions, conventional milling is a superior, even essential, choice.

1. When the surface has hard scale or impurities:

During castings or forgings’ rough machining, the workpiece surface often is highly hard oxide scale or sand. With conventional milling, the tool is cutting from within the material, not striking the hard surface, saving the cutting edge of expensive finishing tool and not risking chipping by down milling against the hard surface directly.

2. When the machine tool or fixture lacks rigidity:

While using mature machine tools or intricate workpiece geometries leading to insecure clamping, the cutting force acting upward due to conventional milling can harm accuracy but can avoid the danger of the workpiece being drawn out of the fixture, offering larger process robustness and guaranteeing safe processing.

3. When processing thin-walled, elastic parts:

In some thin-walled features, down milling’s compressive force can cause deformation of workpieces. The “lift” force of conventional milling can occasionally oppose some of the clamping force, rounding out the cutting action and helping with the retention of part geometry.

Conventional milling is definitely not an archaic process. Its unique flexibility gives it a key position as a machinability assurance tool against unfavorable surface conditions, lacking system stiffness, or special workpiece material composition.

How do down milling and up milling affect surface finish?

From the aspect of machining quality, the relative surface finish of down milling and up milling is the primary issue of concern. The two operations directly regulate the shape of the final workpiece surface through two different physical processes. The difference is particularly critical in common applications such as down milling and up milling of aluminum.

1. Climb milling: The key to achieving a smooth surface

The “thick to thin” shear cutting action of down milling allows chips to drop naturally as the cutter teeth move away from the workpiece, lessening pressure and friction on the machined surface. The clear “cutting” action effectively prevents plastic deformation in the material, creating a smoother, less textured surface. It tends to decrease surface roughness (Ra) by more than one grade compared to standard milling.

2. Conventional milling: Potential Risk of Surface Damage

The “thin-to-thick” transition of conventional milling involves some friction and compression through the first cutting entry of the cutter’s teeth. This contributes to tool wear and the potential for work-hardened surface layers and microcracks to remain on the surface being machined. Surface finish degradation and microburrs caused by upward force generated by departing cutter teeth during cutting, and even observed chatter marks, result.

3. Special Considerations for Aluminum Machining:

Of down milling and conventional milling of aluminum, down milling is to be preferred. Aluminum is a gummy material that sticks easily to the tool. Chip piling and frictional heat developed by conventional milling can easily lead to built-up edge on the cutting edge. Built-up edge can scratch the workpiece surface because of these hard chips. Down milling, with its clean edge and better chip removal, easily avoids this problem so down milling is the preferred process for producing good quality finishes on aluminum parts, e.g., mirror finish.

Generally, down milling vs. up milling surface finish, down milling, with its cleaner cut, is the only way to produce a higher quality surface. especially for finishing soft metals like aluminum, down milling selection is a determining alternative for minimizing surface defects and product appeal improvement.

What are the special considerations for down milling and conventional milling in aluminum machining?

The plasticity, stickiness, and softness of aluminum render down milling compared to conventional milling a singleistically critical choice. It has a direct impact on machining efficiency and surface finish. Machining technique must be optimized to address these concerns.

1. Prefer down milling for the best finish:

To finish aluminum, down milling is highly recommended. Its clean, “cut-off” style of cut readily avoids the material extrusion and flanging with conventional milling, seriously suppressing burrs and tool sticking, and easily generating a mirror-like surface finish.

2. Sharp tools and large chip flutes are crucial:

Regardless of the process, machining aluminum requires special aluminum cutting tools with sharp cutting edge, sharp rake angle, and adequate chip flutes. Cutting forces are minimized by a sharp cutting edge, and unhindered flow of chips prevents scratching of machined surface by chips.

3. Adequate Cooling and Appropriate Parameters:

Air mist or oil mist cooling is recommended, as it reduces temperatures highly effectively and scatters chips through the use of airflow. Furthermore, high cutting speed and proper feed per tooth facilitate improved chip formation and disperse cutting heat.

That is where LS Manufacturing’s milling products have your back—we don’t simply provide theoretical guidance but also an entire process package which is tailored to your own equipment and product, special tools, optimized cutting conditions, and cooling systems so that you’re always and effectively producing high-quality aluminum parts.

In deciding between climb and conventional milling of aluminum, climb milling is the only way to achieve high-quality surfaces.

How to Avoid Common Mistakes in Climb and Conventional Milling?

Just having knowledge of the principles of climb and conventional milling isn’t sufficient to ensure that high-precision milling is always achieved; preventing common errors during operation also matters. These errors tend to nullify the theoretical advantage of the process selection and even cause the failure of the workpiece.

1. Mistake 1: Ignoring Machine Clearance and Rigidity

Blind use of climb milling without verification of machine condition is a common risk. Down milling would be a dragging operation if the leadscrew/nut assembly of the machine tool contains backlash, affecting tool size and possibly also tool damage. It is a best practice to always compensate for backlash before initiating down milling and for workpiece clamping to be stiff enough to accommodate downward cutting forces.

2. Mistake 2: Parameter Settings Mismatch with Process Selection

The majority of operators select the correct down milling method but use conservative cutting parameters that are actually suited for up milling. For example, fear of excessive cutting forces in down milling leads to unrealistically low feed rates, which in turn causes too much friction in certain tool zones and creates excessive wear. The correct approach is to mix down milling with an increased feed rate, as recommended by the toolmaker, for efficient cutting.

3. Mistake 3: Neglecting Chip Control and Cooling

Especially while machining adhesive materials, inappropriate chip management may scratch the machined surface. During down milling, supply sufficient coolant pressure to remove chips from the cutting zone, or utilize the utilization of compressed air for effective chip evacuation to prevent re-scratching well-machined surfaces.

Avoiding these common mistakes is the secret to translating theoretical knowledge of down milling and up milling into consistent productivity. This is the core principle behind LS Manufacturing’s precision milling solutions.

Through conducting professional machine tool evaluations, process parameter tuning, and shop-floor instruction, our firm allows customers to systematically eliminate potential problems and guarantee that every cut delivers the desired accuracy and quality.

How does LS Manufacturing solve customer precision challenges through down milling?

When deciding between down milling and standard milling, theoretical understanding has to be supported by experience. The following case study illustrates how we, with our expert LS Manufacturing milling solutions, turn theoretical benefits into practical advantages for our customers.

1. Customer Dilemma:

A machine shop experiencing a bottleneck machining aluminum engine components used to have high-quality tools, but conventional milling yielded obvious chatter marks on the part surface, substandard roughness, and a 75% pass rate for critical dimensions. The resulting high scrap rate heavily impacted delivery schedules and production costs.

2. LS Manufacturing’s Solution:

By on-site inspection and diagnosis, LS Manufacturing’s technical team confirmed that the cause of the problem was vibration and material sticking to the tool as a result of the conventional milling process. We developed an end-to-end customized milling service solution for this customer:

- First, we completely converted the finishing process into down milling, leveraging its stable cutting forces to suppress vibration.

- Second, we optimized toolpaths and cutting conditions (e.g., increased feed rates).

- Finally, we added a high-pressure, directionally controlled coolant system to provide instant chip evacuation.

3. Results and Value:

The solution came with immediate payback: the workpiece surface finish improved by 30%, and the accuracy of all critical dimensions remained within 0.01mm at all times. As a result, the client’s scrap rate declined significantly, overall production efficiency improved by 20%, and overall production cost was reduced by 15%. This gave the client a significant quality and cost advantage over the competition.

This example shows that the correct decision between up milling and down milling is necessary to achieve high-precision milling.

If you are also facing such precision problems, LS Manufacturing’s custom milling solution will provide you with complete support, from process diagnosis to solution implementation, to release your bottlenecks.

Why choose LS Manufacturing for your milling project?

When your mill project faces delays in accuracy, productivity, or cost, choosing a reliable partner with years of experience is important. LS Manufacturing’s milling services are for this reason, dedicated to translating your blueprints into quality, tangible pieces. Our strength points are:

1. Leading Technology and Equipment:

LS Manufacturing boasts advanced five-axis CNC machining centers and precise checking equipment, having a solid foundation for undertaking complex and demanding custom milling solutions, whereby all machinability processes are precise and accurate.

2. Support from a Team of Experienced Experts:

LS Manufacturing’s technicians and engineers possess an enormous amount of hands-on experience in fields such as aerospace and medical devices. They are not only accustomed to both up-milling as well as down-milling processes but also scrutinize your unique requirements from deep within and optimize process solutions from the ground up.

3. True End-to-End Customization:

LS Manufacturing provides a great deal more than machining. From initial process analysis and midpoint parameter optimization to final quality monitoring, LS Manufacturing’s milling solutions provide end-to-end support throughout the project life cycle, ensuring the final product surpasses expectations.

Whatever the special machining issue you are facing, LS Manufacturing is qualified and confident to repair it using professional custom milling services. Contact us today in order to enable our experienced team to deliver value to your next project.

FAQs

1. Which is better for stainless steel machining: climb milling or conventional milling?

Climb milling is best used in finishing stainless steel. Because its cutting force forces the workpiece against the table, it suppresses vibration and substantially prevents the work hardening tendency of occurring on stainless steel, resulting in improved surface finish and extended tool life. But in the case of roughing operations, or where there is a lack of rigidity on the machine tool or on the workpiece a hardened surface, the conventional milling, through its “inside-out” approach to cutting, avoids direct contact between the cutting edge and the hardened surface, protecting the tool while being more rigid and less likely to fail.

2. How can I determine if my machine is suitable for climb milling?

The critical factor to consider when deciding whether a machine can climb mill is to ascertain its rigidity, guideway condition, and backlash. Dry run the machine to see if there is abnormal vibration or noise during reversal, and check the value of backlash of the table during reverse motion with the help of a dial indicator. If you do not know how to evaluate, LS Manufacturing has a free professional equipment evaluation service that will allow you to evaluate the state of your machine and adjust cutting parameter settings to produce a smooth safe process.

3. What are the advantages of down milling in aluminum machining?

In milling aluminum, down milling’s own strength is minimizing stuck material, with excellent surface finish. Its “thick to thin” shearing-like cutting action cuts cleanly through the material, not tearing or pushing the blade against the soft aluminum and generating burrs. LS Manufacturing, familiar with the properties of aluminum, creates special tools, cutting parameters, and cooling solutions to maximize the advantages of down milling to create efficient and high-precision aluminum machining.

4. Has down milling been completely replaced by conventional milling?

Converse milling is not completely eliminated; it remains uncopyable in practical use under given circumstances. For example, in roughing, a significant amount of stock must be obtained quickly, or while milling workpieces with hardened surface layers or cast-work surfaces. LS Manufacturing always adheres to objective and impartial process analysis. We will propose the most economical and reliable solution of milling for your own workpiece material, equipment condition, and quality level.

Conclusion

The choice between down milling and conventional milling is not a choice between two alternatives; it is an exhaustive choice based on the material to be machined, equipment condition, and quality objectives. Down milling has enormous advantages in precision and efficiency for finishing and high surface quality requirements, but conventional milling is always particularly useful when handling specialized conditions. Awareness of the underlying mechanical principles and applicable limits is the secret to improving machining performance.

Taking advantage of our extensive industry experience, LS Manufacturing is committed to helping customers correctly navigate this process decision point with exactness, making theoretical advantages reality-based productivity increases, helping you to overcome precision issues and take advantage of cost savings and efficiency gains.

Are accuracy, productivity, or surface finish issues ruining your machining? Contact LS Manufacturing today to have a free personalized assessment of your milling solution! Our technicians will sit down and review your specific needs at length and create a cost-effective, efficient, and high-precision machining solution for you.

📞Phone:+86 185 6675 9667

📧Email:info@longshengmfg.com

🌐Website:https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS Manufacturing makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS Manufacturing’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

LS Manufacturing Team

This article was written by various LS Manufacturing contributors. LS Manufacturing is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.