Value comparability

The worth of titanium alloy is normally a lot larger than that of aluminum alloy, primarily as a result of the uncooked materials of titanium alloy are scarce and the manufacturing value is larger. As well as, the processing of titanium alloys can also be harder and requires dearer gear and know-how.| Materials | Value | Essential Influencing Components |

|---|---|---|

| Titanium Alloy | Normally larger than aluminum alloy | 1. Purity: The upper the purity of the titanium alloy, the upper the worth. 2. Form: The extra advanced the form of the titanium alloy part, the harder it’s to process, and the upper the worth. 3. Amount: The worth of titanium alloy parts produced in batches is comparatively decrease. |

| Aluminum Alloy | Normally decrease than titanium alloy | 1. Alloy Elements: The worth distinction of aluminum alloys with completely different alloy parts is kind of giant. 2. Form: The extra advanced the form of the aluminum alloy part, the harder it’s to process, and the upper the worth. 3. Amount: The worth of aluminum alloy parts produced in batches is comparatively decrease. |

Power Comparability

The energy of titanium alloys is far larger than that of aluminum alloys. Because of this titanium alloy parts can face up to higher hundreds and pressures. In functions that require excessive energy and sturdiness, titanium alloys are the best alternative.

Advantages of Titanium Alloy Power:

- Excessive Power-to-Weight Ratio: Titanium alloys are lighter than aluminum alloys, however are stronger.

- Glorious Corrosion Resistance: Titanium alloys have wonderful corrosion resistance and may preserve good efficiency even in harsh environments.

- Excessive-Temperature Stability: Titanium alloys have a better melting level and may preserve good energy and rigidity at excessive temperatures.

Power Traits of Aluminum Alloy:

- Light-weight: Aluminum alloys are light-weight, appropriate for functions that want to scale back weight.

- Straightforward to Process: Aluminum alloys are straightforward to process and may form numerous advanced shapes.

- Good Electrical Conductivity: Aluminum alloys have good electrical conductivity, appropriate for digital gadgets.

- Put on Resistance: Though the hardness of aluminum alloys is not so good as that of titanium alloys, their put on resistance continues to be good.

- Thermal Conductivity: The thermal conductivity of aluminum alloys is best than that of titanium alloys, appropriate for functions that require warmth dissipation.

Performance Comparability

Titanium alloys and aluminum alloys every have their very own strengths and weaknesses by way of efficiency.

Advantages of Titanium Alloy Performance:

- Excessive Power: The excessive energy of titanium alloys makes them excel in functions that should face up to excessive stress and hundreds.

- Glorious Corrosion Resistance: Titanium alloys have wonderful corrosion resistance, enabling them to keep up steady efficiency in numerous harsh environments.

- Excessive-Temperature Stability: The excessive melting level of titanium alloys allows them to keep up good energy and rigidity in excessive temperature environments.

Performance Traits of Aluminum Alloy:

- Good Thermal Conductivity: The thermal conductivity of aluminum alloys is best than that of titanium alloys, making them excel in functions that require warmth dissipation.

- Good Recyclability: Aluminum alloys are straightforward to recycle and reuse, giving them a bonus by way of environmental safety.

- Light-weight: Aluminum alloys are light-weight, making them appropriate for functions that want to scale back weight.

- Straightforward to Process: Aluminum alloys are straightforward to process, able to forming numerous advanced shapes.

- Good Electrical Conductivity: Aluminum alloys have good electrical conductivity, making them appropriate for digital gadgets.

Purposes

Titanium and aluminum alloys are broadly utilized in numerous fields as a result of their distinctive efficiency traits.

Purposes of Titanium Alloys:

- Aerospace: Due to its excessive energy and lightness, titanium alloy is broadly used within the manufacture of aerospace parts equivalent to engine parts, wings, propellers, and many others.

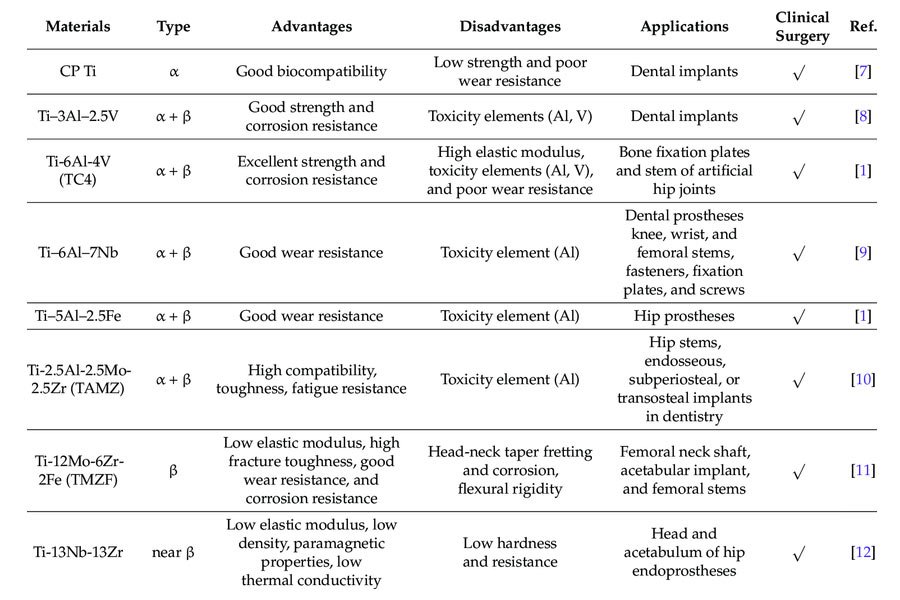

- Medical Tools: The biocompatibility and corrosion resistance of titanium alloys make it a perfect materials for manufacturing medical gadgets and implants, equivalent to bone screws, synthetic joints, dental implants, and many others.

- Chemical Trade: The corrosion resistance of titanium alloys makes it broadly used within the chemical business, equivalent to manufacturing corrosion-resistant gear like response kettles, valves, pipelines, and many others.

- Sports activities Tools: The excessive energy and lightness of titanium alloys make it broadly used within the manufacture of sports activities gear, equivalent to bicycle frames, golf golf equipment, tennis rackets, and many others.

Purposes of Aluminum Alloys:

- Building: Aluminum alloys, with their light-weight, corrosion resistance, and powerful ornamental properties, are broadly used to make architectural parts equivalent to doorways, home windows, curtain partitions, and many others.

- Transportation: Aluminum alloys are broadly used within the manufacture of parts for transportation autos equivalent to automobiles, trains, airplanes, together with our bodies, wheels, interiors, and many others.

- Digital Merchandise: {The electrical} conductivity and warmth dissipation of aluminum alloys make it broadly used within the manufacture of digital product parts, equivalent to laptop warmth sinks, cellphone instances, batteries, and many others.

- Packaging Materials: The corrosion resistance and plasticity of aluminum alloys make them a perfect alternative for manufacturing packaging materials for meals and drinks, equivalent to pull-tab cans, meals packaging bins, and many others.

The way to Select CNC Machining Materials

When selecting CNC machining materials, the next components ought to be taken under consideration:

- Value: Totally different materials could range drastically in worth. Select the fabric with the best cost-effectiveness inside your price range.

- Power: Select the suitable materials in keeping with the atmosphere wherein the product is used and the energy it wants to resist. For instance, if the product wants to resist higher stress or impression, a cloth with larger energy ought to be chosen.

- Performance: Totally different materials have completely different efficiency traits. For instance, some materials have good electrical or thermal conductivity, whereas others have good corrosion resistance or put on resistance.

- Software: Select the suitable materials in keeping with the precise software of the product. For instance, if the product is used for aerospace or medical gadgets, titanium alloy could also be required; if the product is used for building or digital merchandise, aluminum alloy could also be required.

Causes to Select Titanium Alloy

- Excessive Power: Titanium alloys have excessive energy, making them appropriate for merchandise that want to resist higher stress or impression.

- Glorious Corrosion Resistance: Titanium alloys have wonderful corrosion resistance, making them appropriate for the chemical business or marine environments.

- Excessive-Temperature Stability: Titanium alloys have a excessive melting level, making them appropriate for prime temperature environments.

Causes to Select Aluminum Alloy

- Light-weight: Aluminum alloys are light-weight, making them appropriate for merchandise that want to scale back weight.

- Good Electrical and Thermal Conductivity: Aluminum alloys have good electrical and thermal conductivity, making them appropriate for digital merchandise.

- Straightforward to Process: Aluminum alloys are straightforward to process, making them appropriate for merchandise that require advanced shapes.

Causes to Select LongSheng

When selecting LongSheng, the next components could must be thought of:

- Product High quality: The standard of LongSheng’s merchandise could be an vital purpose for selecting it. If its product high quality is widely known, this may very well be a compelling purpose.

- Service High quality: The standard of LongSheng’s companies is also an vital consideration. If it offers high-quality buyer companies, together with pre-sales session and after-sales help, this may very well be an vital purpose for selecting it.

- Value: If LongSheng’s product costs are cheap and cost-effective, this may very well be an vital purpose for selecting it.

- Model Fame: If LongSheng has model popularity, this may very well be an vital purpose for selecting it. Model popularity may embody buyer opinions, business evaluations, and extra.

Conclusion

In abstract, when selecting materials for CNC machining, one should take into account components equivalent to worth, energy, efficiency, and software. Titanium alloys, recognized for his or her excessive energy, wonderful corrosion resistance, and high-temperature stability, are appropriate for merchandise equivalent to aerospace parts and medical gadgets. However, aluminum alloys, acknowledged for his or her lightness, good electrical and thermal conductivity, and ease of processing, are perfect for merchandise utilized in sectors like building and electronics.FAQs

Is titanium stronger than 7075 aluminum?

The toughness of titanium and 7075 aluminum will depend on what you imply by “powerful”. In case you’re referring to hardness, then titanium is usually tougher than 7075 aluminum. Nonetheless, in the event you’re referring to energy, then the energy of 7075 aluminum could also be larger than some sorts of titanium. General, each titanium and 7075 aluminum are very powerful materials, appropriate for numerous high-strength functions.

Which is best: titanium, aluminum, or steel?

The prevalence of titanium, aluminum, and steel will depend on the appliance. Titanium, with its excessive energy, excessive corrosion resistance, and excessive melting level, is appropriate to be used in aerospace and medical gadgets. Aluminum, being gentle and having good electrical conductivity, is appropriate for digital merchandise and light-weight buildings. Steel, with its excessive energy and low value, is appropriate for numerous building and mechanical functions.

Which is best: aluminum or titanium?

The selection between aluminum and titanium additionally will depend on the appliance. In case you want lightness and electrical conductivity, then aluminum could be a more sensible choice. In case you want excessive energy and corrosion resistance, then titanium could be a more sensible choice. General, nobody materials is the perfect in all instances, and the selection of fabric will depend on your particular wants.