CNC machining and extrusion molding are two popular manufacturing processes used in various industries. Both techniques are incredibly versatile and can produce high-quality parts and products. In this article, we’ll delve into the advantages and differences between CNC machining and extrusion molding.

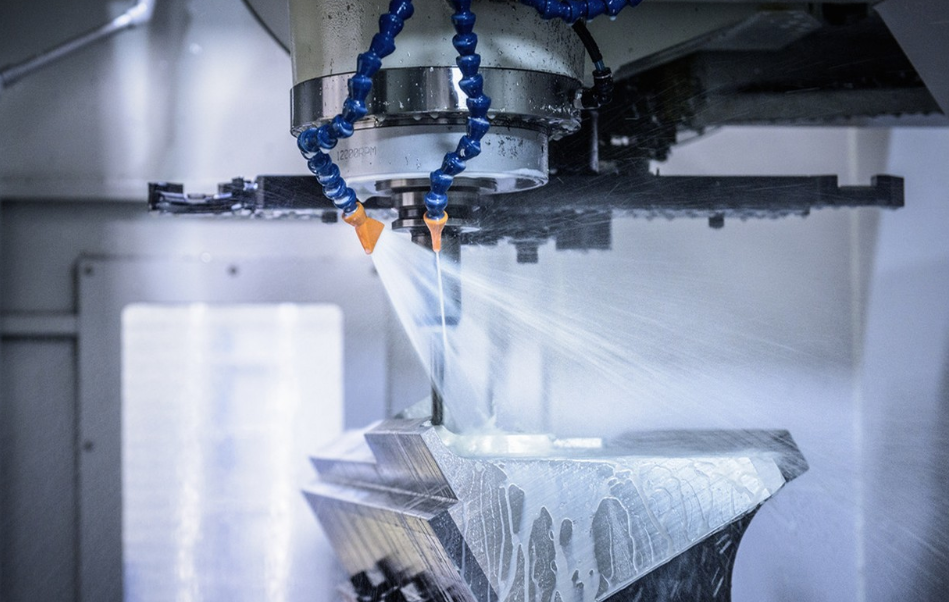

What is CNC Machining?

CNC machining involves the use of computer-controlled machines to create complex parts and components. It is a subtractive manufacturing process that removes material from a block of raw material to create the desired shape. cnc machining custom is ideal for creating precise, intricate parts that require tight tolerances.

One of the main advantages of CNC machining is its accuracy. The computer-controlled machines can create parts with tolerances as low as 0.001 inches. This level of precision is not achievable with other manufacturing processes. CNC Milling machining Center is also incredibly versatile and can work with a wide range of materials, including metals, plastics, and composites.

The Application of CNC Machining

CNC machining can be used to create a wide range of parts and components, including engine components, surgical instruments, and electronic enclosures. The process can work with a variety of materials, including metals, plastics, and composites, making it a versatile choice for a variety of projects.

In the aerospace industry, CNC machining is used to create precision components for aircraft engines, landing gears, and avionics systems. The automotive industry relies on CNC machining for creating engine components, transmission parts, and suspension systems. In the medical industry, CNC machining is used to create surgical instruments, prosthetics, and medical implants. In the electronics industry, CNC machining is used to create enclosures for electronic devices, as well as components for circuit boards.

The Benefits of CNC Machining

CNC machining offers several benefits over other manufacturing processes. One of the main advantages of CNC machining is its accuracy. The computer-controlled machines can create parts with tolerances as low as 0.001 inches, which is not achievable with other manufacturing processes.

Another benefit of CNC machining is its versatility. It can work with a wide range of materials, including metals, plastics, and composites, making it a popular choice in various industries.

CNC machining is also ideal for creating precise, intricate parts that require tight tolerances. This makes it a valuable choice for creating components in industries such as aerospace, medical, and electronics.

Overall, CNC machining is a valuable manufacturing process that can produce high-quality parts and components with a high degree of accuracy and versatility.

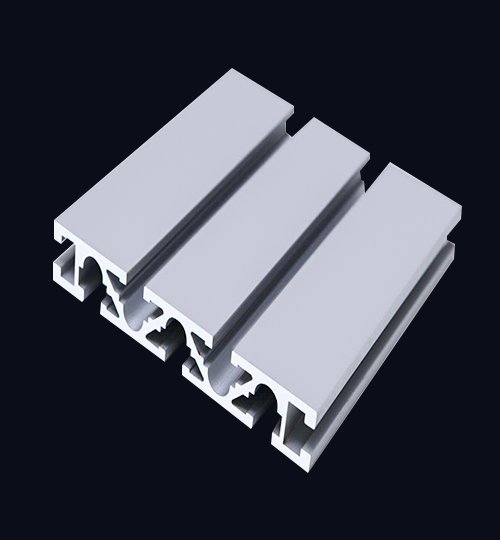

What is Extrusion Molding?

Extrusion molding is a manufacturing process that involves pushing molten plastic through a die to create a specific shape. It is a continuous process, which means that it can produce large volumes of parts quickly and efficiently. Extrusion molding is commonly used to create products such as pipes, tubes, and profiles.

One of the main advantages of extrusion molding is its efficiency. The process is automated and can produce large volumes of parts quickly and consistently. Extrusion molding is also incredibly versatile and can work with a wide range of materials, including thermoplastics and elastomers.

The Application of Extrusion Molding

Extrusion molding is commonly used in the manufacturing of pipes, tubes, and profiles. It’s an efficient and automated process that can produce large volumes of parts quickly and consistently. Extrusion molding is also incredibly versatile and can work with a wide range of materials, including thermoplastics and elastomers.

In the construction industry, extrusion molding is used to produce window frames, door frames, and vinyl siding. In the automotive industry, extrusion molding is used to create hoses, weatherstripping, and seals. Extrusion molding is also used in the production of packaging materials, such as plastic bags and containers.

Overall, extrusion molding is a valuable manufacturing process that can produce high-quality parts and products quickly and efficiently.

The Benefits of Extrusion Molding

Extrusion molding offers several benefits over other manufacturing processes. One of the main advantages of extrusion molding is its efficiency. The process is automated and can produce large volumes of parts quickly and consistently.

Another benefit of extrusion molding is its versatility. It can work with a wide range of materials, including thermoplastics and elastomers, making it a popular choice in various industries.

Extrusion molding is also ideal for creating simple parts with looser tolerances. This makes it a valuable choice for creating components in industries such as construction, automotive, and packaging.

Overall, extrusion molding is a valuable manufacturing process that can produce high-quality parts and products quickly and efficiently.

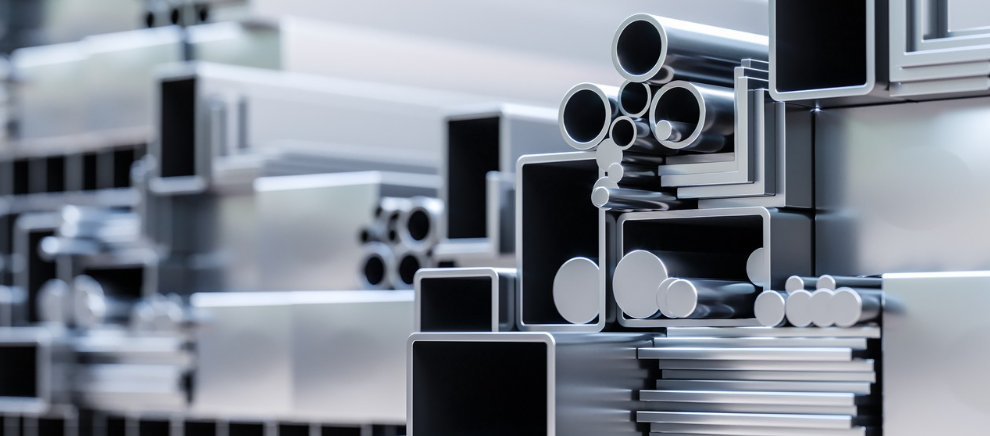

Differences between CNC Machining and Extrusion Molding

CNC machining and extrusion molding are two popular manufacturing processes used in various industries. Although they share some similarities, they also have some key differences. Let’s take a closer look at the differences between CNC machining and extrusion molding.

Firstly, CNC machining is a subtractive process that starts with a block of raw material and removes material to create the desired shape. In contrast, extrusion molding is an additive process that creates the desired shape by pushing molten plastic through a die. This fundamental difference in approach is reflected in the strengths and weaknesses of each process.

Secondly, one of the biggest advantages of CNC machining over extrusion molding is its level of accuracy. CNC machining is incredibly precise and can create parts with tolerances as low as 0.001 inches. This level of precision is not achievable with other manufacturing processes. In contrast, extrusion molding services is less precise and can create parts with tolerances of around 0.010 inches. If your project requires a high degree of accuracy, CNC machining is likely to be the better choice.

Finally, CNC machining is better suited to creating small volumes of complex parts, while extrusion molding is better suited to creating large volumes of simple parts. CNC machining is ideal for creating precise, intricate parts that require tight tolerances. It’s incredibly accurate and can work with a wide range of materials, making it a versatile choice for a variety of projects. However, it’s better suited to creating small volumes of complex parts, so if you’re looking to produce a large number of simple parts, CNC machining might not be the best choice. In contrast, extrusion molding is perfect for creating large volumes of parts quickly and efficiently. It’s automated and can work with a wide range of materials, making it an incredibly versatile manufacturing process.

In summary, CNC machining and extrusion molding are both valuable manufacturing processes that have their advantages and differences. CNC machining is incredibly precise and can create complex parts with tight tolerances, while extrusion molding is efficient and can produce large volumes of parts quickly and consistently. When deciding which process to use, it’s essential to consider the specific requirements of your project and choose the method that best suits your needs.

Conclusion

CNC machining and extrusion molding are both versatile manufacturing processes that have their advantages and differences. cnc turning services is incredibly precise and can create complex parts with tight tolerances, while extrusion molding is efficient and can produce large volumes of parts quickly and consistently. When deciding which process to use, it’s essential to consider the specific requirements of your project and choose the method that best suits your needs.

If you’re trying to decide between CNC machining and extrusion molding for your manufacturing needs, it’s important to understand the advantages and differences of each process.

CNC metal parts machining is ideal for creating precise, intricate parts that require tight tolerances. It’s incredibly accurate and can work with a wide range of materials, making it a versatile choice for a variety of projects. However, it’s better suited to creating small volumes of complex parts, so if you’re looking to produce a large number of simple parts, CNC machining might not be the best choice.

Extrusion molding, on the other hand, is perfect for creating large volumes of parts quickly and efficiently. It’s automated and can work with a wide range of materials, making it an incredibly versatile manufacturing process. However, it’s less precise than CNC machining and is better suited to creating simple parts with looser tolerances.

Ultimately, the choice between CNC machining and extrusion molding will depend on the specific requirements of your project. Consider factors like the complexity of the parts you need to create, the volume of parts you need, and the materials you’ll be working with to determine which process is the best fit.

In summary, CNC machining and extrusion molding are both valuable manufacturing processes that can produce high-quality parts and products. By understanding the advantages and differences of each process, you can make an informed decision about which one to use for your next project.