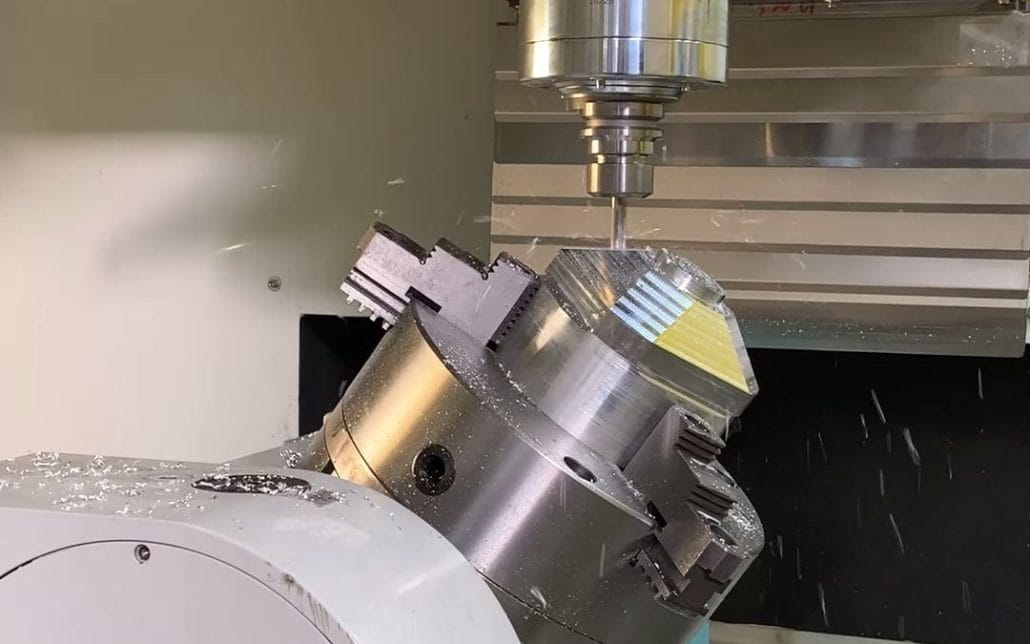

CNC machining technology has revolutionized the manufacturing industry, and it has become an essential tool for many industries, including oil and gas. In this article, we will discuss the benefits and considerations of CNC machining for the oil and gas industry.

CNC Machining for the Oil and Gas Industry Benefits

Precision and Accuracy

The oil and gas industry requires high precision and accuracy when it comes to parts and components. CNC machining can produce parts with the same specifications every time, which eliminates the possibility of human error. This ensures that parts are of high quality and meet the required standards.

Efficiency and Speed

CNC machines can produce parts much faster than traditional machines. They can also work continuously without the need for breaks, resulting in increased efficiency and productivity. This is especially important for the oil and gas industry, where time-to-market is critical.

Flexibility

CNC machines can create a wide range of parts with varying levels of complexity. They can also work with a variety of materials, including metal, plastic, and wood. This makes them an ideal tool for the oil and gas industry, where parts need to be produced quickly and with high precision.

Cost-Effective

CNC machining can be cost-effective for the oil and gas industry in several ways. First, it eliminates the need for expensive tooling and molds, which can be a significant expense for traditional manufacturing methods. Second, it reduces the need for manual labor, which can save businesses money on wages and benefits.

Improved Safety

CNC machines are designed to operate safely and efficiently. They have built-in safety features that protect workers from accidents and injuries. This is particularly important for the oil and gas industry, where workers are often exposed to hazardous materials.

CNC Machining for the Oil and Gas Industry Considerations

Material Selection

The oil and gas industry requires parts and components that can withstand harsh environments and extreme temperatures. It’s important to select the right materials for CNC machining to ensure that the parts meet the required specifications and standards.

Quality Control

Quality control is an essential aspect of CNC machining for the oil and gas industry. It ensures that the parts meet the required specifications and standards. Quality control measures, such as inspections and testing, help identify and correct any errors in the manufacturing process. This ensures that the parts are of high quality and meet the required standards of the industry.

Compliance with Industry Standards

The oil and gas industry has strict quality standards that must be met. It’s important to ensure that the CNC machining process complies with these standards to avoid costly fines and legal issues.

Customization

The oil and gas industry may require customized parts and components for specific applications. It’s important to work with a CNC machining supplier that offers customization options to ensure that the parts meet the specific requirements.

Supplier Selection

It’s important to select a CNC machining supplier with experience in the oil and gas industry. Look for suppliers that have worked with oil and gas companies and have a thorough understanding of the industry’s requirements and regulations.

In conclusion, CNC machining offers several benefits for the oil and gas industry, including precision and accuracy, efficiency and speed, flexibility, cost-effectiveness, and improved safety. By investing in this technology, businesses can increase their productivity, reduce costs, and improve the quality of their products. However, there are several considerations to keep in mind, such as material selection, quality control, compliance with industry standards, customization, and supplier selection. By evaluating these factors, businesses can make an informed decision and ensure the success of their CNC machining projects.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items